Content Menu

● Introduction to SMT Reel Splicing

>> Benefits of SMT Reel Splicing

● Essential Tools for SMT Reel Splicing

>> 1. SMT Splice Tools

>> 2. SMT Splicing Carts

>> 3. SMT Splicing Tape

>> 4. Splice Clips and Pliers

>> 5. Carrier Tape Cutting Tools

● Techniques for Accurate SMT Reel Splicing

● Advanced Considerations in SMT Reel Splicing

>> Automation in SMT Reel Splicing

>> Material Selection

>> Environmental Factors

● Implementing SMT Reel Splicing in Production

● Troubleshooting Common Issues in SMT Reel Splicing

>> 1. Misaligned Components

>> 2. Tape Adhesion Failure

>> 3. Feeder Jams

● Advantages of Continuous SMT Reel Splicing

● Conclusion

● FAQ

>> 1. What are the primary benefits of using SMT reel splicing?

>> 2. What tools are essential for accurate SMT reel splicing?

>> 3. How does automation improve SMT reel splicing?

>> 4. What environmental factors can affect SMT reel splicing?

>> 5. How can I troubleshoot feeder jams caused by poor splices?

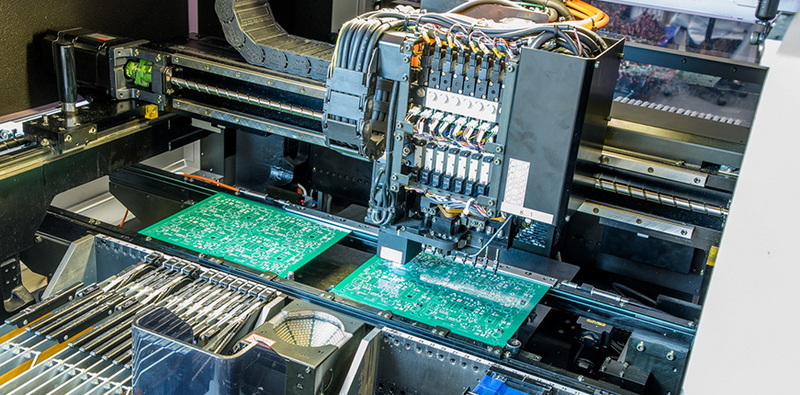

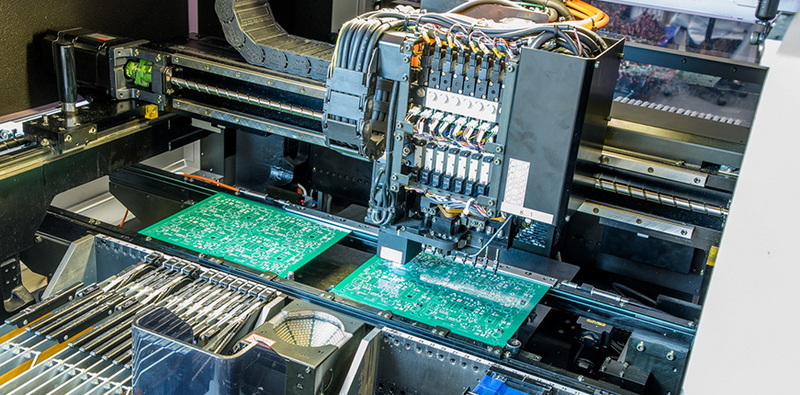

In the realm of Surface Mount Technology (SMT), maintaining continuous production is crucial for efficiency and profitability. One key aspect of achieving this continuity is SMT reel splicing, which involves joining the end of a depleted component reel to the beginning of a new one. This process is essential for minimizing downtime in pick-and-place machines and ensuring that production lines operate smoothly. To perform accurate SMT reel splicing, specific tools and techniques are required. This article will delve into the necessary tools, techniques, and strategies for effective SMT reel splicing.

Introduction to SMT Reel Splicing

SMT reel splicing is a critical operation in electronic manufacturing. It allows for the seamless transition from one reel of components to another, reducing the need for feeder reloads and minimizing production interruptions. The primary goal of splicing is to ensure that the components are accurately aligned and securely attached, enabling smooth feeding through automated assembly equipment.

Benefits of SMT Reel Splicing

1. Increased Throughput: By reducing the time spent on reel changes, SMT reel splicing helps increase the overall throughput of pick-and-place machinery.

2. Reduced Downtime: Minimizing the need for manual handling and feeder reloads significantly reduces production downtime.

3. Cost Savings: Using 100% of the components on a reel reduces waste and saves costs associated with unused components.

4. Improved Workflow: Splicing ensures that production lines remain uninterrupted, which is particularly important in high-volume manufacturing environments.

Essential Tools for SMT Reel Splicing

To achieve accurate and efficient SMT reel splicing, manufacturers rely on several specialized tools:

1. SMT Splice Tools

These are specialized tools designed to join component reel tapes together. They often use brass shims or clips to secure the splice, ensuring durability and precision. For example, the QTEK SMT Splice Tool features locating pins for accurate alignment and rivets a brass splice clip to both reels.

2. SMT Splicing Carts

Splicing carts provide a mobile platform for splicing operations, allowing technicians to perform on-the-fly splicing without removing reels from machines. These carts are typically made from durable materials and offer adjustable configurations to accommodate different reel sizes.

