Content Menu

● Introduction to Rigid Flex PCBs

● Benefits of Rigid Flex PCBs

>> Reduced Size and Weight

>> Improved Reliability

>> Enhanced Signal Integrity

>> Increased Design Flexibility

● Importance of SMT Fixtures in Rigid Flex PCB Assembly

>> Role of SMT Fixtures

>> Challenges in Rigid Flex PCB Assembly

>> Solutions Provided by SMT Fixtures

● Applications of Rigid Flex PCBs with SMT Fixtures

>> Aerospace and Defense

>> Medical Devices

>> Automotive Electronics

>> Consumer Electronics

● Design Challenges and Solutions

>> Bending and Deflection

>> Interconnection Reliability

>> Thermal Management

● Conclusion

● FAQs

>> 1. What are the primary benefits of using rigid flex PCBs in electronic devices?

>> 2. How do SMT fixtures help in the assembly of rigid flex PCBs?

>> 3. What are some common design challenges when working with rigid flex PCBs?

>> 4. In which industries are rigid flex PCBs commonly used?

>> 5. How do rigid flex PCBs contribute to cost savings in electronic device manufacturing?

● Citations:

In the realm of modern electronics, the demand for compact, reliable, and high-performance circuit designs has led to the widespread adoption of rigid flex PCBs. These boards combine the durability of rigid PCBs with the flexibility of flex PCBs, making them ideal for applications where space is limited and reliability is paramount. However, the assembly of these complex circuits requires specialized tools, notably SMT fixtures, to ensure precision and efficiency. This article delves into the importance of using rigid flex PCB SMT fixtures for complex circuit designs, exploring their benefits, applications, and challenges.

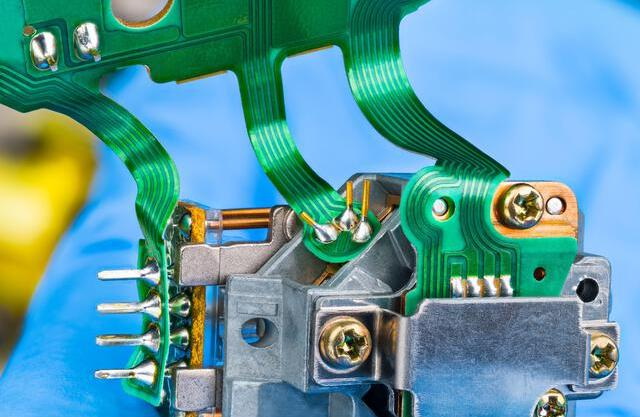

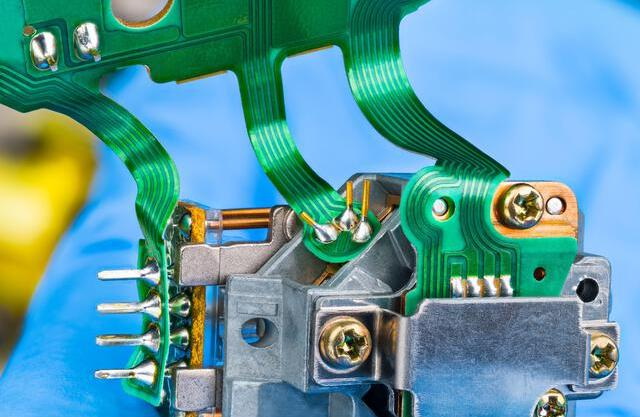

Introduction to Rigid Flex PCBs

Rigid flex PCBs are a type of printed circuit board that integrates both rigid and flexible sections. This integration allows for the creation of compact, lightweight electronic assemblies that can withstand harsh environments and mechanical stress. The rigid sections provide structural support and facilitate the mounting of components, while the flexible sections enable dynamic interconnections without the need for cables or connectors, thereby reducing assembly complexity and enhancing reliability[1][3].

Benefits of Rigid Flex PCBs

Reduced Size and Weight

One of the primary advantages of rigid flex PCBs is their ability to reduce the overall size and weight of electronic devices. By eliminating the need for connectors and cables, these boards enable more compact designs, which are crucial in applications such as portable electronics, aerospace, and medical devices[2][3].

Improved Reliability

The elimination of connectors and cables in rigid flex PCBs significantly reduces the risk of electrical failures due to loose connections or broken wires. Additionally, the flexible sections can absorb mechanical stress, making them more resistant to vibration and motion[1][3].

Enhanced Signal Integrity

Rigid flex PCBs minimize signal loss and interference by reducing the number of interconnects required. This results in improved signal quality and integrity, which is essential for high-speed applications[3].

Increased Design Flexibility

The combination of rigid and flexible sections allows designers to create complex geometries that fit into tight spaces, enabling more innovative and compact product designs[3].

Importance of SMT Fixtures in Rigid Flex PCB Assembly

Role of SMT Fixtures

SMT fixtures play a critical role in the assembly of rigid flex PCBs. These fixtures are designed to hold the flexible sections of the board in place during the surface mount technology (SMT) process, ensuring that components are accurately placed and soldered. This is particularly important because the flexible nature of these boards can make them prone to deformation and misalignment during assembly[6][8].

