Content Menu

● Understanding Surface Mount Technology (SMT)

● Key Components of a Wholesale SMT Full Line

● Advantages of Wholesale SMT Full Lines

>> Enhanced Efficiency

>> Improved Quality Control

>> Scalability and Flexibility

>> Cost-Effectiveness

● Applications of Wholesale SMT Full Lines

● Innovations Driving Future Developments

● Challenges Faced by Electronics Manufacturers

>> High Initial Investment

>> Complexity of Setup

>> Rapid Technological Changes

● Case Studies: Success Stories with Wholesale SMT Production Lines

>> 1. Electronix Solutions Inc.

>> 2. Automatech Technologies Ltd.

>> 3. MedTech Innovations

● Future Trends in Electronics Manufacturing

● Conclusion

● FAQs

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does an SMT full line improve efficiency?

>> 3. What are the key components of an SMT full line?

>> 4. Can a wholesale SMT line accommodate different types of PCBs?

>> 5. What industries benefit from using wholesale SMT production lines?

The electronics manufacturing industry is rapidly evolving, driven by the demand for high-quality products at lower costs and faster production times. One of the most effective ways to achieve these goals is through the adoption of a wholesale Surface Mount Technology (SMT) full line. This article explores the numerous advantages of choosing a wholesale SMT full line for electronics manufacturing, including enhanced efficiency, improved quality control, scalability, and cost-effectiveness.

