Content Menu

● The Evolution of PCB Assembly

>> From Through-Hole to Surface Mount Technology

● Understanding Fully Automated PCB SMT Solution Lines

>> Key Components of an SMT Solution Line

>> The SMT Assembly Process

● Advantages of Choosing a Fully Automated PCB SMT Solution Line

>> Increased Production Speed and Efficiency

>> Enhanced Precision and Consistency

>> Reduced Labor Costs

>> Improved Quality Control

>> Flexibility and Scalability

>> Miniaturization and Higher Component Density

>> Improved Reliability and Longevity

● Implementing a Fully Automated PCB SMT Solution Line

>> Initial Investment and ROI

>> Training and Skill Development

>> Integration with Existing Systems

>> Customization and Optimization

● Future Trends in PCB SMT Assembly

>> Industry 4.0 Integration

>> Artificial Intelligence and Machine Learning

>> Advanced Materials and Components

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical return on investment (ROI) for a fully automated PCB SMT solution line?

>> 2. How does a fully automated PCB SMT solution line handle different PCB sizes and designs?

>> 3. What maintenance requirements are associated with a fully automated PCB SMT solution line?

>> 4. How does a fully automated PCB SMT solution line impact product quality?

>> 5. Can a fully automated PCB SMT solution line handle both high-volume and small-batch production?

● Citations:

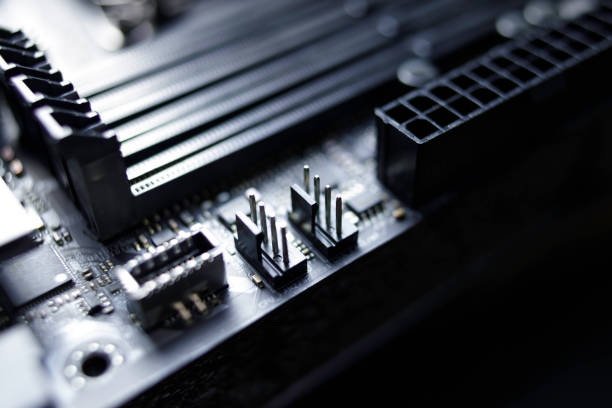

In today's rapidly evolving electronics manufacturing landscape, the demand for high-quality, efficient, and cost-effective production methods has never been greater. As technology continues to advance, printed circuit boards (PCBs) remain the backbone of countless electronic devices. To meet the increasing demand and maintain a competitive edge, manufacturers are turning to fully automated PCB Surface Mount Technology (SMT) solution lines. This comprehensive article will explore the numerous benefits, processes, and considerations of implementing a fully automated PCB SMT solution line in your manufacturing facility.

The Evolution of PCB Assembly

Before delving into the advantages of a fully automated PCB SMT solution line, it's essential to understand the evolution of PCB assembly techniques. Traditionally, through-hole technology was the primary method for assembling electronic components on PCBs. However, as electronics became more compact and complex, Surface Mount Technology emerged as a superior alternative.

