Content Menu

● Introduction

● Essential Tools for SMT Nozzle Maintenance

>> 1. Cleaning Tools

>> 2. Inspection Tools

>> 3. Lubrication Tools

>> 4. Replacement Tools

>> 5. Calibration Tools

● Best Practices for SMT Nozzle Maintenance

● Common Challenges in SMT Nozzle Maintenance

>> 1. Contamination Issues

>> 2. Wear and Tear

>> 3. Compatibility Problems

>> 4. Calibration Difficulties

● Conclusion

● FAQ

>> 1. What is the most common tool used for cleaning SMT nozzles?

>> 2. How often should SMT nozzles be inspected?

>> 3. Can industrial alcohol be used for all types of nozzles?

>> 4. What are the signs that a nozzle needs replacement?

>> 5. Why is calibration important in SMT nozzle maintenance?

● Citations:

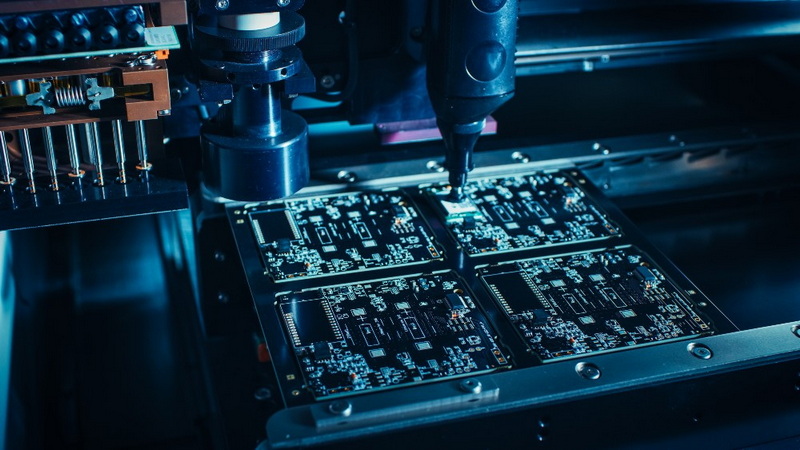

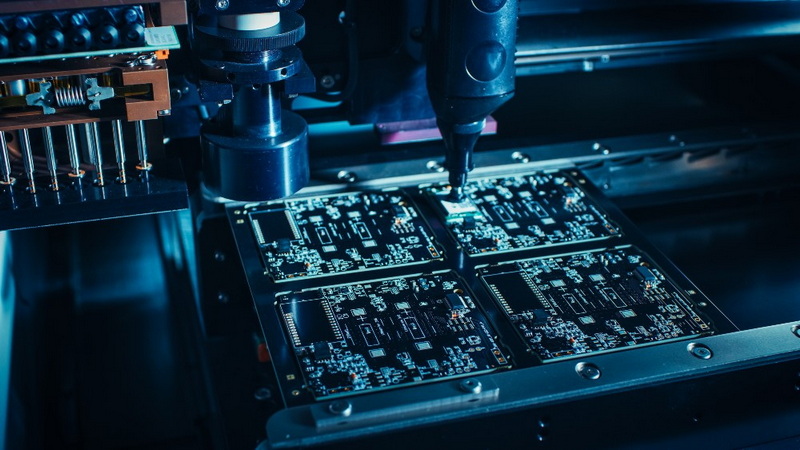

Introduction

Surface Mount Technology (SMT) nozzle maintenance is a critical aspect of ensuring the efficiency and longevity of SMT machines. These nozzles are responsible for the precise placement of components on printed circuit boards (PCBs), making their maintenance crucial for minimizing downtime and maximizing productivity. Using the right tools for maintenance not only enhances the performance of the nozzles but also extends their lifespan. This article will explore the essential tools needed for effective SMT nozzle maintenance, best practices, and frequently asked questions.

Essential Tools for SMT Nozzle Maintenance

1. Cleaning Tools

Cleaning is the first step in maintaining SMT nozzles. Essential cleaning tools include:

- Dust-free cloth: Used to wipe the surface of the nozzle to remove dust and debris. This prevents contamination that can affect performance.

- Fine steel wire: Helps in cleaning small diameter suction nozzles by removing blockages without damaging the nozzle.

- Air gun: Utilized to blow out any remaining particles from the nozzle after initial cleaning. This ensures that no debris is left that could interfere with operation.

- Industrial alcohol: Used with caution to clean the nozzle surface without causing damage. It can effectively dissolve residues but should be used sparingly to avoid corrosion on certain materials.

- Ultrasonic cleaner: For a more thorough cleaning, an ultrasonic cleaner can be employed. This device uses high-frequency sound waves to agitate a cleaning solution, effectively removing contaminants from intricate nozzle designs.

2. Inspection Tools

Regular inspection of SMT nozzles is vital to identify wear and tear early. Tools include:

- Magnifying glass: Allows for a closer look at the nozzle surface for any visible damage or wear, making it easier to spot issues before they become serious.

- Optical microscope: Provides a detailed view of the nozzle's condition, ensuring precision in maintenance and allowing for thorough inspections.

- Digital caliper: This tool measures the dimensions of nozzles accurately, helping in assessing wear and ensuring that replacements meet specifications.

