Content Menu

● Introduction to SMT Reel Sorting

>> Benefits of Effective SMT Reel Sorting

● Essential Tools for SMT Reel Sorting

● Strategies for Effective SMT Reel Sorting

>> Organizational Strategies

>> Technological Integration

● Challenges in SMT Reel Sorting

● Solutions to Challenges

● Advanced Technologies in SMT Reel Sorting

>> Smart Rack Systems

>> Industry 4.0 Integration

● Best Practices for SMT Reel Sorting

● Conclusion

● FAQs

>> 1. What is the purpose of SMT reel sorting?

>> 2. How does smart storage contribute to SMT reel sorting?

>> 3. What role do reel counters play in SMT reel sorting?

>> 4. How can pick-to-light systems enhance SMT reel sorting?

>> 5. What are the benefits of integrating inventory management software with SMT reel sorting systems?

● Citations:

Effective SMT reel sorting is crucial in the electronics manufacturing industry, particularly in surface mount technology (SMT) assembly lines. It involves organizing and managing reels of components efficiently to ensure smooth production processes. This article will explore the essential tools and strategies for effective SMT reel sorting, highlighting their benefits and applications.

Introduction to SMT Reel Sorting

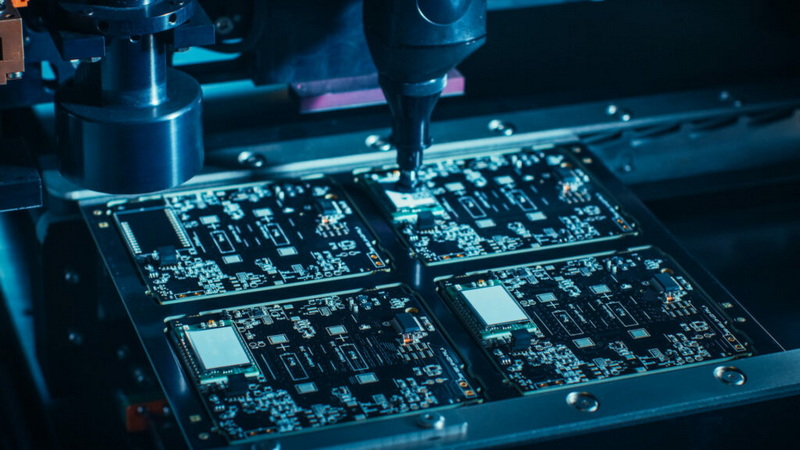

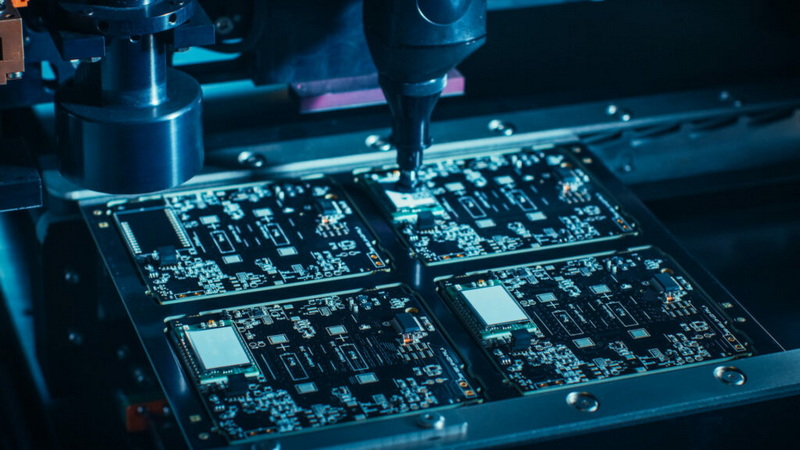

SMT reel sorting is a critical step in electronics manufacturing, as it directly impacts production efficiency and quality. Components such as resistors, capacitors, and ICs are typically stored on reels, which are then fed into pick-and-place machines for assembly onto printed circuit boards (PCBs). Proper sorting ensures that the right components are easily accessible and correctly placed on the PCBs.

Benefits of Effective SMT Reel Sorting

1. Improved Efficiency: Properly sorted reels reduce the time spent searching for specific components, allowing for faster assembly and reducing production delays.

2. Enhanced Accuracy: Sorting helps prevent mix-ups between similar components, ensuring that the correct parts are used in each assembly.