From Through-Hole to Surface Mount Technology

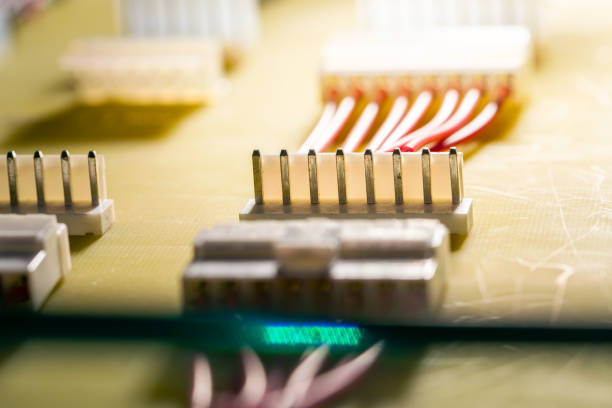

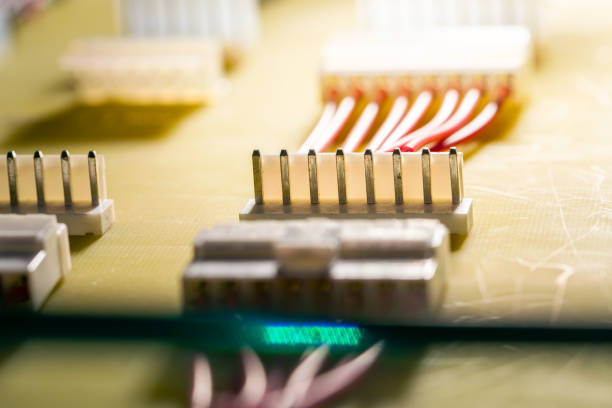

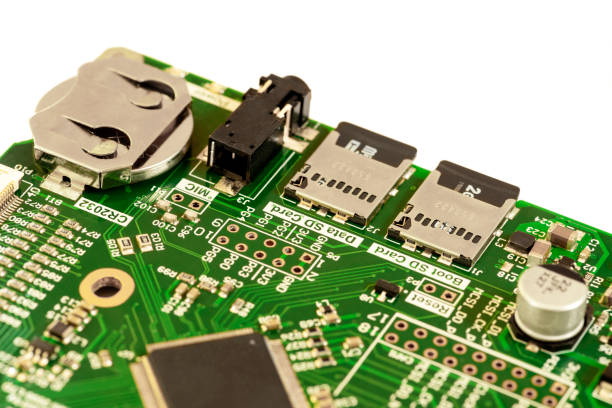

Through-hole technology involves inserting component leads into pre-drilled holes on the PCB and soldering them on the opposite side. While effective, this method has limitations in terms of component density and assembly speed. Surface Mount Technology, on the other hand, allows components to be directly placed and soldered onto the PCB surface, enabling higher component density, faster assembly, and improved performance[1].

Understanding Fully Automated PCB SMT Solution Lines

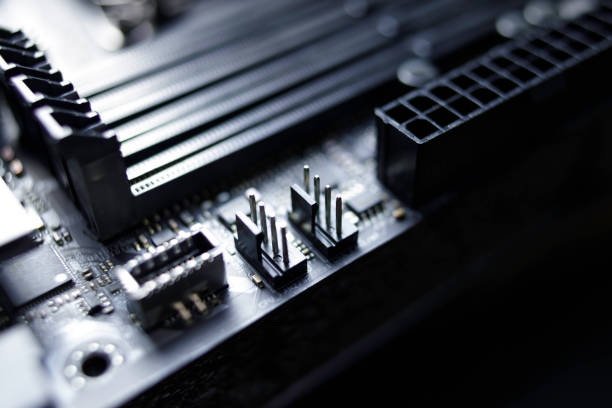

A fully automated PCB SMT solution line represents the pinnacle of modern electronics manufacturing. It combines advanced machinery, robotics, and intelligent software to create a seamless, efficient, and highly accurate assembly process. Let's explore the key components and processes involved in a typical fully automated PCB SMT solution line.

Key Components of an SMT Solution Line

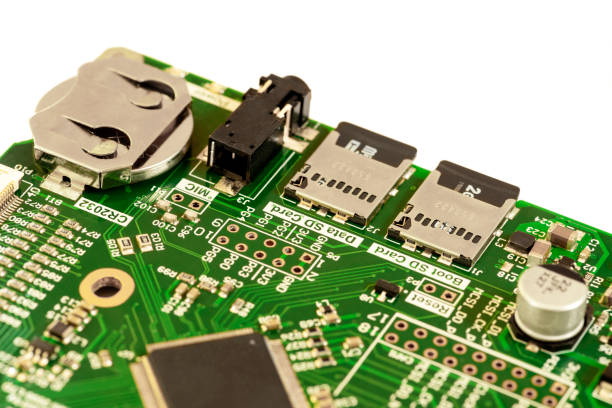

1. Solder Paste Printer: This machine precisely applies solder paste to the PCB pads, ensuring accurate component placement and reliable solder joints[3].

2. Pick and Place Machines: These high-speed robots accurately pick up and place surface mount components onto the PCB with remarkable precision[3].

3. Reflow Oven: This specialized oven melts the solder paste, creating permanent connections between components and the PCB[3].

4. Automated Optical Inspection (AOI) System: This advanced vision system inspects assembled PCBs for defects, ensuring high-quality output[3].

5. Conveyor Systems: These systems transport PCBs between different stages of the assembly process, maintaining a continuous production flow.

The SMT Assembly Process

The fully automated PCB SMT solution line follows a well-defined process to ensure efficient and high-quality production:

1. PCB Loading: Bare PCBs are loaded into the production line, often using automated feeders.

2. Solder Paste Application: The solder paste printer applies a precise amount of solder paste to the PCB pads.

3. Component Placement: Pick and place machines rapidly and accurately position surface mount components onto the PCB.

4. Reflow Soldering: The PCB passes through the reflow oven, where the solder paste melts and forms permanent connections.

