Content Menu

● Understanding SMT Pick and Place Machines

>> Key Features of SMT Pick and Place Machines

● Types of Components Handled by SMT Pick and Place Machines

>> 1. Passive Components

>> 2. Active Components

>> 3. Electromechanical Components

>> 4. Specialized Components

● Factors Affecting Component Handling

>> 1. Component Size

>> 2. Component Weight

>> 3. Component Shape

>> 4. Packaging Type

● Advanced Capabilities of Modern SMT Pick and Place Machines

>> 1. Multi-Head Placement

>> 2. Advanced Vision Systems

>> 3. Automatic Nozzle Change

>> 4. Component Traceability

● Impact on Electronics Manufacturing

>> 1. Increased Efficiency

>> 2. Improved Accuracy

>> 3. Miniaturization

>> 4. Cost Reduction

● Challenges and Limitations

>> 1. Component Compatibility

>> 2. Setup Time

>> 3. Maintenance Requirements

>> 4. Cost

● Future Trends

>> 1. Artificial Intelligence Integration

>> 2. Increased Flexibility

>> 3. Enhanced Integration

>> 4. Sustainability Features

● Conclusion

● FAQ

>> 1. What is the smallest component size that an SMT pick and place machine can handle?

>> 2. How fast can SMT pick and place machines operate?

>> 3. Can SMT pick and place machines handle both SMT and through-hole components?

>> 4. How do SMT pick and place machines ensure accurate component placement?

>> 5. What maintenance is required for SMT pick and place machines?

● Citations:

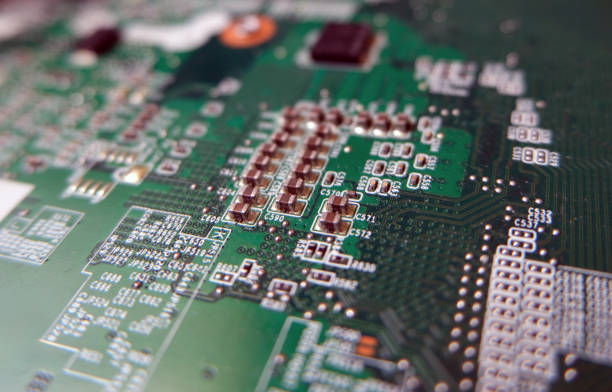

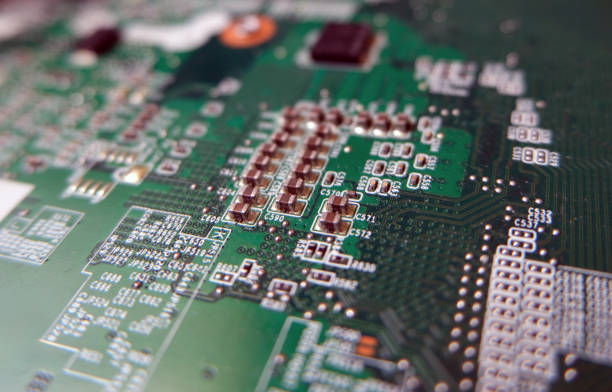

Surface Mount Technology (SMT) pick and place machines are essential tools in modern electronics manufacturing. These sophisticated devices are designed to handle a wide variety of electronic components, placing them with high precision onto printed circuit boards (PCBs). The versatility of these machines is crucial in today's fast-paced electronics industry, where miniaturization and complexity are constantly increasing. This article will explore the various types of components that can be handled by SMT pick and place machines, their capabilities, and the impact they have on electronics manufacturing.

Understanding SMT Pick and Place Machines

Before delving into the types of components these machines can handle, it's important to understand what SMT pick and place machines are and how they function. A pcb smt pick and place machine is a robotic device designed to automatically pick up electronic components from feeders or reels and place them onto a PCB with extreme accuracy[2]. These machines are the backbone of modern electronics assembly lines, capable of placing thousands of components per hour with precision that far exceeds human capabilities.

Key Features of SMT Pick and Place Machines

1. High-Speed Operation: Modern SMT pick and place machines can place components at rates of tens of thousands per hour, making them essential for high-volume production.

