Content Menu

● Understanding SMD Technology

● Essential Tools for SMD Assembly

>> Soldering Station

>> Solder Paste Printer

>> Pick and Place Machine

>> Reflow Oven

>> Hot Air Rework Station

>> Multimeter

>> Microscope or Magnifying Glass

>> Tweezers

>> PCB Holder or Fixture

>> Cleaning Tools

● Additional Tools That Enhance Efficiency

● Best Practices for Successful SMD Assembly

● Conclusion

● Related Questions

>> 1. What Is the Difference Between Through-Hole and Surface Mount Technology?

>> 2. How Do I Choose the Right Solder Paste for My SMD Assembly?

>> 3. Can I Assemble SMDs Without a Pick and Place Machine?

>> 4. What Are Common Issues Faced During SMD Assembly?

>> 5. How Can I Improve My Skills in SMD Assembly?

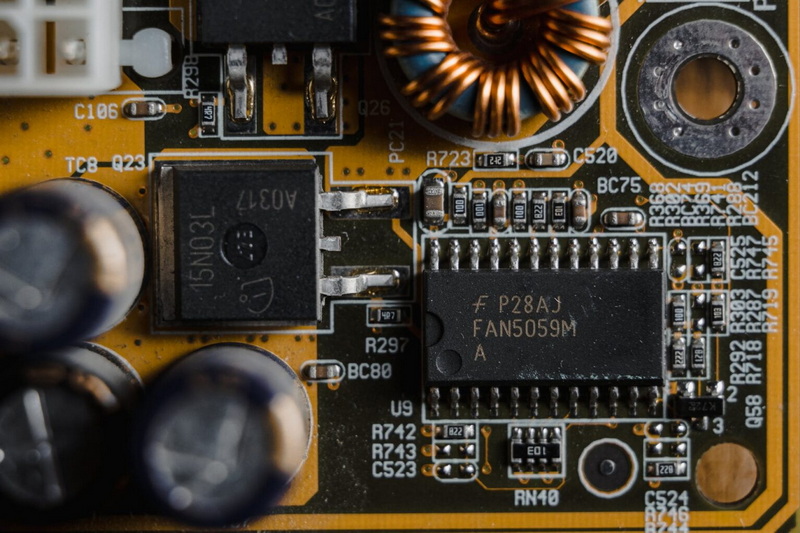

Surface Mount Devices (SMDs) have revolutionized the electronics industry by allowing for smaller, more efficient circuit designs. As technology continues to advance, the demand for SMD assembly tools has grown significantly. This article will explore the essential tools needed for successful SMD assembly, the techniques involved, and the best practices to ensure high-quality results.

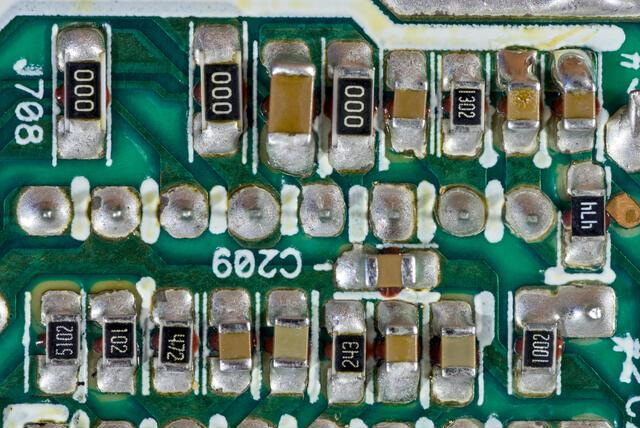

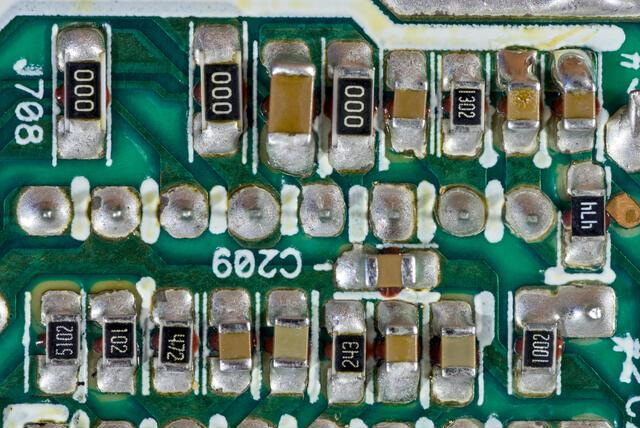

Understanding SMD Technology

SMDs are components that are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components, which require holes to be drilled into the PCB, SMDs are soldered onto pads on the surface. This technology allows for denser packing of components, improved electrical performance, and reduced manufacturing costs.

The advantages of using SMD technology extend beyond mere size reduction. SMDs generally offer better performance due to shorter electrical paths, which can reduce inductance and resistance. This is particularly important in high-frequency applications where signal integrity is crucial. Additionally, the automated assembly processes associated with SMDs lead to increased production efficiency and lower labor costs.

Essential Tools for SMD Assembly

To successfully assemble SMDs, a variety of tools are required. Below is a comprehensive list of essential tools that every electronics assembler should have.

