Content Menu

● Understanding the Reflow Touch Screen SMD Rework Machine

>> What Is a Reflow Touch Screen SMD Rework Machine?

>> Key Features of Reflow Touch Screen SMD Rework Machines

● Why You Should Consider Buying a Reflow Touch Screen SMD Rework Machine

>> Benefits Over Traditional Rework Methods

>> Applications in Industry

● What to Look for When Buying a Reflow Touch Screen SMD Rework Machine

>> 1. Temperature Control and Profiling

>> 2. User Interface and Software

>> 3. Heating Technology

>> 4. Vacuum and Cooling Systems

>> 5. Size and Compatibility

>> 6. Build Quality and Support

● Where to Find Reflow Touch Screen SMD Rework Machines for Sale

● Tips for Using a Reflow Touch Screen SMD Rework Machine

● Maintenance and Troubleshooting

● Future Trends in Reflow Touch Screen SMD Rework Machines

● Conclusion

● FAQ

>> 1. What is the main advantage of a touch screen interface on an SMD rework machine?

>> 2. Can a reflow touch screen SMD rework machine handle all types of SMD components?

>> 3. How does the vacuum system assist in the rework process?

>> 4. What heating technologies are commonly used in these machines?

>> 5. Where can I find reliable reflow touch screen SMD rework machines for sale?

In the world of electronics manufacturing and repair, precision and efficiency are paramount. Surface Mount Device (SMD) rework machines have become essential tools for professionals dealing with printed circuit boards (PCBs). Among these, the reflow touch screen SMD rework machine stands out for its advanced features and user-friendly interface. If you are considering purchasing a reflow touch screen SMD rework machine for sale, this comprehensive guide will walk you through everything you need to know before making your investment.

Understanding the Reflow Touch Screen SMD Rework Machine

What Is a Reflow Touch Screen SMD Rework Machine?

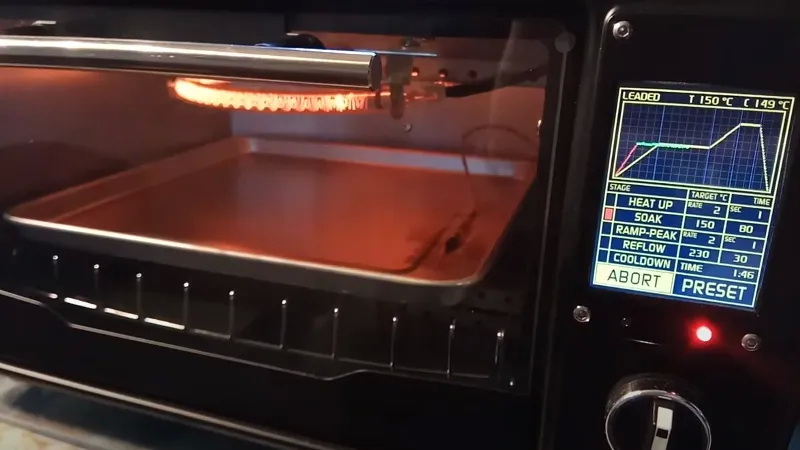

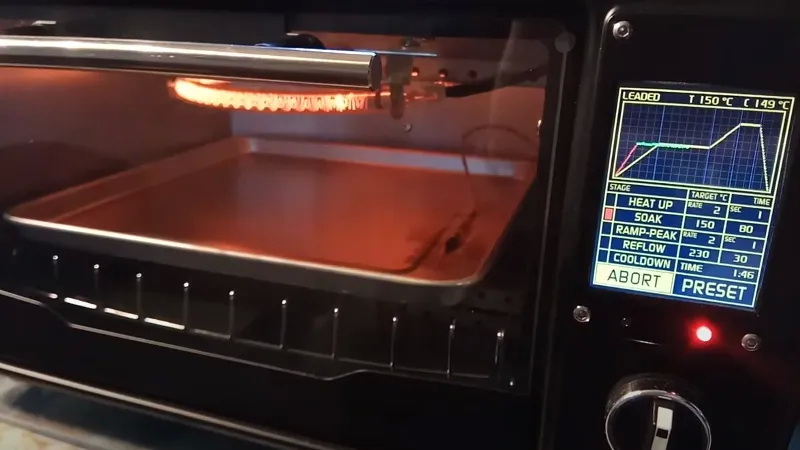

A reflow touch screen SMD rework machine is a specialized device designed to solder and desolder surface mount components on PCBs using controlled heat. The "reflow" process involves melting solder paste to create reliable electrical connections without damaging sensitive components. The touch screen interface simplifies operation, allowing precise control over temperature profiles and timing, which is critical for delicate electronic parts.