3. SMT Splicing Tape

This tape is used to hold the leader of the new reel together with the end of the current reel. It is designed to be strong yet flexible, allowing for smooth movement through assembly equipment. High-quality SMT splicing tape ensures that the splice does not fail during operation.

4. Splice Clips and Pliers

Splice clips are small metal pieces used to reinforce the connection between two reels, while pliers are used to apply these clips securely. These tools ensure that the splice remains intact even under high-speed feeding conditions.

5. Carrier Tape Cutting Tools

Carrier tape cutting tools are essential for preparing the carrier tape for splicing by cutting it to the correct length without damaging the components or tape structure.

Techniques for Accurate SMT Reel Splicing

Achieving precision in SMT reel splicing requires adherence to specific techniques:

1. Preparation: Cut the leader of the new reel to an appropriate length, ensuring no empty pockets are left at either end.

2. Alignment: Align the end of the current reel with the beginning of the new reel so that components are properly positioned within their pockets.

3. Splicing: Apply SMT splicing tape over the joint, ensuring it covers both sides securely. Use splice clips or pliers if necessary to reinforce the connection.

4. Verification: Before feeding into assembly equipment, verify that the splice is secure and aligned correctly.

Advanced Considerations in SMT Reel Splicing

Automation in SMT Reel Splicing

Automation has revolutionized many aspects of electronics manufacturing, including SMT reel splicing. Automated splicing systems can detect when a reel is nearing depletion and automatically splice it with a new one without manual intervention. These systems improve accuracy, reduce labor costs, and further minimize downtime.

Material Selection

The choice of materials used in splicing—such as high-strength tapes or durable splice clips—can significantly impact performance. Investing in high-quality materials ensures reliability during high-speed operations.

Environmental Factors

Environmental conditions such as humidity and temperature can affect adhesive properties of splicing tapes or cause static buildup in carrier tapes. Using anti-static materials and maintaining controlled environmental conditions can mitigate these issues.

Implementing SMT Reel Splicing in Production

To fully integrate SMT reel splicing into your production workflow, consider these strategies:

1. Assess Equipment Compatibility

Ensure that your pick-and-place machinery can recognize and handle spliced reels without interruption or misfeeds.

2. Train Personnel

Provide comprehensive training on using splicing tools and techniques to ensure consistency across operators.

3. Monitor Production Efficiency

Regularly evaluate how effectively your splicing process contributes to overall production efficiency by tracking metrics such as downtime reduction and component utilization rates.

4. Standardize Procedures

Develop standardized procedures for splicing operations to ensure uniformity across shifts and teams.

Troubleshooting Common Issues in SMT Reel Splicing

Even with proper tools and techniques, issues may occasionally arise during SMT reel splicing:

1. Misaligned Components

Misalignment can lead to feeding errors or placement inaccuracies during assembly. Ensure reels are properly aligned before applying tape or clips.

2. Tape Adhesion Failure

If adhesive tape fails during operation, check for dust or oil contamination on surfaces before application. Use high-quality tapes designed specifically for SMT applications.

3. Feeder Jams

Feeder jams may occur if carrier tapes are not cut cleanly or if splice joints are too thick. Use precision cutting tools and avoid excessive layering at splice points.

Advantages of Continuous SMT Reel Splicing

Continuous SMT reel splicing offers several advantages that directly impact production efficiency:

- Higher Throughput: By eliminating frequent machine stops for feeder reloads, continuous splicing increases overall throughput by up to 30%.

- Reduced Machine Wear: Minimizing feeder reloads reduces wear on machine components such as feeders and nozzles.

- Improved Operator Productivity: Operators spend less time reloading feeders, allowing them to focus on other critical tasks.

Conclusion

SMT reel splicing is an indispensable process in modern electronics manufacturing, enabling seamless transitions between component reels while minimizing downtime and waste. By utilizing specialized tools such as splice pliers, cutting tools, and high-quality tapes—and adhering to precise techniques—manufacturers can ensure accurate and reliable splices that support efficient production workflows.

As technology advances, automation in SMT reel splicing continues to enhance productivity by reducing manual intervention and improving accuracy even further. Implementing best practices in training personnel, monitoring efficiency metrics, and using high-quality materials will ensure long-term success in integrating this essential process into your manufacturing operations.

FAQ

1. What are the primary benefits of using SMT reel splicing?

The primary benefits include increased throughput of pick-and-place machinery, reduced downtime due to fewer reel changes, improved material utilization by using all components on a reel, and enhanced workflow efficiency.

2. What tools are essential for accurate SMT reel splicing?

Essential tools include:

- SMT splice tools

- Splice carts

- High-quality SMT splicing tapes

- Splice clips

- Carrier tape cutting tools

3. How does automation improve SMT reel splicing?

Automation reduces manual intervention by detecting low reels automatically and performing precise splices without operator input. This minimizes errors while increasing speed and consistency.

4. What environmental factors can affect SMT reel splicing?

Humidity levels can weaken adhesive bonds in tapes, while static buildup may interfere with feeding mechanisms or damage sensitive components during assembly processes.

5. How can I troubleshoot feeder jams caused by poor splices?

Ensure carrier tapes are cut cleanly using precision cutting tools; avoid creating thick joints by overlapping too many layers at splice points; verify alignment before feeding into machines.