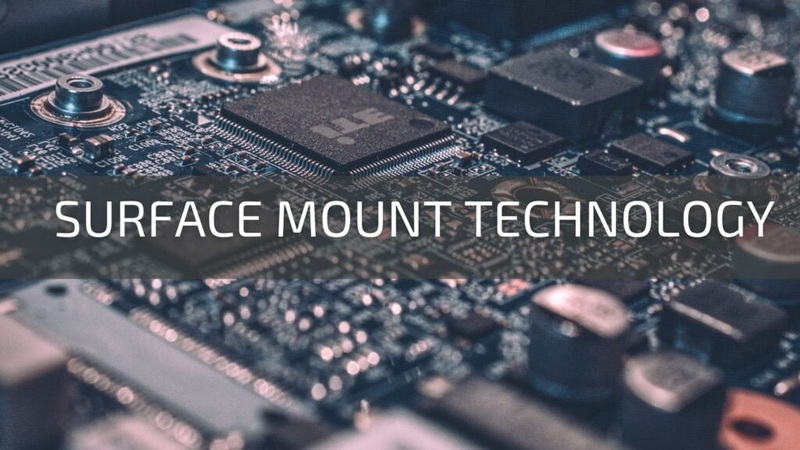

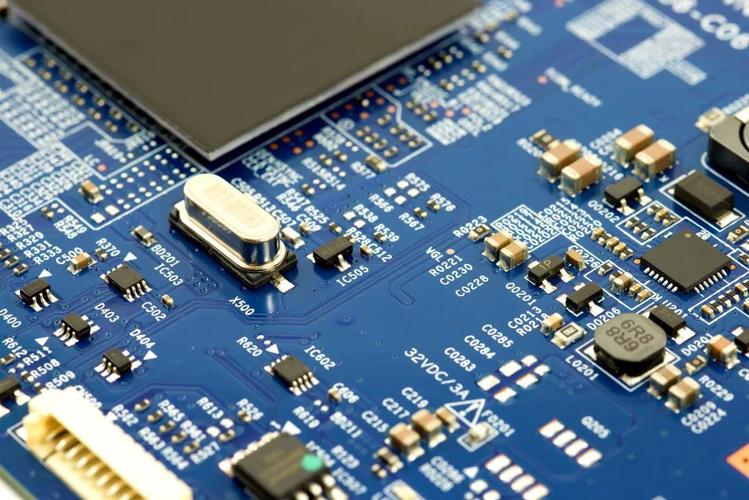

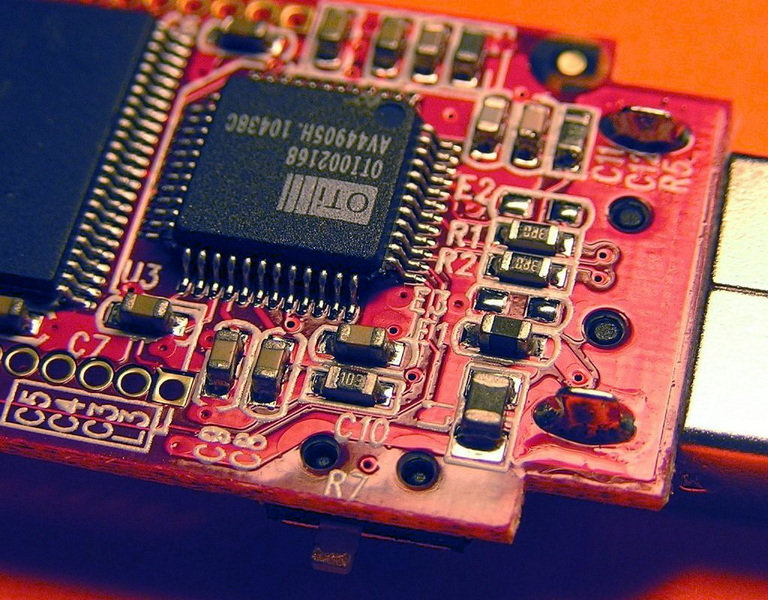

Understanding Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs). This technology has revolutionized the industry by allowing for smaller, lighter devices with greater functionality. The SMT process includes several key stages: solder paste application, component placement, reflow soldering, and inspection.

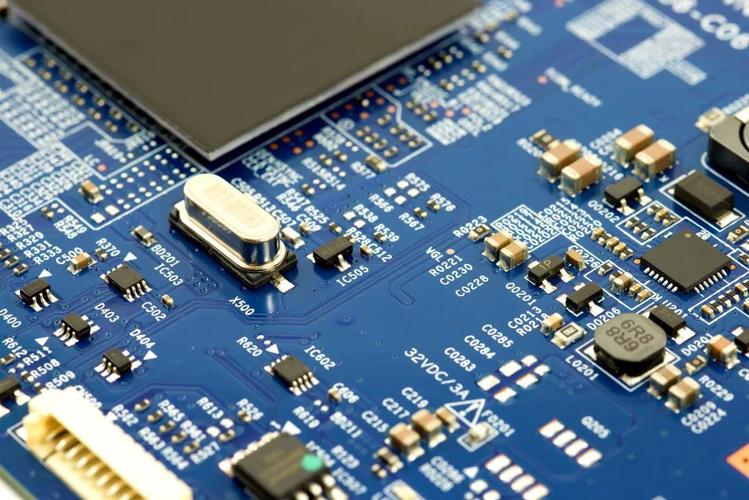

Key Components of a Wholesale SMT Full Line

A wholesale SMT full line consists of various machines and systems that work together to automate the PCB assembly process. The main components include:

- Solder Paste Printers: These machines apply solder paste to the PCB pads where components will be placed. Precision in this step is crucial for ensuring strong solder joints.

- Pick and Place Machines: These devices accurately position electronic components onto the PCB. Speed and accuracy are vital in a wholesale production environment.

- Reflow Ovens: After component placement, PCBs pass through reflow ovens where solder paste is melted to create reliable connections between components and the board.

- Automated Optical Inspection (AOI) Systems: These systems inspect assembled PCBs for defects such as misalignments or missing components, ensuring high-quality output.

- Conveyor Systems: These facilitate the movement of PCBs between different stages of production, minimizing manual handling and increasing throughput.

Advantages of Wholesale SMT Full Lines

Enhanced Efficiency

Wholesale SMT production lines significantly reduce cycle times and labor costs by automating many aspects of the assembly process. This automation allows manufacturers to produce PCBs at a much faster pace and higher volume compared to traditional methods. For instance, while manual assembly may take hours or even days for complex boards, an automated line can complete the same task in a fraction of that time.

