Content Menu

● The Rise of Miniaturization in SMT PCB Packaging

● Automation and Artificial Intelligence in SMT PCB Packaging

● Sustainability and Environmentally Friendly SMT PCB Packaging

● Enhanced Reliability Through Advanced SMT Techniques

● The Role of IoT and 5G in Driving SMT PCB Packaging Innovation

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is SMT PCB packaging, and why is it important?

>> 2. How does miniaturization impact SMT PCB packaging?

>> 3. What role does automation play in SMT PCB packaging?

>> 4. How is sustainability addressed in SMT PCB packaging?

>> 5. What future technologies will influence SMT PCB packaging?

● Citations:

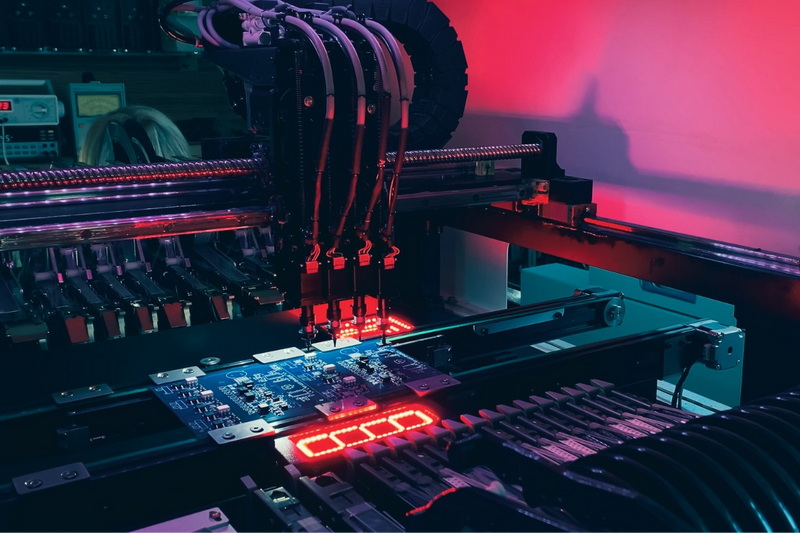

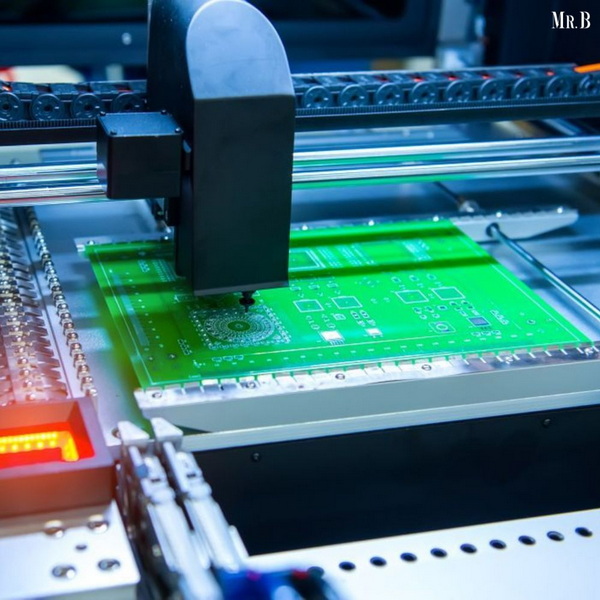

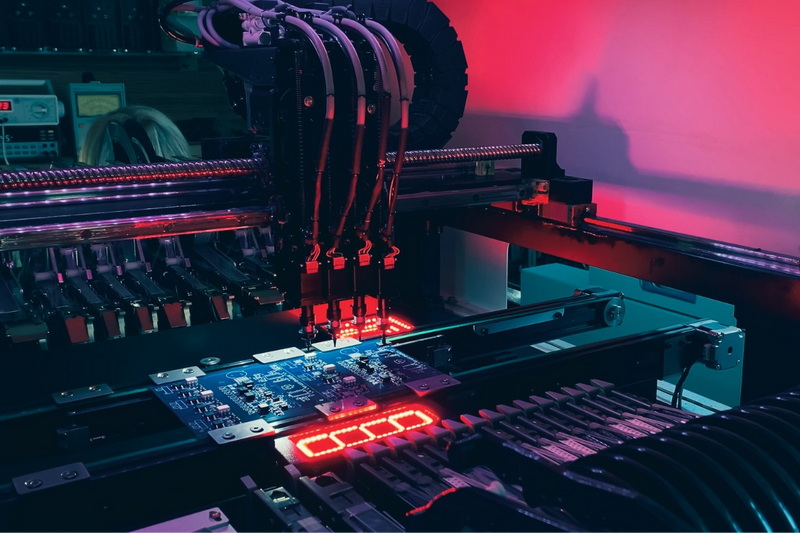

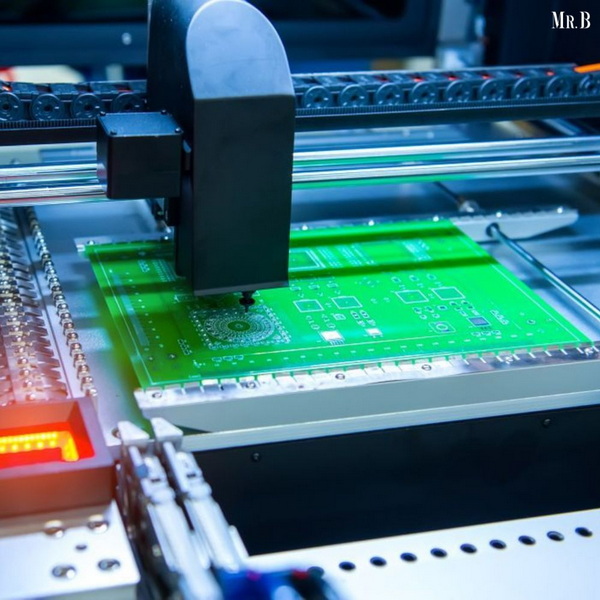

Surface Mount Technology (SMT) PCB packaging is a cornerstone of modern electronics manufacturing, enabling the assembly of compact, high-performance printed circuit boards (PCBs) that power everything from smartphones to medical devices. As technology advances, SMT PCB packaging continues to evolve, driven by trends that address miniaturization, automation, sustainability, and enhanced reliability. This article explores the key trends shaping the future of SMT PCB packaging, highlighting innovations that will define the next generation of electronic devices.

The Rise of Miniaturization in SMT PCB Packaging

One of the most significant trends influencing SMT PCB packaging is miniaturization. The demand for smaller, lighter, and more powerful electronic devices compels manufacturers to develop packaging solutions that can accommodate shrinking component sizes without compromising performance.

- High-Density Interconnect (HDI) PCBs: HDI technology uses blind, buried, and micro-vias to connect layers internally, allowing for denser circuitry and smaller board sizes. This enables more electrical connections per square inch, improving signal integrity and high-speed data transmission, essential for compact devices like smartphones and wearables[7].

- Advanced Packaging Techniques: Innovations such as fan-out wafer-level packaging (FOWLP) and chip-scale packaging (CSP) support higher integration levels while maintaining a small footprint. These methods allow components to be packaged more efficiently, reducing the overall size of PCBs[5].

- Impact on SMT PCB Assembly: SMT facilitates placing smaller components directly on the PCB surface, eliminating the need for drilled holes and enabling more compact layouts. This synergy between SMT and miniaturized packaging supports the trend toward ultra-compact electronics[6].