Challenges in Rigid Flex PCB Assembly

1. Flexibility and Deformation: The flexible sections of rigid flex PCBs can deform or bend during assembly, which requires specialized fixtures to maintain flatness and alignment[6].

2. Component Placement: The SMT process for rigid flex PCBs involves placing components on both rigid and flexible sections. This requires precise alignment and support to prevent displacement during reflow soldering[8].

3. Thermal Management: The integration of rigid and flexible materials poses unique thermal management challenges. SMT fixtures must be designed to accommodate these differences and ensure effective heat dissipation[5].

Solutions Provided by SMT Fixtures

- Precision Alignment: SMT fixtures ensure that the flexible sections of the board are properly aligned and secured, preventing misalignment and ensuring accurate component placement[8].

- Flatness and Stability: By holding the flexible parts in place, fixtures maintain the flatness of the board, which is crucial for even solder paste application and reflow soldering[6].

- Efficient Assembly: The use of SMT fixtures streamlines the assembly process by reducing the complexity associated with handling flexible boards. This leads to faster production times and lower assembly costs[8].

Applications of Rigid Flex PCBs with SMT Fixtures

Aerospace and Defense

In aerospace and defense applications, rigid flex PCBs are used for their ability to withstand harsh environments and provide reliable performance in compact designs. SMT fixtures are essential for ensuring the precision and reliability required in these critical systems[4].

Medical Devices

Medical devices such as pacemakers and wearable health monitors benefit from the compactness and durability of rigid flex PCBs. SMT fixtures help ensure that these devices are assembled with precision, maintaining their reliability and performance[3].

Automotive Electronics

In automotive electronics, rigid flex PCBs are used in control units and advanced driver assistance systems (ADAS). SMT fixtures aid in the efficient assembly of these systems, ensuring they meet the high reliability standards required in the automotive industry[3].

Consumer Electronics

Consumer electronics, including smartphones and tablets, utilize rigid flex PCBs to achieve thinner and more functional designs. SMT fixtures are crucial for maintaining the precision and efficiency needed in high-volume manufacturing[3].

Design Challenges and Solutions

Bending and Deflection

One of the major design challenges is ensuring that the flexible portion of the board can withstand repeated bending without compromising its functionality. This requires careful material selection and component placement to minimize stress concentrations[5].

Interconnection Reliability

Ensuring reliable interconnections between rigid and flexible sections is critical. Techniques such as teardrops and staggered striplines can enhance interconnect robustness[5].

Thermal Management

Proper thermal management is essential to prevent overheating. Designers must consider thermal vias and material differences to ensure effective heat dissipation[5].

Conclusion

In conclusion, rigid flex PCB SMT fixtures are indispensable for the efficient and reliable assembly of complex circuit designs. These fixtures address the unique challenges posed by the flexible nature of rigid flex PCBs, ensuring precision, stability, and efficiency in the assembly process. As technology continues to evolve, the demand for compact, reliable, and high-performance electronic devices will only increase, making the role of rigid flex PCB SMT fixtures even more critical.

FAQs

1. What are the primary benefits of using rigid flex PCBs in electronic devices?

Rigid flex PCBs offer several benefits, including reduced size and weight, improved reliability, enhanced signal integrity, and increased design flexibility. They are ideal for applications requiring compact and reliable electronics in challenging environments[3].

2. How do SMT fixtures help in the assembly of rigid flex PCBs?

SMT fixtures are crucial for holding the flexible sections of rigid flex PCBs in place during assembly, ensuring precision alignment and preventing deformation. This leads to more efficient and reliable assembly processes[6][8].

3. What are some common design challenges when working with rigid flex PCBs?

Common design challenges include ensuring the flexible portion can withstand bending, maintaining interconnection reliability, managing thermal differences, and optimizing component placement to minimize stress concentrations[5].

4. In which industries are rigid flex PCBs commonly used?

Rigid flex PCBs are widely used in industries such as aerospace, medical devices, automotive electronics, consumer electronics, and industrial equipment. They are favored for their ability to provide compact, reliable, and high-performance electronic systems[3][4].

5. How do rigid flex PCBs contribute to cost savings in electronic device manufacturing?

Rigid flex PCBs can lead to cost savings by reducing material usage, simplifying assembly, and minimizing the number of components required. This results in lower production costs and faster time to market[2].