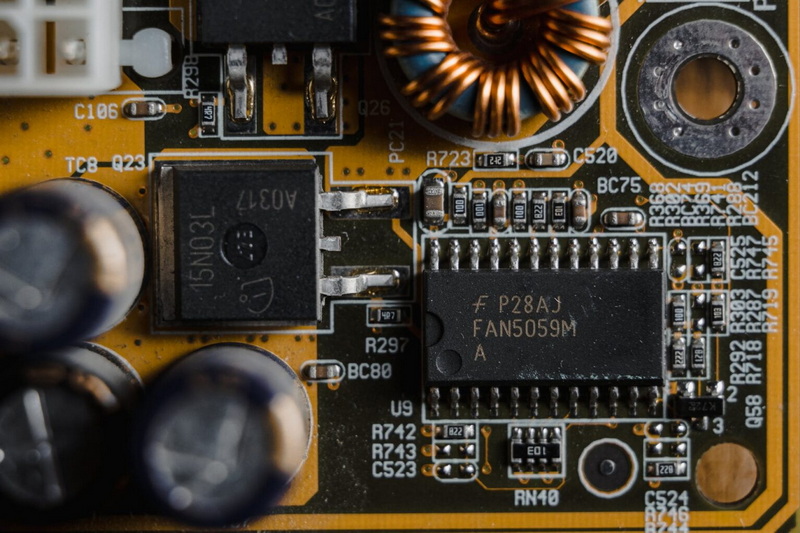

Soldering Station

A high-quality soldering station is crucial for any SMD assembly process. These stations typically feature adjustable temperature settings and a variety of soldering tips suitable for different types of components.

- Benefits: Precise temperature control helps prevent damage to sensitive components, while interchangeable tips allow for versatility in soldering various sizes of SMDs. A digital soldering station can also provide feedback on tip temperature and allow for programmable profiles tailored to specific soldering tasks.

Solder Paste Printer

For efficient soldering of SMDs, a solder paste printer is essential. This tool applies solder paste to the PCB pads where the SMDs will be placed.

- Benefits: A solder paste printer ensures an even distribution of solder paste, minimizing defects and improving joint reliability. The use of stencil printing methods can enhance precision by controlling the amount of paste applied, which is critical for fine-pitch components.

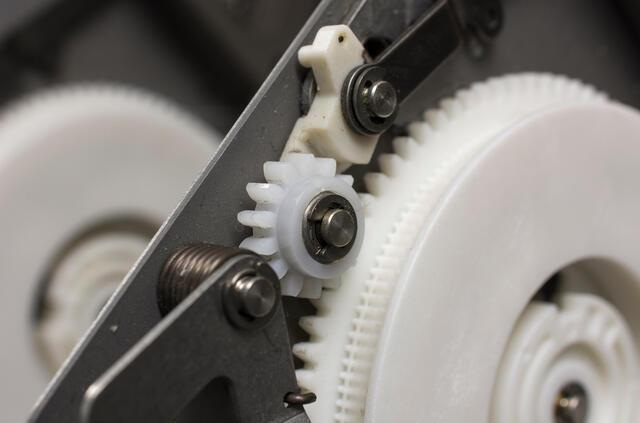

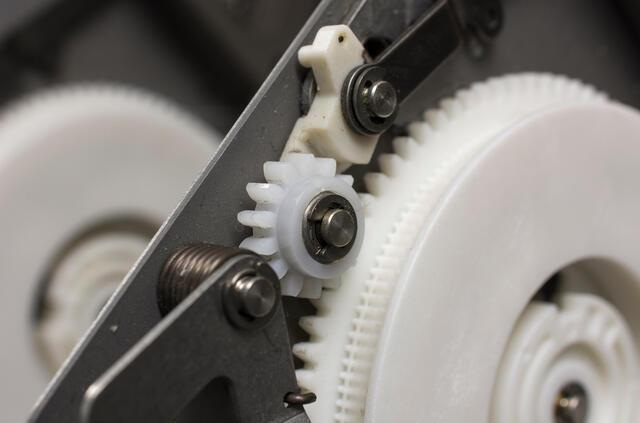

Pick and Place Machine

A pick and place machine automates the process of placing SMDs onto the PCB. This tool uses suction cups to pick up components and accurately place them on the correct pads.

- Benefits: Automating component placement increases speed and accuracy, reducing labor costs and minimizing human error. Modern pick and place machines come equipped with vision systems that can verify component placement in real-time, further enhancing assembly quality.

Reflow Oven

After placing the SMDs on the PCB with solder paste, a reflow oven is used to melt the solder and create strong electrical connections.

- Benefits: Reflow ovens provide controlled heating profiles that ensure even melting of solder paste without damaging sensitive components. Advanced reflow ovens offer features like nitrogen atmospheres to reduce oxidation during soldering, which can improve joint reliability.

Hot Air Rework Station

A hot air rework station is essential for repairing or replacing SMDs on a PCB. This tool uses hot air to heat specific areas of the board, allowing for easy removal and replacement of components.