2. Precision Placement: These machines can place components with accuracy down to micrometers, ensuring proper alignment and connection on the PCB.

3. Flexibility: They can handle a wide range of component sizes and types, from tiny resistors to large integrated circuits.

4. Vision Systems: Advanced optical systems allow the machines to inspect components and ensure correct orientation before placement.

5. Programmability: SMT pick and place machines can be programmed to handle different PCB layouts and component configurations, making them versatile for various production needs.

Types of Components Handled by SMT Pick and Place Machines

SMT pick and place machines are designed to handle a vast array of surface mount components. Let's explore the main categories of components these machines can work with:

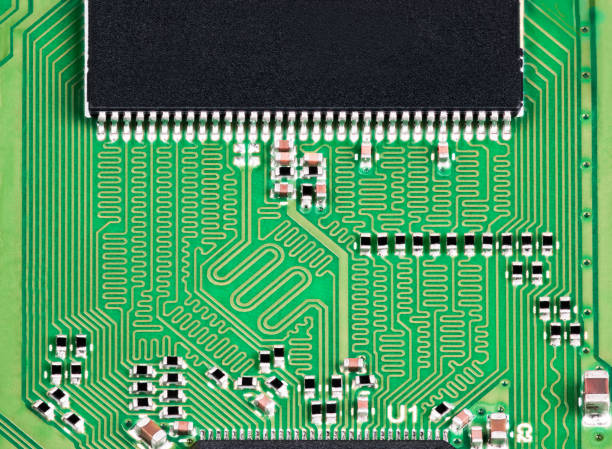

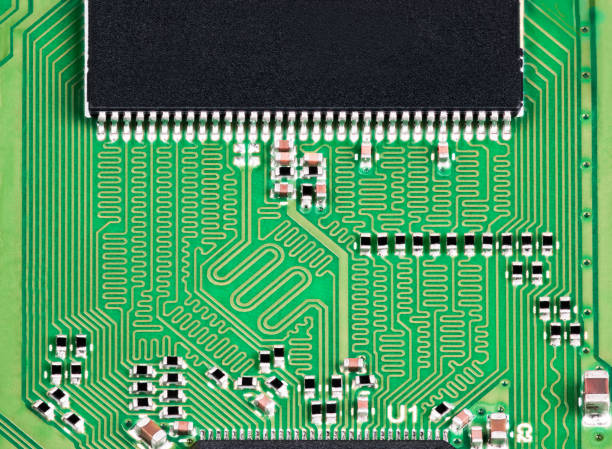

1. Passive Components

Passive components are the most common type of components placed by SMT machines. These include:

- Resistors: Surface mount resistors come in various sizes, from tiny 0201 packages to larger 2512 packages. SMT machines can handle all these sizes efficiently.

- Capacitors: Like resistors, capacitors come in various sizes and types, including ceramic, tantalum, and electrolytic capacitors. SMT machines are adept at placing these components accurately.

- Inductors: Surface mount inductors, which are crucial for power management and signal filtering, can also be placed by these machines.

2. Active Components

Active components are more complex and often require more precise placement. SMT pick and place machines are capable of handling:

- Integrated Circuits (ICs): From simple logic gates to complex microprocessors, SMT machines can place a wide range of ICs. This includes packages like SOICs, QFPs, BGAs, and even fine-pitch components.

- Transistors: Various types of surface mount transistors, including MOSFETs and BJTs, can be placed accurately.

