Content Menu

● Introduction to SMT and PCB Spacers

>> Surface Mount Technology (SMT)

>> PCB Spacers in SMT

● Benefits of Using PCB Spacers SMT

>> Enhanced Stability and Reliability

>> Streamlined Assembly Process

>> Cost Efficiency

● Design Considerations for PCB Spacers SMT

● Types of PCB Spacers SMT

● Applications of PCB Spacers SMT

● Challenges and Limitations

● Future Trends in SMT and PCB Spacers

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using PCB spacers SMT?

>> 2. How do PCB spacers SMT contribute to thermal management?

>> 3. What types of PCB spacers are available for SMT applications?

>> 4. How do PCB spacers SMT enhance the assembly process?

>> 5. What are the key design considerations for incorporating PCB spacers SMT into PCB designs?

● Citations:

In the realm of electronic manufacturing, Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. As technology advances, the demand for more compact, efficient, and reliable electronic systems has led to the widespread adoption of Surface Mount Technology (SMT). One crucial component in SMT assemblies is the PCB spacer, which plays a vital role in enhancing the stability, performance, and longevity of electronic circuits. In this article, we will delve into the importance of PCB spacers in SMT and explore why they are essential for your circuit design.

Introduction to SMT and PCB Spacers

Surface Mount Technology (SMT)