Citations:

[1] https://www.viasion.com/blog/rigid-flex-pcb-fabrication/

[2] https://www.epectec.com/articles/why-rigid-flex-pcbs-are-ideal-for-portable-electronic-devices.html

[3] https://www.capelfpc.com/news/rigid-flex-pcb-assembly-a-comprehensive-guide-to-manufacturing-and-applications/

[4] https://www.allflexinc.com/blog/understanding-rigid-flex-circuit-boards-applications-and-advantages-of-rigid-flex-pcb/

[5] https://www.capelfpc.com/news/what-are-the-common-design-challenges-when-using-rigid-flex-pcbs/

[6] https://www.grande-pcba.com/how-to-eliminatethe-uneven-issue-of-fpc-assembly/

[7] https://www.printedcircuits.com/blog/common-rigid-flex-printed-circuit-board-issues-and-how-to-avoid-them/

[8] https://www.nextpcb.com/pcb-vocabulary/rigid-flex-pcb-assembly

[9] https://morepcb.com/multilayer-rigid-flexible-pcb/

[10] https://resources.altium.com/p/rigid-flex-pcbs-advantages-and-challenges

[11] https://www.capelfpc.com/news/are-rigid-flex-circuit-boards-compatible-with-surface-mount-technology-smt/

[12] https://www.protoexpress.com/faq/flex-pcb-prototypes/

[13] https://jlcpcb.com/help/article/PCB-ASSEMBLY-FIXTURES

[14] https://resources.pcb.cadence.com/blog/reflow-and-rework-rules-for-flex-pcbas

[15] https://www.pcbonline.com/blog/fpc-smt.html

[16] https://www.linkedin.com/posts/hitechpcb_the-advantages-of-rigid-flex-pcb-board-1-activity-7283383551348146177-s5r7

[17] https://www.eevblog.com/forum/manufacture/fixtures-for-flex-pcb-assembly/

[18] https://www.pentalogix.com/products/flex-and-rigid-flex-pcbs

[19] https://www.epectec.com/articles/cost-benefits-of-using-rigid-flex-pcb-vs-rigid-pcb-and-cable-assembly.html

[20] https://www.protoexpress.com/blog/dfm-flex-rigid-flex-pcbs-utilizing-smt/

[21] https://www.epectec.com/articles/how-rigid-flex-pcb-design-configurations-are-advancing.html

[22] https://eda.sw.siemens.com/en-US/pcb/engineering-productivity-and-efficiency/advanced-design/rigid-flex-pcb-design/

[23] https://www.protoexpress.com/blog/5-must-knows-for-your-first-flex-design/

[24] https://www.pcbunlimited.com/products/rigid-flex-pcbs

[25] https://www.fastlinepcb.com/rigid-flex-pcb-smt-fixture/

[26] https://www.pentalogix.com/blog/2021/03/04/flex-rigid-flex-pcbs/

[27] https://www.capelfpc.com/news/what-are-the-applications-of-rigid-flex-circuit-boards/

[28] https://www.pcbcart.com/article/content/flexible-pcb-assembly-technology.html

[29] https://www.fpcway.com/pcb-service/Rigid-flex_PCB_Assembly_Service.html

[30] https://www.protoexpress.com/kb/flex-pcb-assembly/

[31] https://www.alibaba.com/showroom/rigid-flex-pcb-smt-fixture.html

[32] https://www.capelfpc.com/turnkey-8-layer-rigid-flex-pcb-boards-fabrication-and-assembly-for-vr-smart-glasses-product/

[33] https://greatpcb.com/fcb-fab/rigid-flex/

[34] https://www.rigiflex.com/blog/a-detailed-discussion-on-pcb-assembly-problems-and-their-solutions/

[35] https://www.capelfpc.com/news/preventing-rigid-flex-pcb-delamination-effective-strategies-to-ensure-quality-and-reliability/

[36] https://www.tortai-tech.com/pcb-assembly-manufacturing-reflow-soldering-prone-to-7-problems-and-solutions/

[37] https://www.globalsmt.net/articles-and-papers/addressing-the-challenges-of-flex-circuit-assembly/

[38] https://www.protoexpress.com/blog/avoiding-common-flex-pcb-errors/

[39] https://www.linkedin.com/advice/3/what-common-challenges-pitfalls-working

[40] https://www.capelfpc.com/news/solving-common-failures-of-rigid-flex-boards-strategies-and-best-practices/

[41] https://www.reddit.com/r/PrintedCircuitBoard/comments/1h1yvoy/disconnected_traces_8layer_rigidflex_pcbs/

[42] https://www.hemeixinpcb.com/company/news/356-design-guidelines-and-challenges-for-rigid-flex-pcb-manufacturing.html

[43] https://www.circuitsassembly.com/ca/features-itemid-fix/423-the-flexperts/25764-the-flexperts-1603.html

[44] https://www.rigiflex.com/faq

[45] https://www.linkedin.com/pulse/preparing-rigid-flex-pcb-documentation-manufacturing-vqbec

[46] https://www.pcbway.com/blog/PCB_Assembly/Some_Points_of_Flex_PCB_Assembly.html

[47] https://www.hemeixinpcb.com/company/faq/53-rigid-flex-pcb-faq.html

[48] https://www.hemeixinpcb.com/company/faq/51-flex-pcb-board-faq.html

[49] https://www.bestfpc.com/news/what-is-the-difference-between-assembling-flex-and-rigid-boards.html

[50] https://www.venture-mfg.com/flex-pcb-assembly/

[51] https://www.fastlink-electronics.com/products/rigid-flex-pcb/

[52] https://www.capelfpc.com/fast-10-layer-rigid-flex-circuit-boards-prototype-pcb-manufacturer-for-industrial-control-product/

[53] https://forum.kicad.info/t/method-of-work-for-generating-rigid-flex-design/3861