Miniaturization drives the continuous improvement of SMT PCB packaging, enabling manufacturers to meet consumer demands for portable and multifunctional devices.

Automation and Artificial Intelligence in SMT PCB Packaging

Automation is revolutionizing SMT PCB packaging by enhancing production efficiency, accuracy, and scalability.

- Automated Assembly Lines: Modern SMT assembly lines employ robotics and automated pick-and-place machines that reduce labor costs and minimize human error. These systems improve throughput and ensure consistent quality in high-volume manufacturing[8].

- AI and Machine Learning Integration: Artificial intelligence is increasingly used to optimize PCB layouts, predict and detect defects, and streamline quality control. Machine learning algorithms can analyze vast amounts of data to identify potential flaws early in the assembly process, reducing waste and improving yield[2][9].

- Smart Inspection Systems: Automated optical inspection (AOI) and X-ray inspection systems powered by AI enable real-time monitoring of solder joints and component placement, further enhancing reliability and reducing rework[9].

The integration of AI and automation in SMT PCB packaging is setting new standards for precision and efficiency, essential for meeting the demands of next-generation electronics.

Sustainability and Environmentally Friendly SMT PCB Packaging

Environmental concerns are increasingly influencing SMT PCB packaging practices, emphasizing the need for sustainable manufacturing.

- Lead-Free Soldering: The shift toward lead-free soldering techniques reduces toxic waste and complies with global environmental regulations such as RoHS. Lead-free processes also contribute to lowering the carbon footprint of PCB assembly[8][10].

- Eco-Friendly Materials: Manufacturers are adopting halogen-free laminates and organic substrates that are less harmful to the environment. These materials support recyclability and reduce hazardous emissions during production[10].

- Pollution Control Measures: From design to production, companies are implementing pollution control strategies to minimize environmental impact, including energy-efficient equipment and waste reduction protocols[8].

Sustainability in SMT PCB packaging is becoming a critical factor, aligning industry practices with global efforts to protect the environment.

Enhanced Reliability Through Advanced SMT Techniques

Reliability remains a paramount concern in SMT PCB packaging, especially as devices become more complex and operate in demanding environments.

- Thermal Management: Advanced SMT designs incorporate materials and packaging methods that improve heat dissipation, reducing thermal stress and extending component lifespan. Effective thermal management is crucial for high-performance applications[9].