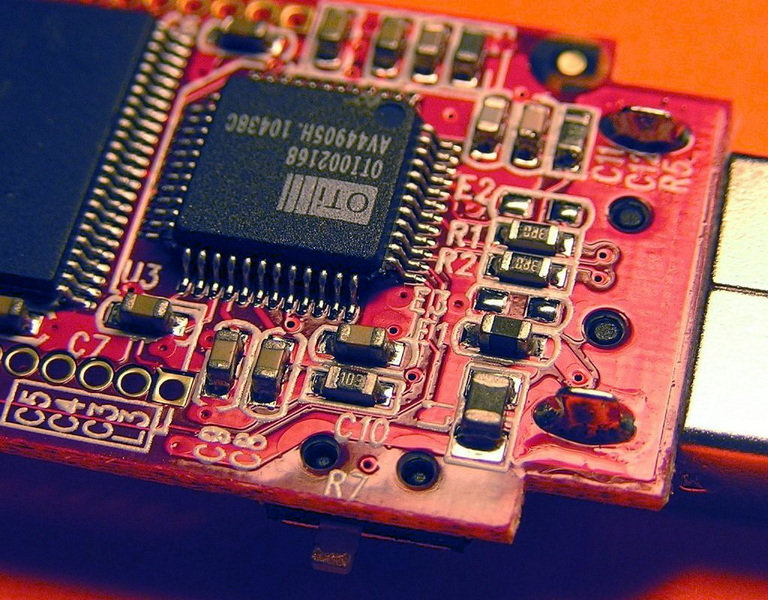

Improved Quality Control

With integrated inspection systems and quality assurance protocols, wholesale SMT lines ensure that PCBs meet stringent quality standards. This reduces defects and rework, enhancing overall product reliability. Automated inspections can detect issues early in the production process, allowing for timely corrections. Additionally, many modern SMT lines utilize advanced technologies such as machine vision systems that provide real-time feedback on assembly quality.

Scalability and Flexibility

Wholesale SMT production lines are designed to be highly scalable. Manufacturers can adjust production capacity according to demand fluctuations without significant downtime or reconfiguration costs. The modular design allows customization to accommodate diverse PCB designs and production requirements. For example, if a manufacturer anticipates an increase in demand for a particular product line, they can easily scale up their operations without needing extensive retraining or new equipment.

Cost-Effectiveness

While the initial investment in a wholesale SMT full line can be substantial, the long-term savings are significant. Reduced labor costs, improved material utilization, and higher throughput contribute to enhanced profitability in electronics manufacturing operations. Furthermore, bulk purchasing of components through wholesale channels often leads to lower material costs per unit produced.

Applications of Wholesale SMT Full Lines

Wholesale SMT production lines are versatile and applicable across various sectors:

- Consumer Electronics: From smartphones to home appliances, these lines enable efficient manufacturing of consumer electronics with precision. The rapid pace of innovation in this sector necessitates quick turnaround times that SMT lines can provide.

- Industrial Equipment: High-quality PCB assemblies are essential for control systems and sensors in industrial machinery. The reliability of these assemblies directly impacts operational efficiency and safety.

- Automotive Electronics: The automotive industry relies on robust electronic components for safety features and infotainment systems. With increasing electronic content in vehicles, manufacturers must ensure high standards in PCB assembly.

- Medical Devices: Stringent quality standards in medical device manufacturing necessitate reliable PCB assemblies produced with high precision. Compliance with regulations such as ISO 13485 is critical for manufacturers in this field.

Innovations Driving Future Developments

The future of wholesale SMT production lines is being shaped by several key innovations:

- Artificial Intelligence (AI) and Machine Learning: These technologies enhance predictive maintenance and process optimization, leading to improved efficiency. AI algorithms can analyze data from production processes to identify patterns that indicate potential failures before they occur.

