Content Menu

● The Rise of China's Electronics Manufacturing Industry

>> Factors Contributing to China's Dominance

● Advantages of China Electronics SMT SMD PCB Assembly

>> Cost-Effectiveness

>> Advanced Technology and Equipment

>> Comprehensive Supply Chain Ecosystem

● The SMT SMD PCB Assembly Process in China

>> Surface Mount Technology (SMT)

>>> Advantages of SMT in China's Electronics Manufacturing:

>> The SMT PCB Assembly Process

● China's Expertise in SMD Technology

>> Advantages of SMD in China's Electronics Manufacturing:

● Quality Assurance in China's Electronics SMT SMD PCB Assembly

● The Future of China's Electronics SMT SMD PCB Assembly Industry

● Challenges and Considerations

● Conclusion

● FAQ

>> 1. What are the main advantages of choosing China for electronics SMT SMD PCB assembly?

>> 2. How does China ensure quality in electronics SMT SMD PCB assembly?

>> 3. What is the difference between SMT and SMD in electronics assembly?

>> 4. How has China become a leader in the global electronics manufacturing industry?

>> 5. What challenges might companies face when choosing China for electronics SMT SMD PCB assembly?

● Citations:

In the rapidly evolving world of electronics manufacturing, China has emerged as a global leader, particularly in the realm of SMT (Surface Mount Technology), SMD (Surface Mount Device), and PCB (Printed Circuit Board) assembly. This article explores the numerous advantages of choosing China for electronics SMT SMD PCB assembly, delving into the factors that have propelled China to the forefront of this industry.

The Rise of China's Electronics Manufacturing Industry

China's ascent in the electronics manufacturing sector has been nothing short of remarkable. Over the past few decades, the country has transformed itself into the world's largest producer of electronic goods, accounting for more than half of all electronics manufactured globally[5]. This dominance extends to various segments of the industry, including the production of mobile phones, printed circuit boards, and the installation of semiconductors[5].

Factors Contributing to China's Dominance

Several key factors have contributed to China's preeminence in electronics SMT SMD PCB assembly:

1. Manufacturing Powerhouse: China has built an extensive network of factories and supply chains capable of handling mass production of electronics at competitive prices[2].

2. Economies of Scale: The sheer volume of production in China allows manufacturers to benefit from economies of scale, reducing per-unit costs and enabling them to offer high-quality electronics at unbeatable prices[2].

3. Specialized Industrial Zones: Cities like Shenzhen have become dedicated hubs for electronics manufacturing, fostering ecosystems where suppliers, engineers, and manufacturers collaborate efficiently[2].

4. Skilled Workforce: China has invested heavily in education and vocational training, ensuring a continuous supply of skilled workers for its electronics industry[2].

Advantages of China Electronics SMT SMD PCB Assembly

Cost-Effectiveness

One of the primary reasons companies choose China for electronics SMT SMD PCB assembly is the significant cost advantage. Chinese manufacturers have mastered the art of producing high-quality electronics at lower costs without compromising on quality[1][2]. This cost-effectiveness stems from several factors:

1. Lower Labor Costs: Despite rising wages in recent years, China's labor costs remain competitive compared to many developed countries[4].

2. Affordable Raw Materials: China's position as a major global supplier of raw materials and components for electronics manufacturing allows PCB manufacturers to source materials at lower prices[4].

3. Reduced Overhead Expenses: Lower costs for rent, utilities, and taxes contribute to the overall cost-effectiveness of manufacturing in China[4].

Advanced Technology and Equipment

China's electronics manufacturing industry is not just about low costs; it's also at the forefront of technological advancement:

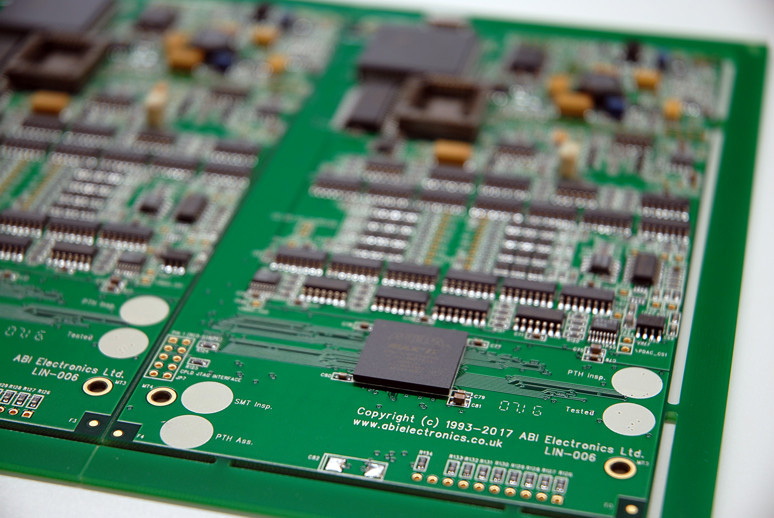

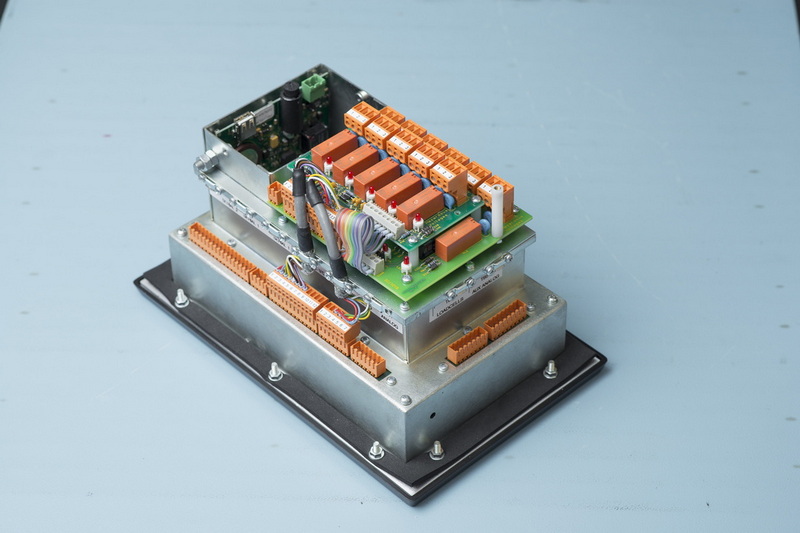

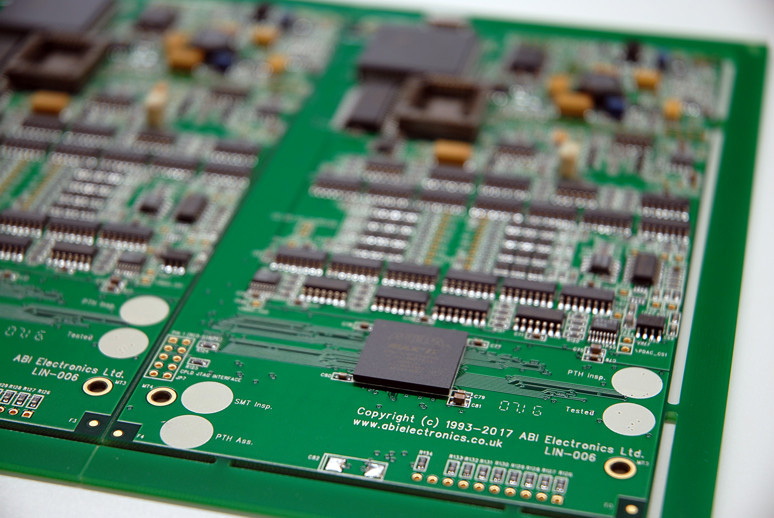

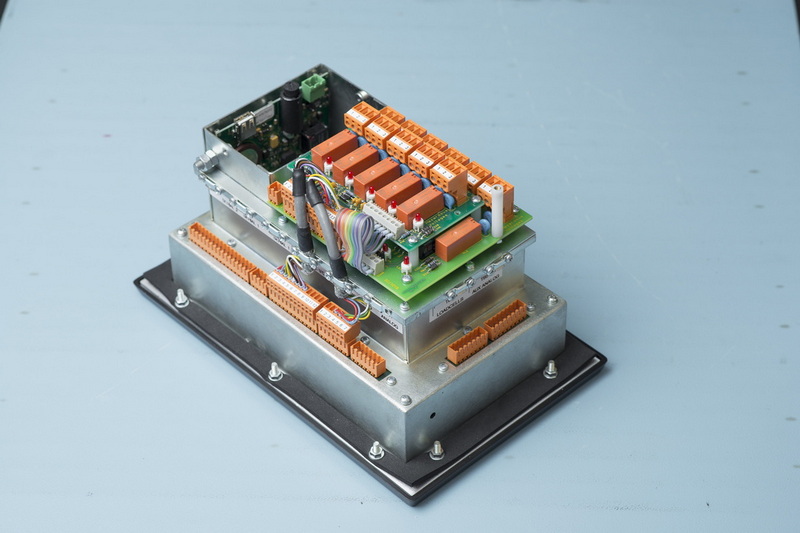

1. State-of-the-Art Facilities: Chinese manufacturers have invested heavily in advanced equipment and facilities, enabling them to produce PCBs that meet stringent quality standards[1].

2. Automated Production: The use of advanced SMT technology, including pick-and-place machines, has significantly enhanced product reliability, consistency, and production speed[3].

3. High-Precision Equipment: Chinese factories utilize high-speed component placement machines and high-precision optical inspection machines to ensure quality and accuracy in PCB assembly[7].

Comprehensive Supply Chain Ecosystem

China's electronics manufacturing industry benefits from a robust and comprehensive supply chain ecosystem:

1. Proximity to Component Suppliers: The vast network of suppliers for components like semiconductors, batteries, and screens allows for faster production times and lower transportation costs[2].

2. Vertical Integration: Many Chinese electronics companies control various parts of their supply chains, from raw materials to final assembly, increasing efficiency and reducing reliance on external suppliers[2].

3. Global Connectivity: China's well-developed ports, transportation infrastructure, and trade agreements facilitate quick and efficient shipping of electronics to markets worldwide[2].

The SMT SMD PCB Assembly Process in China

Surface Mount Technology (SMT)

SMT is a crucial technique in modern electronics assembly, particularly in China's manufacturing landscape. This method involves directly placing and soldering components onto the surface of PCBs, as opposed to through-hole technology where component leads are inserted through holes in the board[3].

Advantages of SMT in China's Electronics Manufacturing:

1. Automation: SMT allows for highly automated PCB assembly, enhancing efficiency and consistency[3].

2. Miniaturization: It enables the use of smaller components, leading to more compact and lightweight electronic devices[3].

