Content Menu

● The Advics Advantage in PCB Assembly

>> State-of-the-Art SMT Capabilities

>> Cutting-Edge Equipment and Processes

● Quality Assurance: The Cornerstone of Advics Terre Haute

>> Rigorous Testing and Inspection

>> Traceability and Documentation

● Innovation and Flexibility in PCB Design

>> Accommodating Complex Designs

>> Prototype to Production

● The Human Element: Expertise and Experience

>> Skilled Workforce

>> Continuous Training and Development

● Environmental Responsibility

>> RoHS Compliance

>> Energy Efficiency

● Global Reach, Local Support

● Industry-Specific Expertise

>> Understanding Automotive Standards

>> Experience with Safety-Critical Systems

● Advanced Manufacturing Techniques

>> Selective Soldering

>> Conformal Coating

>> In-Circuit Testing (ICT)

● Commitment to Innovation

>> Research and Development

>> Collaboration with Industry Partners

● Customer-Centric Approach

>> Customized Solutions

>> Transparent Communication

>> Rapid Prototyping Services

● Conclusion

● Frequently Asked Questions

>> 1. What is Surface Mount Technology (SMT) and how does Advics Terre Haute utilize it in PCB assembly?

>> 2. How does Advics Terre Haute ensure the quality of their PCB assemblies?

>> 3. Can Advics Terre Haute handle both prototype and high-volume PCB assembly?

>> 4. What types of components and PCB designs can Advics Terre Haute work with?

>> 5. How does Advics Terre Haute stay current with the latest PCB assembly technologies?

● Citations:

In the rapidly evolving world of automotive technology, precision and reliability are paramount. Advics Manufacturing in Terre Haute, Indiana, stands out as a leading provider of high-quality PCB assembly services, particularly in the realm of automotive brake systems. With a focus on Surface Mount Technology (SMT) and advanced PCB manufacturing techniques, Advics Terre Haute has established itself as a go-to partner for companies seeking top-tier electronic components for their vehicles.

The Advics Advantage in PCB Assembly

Advics Terre Haute brings a wealth of experience and expertise to the table when it comes to PCB assembly. As a part of the global Advics group, the Terre Haute facility benefits from a rich heritage of automotive innovation and a commitment to excellence that permeates every aspect of their operations.

State-of-the-Art SMT Capabilities

Surface Mount Technology is at the heart of modern PCB assembly, and Advics Terre Haute is at the forefront of this technology. Their advanced SMT lines are capable of handling components as small as 01005 imperial (0402 metric), ensuring that even the most compact and complex designs can be accommodated[6]. This level of precision is crucial for the intricate brake systems that Advics specializes in, where every millimeter counts.

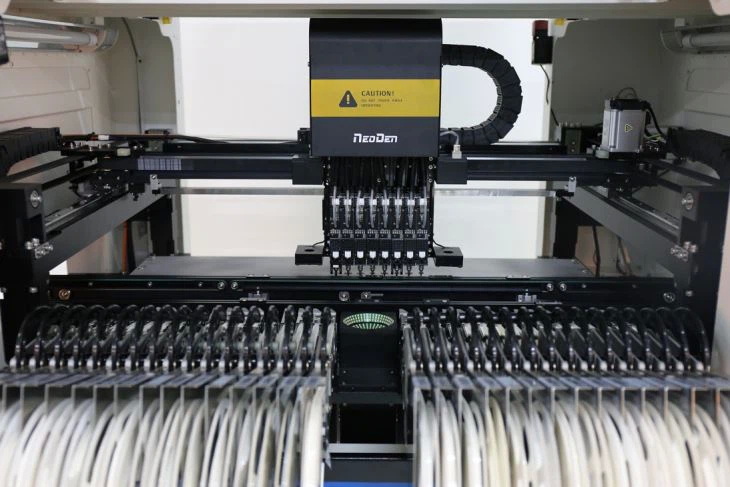

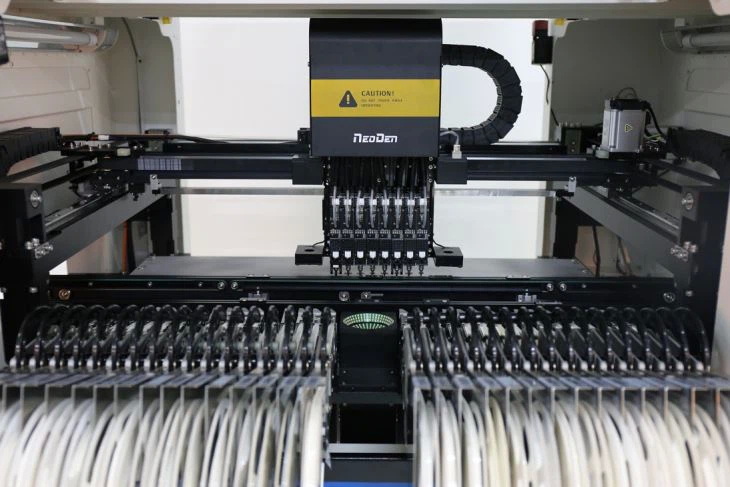

Cutting-Edge Equipment and Processes

The facility is equipped with the latest in PCB assembly technology, including:

- High-precision screen printers with accuracy down to 0.08mm

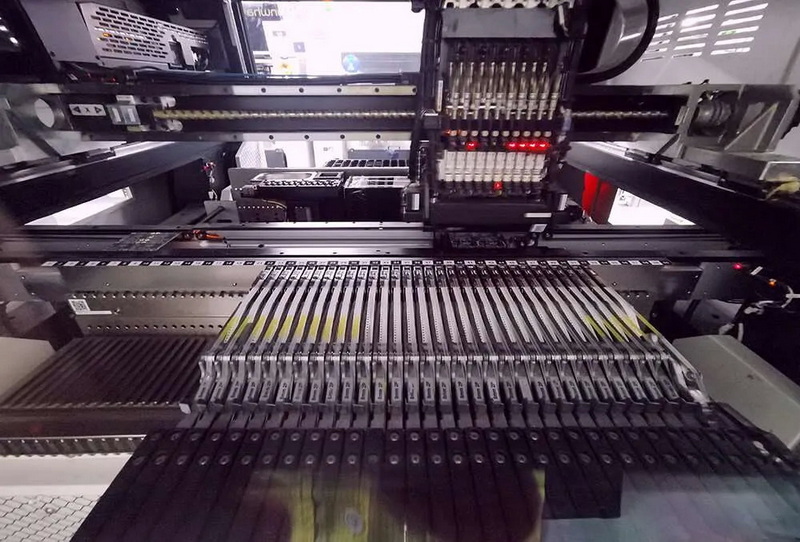

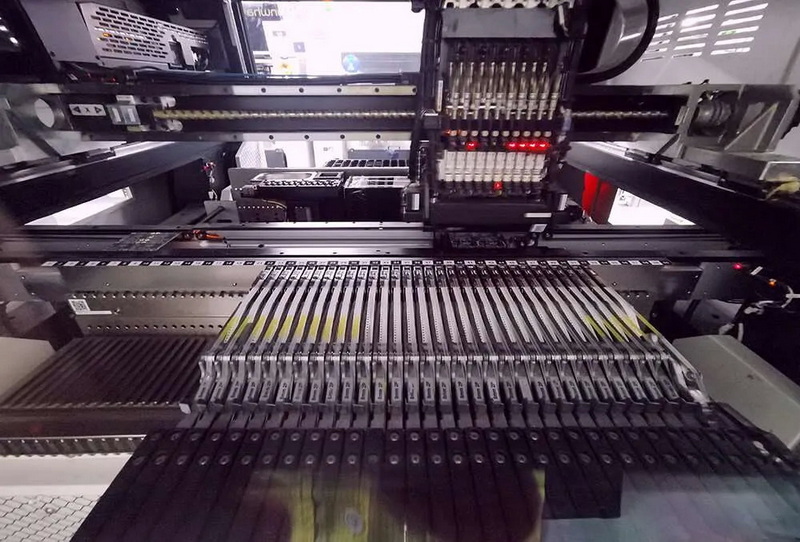

- Advanced pick-and-place machines with placement accuracy of 0.025mm

- Reflow ovens with KIC profiler technology for optimal soldering

- 3D Automated Optical Inspection (AOI) systems with SPC reporting capabilities

These technologies ensure that every PCB produced meets the highest standards of quality and reliability[6].

Quality Assurance: The Cornerstone of Advics Terre Haute

Quality is not just a buzzword at Advics Terre Haute; it's a fundamental principle that guides every aspect of their PCB assembly process.

Rigorous Testing and Inspection

Every PCB undergoes multiple quality checks throughout the assembly process:

1. Solder Paste Inspection (SPI) using 3D inline systems

2. Automated Optical Inspection (AOI) with advanced 3D capabilities

3. X-ray inspection for BGA and other hidden solder joints

4. Functional testing tailored to specific product requirements

These multi-layered inspection processes ensure that defects are caught and corrected early, maintaining the highest quality standards[6].