3. Cost Savings: By minimizing errors and reducing waste, companies can save on material costs and avoid costly rework.

Essential Tools for SMT Reel Sorting

Several tools are essential for effective SMT reel sorting:

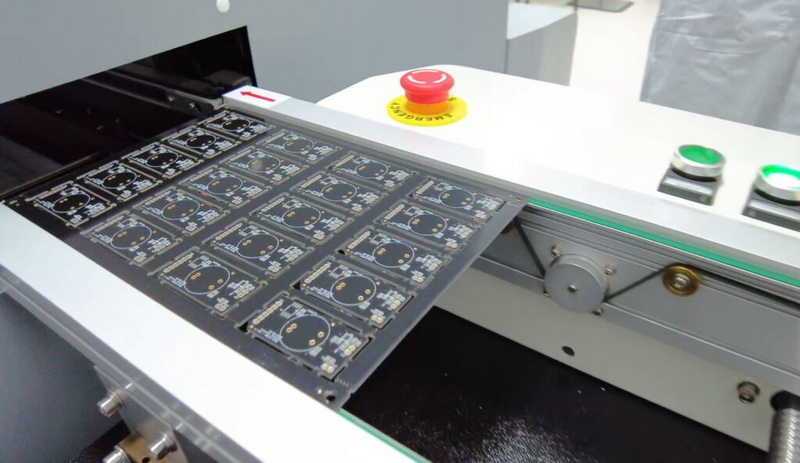

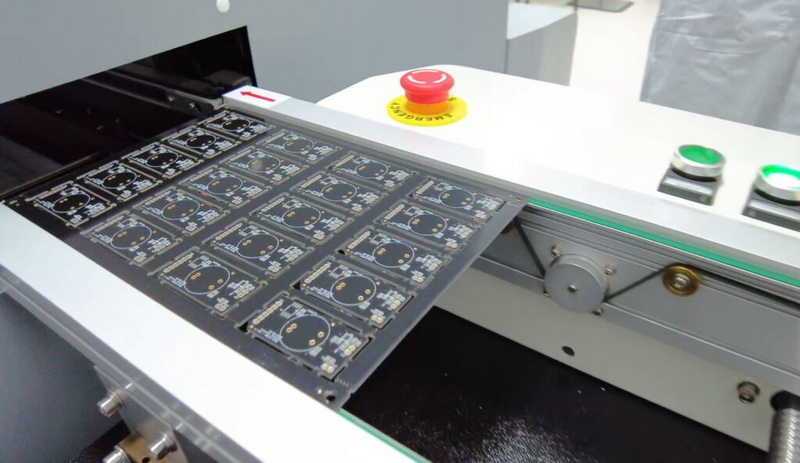

1. Smart Storage Solutions: These include intelligent rack systems that can store hundreds of reels per square foot, utilizing every cubic inch without waste. Systems like Inovaxe's Smart Storage Solutions use sensors and LEDs to detect when reels are added or removed, lighting up required parts for quick retrieval. For instance, advanced smart SMT reel storage systems can store up to 720 reels in a small space, streamlining component flow between warehouse and production[1].

2. Reel Counters: Accurate counting of components on reels is vital for inventory management. SMD reel counters ensure that the number of components on each reel is accurately tracked, helping maintain precise inventory levels. Regular maintenance and calibration of these counters are crucial to ensure accuracy and reliability[2][4].

3. Labeling and Identification Systems: Proper labeling of reels with component type, value, and quantity helps in quick identification and retrieval. This can be integrated with inventory management software for real-time tracking.

4. Pick-to-Light Systems: These systems use visual cues to guide operators in picking the correct reels for assembly, enhancing efficiency and reducing errors. Enhanced pick-to-light systems with location sensors can further improve inventory management by tracking the location of reels within racks[7].

5. Automated Pick-and-Place Machines: These machines are central to SMT assembly, using vacuum needles to pick components from reels and place them on PCBs. They require well-sorted reels to function efficiently.

Strategies for Effective SMT Reel Sorting

Organizational Strategies

1. Size-Based Sorting: Reels can be sorted by component size (e.g., 0603, 0805) to facilitate easy access and reduce confusion during assembly.

2. Component Type Sorting: Separating reels by component type (resistors, capacitors, etc.) helps in managing inventory and streamlining production processes.

3. Value-Based Sorting: For components like resistors and capacitors, sorting by value (e.g., resistance or capacitance) can be beneficial for quick identification.

Technological Integration

1. Inventory Management Software: Integrating reel storage systems with inventory management software allows for real-time tracking of component usage and automatic updates of stock levels.

2. Lean Manufacturing Principles: Applying lean principles helps minimize waste, reduce setup times, and improve workflow efficiency in SMT assembly lines[5].

Challenges in SMT Reel Sorting

Despite the benefits, SMT reel sorting faces several challenges:

1. Space Constraints: Limited storage space can hinder efficient sorting and accessibility of reels.

2. Component Variety: Managing a wide range of components with different sizes and values can be complex.

3. Static Protection: Sensitive electronic components require protection from electrostatic discharge (ESD) during storage and handling.