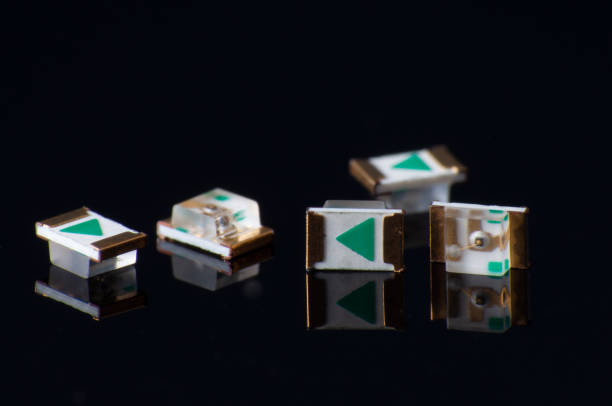

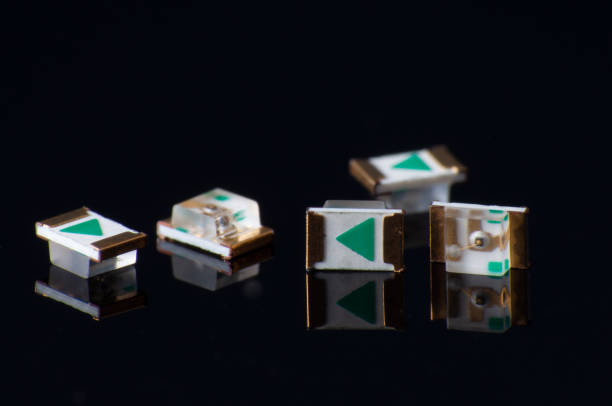

- Diodes: SMT machines can handle different types of diodes, including rectifier diodes, Zener diodes, and LEDs.

3. Electromechanical Components

While less common, many SMT pick and place machines can also handle certain electromechanical components:

- Switches: Small surface mount switches can be placed by these machines.

- Connectors: Some types of surface mount connectors can be handled, although larger connectors might require manual placement.

- Relays: Certain small surface mount relays can be placed by SMT machines.

4. Specialized Components

Modern SMT pick and place machines are increasingly capable of handling more specialized components:

- RF Components: Components used in radio frequency circuits, such as filters and antennas, can often be placed by SMT machines.

- Optoelectronic Components: This includes components like photodiodes, phototransistors, and optocouplers.

- MEMS Devices: Micro-Electro-Mechanical Systems (MEMS) components, used in sensors and actuators, can be placed by advanced SMT machines.

Factors Affecting Component Handling

Several factors influence the ability of a pcb smt pick and place machine to handle different components:

1. Component Size

SMT pick and place machines can handle a wide range of component sizes, from tiny 0201 packages (0.6 mm × 0.3 mm) to much larger components. However, the exact size range depends on the specific machine model. High-end machines can handle components as small as 01005 (0.4 mm × 0.2 mm) and as large as 50 mm × 50 mm or even bigger[1].

2. Component Weight

The weight of components affects how they can be picked and placed. Lighter components can be handled with vacuum nozzles, while heavier components might require mechanical grippers. Most SMT machines are designed to handle components weighing from a fraction of a gram to several grams.

3. Component Shape

While most SMT components are rectangular or square, some have irregular shapes. Advanced SMT machines use vision systems to recognize and correctly orient these components before placement.

4. Packaging Type

Components come in various packaging types, including:

- Tape and reel

- Trays

- Tubes

- Bulk

SMT pick and place machines must be compatible with these different packaging types to handle a wide range of components effectively.

Advanced Capabilities of Modern SMT Pick and Place Machines

As technology advances, SMT pick and place machines are becoming more sophisticated, offering new capabilities:

1. Multi-Head Placement

Many modern machines feature multiple placement heads, allowing them to pick and place several components simultaneously, greatly increasing throughput.

2. Advanced Vision Systems

High-resolution cameras and sophisticated image processing algorithms allow machines to inspect components for defects and ensure precise placement.

3. Automatic Nozzle Change

To handle different component types and sizes, some machines can automatically switch between different nozzle types during operation.

4. Component Traceability

Advanced machines can track individual components from their reels to their placement on the PCB, enhancing quality control and traceability.

Impact on Electronics Manufacturing

The ability of SMT pick and place machines to handle a wide variety of components has revolutionized electronics manufacturing:

1. Increased Efficiency

By automating the placement of components, these machines have dramatically increased the speed and efficiency of PCB assembly.

2. Improved Accuracy

The precision of SMT machines far exceeds what is possible with manual placement, leading to higher quality and more reliable electronic products.

3. Miniaturization

The ability to place tiny components accurately has enabled the trend towards smaller, more compact electronic devices.

4. Cost Reduction

While SMT machines represent a significant initial investment, they can greatly reduce labor costs and increase production volume, leading to overall cost savings in manufacturing.