3. Improved Performance: The shorter distances between components on SMT-assembled boards can improve signal transmission and overall device performance[3].

The SMT PCB Assembly Process

The SMT PCB assembly process in China typically follows these steps:

1. Design Input: The process begins with inputting design files into pick-and-place machines, eliminating the need for manual insertion of component pins[3].

2. Solder Paste Application: A thin layer of solder paste is applied to the PCB using a stencil.

3. Component Placement: SMT machines precisely place components onto the PCB.

4. Reflow Soldering: The board passes through a reflow oven, melting the solder paste and securing the components in place.

5. Inspection and Testing: Automated optical inspection (AOI) and functional testing ensure the quality of the assembled PCB.

China's Expertise in SMD Technology

Surface Mount Devices (SMDs) are components designed for SMT assembly. China's expertise in SMD technology is a crucial factor in its dominance of the electronics manufacturing industry.

Advantages of SMD in China's Electronics Manufacturing:

1. Space Efficiency: SMDs are smaller than traditional through-hole components, allowing for more compact PCB designs[3].

2. Cost-Effectiveness: The smaller size of SMDs often translates to lower material costs.

3. Improved Performance: SMDs typically offer better high-frequency performance due to their smaller lead lengths and reduced parasitic capacitance.

4. Automated Assembly: SMDs are well-suited for automated pick-and-place machines, increasing production efficiency.

Quality Assurance in China's Electronics SMT SMD PCB Assembly

Despite the cost advantages, China's electronics manufacturing industry places a strong emphasis on quality:

1. Compliance with International Standards: Chinese PCB manufacturers adhere to international quality standards and implement robust quality management systems[7].

2. Advanced Inspection Systems: The use of intelligent inspection systems ensures accurate mounting of electronic parts[7].

3. Stringent Testing: With the trend towards smaller and more compact devices, Chinese manufacturers follow strict test standards to verify the quality and reliability of assembled PCBs[7].