Traceability and Documentation

Advics Terre Haute implements a comprehensive traceability system. All components are tracked from receiving through to final assembly, with lot codes and date codes recorded in a cloud-based ERP system. This level of detail allows for quick identification and resolution of any issues that may arise, as well as providing valuable data for continuous improvement initiatives[6].

Innovation and Flexibility in PCB Design

The automotive industry is constantly evolving, and Advics Terre Haute is well-positioned to meet these changing demands.

Accommodating Complex Designs

With the ability to handle BGA components with pitches as fine as 0.35mm and QFN packages with 0.4mm pitch, Advics Terre Haute can accommodate even the most advanced PCB designs. Their capabilities extend to a wide range of component sizes and types, ensuring that they can meet the diverse needs of the automotive industry[6].

Prototype to Production

Whether you're in the early stages of product development or ready for full-scale production, Advics Terre Haute has the flexibility to meet your needs. Their experienced engineering team can work with you to optimize your design for manufacturability, ensuring a smooth transition from prototype to production.

The Human Element: Expertise and Experience

While advanced technology is crucial, it's the people at Advics Terre Haute that truly set them apart.

Skilled Workforce

The production team at Advics Terre Haute is comprised of highly skilled operators and technicians. Many, like Production Engineer Ross Martin, bring years of experience in new product development and manufacturing processes to their roles. This expertise ensures that every PCB is assembled with the utmost care and attention to detail[5].

Continuous Training and Development

Advics Terre Haute invests heavily in the ongoing training and development of its workforce. This commitment to learning ensures that the team is always up-to-date with the latest technologies and best practices in PCB assembly.

Environmental Responsibility

In today's automotive industry, environmental considerations are more important than ever. Advics Terre Haute is committed to sustainable manufacturing practices.

RoHS Compliance

All PCBs assembled at the Terre Haute facility are compliant with RoHS (Restriction of Hazardous Substances) regulations, ensuring that they meet global environmental standards.

Energy Efficiency

The facility employs energy-efficient equipment and processes, minimizing its environmental footprint while maintaining high production standards.

Global Reach, Local Support

As part of the global Advics group, the Terre Haute facility benefits from a vast network of resources and expertise. However, they also offer the advantages of a local supplier:

- Shorter lead times for North American customers

- Easier communication and collaboration

- Flexibility to meet changing demands quickly

This combination of global resources and local presence makes Advics Terre Haute an ideal partner for companies seeking reliable PCB assembly services.

Industry-Specific Expertise

While Advics Terre Haute's PCB assembly capabilities are applicable across various industries, their specialization in automotive brake systems gives them unique insights into the specific requirements of this sector.

Understanding Automotive Standards

The team at Advics Terre Haute is well-versed in automotive industry standards such as IATF 16949, ensuring that all PCBs meet or exceed the rigorous quality and reliability requirements of the automotive sector.

Experience with Safety-Critical Systems

Given their focus on brake systems, Advics Terre Haute has extensive experience in assembling PCBs for safety-critical applications. This expertise translates into enhanced reliability and performance for all PCB assemblies, regardless of their end application.

Advanced Manufacturing Techniques

Advics Terre Haute employs a range of advanced manufacturing techniques to ensure the highest quality PCB assemblies:

Selective Soldering

For mixed-technology boards that combine SMT and through-hole components, Advics Terre Haute offers selective soldering capabilities. This technique allows for precise soldering of through-hole components without subjecting the entire board to the reflow process, reducing thermal stress on sensitive components.

Conformal Coating

To protect PCBs from environmental factors such as moisture, dust, and chemicals, Advics Terre Haute offers conformal coating services. This thin protective layer enhances the durability and reliability of the PCBs, making them suitable for harsh automotive environments.

In-Circuit Testing (ICT)

Advics Terre Haute utilizes in-circuit testing to verify the correct assembly of PCBs. This automated testing method checks for shorts, opens, resistance, capacitance, and other circuit parameters, ensuring that each board functions as intended.

Commitment to Innovation

The automotive industry is at the forefront of technological innovation, and Advics Terre Haute is committed to staying ahead of the curve.

Research and Development

Advics invests heavily in research and development, constantly exploring new technologies and processes to improve their PCB assembly capabilities. This commitment to innovation ensures that their customers always have access to the latest advancements in electronic manufacturing.

Collaboration with Industry Partners

Advics Terre Haute maintains close relationships with equipment manufacturers, component suppliers, and industry associations. These partnerships allow them to stay informed about emerging trends and technologies in PCB assembly.