- Advanced Robotics: Robotic automation increases handling speed and flexibility in production processes. Collaborative robots (cobots) can work alongside human operators to enhance productivity without compromising safety.

- Smart Manufacturing Integration: Real-time monitoring and data analytics optimize production efficiency and quality control in wholesale SMT lines. By integrating IoT devices into manufacturing processes, companies can gather valuable data that informs decision-making.

Challenges Faced by Electronics Manufacturers

Despite the numerous advantages offered by wholesale SMT full lines, manufacturers may face several challenges:

High Initial Investment

The upfront cost associated with purchasing an entire SMT line can be daunting for smaller manufacturers. However, many companies view this as a long-term investment that will yield substantial returns over time through increased efficiency and reduced operational costs.

Complexity of Setup

Setting up an SMT line requires careful planning and expertise. Manufacturers must consider factors such as layout design, equipment selection, and workforce training to ensure smooth operations from day one.

Rapid Technological Changes

The fast-paced nature of technology means that manufacturers must continually adapt their processes to keep up with new developments. This may involve regular upgrades to equipment or software systems to remain competitive.

Case Studies: Success Stories with Wholesale SMT Production Lines

1. Electronix Solutions Inc.

- Faced challenges with manual assembly processes leading to low throughput.

- Implemented a wholesale PCB SMT Production Line from Techtronics Manufacturing Systems.

- Achieved significant improvements in productivity (up by 40%), quality (defect rates reduced by 30%), and cost-effectiveness (overall operational costs lowered by 25%).

2. Automatech Technologies Ltd.

- Needed a scalable solution for rapid production volume increases.

- Partnered with SMT Solutions Co. for a customized wholesale PCB SMT Production Line.

- Successfully scaled production capacity while reducing time-to-market for their IoT devices from six months to just three months.

3. MedTech Innovations

- Required high precision for medical device PCBs due to strict regulatory standards.

- Adopted an advanced wholesale SMT line equipped with AI-driven inspection systems.

- Resulted in zero recalls over two years due to enhanced quality control measures implemented during production.

Future Trends in Electronics Manufacturing

As technology continues to evolve, several trends are likely to shape the future landscape of electronics manufacturing:

- Sustainability Initiatives: Manufacturers are increasingly focusing on sustainable practices by minimizing waste and using eco-friendly materials in their processes.

- Customization Demand: The rise of consumer demand for personalized products will drive manufacturers to adopt flexible manufacturing techniques that allow for quick changes in design without extensive downtime.

- Global Supply Chain Optimization: As supply chain disruptions become more common due to geopolitical tensions or pandemics, manufacturers will need to develop strategies that enhance resilience while maintaining cost-effectiveness.

Conclusion

In conclusion, investing in a wholesale SMT full line represents a transformative approach to electronics manufacturing. The benefits include enhanced efficiency, improved quality control, scalability, and long-term cost savings. As technology continues to advance and market demands grow, manufacturers that adopt these innovative solutions will be well-positioned to thrive in an increasingly competitive landscape.

FAQs

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for smaller devices with greater functionality.

2. How does an SMT full line improve efficiency?

An SMT full line automates many aspects of the assembly process, significantly reducing cycle times and labor costs while increasing throughput compared to traditional methods.

3. What are the key components of an SMT full line?

Key components include solder paste printers, pick-and-place machines, reflow ovens, automated optical inspection systems, and conveyor systems that facilitate the movement of PCBs through various stages of production.

4. Can a wholesale SMT line accommodate different types of PCBs?

Yes, wholesale SMT lines are designed to be modular and customizable, allowing manufacturers to adjust configurations based on diverse PCB designs and production requirements.

5. What industries benefit from using wholesale SMT production lines?

Industries such as consumer electronics, industrial equipment manufacturing, automotive electronics, and medical devices all benefit from the precision and efficiency provided by wholesale SMT production lines.