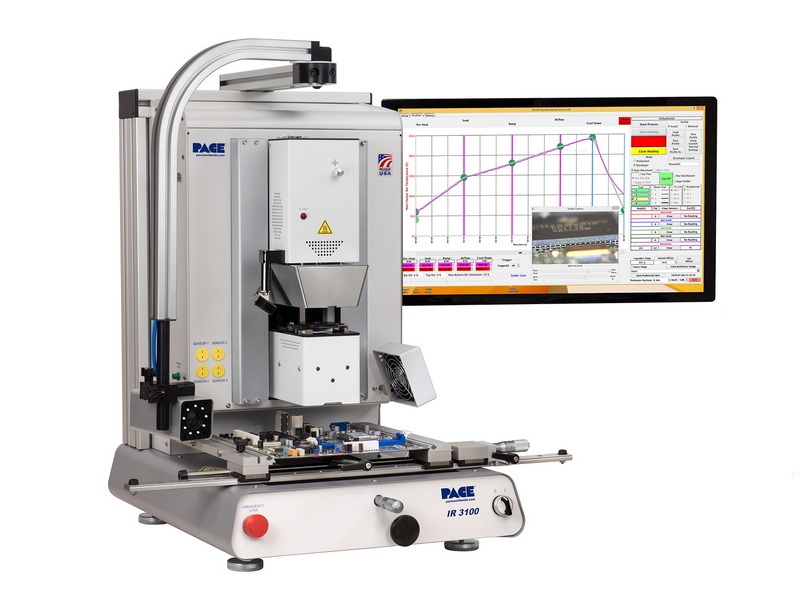

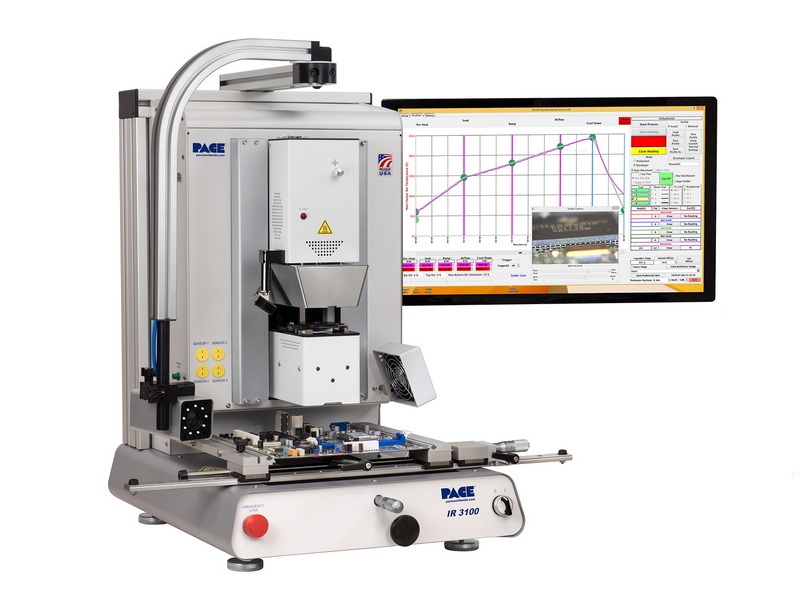

This machine integrates multiple technologies such as infrared heating, hot air circulation, vacuum suction, and cooling systems, all controlled via an intuitive touch screen panel. This combination ensures that the rework process is not only efficient but also highly repeatable and safe for the components and the PCB.