3. Lubrication Tools

Proper lubrication ensures smooth operation of the nozzle mechanism. Tools required are:

- Special grease: Applied to the holder claws and other moving parts to prevent wear and ensure smooth operation.

- Lubrication applicator: Ensures even distribution of grease, which is essential for maintaining optimal performance of moving parts.

- Oil syringe: For precise application of lubricant in hard-to-reach areas, an oil syringe can help maintain cleanliness while ensuring that lubrication is applied where needed.

4. Replacement Tools

When nozzles are beyond repair, replacement is necessary. Tools include:

- Nozzle replacement kit: Contains all necessary components for replacing worn-out nozzles, ensuring that replacements can be made quickly and efficiently.

- Screwdrivers: Used for disassembling and assembling nozzle parts, making it easier to replace components as needed.

- Tweezers: Precision tweezers are essential for handling small parts without causing damage or contamination during replacement processes.

5. Calibration Tools

Calibration is essential for maintaining the accuracy of component placement. Tools include:

- Calibration jig: Used to adjust the nozzle alignment to ensure that it operates within specified tolerances.

- Software tools: Assist in fine-tuning the nozzle settings for optimal performance, helping to maintain precision in component placement.

- Test boards: These boards are used during calibration processes to verify that nozzles are functioning correctly by testing their placement accuracy with various components.

Best Practices for SMT Nozzle Maintenance

To ensure the effectiveness of the maintenance process, consider the following best practices:

- Regular cleaning schedule: Establish a routine cleaning schedule to prevent buildup of debris that can lead to operational issues. A weekly cleaning routine may be beneficial depending on production volume.

- Proper handling techniques: Handle nozzles with care to avoid accidental damage during maintenance or replacement processes. Wearing gloves can help prevent oils from fingers contaminating the nozzles.

- Use of appropriate cleaning agents: Select cleaning agents that are compatible with the nozzle material to prevent corrosion or degradation over time. Always refer to manufacturer guidelines when choosing cleaning solutions.

- Documentation of maintenance activities: Keep detailed records of all maintenance activities, including cleaning schedules, inspections, and replacements. This documentation helps track performance trends and identify recurring issues.

- Training personnel: Ensure that all personnel involved in SMT nozzle maintenance are adequately trained on best practices and proper tool usage. Regular training sessions can help maintain high standards in maintenance quality.

Common Challenges in SMT Nozzle Maintenance

Despite having the right tools and practices in place, several challenges may arise during SMT nozzle maintenance:

1. Contamination Issues

Contamination from dust or residues can lead to poor performance or even failure of nozzles. Implementing strict cleanliness protocols is essential in minimizing these risks.

2. Wear and Tear

Over time, even with proper maintenance, nozzles will experience wear due to constant use. Regular inspections are crucial to catch these issues before they lead to significant downtime or production errors.

3. Compatibility Problems

Different types of components may require specific nozzles; using incorrect ones can lead to misplacement or damage during assembly. Keeping an organized inventory of various nozzle types can help mitigate this issue.

4. Calibration Difficulties

Calibration can be challenging if tools are not properly maintained or if there is a lack of understanding about how adjustments affect overall machine performance. Regular training on calibration techniques is beneficial for operators.

Conclusion

In conclusion, maintaining SMT nozzles with the right tools is essential for the efficient operation of SMT machines. Regular maintenance not only improves the performance of the nozzles but also extends their lifespan, ensuring consistent quality in PCB assembly. By investing in proper cleaning, inspection, lubrication, replacement, and calibration tools, manufacturers can significantly enhance their production efficiency and reduce downtime associated with nozzle issues.

Implementing best practices in maintenance routines while addressing common challenges will further contribute to achieving optimal results in SMT operations. An organized approach towards tool management and personnel training will ensure that every aspect of SMT nozzle maintenance is handled effectively.

FAQ

1. What is the most common tool used for cleaning SMT nozzles?

- Answer: Dust-free cloth and air gun are commonly used for cleaning SMT nozzles due to their effectiveness in removing dust and debris without causing damage.

2. How often should SMT nozzles be inspected?

- Answer: Regular inspections should be conducted weekly to ensure optimal performance and identify any potential issues early on.

3. Can industrial alcohol be used for all types of nozzles?

- Answer: Industrial alcohol should be used cautiously as it may damage some nozzle surfaces; always check compatibility before use.

4. What are the signs that a nozzle needs replacement?

- Answer: Visible wear and tear or reduced suction efficiency are clear indicators that a nozzle needs replacement to maintain operational integrity.

5. Why is calibration important in SMT nozzle maintenance?

- Answer: Calibration ensures precision in component placement, which is crucial for maintaining quality in PCB assembly and preventing defects during production.

Citations:

[1] https://www.smtneoden.com/news/how-to-maintain-and-check-smt-suction-nozzle/

[2] https://www.zjyingxing.com/info/how-to-clean-the-nozzle-of-smt-machine-80130038.html

[3] https://silmantech.com/smt-placement-machine-nozzle-cleaning/

[4] https://goldlandsmt.com/how-to-maintain-an-smt-machine/

[5] https://smtnet.com/library/files/upload/preventative-maintenance-smt.pdf