Solutions to Challenges

1. Vertical Storage Solutions: Using vertical shelving and carousels can maximize storage space, allowing more reels to be stored in a smaller footprint. This not only saves space but also enhances efficiency by reducing search times[6].

2. ESD Protection Measures: Implementing ESD-safe storage and handling practices ensures component integrity. Features such as climate control and moisture protection in storage systems help maintain stable conditions for sensitive components[3][6].

3. Automated Systems: Investing in automated pick-to-light and inventory management systems can streamline sorting and retrieval processes.

Advanced Technologies in SMT Reel Sorting

Smart Rack Systems

Modern SMT reel racks are evolving with advanced technologies like pick-to-light systems and location sensors. These smart racks not only improve the efficiency of picking components but also enable real-time inventory tracking and management[7]. The integration of sensors and LEDs in these systems helps operators quickly locate specific reels, reducing errors and increasing productivity.

Industry 4.0 Integration

SMT reel storage solutions are becoming increasingly compatible with Industry 4.0 standards, offering full traceability and easy integration with factory MRP software. This allows for seamless communication between different production stages, enhancing overall manufacturing efficiency[1].

Best Practices for SMT Reel Sorting

1. Regular Inventory Audits: Conduct regular audits to ensure that inventory levels are accurate and up-to-date.

2. Component Verification: Verify the type and quantity of components on each reel before use to prevent errors.

3. Training Personnel: Ensure that personnel handling SMT reels are trained on the latest practices and technologies to maximize efficiency and accuracy.

Conclusion

Effective SMT reel sorting is critical for maintaining efficiency, accuracy, and cost-effectiveness in electronics manufacturing. By utilizing smart storage solutions, reel counters, labeling systems, pick-to-light systems, and automated pick-and-place machines, companies can optimize their SMT assembly processes. Implementing organizational strategies and integrating technology can further enhance these processes.

FAQs

1. What is the purpose of SMT reel sorting?

- SMT reel sorting is essential for organizing components efficiently, ensuring they are easily accessible and correctly placed on PCBs during assembly.

2. How does smart storage contribute to SMT reel sorting?

- Smart storage solutions optimize space, improve efficiency, and protect component integrity by using sensors and LEDs to guide retrieval and track inventory in real-time.

3. What role do reel counters play in SMT reel sorting?

- Reel counters ensure accurate tracking of component quantities on each reel, aiding in precise inventory management and reducing errors.

4. How can pick-to-light systems enhance SMT reel sorting?

- Pick-to-light systems use visual cues to guide operators in selecting the correct reels, enhancing efficiency and reducing errors during assembly.

5. What are the benefits of integrating inventory management software with SMT reel sorting systems?

- Integration allows for real-time tracking of component usage, automatic updates of stock levels, and improved decision-making based on accurate inventory data.

Citations:

[1] https://www.orion-industry.com/smt-placement/ADVANCED-SMD-SMART-STORAGE.pdf

[2] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[3] https://www.neotel-technology.de/what-is-smt-reel-storage-solution/

[4] https://www.seamarkzm.com/how-smd-reel-counter-machines-optimize-smt-assembly.html

[5] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[6] https://www.southwestsolutions.com/ssg/material-handling/smt-reel-storage-solutions/

[7] https://en.neotel.tech/2023/01/04/smt-reel-rack-from-the-past-to-the-future/

[8] https://www.seamarkzm.com/benefits-of-using-smt-component-counters-for-assembly-line-efficiency.html

[9] https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4633194

[10] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[11] https://www.riverpublishers.com/downloadchapter.php?file=RP_9788770228282C17.pdf

[12] https://smtmachineline.com/smd-reel-storage-solution-vs-storage-rack/

[13] https://vohrum.com/from-concept-to-completion-best-practices-in-smt-design-assembly-and-testing-for-high-performance-pcbs/

[14] https://www.mdpi.com/2306-5729/10/2/16

[15] https://cornerstone.lib.mnsu.edu/cgi/viewcontent.cgi?article=2230&context=etds

[16] https://asselems.com/en/best-practices-in-smt-assembly

[17] https://patents.google.com/patent/US20160205819/no

[18] https://www.reddit.com/r/AskElectronics/comments/11mspyt/storing_smt_reels/

[19] https://resources.pcb.cadence.com/blog/2020-how-to-optimize-pcb-design-for-smt-assembly-process-flow

[20] https://electronics.stackexchange.com/questions/168884/smt-reel-taking-a-couple-of-parts-off-the-reel