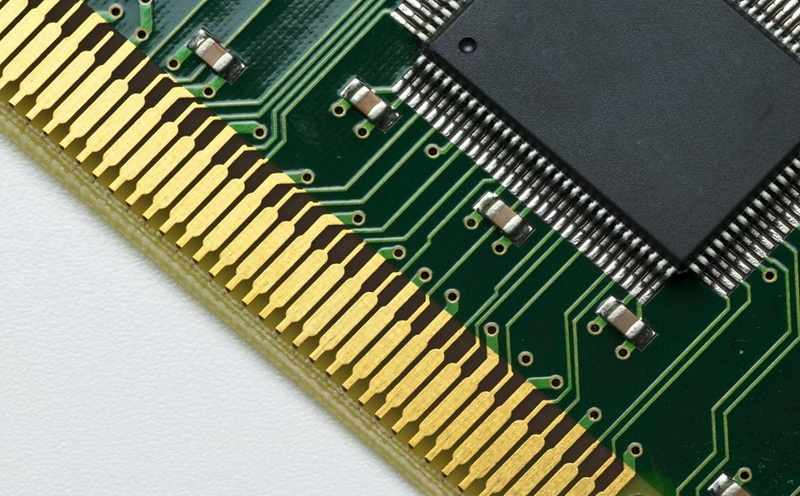

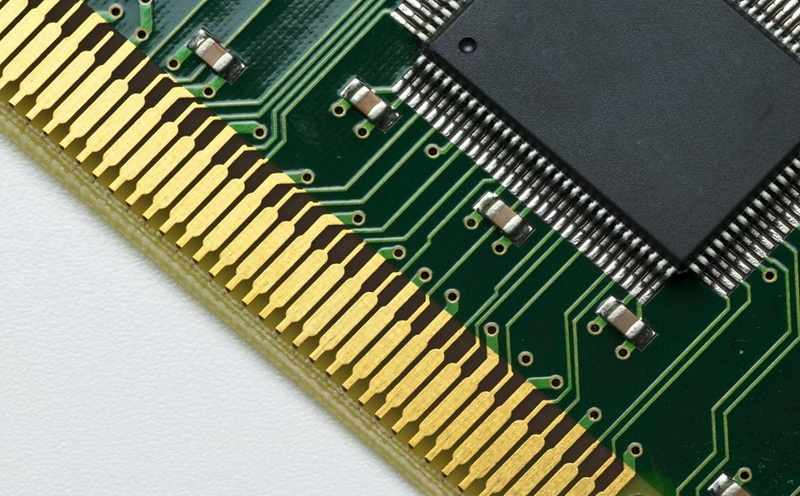

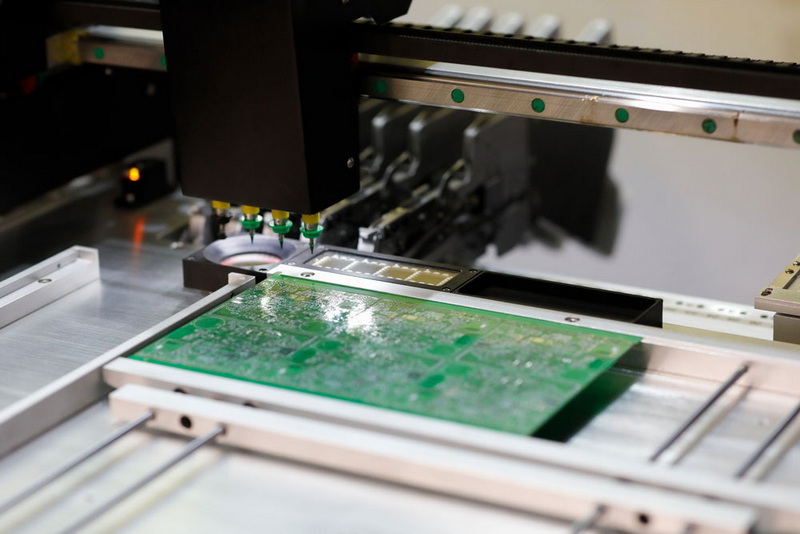

SMT is a method of mounting electronic components directly onto the surface of a PCB. This technique has revolutionized the electronics industry by enabling the production of smaller, lighter, and more complex electronic devices. SMT components are compact, with shorter leads or no leads at all, which reduces electromagnetic interference (EMI) and radio frequency interference (RFI), thereby improving signal integrity and performance[1][6].

The process involved in SMT assembly includes applying solder paste to the PCB using stencils, attaching SMT components, and using a reflow method for soldering[1]. SMT supports microelectronics by allowing more components to be placed closer together on the board, leading to designs that are more lightweight and compact[1].

PCB Spacers in SMT

PCB spacers, including those designed for SMT, are used to provide physical separation between PCBs or between a PCB and its mounting surface. These spacers are essential for maintaining airflow, reducing thermal stress, and preventing mechanical damage to components. In SMT, spacers are often surface-mounted, allowing them to be integrated seamlessly into the automated assembly process. This integration enhances production efficiency by minimizing manual handling and reducing the risk of PCB damage during assembly[3][4].

Benefits of Using PCB Spacers SMT

Enhanced Stability and Reliability

1. Mechanical Support: SMT spacers provide mechanical support to PCBs, ensuring they are securely positioned and protected from vibrations and mechanical stress. This is particularly important in applications where the PCBs are exposed to harsh environments[3].

2. Thermal Management: By maintaining a gap between PCBs or between a PCB and its mounting surface, SMT spacers facilitate better airflow and heat dissipation. This reduces thermal stress on components, enhancing their lifespan and reliability[6].

3. Electromagnetic Compatibility (EMC): Proper spacing can also contribute to better EMC performance by reducing electromagnetic coupling between components or boards[2].