5. Cooling: The assembled PCB is cooled to solidify the solder joints.

6. Inspection: The AOI system thoroughly inspects the assembled PCB for any defects or issues.

7. Unloading or Further Processing: Completed PCBs are either unloaded or moved to additional assembly stages if required[5].

Advantages of Choosing a Fully Automated PCB SMT Solution Line

Implementing a fully automated PCB SMT solution line offers numerous benefits that can significantly enhance your manufacturing capabilities and overall competitiveness in the electronics industry.

Increased Production Speed and Efficiency

One of the most significant advantages of a fully automated PCB SMT solution line is the dramatic increase in production speed and efficiency. Automated systems can assemble thousands of components per hour, far surpassing the capabilities of manual assembly methods[1]. This high-speed production allows manufacturers to meet tight deadlines and handle large-volume orders with ease.

Enhanced Precision and Consistency

Automated SMT assembly systems ensure precise placement of components, improving overall product quality and consistency[1]. The use of advanced vision systems and robotics minimizes human error, resulting in more reliable and uniform PCB assemblies. This level of precision is particularly crucial for complex, high-density PCBs used in modern electronic devices.

Reduced Labor Costs

By automating the assembly process, manufacturers can significantly lower labor expenses while increasing production output[1]. This reduction in labor costs can lead to improved profit margins and greater competitiveness in the market. Additionally, automation allows for 24/7 production capabilities without the need for shift changes or breaks.

Improved Quality Control

Fully automated PCB SMT solution lines incorporate advanced inspection and testing systems that help detect defects and ensure reliable end products[1]. Automated Optical Inspection (AOI) systems can identify issues such as misaligned components, solder bridges, or missing parts with a level of accuracy and speed that surpasses human capabilities. This results in higher overall product quality and reduced warranty claims.

Flexibility and Scalability

SMT solution lines can easily adapt to different component sizes and types, allowing manufacturers to handle various products efficiently[1]. This flexibility enables quick changeovers between different PCB designs, making it ideal for both high-volume production and small batch runs. As your production needs grow, automated SMT lines can be scaled up to meet increased demand without significant disruptions to your manufacturing process.

Miniaturization and Higher Component Density

The small size of components used in SMT PCB assembly allows for fitting many more parts on a given PCB area. This high-density capability enables miniaturization and weight reduction for electronic products, making it possible to create smaller, lighter, and more feature-rich devices[2].

Improved Reliability and Longevity

The precision soldering of tiny SMT joints creates robust interconnections between components and the PCB surface. This generally results in improved reliability and longer lifespans for SMT assembled PCBs over through-hole assemblies, especially under thermal cycling and vibration stresses[2].

Implementing a Fully Automated PCB SMT Solution Line

While the benefits of a fully automated PCB SMT solution line are clear, implementing such a system requires careful planning and consideration. Here are some key factors to keep in mind when transitioning to an automated SMT assembly process:

Initial Investment and ROI

Implementing a fully automated PCB SMT solution line requires a significant upfront investment in equipment, software, and training. However, the long-term benefits in terms of increased productivity, reduced labor costs, and improved quality often result in a favorable return on investment (ROI). It's essential to conduct a thorough cost-benefit analysis to determine the most suitable configuration for your specific production needs.

Training and Skill Development

While automation reduces the need for manual assembly, it creates a demand for skilled technicians who can operate, maintain, and troubleshoot the advanced equipment. Investing in comprehensive training programs for your staff is crucial to ensure smooth operation and maximize the benefits of your automated SMT solution line.

Integration with Existing Systems

When implementing a fully automated PCB SMT solution line, it's important to consider how it will integrate with your existing manufacturing processes and systems. This may include updating your production planning software, inventory management systems, and quality control procedures to align with the new automated workflow.

Customization and Optimization

Every manufacturing facility has unique requirements and challenges. Working closely with SMT equipment suppliers and automation experts can help you customize and optimize your automated solution line to best suit your specific production needs and goals.

Future Trends in PCB SMT Assembly

As technology continues to advance, the future of PCB SMT assembly looks promising. Some emerging trends to watch include:

Industry 4.0 Integration

The integration of Industry 4.0 principles, such as the Internet of Things (IoT) and big data analytics, is set to revolutionize PCB SMT assembly further. These technologies will enable real-time monitoring, predictive maintenance, and data-driven optimization of the production process.

