Content Menu

● Introduction

● Cost-Effectiveness

>> Competitive Pricing

>> Reduced Production Costs

>> Detailed Cost Breakdown

● Technological Advancements

>> State-of-the-Art Facilities

>> Research and Development

>> Integration of Smart Technologies

● Skilled Labor Force

>> Availability of Skilled Workers

>> Continuous Training Programs

● Supply Chain Efficiency

>> Proximity to Component Suppliers

>> Streamlined Logistics

● Quality Assurance

>> Stringent Quality Control Measures

>> Advanced Testing Procedures

>> Use of Modern Inspection Technologies

● Flexibility and Scalability

>> Adaptability to Client Needs

>> Scalability of Operations

● Intellectual Property Protection

>> Stronger IP Regulations

>> Legal Frameworks for Enforcement

● Environmental Considerations

>> Commitment to Sustainable Practices

>> Compliance with International Standards

● Future Trends Influencing SMT PCB Assembly

● Conclusion

● FAQ

>> 1. What is SMT PCB assembly?

>> 2. Why is China considered a leader in PCB assembly?

>> 3. How does outsourcing PCB assembly to China affect lead times?

>> 4. What measures do Chinese manufacturers take to ensure quality?

>> 5. Are there concerns about intellectual property when outsourcing to China?

● Citations:

Introduction

In the rapidly evolving world of electronics, the demand for efficient and high-quality manufacturing processes is paramount. Surface Mount Technology (SMT) has become a standard in the production of printed circuit boards (PCBs), which are essential components in virtually all electronic devices. Among the various countries involved in SMT PCB assembly, China stands out as a leading choice for many businesses. This article will explore the reasons why companies opt for SMT PCB assembly in China, examining factors such as cost-effectiveness, technological advancements, skilled labor, supply chain efficiency, quality assurance, flexibility, intellectual property protection, and environmental considerations.

Cost-Effectiveness

Competitive Pricing

One of the most compelling reasons to choose China for SMT PCB assembly is the cost advantage. Chinese manufacturers offer competitive pricing due to lower labor costs and economies of scale. The ability to produce large quantities at a lower price point makes China an attractive option for businesses looking to minimize expenses while maintaining quality.

Reduced Production Costs

In addition to lower labor costs, China's manufacturing infrastructure allows for reduced production costs. The availability of raw materials and components at competitive prices further enhances this advantage. Companies can save significantly on both direct and indirect costs by outsourcing their PCB assembly to China.

Detailed Cost Breakdown

The cost structure of SMT assembly in China includes several elements:

- Solder Stencil Making: Essential for applying solder paste accurately on the PCB.

- Pick-and-Place Machine Programming: Automation reduces labor costs and increases efficiency.

- Reflow Soldering Process: Ensures strong connections between components and PCB.

- Labor Charges: Typically lower in China compared to Western countries.

- Quality Inspection Methods: Critical for maintaining standards but can vary in cost depending on the level of scrutiny required.

For dual-sided SMT assembly, costs can increase significantly due to the need for additional processes like solder stencil making and reflow soldering on both sides of the board.

Technological Advancements

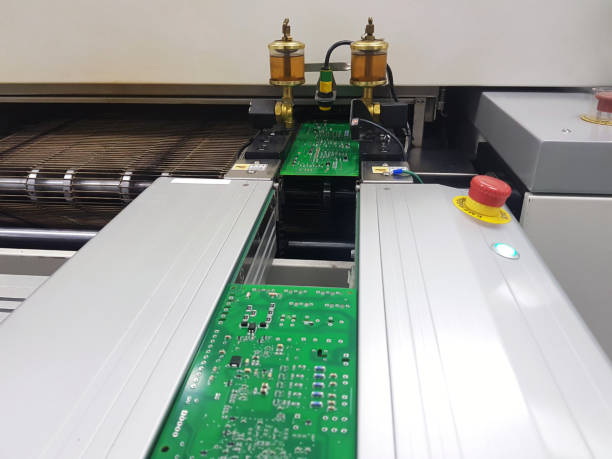

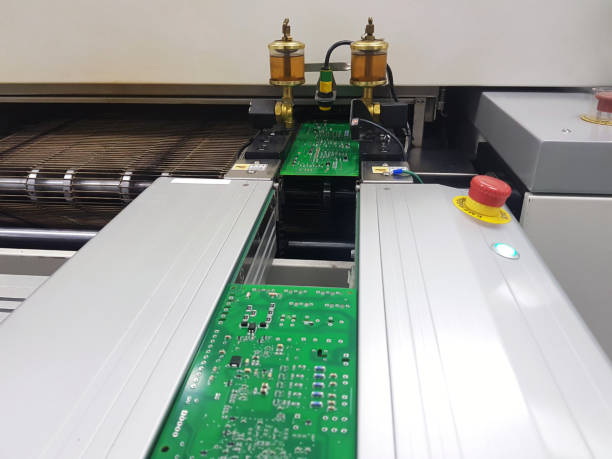

State-of-the-Art Facilities

China has made significant investments in advanced manufacturing technologies. Many PCB assembly facilities are equipped with state-of-the-art machinery that enhances production efficiency and quality. Automated processes reduce human error and increase precision, resulting in higher-quality products.