Streamlined Assembly Process

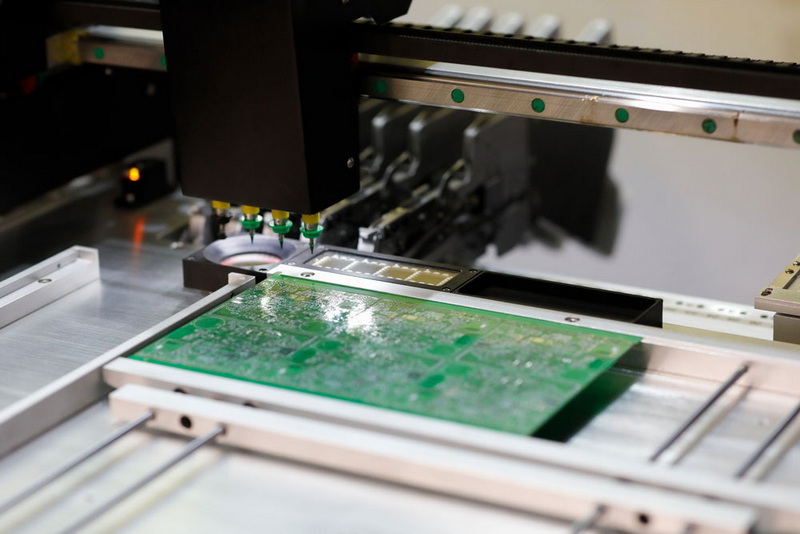

1. Automated Assembly: SMT spacers are designed to be compatible with automated assembly equipment, allowing them to be installed simultaneously with other SMT components. This streamlines the production process, reducing assembly time and minimizing the risk of human error[4][7].

2. Reduced Handling: By integrating spacers into the SMT assembly line, the need for manual handling is decreased, which reduces the risk of damage to PCBs during assembly[4].

Cost Efficiency

1. Reduced Scrap: The use of SMT spacers in automated assembly lines helps minimize scrap rates by ensuring accurate placement and reducing the likelihood of component misalignment[4].

2. Lower Production Costs: The efficiency and reliability of the SMT process, including the use of spacers, contribute to lower overall production costs. This is particularly beneficial for high-volume manufacturing[1][2].

Design Considerations for PCB Spacers SMT

When designing PCBs that incorporate SMT spacers, several factors must be considered to ensure optimal performance and reliability:

1. Component Placement: Ensure that spacers are placed in a way that does not interfere with signal paths or component placement. This requires careful planning during the PCB design phase[3].

2. Thermal Management: Consider the thermal requirements of your design and ensure that spacers are used to enhance heat dissipation where necessary[6].

3. Mechanical Stress: Assess the mechanical stress that PCBs may be subjected to and select spacers that provide adequate support and protection[3].

4. Automated Assembly Compatibility: Ensure that spacers are compatible with automated assembly equipment to streamline the production process[4].

5. Material Selection: The choice of material for spacers must be compatible with the PCB and components, ensuring durability and reliability under various environmental conditions[8].

Types of PCB Spacers SMT

PCB spacers designed for SMT come in various forms, including standard and custom-made options. These spacers can be soldered or screwed onto the PCB, depending on the application requirements. Some notable types include:

1. SMD Spacers: These are standard or custom metal parts that are soldered onto the PCB. They are often delivered in reels for SMT processes, facilitating automated assembly[3].

2. TDU Surface-Mount Spacers: These innovative spacers are designed for seamless integration with other SMT components, offering benefits such as reduced PCB handling and minimized risk of board damage[4].

3. SMT Standoffs: These provide enhanced stability and support for PCBs, ensuring proper alignment and spacing. They are crucial for applications requiring robust mechanical connections[8].

Applications of PCB Spacers SMT

PCB spacers SMT are used across a wide range of industries due to their versatility and reliability:

1. Consumer Electronics: In devices such as smartphones, laptops, and gaming consoles, SMT spacers help maintain compact designs while ensuring component reliability[2].

2. Medical Equipment: Medical devices, such as diagnostic tools and imaging equipment, rely on SMT spacers for stability and thermal management[2].

3. Automotive Industry: In automotive electronics, SMT spacers are used to support PCBs in harsh environments, ensuring reliability and performance[2].

4. Aerospace and Defense: The compact and lightweight nature of SMT assemblies, supported by spacers, is critical in aerospace and defense applications where space and weight are limited[2].

Challenges and Limitations

While PCB spacers SMT offer numerous benefits, there are also challenges and limitations to consider:

1. Design Complexity: Incorporating spacers into PCB designs requires careful planning to ensure they do not interfere with component placement or signal paths[3].