Customer-Centric Approach

At the heart of Advics Terre Haute's success is their unwavering commitment to customer satisfaction.

Customized Solutions

Recognizing that each customer has unique requirements, Advics Terre Haute offers customized PCB assembly solutions. Their team works closely with customers to understand their specific needs and develop tailored manufacturing processes.

Transparent Communication

Open and honest communication is a cornerstone of Advics Terre Haute's customer relationships. They provide regular updates on project status, proactively address any issues that arise, and welcome customer feedback as part of their continuous improvement process.

Rapid Prototyping Services

For customers in the early stages of product development, Advics Terre Haute offers rapid prototyping services. This allows for quick iteration and testing of designs, accelerating the product development cycle.

Conclusion

Choosing Advics Terre Haute for PCB assembly means partnering with a company that combines global expertise with local support, cutting-edge technology with skilled craftsmanship, and a deep understanding of automotive requirements with a commitment to innovation. Their advanced SMT capabilities, rigorous quality control processes, and customer-centric approach make them an ideal choice for companies seeking reliable, high-quality PCB assembly services.

Whether you're developing next-generation brake systems or any other electronic component for the automotive industry, Advics Terre Haute has the expertise, technology, and dedication to quality that can help bring your products to life. With their comprehensive range of services, from prototyping to full-scale production, they are well-equipped to support your PCB assembly needs at every stage of your product lifecycle.

In an industry where precision, reliability, and innovation are paramount, Advics Terre Haute stands out as a trusted partner capable of meeting the most demanding requirements. Their commitment to excellence, combined with their specialized knowledge of automotive systems, positions them as a leader in PCB assembly for the automotive sector and beyond.

Frequently Asked Questions

1. What is Surface Mount Technology (SMT) and how does Advics Terre Haute utilize it in PCB assembly?

Surface Mount Technology is a method of producing electronic circuits where components are mounted directly onto the surface of printed circuit boards. Advics Terre Haute utilizes advanced SMT equipment, including high-precision pick-and-place machines and reflow ovens, to assemble PCBs with exceptional accuracy and efficiency. Their SMT capabilities allow for the placement of components as small as 01005 imperial size, enabling the production of compact and complex PCB designs crucial for modern automotive electronics.

2. How does Advics Terre Haute ensure the quality of their PCB assemblies?

Advics Terre Haute implements a multi-layered quality assurance process that includes:

- 3D Solder Paste Inspection (SPI) to verify correct solder paste application

- Automated Optical Inspection (AOI) to detect defects after component placement and soldering

- X-ray inspection for hidden solder joints

- In-Circuit Testing (ICT) to verify electrical functionality

- Functional testing tailored to specific product requirements

Additionally, they maintain rigorous traceability systems and adhere to automotive industry standards such as IATF 16949.

3. Can Advics Terre Haute handle both prototype and high-volume PCB assembly?

Yes, Advics Terre Haute is equipped to handle PCB assembly needs from prototype to high-volume production. Their flexible manufacturing setup allows them to efficiently produce small batches for prototyping and testing, as well as scale up to full production runs. Their engineering team can also assist with design for manufacturability, ensuring a smooth transition from prototype to mass production.

4. What types of components and PCB designs can Advics Terre Haute work with?

Advics Terre Haute has extensive capabilities in PCB assembly, including:

- BGA components with pitches as fine as 0.35mm

- QFN packages with 0.4mm pitch

- Components ranging from 01005 imperial size to large 6-inch components

- Mixed-technology boards combining SMT and through-hole components

- Complex designs with fine-pitch connectors and dense component placement

Their advanced equipment and skilled workforce allow them to handle a wide range of PCB designs and component types.

5. How does Advics Terre Haute stay current with the latest PCB assembly technologies?

Advics Terre Haute maintains its technological edge through:

- Continuous investment in state-of-the-art equipment

- Ongoing training and development programs for their workforce

- Active participation in industry associations and partnerships with technology providers

- A robust research and development program that explores emerging technologies and processes

- Regular collaboration with customers to understand evolving needs and requirements in PCB assembly

Citations:

[1] https://www.indeed.com/q-advics-jobs.html

[2] https://www.marklines.com/en/top500/aisin

[3] https://www.ipc.org/TOC/IPC-AJ-820A.pdf

[4] https://www.aisinworld.com/locations/

[5] https://www.linkedin.com/in/ross-martin-0b54541a

[6] https://www.a2zems.com/surface-mount-technology

[7] https://www.linkedin.com/company/advics-na

[8] https://www.indeed.com/cmp/Advics-Manufacturing/reviews?fcountry=US&floc=Terre+Haute%2C+IN