Key Features of Reflow Touch Screen SMD Rework Machines

- Precise Temperature Control: Advanced temperature sensors and programmable profiles ensure components are heated uniformly without overheating.

- Touch Screen Interface: Intuitive controls and real-time monitoring make the rework process more accessible and reduce operator errors.

- Vacuum and Cooling Systems: Many models include built-in vacuum pumps for component removal and cooling fans or air blades to quickly cool the PCB after reflow, protecting components and the board.

- Alignment Systems: Some machines feature optical alignment tools to position components accurately before reflow, improving yield and reducing rework time.

- Multi-Zone Heating: Some advanced machines offer multi-zone heating control, allowing different areas of the PCB to be heated at different rates, which is especially useful for complex boards with mixed component types.

Why You Should Consider Buying a Reflow Touch Screen SMD Rework Machine

Benefits Over Traditional Rework Methods

Traditional soldering methods, such as manual soldering irons or hot air guns, can be imprecise and risk damaging components or PCBs. The reflow touch screen SMD rework machine offers:

- Higher Precision: Controlled heat application reduces the risk of thermal damage.

- Repeatability: Programmable profiles ensure consistent results across multiple boards.

- Efficiency: Faster rework cycles with automated temperature control and cooling.

- Versatility: Suitable for a wide range of SMD components, including BGAs, QFNs, CSPs, and LEDs.

- Reduced Human Error: The touch screen interface and automated processes minimize operator mistakes, which is critical in high-volume or high-precision environments.

Applications in Industry

These machines are widely used in:

- Electronics manufacturing for prototyping and small-batch production.

- Repair and refurbishment of consumer electronics such as smartphones, tablets, and laptops.

- Research and development labs requiring precise component placement and rework.

- Quality control and failure analysis departments.

- Educational institutions teaching electronics assembly and repair techniques.

What to Look for When Buying a Reflow Touch Screen SMD Rework Machine

1. Temperature Control and Profiling

The ability to create and save multiple temperature profiles is crucial. Look for machines that offer:

- Accurate temperature sensors for both the PCB and components.

- Adjustable ramp-up and cool-down rates.

- Real-time temperature monitoring and feedback.

- Safety features to prevent overheating.

- The ability to customize profiles for different solder pastes and component types, which can vary widely in their thermal requirements.

2. User Interface and Software

A responsive and easy-to-use touch screen interface enhances productivity. Consider:

- Intuitive menu navigation.

- Real-time graphical display of temperature profiles.

- Capability to save and recall profiles.

- Software updates and support availability.

- Multi-language support if your team is international.

- Remote monitoring or control features, which some advanced machines offer, allowing technicians to oversee the rework process from a distance.

3. Heating Technology

Different machines use various heating methods:

- Infrared (IR) Heating: Focused IR heating targets components precisely, minimizing heat spread to adjacent parts.

- Hot Air Heating: Provides uniform heat but may affect nearby components if not controlled properly.

- Convection Heating: Offers even heat distribution but can be slower.

- Combination Heating: Some machines combine IR and hot air to optimize heating efficiency and precision.

Choosing the right heating technology depends on the types of components you work with and the complexity of your PCBs.

4. Vacuum and Cooling Systems

Efficient component removal and cooling are essential for quality rework:

- Built-in vacuum pumps help safely lift components without damage.

- Cooling fans or air blades rapidly cool the PCB post-reflow, preventing thermal stress.

- Some machines offer adjustable vacuum strength and cooling airflow to accommodate different component sizes and sensitivities.

5. Size and Compatibility

Ensure the machine can accommodate the size of your PCBs and the types of components you work with. Some machines support small to extra-large boards and a variety of SMD packages. Consider:

- Maximum PCB dimensions.

- Maximum component height.

- Compatibility with leaded and lead-free soldering processes.

6. Build Quality and Support

- Durable construction for long-term use.

- Availability of spare parts and consumables.

- Manufacturer's warranty and technical support.

- Training resources or user manuals.

- User community or forums for troubleshooting and tips.