2. Cost Considerations: While SMT spacers can reduce production costs in the long run, the initial investment in custom or specialized spacers may be higher[2].

3. Material Selection: The choice of material for spacers must be compatible with the PCB and components, ensuring durability and reliability under various environmental conditions[8].

Future Trends in SMT and PCB Spacers

The future of SMT and PCB spacers is closely tied to advancements in miniaturization and automation. As manufacturers aim to pack more functionality into smaller devices, the role of SMT spacers will become even more critical for maintaining component reliability and performance[5]. Additionally, integrating SMT with other technologies like 3D printing will offer new opportunities for design flexibility and customization[5].

Conclusion

PCB spacers SMT are essential components in modern electronic circuit design, offering enhanced stability, reliability, and efficiency in SMT assemblies. By understanding the benefits and design considerations of these spacers, engineers can create more robust and compact electronic systems. As technology continues to evolve, the role of PCB spacers in SMT will remain critical for achieving high-performance and cost-effective electronic devices.

Frequently Asked Questions

1. What are the primary benefits of using PCB spacers SMT?

PCB spacers SMT provide enhanced mechanical support, improved thermal management, and streamlined assembly processes. They are essential for maintaining the reliability and performance of electronic circuits.

2. How do PCB spacers SMT contribute to thermal management?

PCB spacers SMT facilitate better airflow and heat dissipation by maintaining a gap between PCBs or between a PCB and its mounting surface. This reduces thermal stress on components, enhancing their lifespan and reliability.

3. What types of PCB spacers are available for SMT applications?

PCB spacers for SMT include standard and custom-made options, such as SMD spacers and TDU surface-mount spacers. These can be soldered or screwed onto the PCB, depending on the application requirements.

4. How do PCB spacers SMT enhance the assembly process?

PCB spacers SMT are designed to be compatible with automated assembly equipment, allowing them to be installed simultaneously with other SMT components. This reduces assembly time, minimizes manual handling, and decreases the risk of PCB damage.

5. What are the key design considerations for incorporating PCB spacers SMT into PCB designs?

Key design considerations include ensuring that spacers do not interfere with signal paths or component placement, assessing thermal management needs, and selecting spacers that provide adequate mechanical support and are compatible with automated assembly processes.

Citations:

[1] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[2] https://www.altestcorp.com/surface-mount-technology/

[3] https://jhdpcb.com/pcb-assembly/smt-assembly/

[4] https://www.pencomsf.com/articles-updates/tdu-surface-mount-spacers/

[5] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[6] https://www.wevolver.com/article/pcb-mounting

[7] https://www.buerklin.com/en/electronic-competence/electrical-manufacturing/optimise-manufacturing-with-smt-spacer-bolts/

[8] https://www.fivetk.com/e-news/pcb-standoffs/

[9] https://www.digikey.com/en/product-highlight/w/wurth-electronics/smt-spacers

[10] https://www.essentracomponents.com/en-us/s/pcb-spacers

[11] https://www.keyelco.com/category.cfm/Spacers-Standoffs/Standoffs-Spacers-Inserts-Surface-Mount/id/1335

[12] https://novaenginc.com/future-of-circuit-board-assembly/

[13] https://www.we-online.com/files/pdf1/final_smarter-designs-with-smt-spacers.pdf

[14] https://learn.sparkfun.com/tutorials/designing-pcbs-advanced-smd/all

[15] https://www.tech-sparks.com/pcb-technology-trends/

[16] https://www.essentracomponents.com/en-us/news/solutions/pcb-electronics/a-guide-to-pcb-spacers

[17] https://www.andwinpcb.com/aluminium-pcb-spacer/

[18] https://www.pentalogix.com/blog/2023/11/17/the-future-of-pcb-fabrication-emerging-technologies-and-trends/

[19] https://www.youtube.com/watch?v=hudb5a-Z674

[20] https://www.advancedpcb.com/en-us/blog/the-most-common-uses-of-printed-circuit-boards-with-smt-technology/