Content Menu

● Understanding SMT Nozzles

>> Importance of Nozzle Cleaning

● Types of SMT Nozzle Cleaning Tools

>> 1. Automated SMT Nozzle Cleaners

>>> Advantages of Automated Cleaners

>> 2. Ultrasonic Cleaners

>>> How Ultrasonic Cleaning Works

>> 3. Manual Cleaning Tools

>>> Limitations of Manual Cleaning

>> 4. Smart Nozzle Cleaners

>>> Benefits of Smart Technology

>> 5. Specialized Cleaning Solutions

>>> Choosing the Right Solution

● Factors to Consider When Choosing a Cleaning Tool

● Best Practices for SMT Nozzle Cleaning

>> Implementing a Training Program

● Conclusion

● FAQ

>> 1. What is an SMT nozzle cleaner?

>> 2. How often should SMT nozzles be cleaned?

>> 3. Can ultrasonic cleaners be used for all types of SMT nozzles?

>> 4. What are the benefits of automated nozzle cleaners?

>> 5. Are there any risks associated with manual nozzle cleaning?

● Citations:

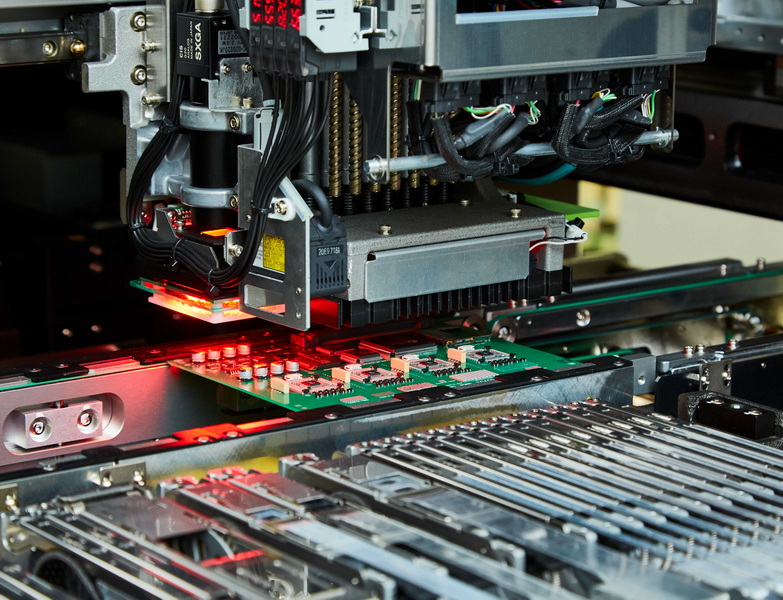

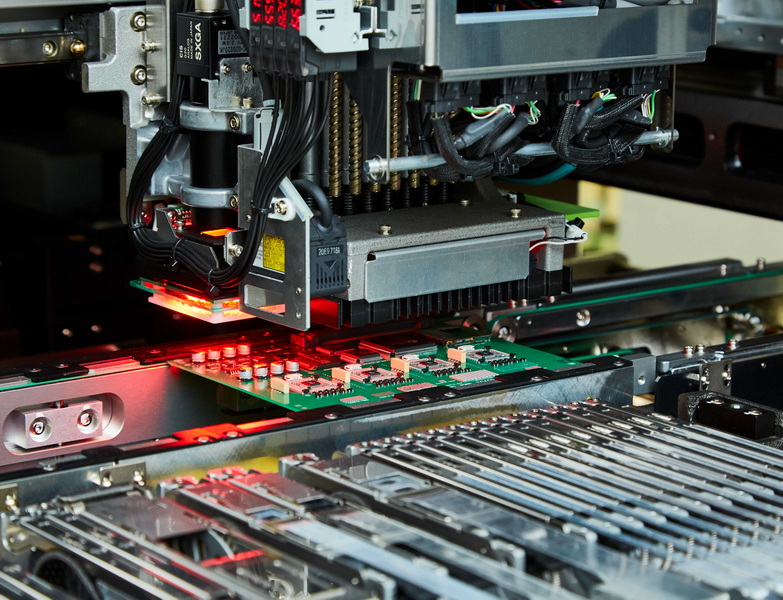

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the assembly of printed circuit boards (PCBs). A critical component of this process is the nozzle used in pick-and-place machines, which must be kept clean to ensure optimal performance. This article explores the various tools available for SMT nozzle cleaning, their features, and how they contribute to maintaining the efficiency and longevity of SMT operations.