The Future of China's Electronics SMT SMD PCB Assembly Industry

As China's electronics manufacturing industry continues to evolve, several trends are shaping its future:

1. Moving Up the Value Chain: Chinese companies are increasingly focusing on higher-value electronics production, which could lead to increased profit margins[5].

2. Continued Technological Advancement: Ongoing investments in research and development are likely to keep China at the forefront of electronics manufacturing technology[7].

3. Emphasis on Sustainability: As global awareness of environmental issues grows, Chinese manufacturers are likely to place more emphasis on sustainable manufacturing practices.

4. Adapting to Global Changes: China's electronics manufacturing industry has shown resilience and adaptability in the face of global challenges, a trait that will be crucial for its continued dominance.

Challenges and Considerations

While the advantages of choosing China for electronics SMT SMD PCB assembly are numerous, there are also challenges to consider:

1. Intellectual Property Concerns: Some companies may have concerns about protecting their intellectual property when manufacturing in China.

2. Communication and Cultural Differences: Language barriers and cultural differences can sometimes lead to misunderstandings or delays.

3. Quality Control: While many Chinese manufacturers produce high-quality products, thorough quality control measures are essential to ensure consistent quality.

4. Shipping and Logistics: Despite China's well-developed infrastructure, shipping times and costs can be a consideration for some companies.

Conclusion

China's dominance in electronics SMT SMD PCB assembly is the result of a unique combination of factors, including cost-effectiveness, advanced technology, a comprehensive supply chain ecosystem, and a skilled workforce. While challenges exist, the advantages of manufacturing in China continue to make it an attractive option for companies worldwide.

As the global electronics industry continues to evolve, China's role as a manufacturing powerhouse is likely to persist. However, to maintain its competitive edge, the country will need to continue investing in technology, improving quality standards, and addressing concerns related to intellectual property protection.

For companies considering their options for electronics manufacturing, China's SMT SMD PCB assembly capabilities offer a compelling proposition. By leveraging China's expertise in this field, businesses can benefit from cost-effective, high-quality production that meets the demands of today's fast-paced electronics market.

FAQ

1. What are the main advantages of choosing China for electronics SMT SMD PCB assembly?

The main advantages include cost-effectiveness due to lower labor and material costs, access to advanced technology and equipment, a comprehensive supply chain ecosystem, and a skilled workforce. China's ability to produce high-quality electronics at competitive prices makes it an attractive option for many companies.

2. How does China ensure quality in electronics SMT SMD PCB assembly?

China ensures quality through compliance with international standards, implementation of robust quality management systems, use of advanced inspection systems, and stringent testing procedures. Many Chinese manufacturers have invested in state-of-the-art equipment and facilities to produce PCBs that meet high-quality standards.

3. What is the difference between SMT and SMD in electronics assembly?

SMT (Surface Mount Technology) refers to the method of directly mounting components onto the surface of a PCB. SMD (Surface Mount Device) refers to the electronic components designed for use with SMT. SMT is the process, while SMDs are the components used in this process.

4. How has China become a leader in the global electronics manufacturing industry?

China has become a leader through a combination of factors, including massive investment in manufacturing infrastructure, development of specialized industrial zones, cultivation of a skilled workforce, and the creation of a comprehensive supply chain ecosystem. These factors have allowed China to produce electronics at scale and at competitive prices.

5. What challenges might companies face when choosing China for electronics SMT SMD PCB assembly?

Potential challenges include intellectual property concerns, communication and cultural differences, quality control issues, and shipping and logistics considerations. However, many of these challenges can be mitigated through careful partner selection and robust management practices.

Citations:

[1] https://www.cesgate.com/newsinfo/6326816.html

[2] https://industrywired.com/why-is-china-the-leading-electronic-market/

[3] https://www.fs-pcba.com/smt-pcba/

[4] https://www.pcbelec.com/benefits-and-challenges-of-china-pcb-prototype.html

[5] https://arcadiasourcing.net/blog/electronic-manufacturing-companies-in-china-dominate/

[6] https://www.jhdpcba.com/zxbk

[7] https://www.electricalandcontrol.com/what-to-expect-from-pcb-assembly-services-in-china/

[8] https://arc-group.com/china-electronics-manufacturing-sourcing/

[9] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345

[10] https://www.rocket-pcb.com/what-are-the-advantages-of-manufacturing-pcb-in-china