- Improved Soldering and Assembly Processes: Innovations in solder paste formulations and reflow profiles enhance joint quality, reducing defects such as solder voids and cracks. Automated inspection further ensures consistent assembly quality[9].

- Robust Material Selection: The use of high-quality substrates and bonding materials increases resistance to mechanical stress, vibration, and environmental factors, boosting overall device durability[5].

These advancements in SMT PCB packaging techniques contribute to the production of reliable electronics that meet stringent industry standards.

The Role of IoT and 5G in Driving SMT PCB Packaging Innovation

The expansion of the Internet of Things (IoT) and the rollout of 5G networks are accelerating the demand for sophisticated SMT PCB packaging solutions.

- IoT Device Requirements: IoT devices require compact, low-power, and highly integrated PCBs to support wireless communication and sensor functionality. SMT packaging must accommodate these needs while maintaining cost-effectiveness[1][10].

- 5G Technology Demands: 5G infrastructure and devices demand PCBs capable of high-frequency signal transmission with minimal loss. Advanced SMT packaging techniques, including high-density interconnects and improved materials, enable these capabilities[7].

- System-in-Package (SiP) and Flip-Chip Technologies: These packaging methods integrate multiple chips and components into a single package, optimizing space and performance for IoT and 5G applications[10].

The convergence of IoT and 5G technologies is a powerful catalyst for innovation in SMT PCB packaging, pushing the boundaries of what is possible in electronic design.

Conclusion

The future of SMT PCB packaging is being shaped by a combination of miniaturization, automation, sustainability, enhanced reliability, and the demands of emerging technologies like IoT and 5G. Advances in high-density interconnects, AI-driven assembly processes, eco-friendly materials, and sophisticated thermal management are driving the industry toward smaller, smarter, and more sustainable electronic devices. As these trends continue to evolve, SMT PCB packaging will remain a critical enabler of innovation across consumer electronics, automotive, medical, and telecommunications sectors, ensuring that electronic devices meet the ever-increasing expectations of performance, reliability, and environmental responsibility.

Frequently Asked Questions (FAQ)

1. What is SMT PCB packaging, and why is it important?

SMT PCB packaging refers to the method of mounting electronic components directly onto the surface of printed circuit boards using Surface Mount Technology. It is important because it allows for smaller, lighter, and more efficient electronic devices, enabling high-density component placement and automated assembly processes[6][8].

2. How does miniaturization impact SMT PCB packaging?

Miniaturization drives the need for smaller components and denser PCB layouts. SMT PCB packaging supports this trend by enabling the placement of tiny surface-mounted components, which reduces board size and weight while maintaining or improving device functionality[5][7].

3. What role does automation play in SMT PCB packaging?

Automation enhances the efficiency and accuracy of SMT PCB assembly by using robotic pick-and-place machines, AI-driven inspection systems, and machine learning algorithms. This reduces errors, lowers production costs, and improves product quality[2][8][9].

4. How is sustainability addressed in SMT PCB packaging?

Sustainability is addressed through lead-free soldering, the use of eco-friendly materials like halogen-free laminates, and pollution control measures during manufacturing. These efforts reduce environmental impact and comply with regulatory standards[8][10].

5. What future technologies will influence SMT PCB packaging?

Future technologies influencing SMT PCB packaging include advanced packaging methods like fan-out wafer-level packaging, System-in-Package (SiP), AI-enhanced assembly lines, and materials that improve thermal management and electrical performance. The growth of IoT and 5G also drives demand for innovative packaging solutions[1][5][10].

Citations:

[1] https://novaenginc.com/future-of-circuit-board-assembly/

[2] https://www.linkedin.com/pulse/future-pcb-assembly-trends-you-need-know-bill-haifeng-re1gc

[3] https://www.semiconductors.org/wp-content/uploads/2020/09/Santosh-Kumar_Yole_Advanced-Packaging-Current-Trends-and-Challenges.pdf

[4] https://www.pcbnet.com/blog/future-printed-circuit-boards-trends-to-watch-for/

[5] https://www.deepblock.net/blog/packaging

[6] https://arkcircuits.com/blog/impact-of-smt-on-modern-pcb-design/

[7] https://www.rs-online.com/designspark/latest-pcb-technology-and-industry-trends

[8] https://mermarinc.com/2020/05/28/the-future-development-trends-and-scope-of-smt-pcb-assembly/

[9] https://www.andwinpcb.com/innovations-in-surface-mount-technology-for-enhanced-electronics/

[10] https://www.globenewswire.com/news-release/2024/10/09/2960347/28124/en/Global-Semiconductor-Packaging-Materials-Research-Report-2023-2028-Miniaturization-of-Electronic-Devices-Drives-Growth-IoT-Expansion-Fuels-Demand.html

[11] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[12] https://www.unmannedsystemstechnology.com/feature/mpl-explains-the-evolution-of-smt-technology/