Understanding SMT Nozzles

SMT nozzles are specialized components that handle the precise placement of electronic components onto PCBs. These nozzles can accumulate residue from solder paste, dust, and other contaminants, which can lead to misplacement or damage to components. Regular cleaning of these nozzles is essential to maintain accuracy and reduce downtime in production lines.

Importance of Nozzle Cleaning

- Enhanced Accuracy: Clean nozzles ensure precise placement of components, reducing the risk of errors.

- Increased Lifespan: Regular cleaning extends the life of nozzles by preventing buildup that can lead to wear and tear.

- Reduced Downtime: Efficient cleaning processes minimize interruptions in production, allowing for smoother operations.

- Cost Efficiency: By maintaining clean nozzles, manufacturers can avoid costly rework and scrap due to misplaced components.

Types of SMT Nozzle Cleaning Tools

There are several tools and machines designed specifically for SMT nozzle cleaning. Below are some of the most effective options available on the market:

1. Automated SMT Nozzle Cleaners

Automated nozzle cleaners are designed to handle multiple nozzles simultaneously, offering high efficiency and consistent results. These machines often use high-pressure deionized (DI) water or ultrasonic cleaning methods.

- Example Models:

- BNC-8000: This machine can clean up to 30 nozzles at once with a washing cycle time adjustable to meet specific needs.

- HS-800: Capable of washing 30 nozzles simultaneously using high-pressure DI water, this model is known for its excellent cleaning performance.

Advantages of Automated Cleaners

Automated cleaners significantly reduce labor costs and human error. They provide consistent cleaning results that are crucial for maintaining quality standards in high-volume production environments. Additionally, many automated systems can be integrated into existing production lines, allowing for seamless operation.

2. Ultrasonic Cleaners

Ultrasonic cleaners utilize high-frequency sound waves to agitate a cleaning solution, effectively removing contaminants from nozzles. They are particularly useful for intricate designs where traditional cleaning methods may fail.

- Advantages:

- Thorough cleaning of small internal passages.

- Effective removal of stubborn residues without damaging the nozzle surface.

- Versatile use for various components beyond just nozzles.

How Ultrasonic Cleaning Works

The ultrasonic cleaning process involves immersing the nozzles in a tank filled with a specially formulated cleaning solution. The ultrasonic waves create millions of tiny bubbles that implode upon contact with surfaces, dislodging dirt and contaminants. This method is highly effective for complex geometries found in many SMT nozzles.

3. Manual Cleaning Tools

For smaller operations or specific maintenance tasks, manual cleaning tools such as brushes and wipes can be effective. However, these methods require skilled operators to ensure thorough cleaning without damaging the nozzles.

- Recommended Practices:

- Use soft brushes to avoid scratching surfaces.

- Employ lint-free wipes with appropriate cleaning solutions.

- Implement a checklist for manual cleaning processes to ensure consistency.

Limitations of Manual Cleaning

While manual cleaning can be effective, it often lacks the consistency and thoroughness offered by automated solutions. Additionally, it is more labor-intensive and may lead to variability in results depending on the operator's skill level.

4. Smart Nozzle Cleaners

These advanced systems automate not only the cleaning process but also inspection and maintenance scheduling. They utilize ultra-pure water for consistent results and can handle a variety of nozzle types.

- Key Features:

- Automated inspection capabilities.

- Integration with production schedules for optimal efficiency.

- Data logging features that allow manufacturers to track performance over time.

Benefits of Smart Technology

Smart nozzle cleaners represent a significant advancement in SMT maintenance technology. By integrating data analytics into the cleaning process, manufacturers can predict when maintenance is needed based on usage patterns, thereby preventing unexpected downtimes.

5. Specialized Cleaning Solutions

Some manufacturers offer proprietary cleaning solutions designed specifically for SMT nozzles. These solutions are formulated to enhance the effectiveness of both manual and automated cleaning processes.

