Content Menu

● Understanding BGA Technology and Its Importance

● Key Considerations for Choosing BGA PCB Welding Machines

>> 1. Temperature Control and Profiling

>> 2. Alignment and Placement Accuracy

>> 3. Reflow Capabilities

>> 4. Board Size and Component Compatibility

>> 5. Production Volume and Automation

>> 6. Rework and Repair Capabilities

>> 7. Quality Control and Inspection Features

>> 8. Software and User Interface

>> 9. Maintenance and Support

>> 10. Cost and Return on Investment

● Advanced Features in Modern BGA PCB Welding Machines

>> Artificial Intelligence and Machine Learning

>> Internet of Things (IoT) Integration

>> Virtual and Augmented Reality

● Environmental Considerations

● Conclusion

● FAQ

>> 1. What is BGA technology and why is it important in PCB assembly?

>> 2. How does temperature control affect BGA PCB welding?

>> 3. What are the advantages of automated BGA PCB welding machines?

>> 4. How important is post-welding inspection in BGA PCB assembly?

>> 5. What environmental factors should be considered when choosing a BGA PCB welding machine?

● Citations:

In the rapidly evolving world of electronics manufacturing, Ball Grid Array (BGA) technology has become a cornerstone of modern Printed Circuit Board (PCB) assembly. The increasing complexity and miniaturization of electronic devices have made BGA components an essential part of Surface Mount Technology (SMT) processes. As such, choosing the right BGA PCB welding machine is crucial for ensuring high-quality, reliable, and efficient production. This article will explore the key factors to consider when selecting BGA PCB welding equipment, providing insights into the technology, its applications, and the critical decision-making process.

Understanding BGA Technology and Its Importance

Before delving into the selection criteria for BGA PCB welding machines, it's essential to understand what BGA technology is and why it's so important in modern electronics manufacturing.

BGA is a type of surface-mount packaging used for integrated circuits. Unlike traditional leaded packages, BGA components have an array of solder balls on the underside of the package, which are used to conduct electrical signals and provide mechanical support when mounted onto a PCB[1]. This design allows for a higher density of connections in a smaller area, making it ideal for complex, high-performance electronic devices.

The importance of BGA technology in PCB assembly cannot be overstated. It offers several advantages over other packaging types:

1. Higher I/O density

2. Improved electrical performance

3. Better heat dissipation

4. Smaller footprint

5. Enhanced reliability

Given these benefits, it's clear why BGA components have become so prevalent in modern electronics. However, the process of soldering BGA components to PCBs requires specialized equipment and expertise.

Key Considerations for Choosing BGA PCB Welding Machines

When selecting a BGA PCB welding machine, there are several crucial factors to consider. These factors will influence not only the quality of your production but also your operational efficiency and overall costs.

1. Temperature Control and Profiling

One of the most critical aspects of BGA soldering is precise temperature control. The ideal BGA PCB welding machine should offer:

- Multi-zone heating capabilities

- Accurate temperature sensing and control

- Ability to create and store custom temperature profiles

Advanced machines often feature three temperature zones: top heating for the BGA component, bottom heating for the PCB, and a separate zone for preheating[3]. This allows for precise control over the entire soldering process, ensuring that both the BGA component and the PCB reach the correct temperatures at the right times.