Where to Find Reflow Touch Screen SMD Rework Machines for Sale

When searching for a reflow touch screen SMD rework machine for sale, consider:

- Reputable Manufacturers and Suppliers: Companies like DHSinobgas, PDR, and Quick offer advanced models with proven technology and reliable after-sales support.

- Online Marketplaces: Verified sellers on platforms specializing in electronic manufacturing equipment such as Alibaba, Made-in-China, or specialized industrial equipment sites.

- Local Distributors: May provide better after-sales support, training, and faster delivery.

- Used Equipment: Can be cost-effective but verify condition, calibration, and warranty status. Buying from certified refurbishers is recommended.

Tips for Using a Reflow Touch Screen SMD Rework Machine

- Always calibrate the machine before use to ensure temperature accuracy.

- Use appropriate flux and solder paste compatible with your components and the machine's heating profile.

- Follow recommended temperature profiles for each component type to avoid damage.

- Monitor the reflow process via the touch screen and any available cameras or sensors.

- Allow proper cooling time to avoid thermal shock and ensure solder joint integrity.

- Regularly clean the machine's heating elements and vacuum system to maintain performance.

- Train operators thoroughly on the machine's software and hardware features to maximize efficiency and reduce errors.

Maintenance and Troubleshooting

Proper maintenance is key to extending the life of your reflow touch screen SMD rework machine:

- Routine Cleaning: Remove solder residues and flux buildup from heating elements and vacuum nozzles.

- Sensor Calibration: Periodically check and calibrate temperature sensors to maintain accuracy.

- Software Updates: Keep the machine's firmware and software up to date to benefit from new features and bug fixes.

- Component Replacement: Replace worn-out parts such as vacuum pumps, heating lamps, or cooling fans as needed.

- Troubleshooting Common Issues: Learn to identify and resolve common problems like uneven heating, vacuum failure, or touch screen malfunctions.

Future Trends in Reflow Touch Screen SMD Rework Machines

The electronics industry is evolving rapidly, and so are rework technologies. Some emerging trends include:

- AI and Machine Learning Integration: Machines that can learn optimal reflow profiles based on component type and past performance.

- Enhanced Automation: Robotic arms integrated with rework machines for fully automated component placement and removal.

- Improved User Interfaces: More interactive and customizable touch screen controls with augmented reality (AR) support for training and troubleshooting.

- Energy Efficiency: Machines designed to reduce power consumption while maintaining performance.

- Compact and Portable Designs: For field repairs and on-site rework in various industries.

Conclusion

Investing in a reflow touch screen SMD rework machine can significantly enhance the quality and efficiency of your PCB rework processes. Understanding the machine's features, heating technologies, and operational requirements is essential to select the right model for your needs. Whether you are in manufacturing, repair, or R&D, a well-chosen reflow touch screen SMD rework machine will provide precise control, repeatability, and versatility, ensuring high-quality soldering results and protecting your valuable components.

When searching for a reflow touch screen SMD rework machine for sale, prioritize machines with advanced temperature control, a user-friendly touch screen interface, reliable vacuum and cooling systems, and strong manufacturer support. Proper use and maintenance will maximize your investment and improve your production or repair outcomes.

FAQ

1. What is the main advantage of a touch screen interface on an SMD rework machine?

The touch screen interface offers intuitive control, real-time monitoring, and easy access to programmable temperature profiles, reducing operator errors and improving efficiency.

2. Can a reflow touch screen SMD rework machine handle all types of SMD components?

Most machines support a wide range of components, including BGAs, QFNs, CSPs, and LEDs, but it's important to verify compatibility with your specific components before purchase.

3. How does the vacuum system assist in the rework process?

The built-in vacuum pump safely removes components from the PCB without causing damage, making the desoldering process more efficient and reliable.

4. What heating technologies are commonly used in these machines?

Infrared (IR) heating, hot air heating, and convection heating are common. IR heating is preferred for precise, localized heating, while hot air and convection provide more uniform heat distribution.

5. Where can I find reliable reflow touch screen SMD rework machines for sale?

Reputable manufacturers like DHSinobgas and PDR offer advanced machines. You can also find them through specialized online marketplaces and local distributors.