- Types of Cleaning Solutions:

- Solvent-based cleaners that dissolve solder paste residues.

- Biodegradable detergents that are environmentally friendly.

Choosing the Right Solution

Selecting an appropriate cleaner is crucial as some solvents may be too harsh for certain nozzle materials. Always consult manufacturer guidelines when choosing a cleaning solution to avoid damaging sensitive components.

Factors to Consider When Choosing a Cleaning Tool

When selecting an SMT nozzle cleaning tool, consider the following factors:

- Type of Nozzle: Different nozzles may require specific cleaning methods or tools.

- Production Volume: High-volume operations may benefit more from automated solutions.

- Budget Constraints: Evaluate the cost-effectiveness of each option based on your operational needs.

- Ease of Use: Tools that require minimal training can save time and reduce errors during operation.

- Maintenance Requirements: Consider how easy it is to maintain and service each tool over time.

Best Practices for SMT Nozzle Cleaning

To maximize the effectiveness of your chosen cleaning method, follow these best practices:

1. Regular Maintenance Schedule: Establish a routine cleaning schedule based on production volume and nozzle usage.

2. Use Appropriate Cleaning Solutions: Ensure that any solvents or detergents used are compatible with your nozzle materials.

3. Monitor Performance: Keep track of nozzle performance metrics to identify when cleaning is necessary.

4. Train Personnel: Ensure that staff are trained in proper cleaning techniques to prevent damage during maintenance.

5. Document Cleaning Procedures: Maintain records of all cleaning activities to track performance improvements over time.

Implementing a Training Program

Investing in training programs for operators can significantly enhance the effectiveness of your maintenance efforts. Training should cover:

- Proper use of each type of cleaner

- Safety protocols when handling chemicals

- Troubleshooting common issues related to nozzle performance

Conclusion

Maintaining clean SMT nozzles is crucial for ensuring high-quality electronic assembly processes. With various tools available—from automated cleaners to ultrasonic systems—manufacturers can choose options that best fit their operational needs. By implementing regular maintenance schedules and utilizing appropriate cleaning methods, businesses can enhance productivity, reduce downtime, and extend the lifespan of their equipment.

In summary, investing in proper tools and techniques for SMT nozzle cleaning not only improves manufacturing efficiency but also contributes significantly to product quality and reliability. As technology advances, staying informed about new developments in nozzle cleaning will further enhance operational capabilities within the electronics manufacturing sector.

FAQ

1. What is an SMT nozzle cleaner?

An SMT nozzle cleaner is a specialized machine designed to remove contaminants from pick-and-place machine nozzles to ensure accurate component placement.

2. How often should SMT nozzles be cleaned?

The frequency of cleaning depends on production volume and type of components used; however, establishing a regular maintenance schedule is recommended.

3. Can ultrasonic cleaners be used for all types of SMT nozzles?

While ultrasonic cleaners are effective for many types, they may not be suitable for all designs; it's important to check compatibility with specific nozzle types.

4. What are the benefits of automated nozzle cleaners?

Automated nozzle cleaners provide consistent results, reduce labor costs, improve efficiency by handling multiple nozzles at once, and minimize downtime in production lines.

5. Are there any risks associated with manual nozzle cleaning?

Yes, manual cleaning poses risks such as potential damage to delicate nozzle surfaces or inconsistent cleaning results if not performed correctly.

Citations:

[1] https://www.smt-nozzle.com/smt-equipment/smt-nozzle-cleaner.htm

[2] https://dezsmartech.com/product/smt-nozzle-cleaning-machine/

[3] https://www.odm-technology.com/mobile/prod/auto-smt-nozzle-cleaner

[4] http://www.bstkor.com/eng/product/bnc8000.html

[5] https://smt.fuji.co.jp/en/topics/3439

[6] https://www.pcbunlimited.com/products/hs-800-smt-nozzle-cleaning-machine

[7] https://kyoritsuelectric.com/products/pcba-tools-and-other-peripherals/smt-cleaning-systems/nozzle-cleaning-machine/

[8] https://smt.fuji.co.jp/en/product/smartnozzle