Research and Development

Chinese manufacturers are increasingly focusing on research and development (R&D) to stay competitive in the global market. This commitment to innovation allows them to adopt new technologies and improve existing processes, ensuring that they can meet the evolving needs of their clients.

Integration of Smart Technologies

The integration of smart technologies such as AI-enabled machines is transforming SMT processes. These machines optimize production lines by improving yields and reducing downtime through predictive maintenance capabilities. As a result, manufacturers can achieve higher efficiency levels while maintaining product quality.

Skilled Labor Force

Availability of Skilled Workers

China boasts a large pool of skilled workers trained in electronics manufacturing. Many technicians and engineers possess specialized knowledge in SMT processes, ensuring that products are assembled with precision and care. The availability of this skilled labor force is a significant advantage for companies seeking high-quality PCB assembly services.

Continuous Training Programs

To maintain their competitive edge, many Chinese manufacturers invest in continuous training programs for their employees. This commitment to workforce development ensures that workers are up-to-date with the latest technologies and practices in SMT PCB assembly.

Supply Chain Efficiency

Proximity to Component Suppliers

China's well-established supply chain is another reason why companies choose it for SMT PCB assembly. The proximity to component suppliers means shorter lead times and reduced shipping costs. This efficiency allows companies to respond quickly to market demands and changes.

Streamlined Logistics

Chinese manufacturers have developed streamlined logistics systems that facilitate efficient transportation of materials and finished products. This capability minimizes delays and ensures that companies can meet tight deadlines without compromising quality.

Quality Assurance

Stringent Quality Control Measures

Quality assurance is critical in electronics manufacturing, and Chinese manufacturers have implemented stringent quality control measures. Many facilities adhere to international standards such as ISO 9001, ensuring that products meet high-quality benchmarks.

Advanced Testing Procedures

In addition to quality control measures, many Chinese manufacturers employ advanced testing procedures throughout the production process. These tests help identify potential issues early on, reducing the likelihood of defects in finished products.

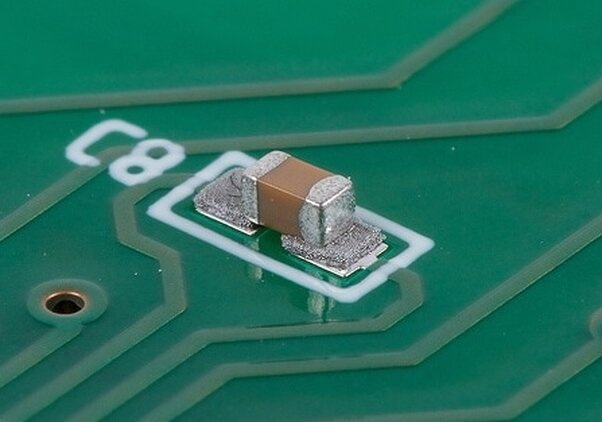

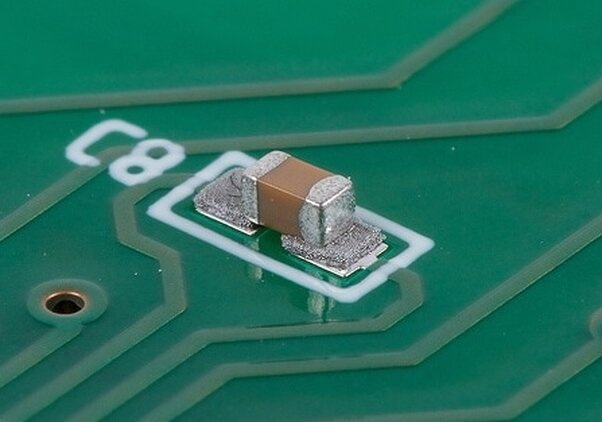

Use of Modern Inspection Technologies

Technologies such as Automated Optical Inspection (AOI) and X-ray inspection are commonly used in Chinese PCB assembly facilities to ensure that solder joints meet required standards. These technologies enhance defect detection rates, leading to improved overall product reliability.

Flexibility and Scalability

Adaptability to Client Needs

Chinese manufacturers are known for their flexibility in meeting client requirements. Whether it's adjusting production volumes or accommodating specific design changes, these manufacturers can adapt quickly to customer needs.

Scalability of Operations

As businesses grow, their manufacturing needs may change. Chinese manufacturers have the capacity to scale operations up or down based on demand, making them an ideal partner for companies looking for long-term collaboration.

Intellectual Property Protection

Stronger IP Regulations

Concerns about intellectual property (IP) theft have historically deterred some companies from outsourcing manufacturing to China. However, recent reforms have strengthened IP regulations, providing better protection for foreign businesses operating in China.