Artificial Intelligence and Machine Learning

AI and machine learning algorithms are being developed to enhance the capabilities of automated SMT systems. These technologies can improve component placement accuracy, optimize production schedules, and even predict and prevent potential defects before they occur.

Advanced Materials and Components

As electronic devices become more sophisticated, new materials and component types are being developed. Automated SMT solution lines will need to adapt to handle these advanced components, such as flexible PCBs, embedded components, and 3D-printed electronics.

Conclusion

Choosing a fully automated PCB SMT solution line represents a significant step forward in electronics manufacturing capabilities. The benefits of increased production speed, enhanced precision, reduced labor costs, and improved quality control make it an attractive option for manufacturers looking to stay competitive in today's fast-paced electronics industry. While the initial investment may be substantial, the long-term advantages in terms of efficiency, scalability, and product quality often justify the cost.

As technology continues to evolve, fully automated PCB SMT solution lines will play an increasingly crucial role in meeting the demands of modern electronic device production. By embracing this advanced manufacturing approach, companies can position themselves at the forefront of innovation, ready to tackle the challenges and opportunities of the future electronics landscape.

Frequently Asked Questions

1. What is the typical return on investment (ROI) for a fully automated PCB SMT solution line?

The ROI for a fully automated PCB SMT solution line can vary depending on factors such as production volume, product complexity, and labor costs. However, many manufacturers report seeing a positive ROI within 12-24 months of implementation. The increased production speed, reduced labor costs, and improved quality control contribute significantly to cost savings and increased revenue over time.

2. How does a fully automated PCB SMT solution line handle different PCB sizes and designs?

Modern fully automated PCB SMT solution lines are designed with flexibility in mind. They can typically handle a wide range of PCB sizes and designs through adjustable conveyor systems, programmable pick and place machines, and customizable solder paste stencils. Many systems allow for quick changeovers between different PCB types, minimizing downtime and maximizing production efficiency.

3. What maintenance requirements are associated with a fully automated PCB SMT solution line?

While automated SMT lines reduce manual labor in assembly, they do require regular maintenance to ensure optimal performance. This typically includes:

- Daily cleaning of critical components

- Regular calibration of pick and place machines and inspection systems

- Periodic replacement of wear parts such as nozzles and conveyor belts

- Software updates and system diagnostics

It's essential to follow the manufacturer's recommended maintenance schedule and train staff in proper maintenance procedures to maximize the lifespan and efficiency of the equipment.

4. How does a fully automated PCB SMT solution line impact product quality?

Fully automated PCB SMT solution lines generally lead to significant improvements in product quality. The precision of automated component placement, consistent solder paste application, and advanced inspection systems result in fewer defects and more reliable PCB assemblies. Additionally, the reduction in human error and the ability to maintain consistent production parameters contribute to higher overall quality and reduced variability between production runs.

5. Can a fully automated PCB SMT solution line handle both high-volume and small-batch production?

Yes, modern fully automated PCB SMT solution lines are designed to be versatile and can handle both high-volume and small-batch production efficiently. For high-volume production, these systems excel in maintaining consistent output at high speeds. For small-batch production, quick changeover capabilities and programmable equipment allow for rapid switching between different PCB designs. This flexibility makes automated SMT lines suitable for a wide range of manufacturing scenarios, from mass production to prototype development.

Citations:

[1] https://www.smtfactory.com/what-is-an-smt-line-and-how-can-it-improve-your-pcb-assembly-process.html

[2] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[3] https://www.pcbonline.com/blog/pcb-assembly-services.html

[4] https://patents.google.com/patent/CN112040669B/zh

[5] https://www.smtfactory.com/Streamlining-Operations-How-Automation-Enhances-SMT-Line-Productivity-id47973586.html

[6] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[7] https://www.pcbgogo.com/Article/How_does_double_sided_SMT_assembly_work_.html

[8] https://www.global.toshiba/ww/company/digitalsolution/articles/tsoul/solution/s020.html

[9] https://m.smt11.com/solution/Consumer-Electronics/Exploring-the-Benefits-of-SMT-Production-Line-and-DIP-Line-in-Power-Supply-PCBA-Manufacturing-56.html

[10] https://versae.com/smt-assembly-faq/

[11] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[12] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-pcb-assembly-processes-benefits-and-applications/