Challenges and Limitations

Despite their advanced capabilities, SMT pick and place machines do face some challenges:

1. Component Compatibility

Not all components are designed for automated placement. Some specialized or oversized components may still require manual placement.

2. Setup Time

Configuring the machine for different PCB layouts and component sets can be time-consuming, especially for small production runs.

3. Maintenance Requirements

These complex machines require regular maintenance and calibration to ensure consistent performance.

4. Cost

High-end SMT pick and place machines can be very expensive, which may be prohibitive for smaller manufacturers.

Future Trends

The future of SMT pick and place machines looks promising, with several trends emerging:

1. Artificial Intelligence Integration

AI algorithms are being developed to optimize component placement strategies and predict maintenance needs.

2. Increased Flexibility

Future machines may offer even greater flexibility in handling different component types and sizes.

3. Enhanced Integration

SMT machines are likely to become more tightly integrated with other aspects of the manufacturing process, such as inventory management and quality control systems.

4. Sustainability Features

As environmental concerns grow, future machines may incorporate features to reduce energy consumption and minimize waste.

Conclusion

SMT pick and place machines are versatile and powerful tools in electronics manufacturing, capable of handling a wide array of components with high speed and precision. From tiny passive components to complex integrated circuits, these machines can place almost any surface mount component onto PCBs. Their capabilities have enabled the production of increasingly complex and miniaturized electronic devices that we rely on in our daily lives.

As technology continues to advance, we can expect SMT pick and place machines to become even more sophisticated, handling an even wider range of components with greater efficiency and precision. This ongoing evolution will continue to drive innovation in electronics manufacturing, enabling the creation of new and exciting products that push the boundaries of what's possible in electronic design.

The pcb smt pick and place machine stands at the heart of modern electronics manufacturing, a testament to the incredible progress we've made in automation and precision engineering. As we look to the future, these machines will undoubtedly play a crucial role in shaping the next generation of electronic devices, from smartphones and laptops to advanced medical equipment and autonomous vehicles.

FAQ

1. What is the smallest component size that an SMT pick and place machine can handle?

High-end SMT pick and place machines can handle components as small as the 01005 package size, which measures just 0.4 mm × 0.2 mm. However, the exact minimum size depends on the specific machine model and its capabilities.

2. How fast can SMT pick and place machines operate?

Modern SMT pick and place machines can operate at incredibly high speeds, with some high-end models capable of placing up to 120,000 components per hour or more. However, the actual speed depends on factors such as component size, placement accuracy requirements, and the complexity of the PCB layout.

3. Can SMT pick and place machines handle both SMT and through-hole components?

While SMT pick and place machines are primarily designed for surface mount components, some advanced models can handle certain types of through-hole components. However, for most through-hole components, separate insertion machines or manual assembly is still required.

4. How do SMT pick and place machines ensure accurate component placement?

SMT pick and place machines use a combination of precise mechanical systems and advanced vision technology to ensure accurate placement. They typically employ high-resolution cameras to inspect components and recognize PCB features, allowing them to place components with micrometer-level precision.

5. What maintenance is required for SMT pick and place machines?

Regular maintenance is crucial for SMT pick and place machines to ensure consistent performance. This typically includes cleaning and lubricating mechanical parts, calibrating vision systems, replacing worn nozzles, and updating software. The frequency and extent of maintenance depend on the machine's usage and the manufacturer's recommendations.

Citations:

[1] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

[2] https://www.smtfactory.com/What-Is-A-Pick-And-Place-Machine-id43068756.html

[3] https://www.tronstol.com/products/pick-and-place-machine/

[4] https://ngpd.nikon.com/en/glossary/pick-and-place-machine.html

[5] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[6] https://www.smtfactory.com/introduction-of-smt-pick-and-place-machine

[7] https://en.wikipedia.org/wiki/Pick-and-place_machine

[8] https://www.manufacturingtomorrow.com/news/2024/06/24/choosing-the-right-smt-pick-and-place-machine-a-comprehensive-guide-for-different-buyers/22957/

[9] https://www.restronicsmetro.com/blog/everything-you-need-to-know-about-smt-pick-and-place-machines