Legal Frameworks for Enforcement

The Chinese government has established legal frameworks that allow foreign companies to enforce their IP rights more effectively than before. This improvement helps build trust between foreign businesses and Chinese manufacturers.

Environmental Considerations

Commitment to Sustainable Practices

Many Chinese manufacturers are increasingly adopting sustainable practices in their operations. This commitment includes reducing waste, minimizing energy consumption, and implementing eco-friendly production methods.

Compliance with International Standards

Chinese manufacturers are also working towards compliance with international environmental standards such as RoHS (Restriction of Hazardous Substances). This compliance not only benefits the environment but also aligns with the values of many global companies focused on sustainability.

Future Trends Influencing SMT PCB Assembly

As technology continues to evolve, several trends are shaping the future landscape of SMT PCB assembly:

- Miniaturization: The ongoing trend toward smaller electronic devices requires innovative solutions that SMT offers through its compact component designs.

- 5G Integration: The rollout of 5G technology demands high-performance PCBs capable of handling increased data rates; thus driving further advancements in SMT techniques.

- Automation: Industry 4.0 principles are being integrated into manufacturing processes, enhancing automation through robotics and AI technologies which improve efficiency.

- Advanced Materials: The use of new materials that facilitate better electrical performance is becoming increasingly important as devices become more complex.

- Sustainability: With growing environmental concerns, there is an increasing demand for eco-friendly materials and processes within electronics manufacturing.

Conclusion

Choosing China for SMT PCB assembly offers numerous advantages including cost-effectiveness, technological advancements, a skilled labor force, supply chain efficiency, quality assurance, flexibility, improved intellectual property protection, and a commitment to sustainability. As businesses continue to navigate the complexities of global manufacturing, China remains a top choice for companies seeking reliable partners in PCB assembly.

In summary, the combination of competitive pricing, advanced technology, skilled labor availability, efficient logistics systems, stringent quality control measures, adaptability to client needs, stronger IP regulations, and environmental considerations makes China an attractive destination for SMT PCB assembly.

FAQ

1. What is SMT PCB assembly?

SMT PCB assembly refers to the process of mounting electronic components directly onto printed circuit boards using surface mount technology (SMT). This method allows for higher density and smaller circuit boards compared to traditional through-hole technology.

2. Why is China considered a leader in PCB assembly?

China is considered a leader in PCB assembly due to its combination of low labor costs, advanced manufacturing technologies, a large pool of skilled workers, efficient supply chains, and stringent quality control measures.

3. How does outsourcing PCB assembly to China affect lead times?

Outsourcing PCB assembly to China can significantly reduce lead times due to the proximity of component suppliers and streamlined logistics systems that facilitate faster transportation of materials and finished products.

4. What measures do Chinese manufacturers take to ensure quality?

Chinese manufacturers implement stringent quality control measures throughout the production process and employ advanced testing procedures like AOI inspection to identify potential issues early on. Many adhere to international standards such as ISO 9001.

5. Are there concerns about intellectual property when outsourcing to China?

While concerns about intellectual property theft have existed historically, recent reforms in China have strengthened IP regulations and enforcement mechanisms providing better protection for foreign businesses operating within the country.

Citations:

[1] https://www.7pcb.com/blog/surface-mount-smt-assembly-cost-china

[2] https://www.raypcb.com/smt-manufacturer/

[3] https://www.hct-smt.com/blog/inside-look--exploring-china-s-smt-assembly-machine-components

[4] https://www.viasion.com/smt-assembly/

[5] https://www.grandviewresearch.com/industry-analysis/surface-mount-technology-market-report

[6] https://newventureresearch.com/shop/https-newventureresearch-com-wp-content-uploads-smt2020-rs-pdf/

[7] https://www.raypcb.com/top-10-pcb-assembly-manufacturers-in-china/

[8] https://leadsintec.com/pcb-assembly-technology-comparison-smt-vs-tht/

[9] https://www.mycronic.com/product-areas/pcb-assembly/solutions/case-stories/

[10] https://morepcb.com/smt/

[11] https://madpcb.com/smt-assembly/

[12] https://hilelectronic.com/chinese-chips/

[13] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=151&maxrows=10

[14] https://www.hitech-pcba.com/smt-pcb-assembly

[15] https://www.technotronix.us/pcbblog/top-trends-in-printed-circuit-board-manufacturing-for-2024/

[16] https://smt.asmpt.com/en/news-center/case-studies/

[17] https://www.pcbjhy.com/pcb-assembly-service/

[18] https://www.pcbelec.com/turnkey-pcb-manufacturing-and-assembly-benefits.html

[19] https://smt.asmpt.com/en/news-center/case-studies/new-reference-site-in-zhongqing/

[20] https://productronica.com/en/trade-fair/trade-fair-topics/smt/

[21] https://www.nbk1560.com/en/resources/mechatronics/article/SMT/?SelectedLanguage=en

[22] https://www.pcbtok.com/smt-assembly/

[23] https://www.viasion.com/pcb-assembly/