- Benefits: The ability to target specific components minimizes damage to surrounding parts and enables efficient repairs. Many hot air rework stations also come with interchangeable nozzles for different component sizes and shapes.

Multimeter

A multimeter is an indispensable tool for testing electrical connections and ensuring that SMDs are functioning correctly after assembly.

- Benefits: Multimeters can measure voltage, current, and resistance, providing valuable feedback during the testing phase. Some advanced models also offer features such as frequency measurement and diode testing.

Microscope or Magnifying Glass

Due to the small size of SMDs, a microscope or magnifying glass is essential for inspecting solder joints and ensuring proper placement.

- Benefits: Enhanced visibility allows for better quality control and helps identify defects that may not be visible to the naked eye. Digital microscopes can provide magnification levels suitable for inspecting even the smallest components while allowing images or videos to be captured for documentation purposes.

Tweezers

Precision tweezers are vital for handling small SMD components during assembly. They allow for accurate placement without damaging delicate parts.

- Benefits: Fine-tipped tweezers provide better control when working with tiny components, increasing efficiency during manual assembly processes. Anti-static tweezers are particularly important as they prevent electrostatic discharge (ESD) that could damage sensitive electronic components.

PCB Holder or Fixture

A PCB holder or fixture stabilizes the board during assembly, making it easier to work on without risking damage or misalignment.

- Benefits: A secure hold allows assemblers to focus on precision work without worrying about shifting or dropping the board. Adjustable holders can accommodate various board sizes and shapes, enhancing versatility in different projects.

Cleaning Tools

Cleaning tools such as brushes and solvents are necessary for removing excess solder paste or flux residue after assembly.

- Benefits: Proper cleaning enhances reliability by preventing corrosion and ensuring optimal electrical performance. Using appropriate cleaning agents ensures that residues do not interfere with electrical connections or cause long-term reliability issues.

Additional Tools That Enhance Efficiency

In addition to the primary tools listed above, several other tools can enhance efficiency in SMD assembly:

- Stencil Cleaners: These help maintain cleanliness in stencil printing processes by removing excess solder paste from stencils after use.

- ESD Protection Equipment: ESD wrist straps and mats protect sensitive electronic components from static electricity during handling.

- Software Tools: Design software that integrates with assembly processes can streamline workflow from design through production by managing BOM (Bill of Materials) data effectively.

- Inspection Cameras: These cameras can be used alongside microscopes to provide real-time video feeds during assembly, allowing teams to monitor processes closely.

- Heat Gun: A versatile tool that can assist in preheating PCBs before reflow or when working with heat-sensitive materials during repairs.

Best Practices for Successful SMD Assembly

To achieve high-quality results in SMD assembly, it is essential to follow best practices throughout the process:

- Ensure all tools are calibrated and in good working condition before starting.

- Use proper techniques when applying solder paste to avoid bridging between pads.

- Maintain a clean workspace to prevent contamination of components.

- Regularly inspect assembled boards under magnification to catch defects early.

- Implement a testing phase after assembly to verify functionality before deployment.

- Train staff regularly on new technologies and techniques in SMD assembly.

- Utilize simulation software during design phases to anticipate potential issues before physical assembly begins.

- Document all processes meticulously; this not only aids in troubleshooting but also helps maintain consistency across production runs.

Conclusion

Successful SMD assembly requires a combination of specialized tools and best practices tailored to meet the demands of modern electronics manufacturing. By investing in high-quality equipment such as soldering stations, pick and place machines, reflow ovens, and other essential tools mentioned above, assemblers can ensure efficient processes and reliable products. As technology continues to evolve, staying updated with new tools and techniques will be essential for maintaining competitiveness in the industry.

The integration of automation into SMD assembly processes has transformed how electronics are manufactured today; however, human oversight remains critical in ensuring quality standards are met consistently throughout production cycles. By understanding both the tools available and best practices in their application, manufacturers can optimize their operations while delivering high-quality electronic products that meet market demands.

Related Questions

1. What Is the Difference Between Through-Hole and Surface Mount Technology?

Through-hole technology involves inserting component leads into holes drilled in a PCB, while surface mount technology (SMT) involves mounting components directly onto the surface of the PCB without drilling holes. SMT allows for smaller designs and more efficient manufacturing processes.

2. How Do I Choose the Right Solder Paste for My SMD Assembly?

Choosing the right solder paste depends on several factors including component size, pad design, and reflow profile. It's important to select a paste that matches your specific application requirements while ensuring compatibility with your reflow oven settings.

3. Can I Assemble SMDs Without a Pick and Place Machine?

Yes, it is possible to assemble SMDs manually using tweezers and a soldering iron; however, this method is less efficient than using a pick-and-place machine, especially for larger production runs where speed and accuracy are critical.

4. What Are Common Issues Faced During SMD Assembly?

Common issues include misalignment of components, insufficient solder joints, solder bridging between pads, and damage from excessive heat during reflow. Implementing quality control measures can help mitigate these problems.

5. How Can I Improve My Skills in SMD Assembly?

Improving skills in SMD assembly involves practice, attending workshops or training sessions, studying best practices in electronics manufacturing, and staying updated with new technologies in SMT processes.