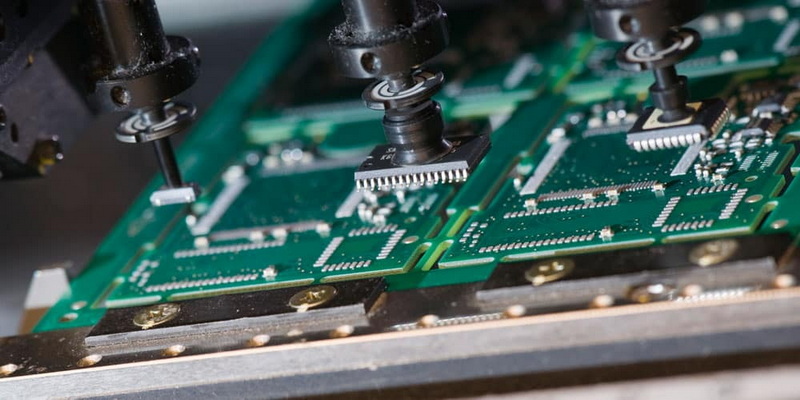

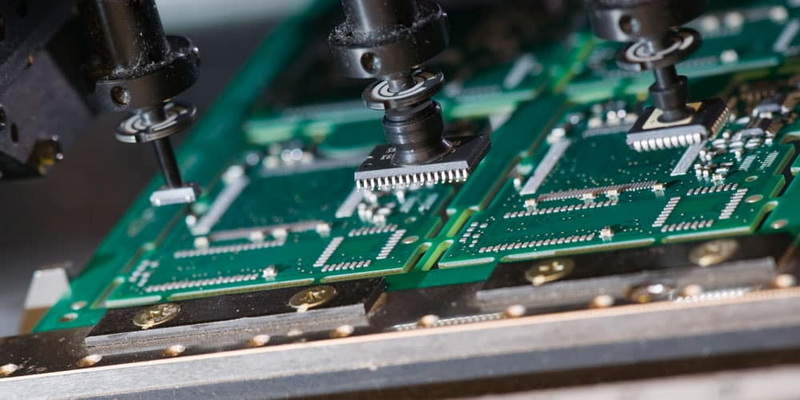

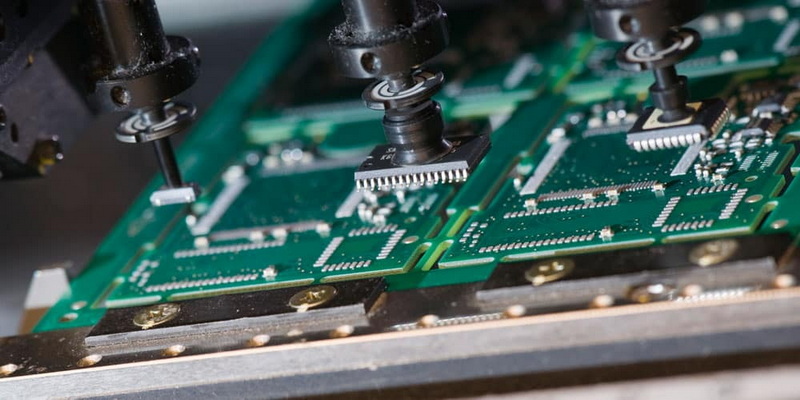

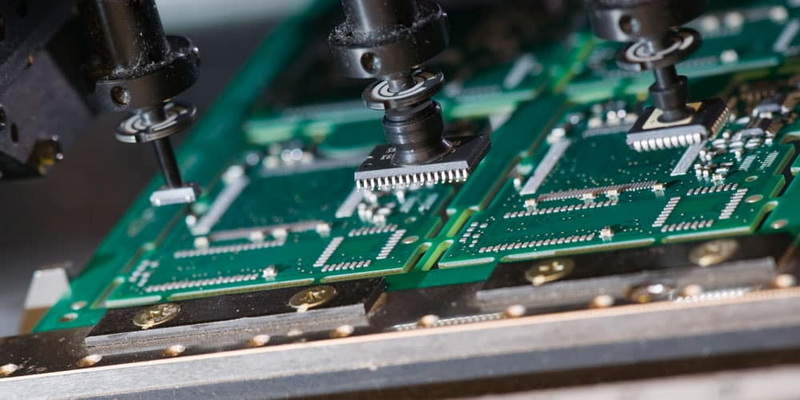

2. Alignment and Placement Accuracy

Proper alignment of BGA components is crucial for successful soldering. Look for machines that offer:

- High-precision placement systems

- Optical alignment capabilities

- Automated placement options for high-volume production

Some advanced BGA PCB welding machines incorporate vision systems that can detect and correct misalignments automatically, reducing the risk of soldering defects.

3. Reflow Capabilities

The reflow process is critical in BGA soldering. Consider machines that provide:

- Controlled heating and cooling rates

- Even heat distribution across the entire BGA array

- Compatibility with lead-free solders

Modern BGA PCB welding equipment often uses infrared or hot air reflow technologies, each with its own advantages. Infrared systems offer precise heating, while hot air systems provide more uniform heat distribution.

4. Board Size and Component Compatibility

The size of PCBs and BGA components you work with will dictate the specifications of the welding machine you need. Consider:

- Maximum board size the machine can accommodate

- Range of BGA package sizes supported

- Flexibility to handle different component types (e.g., SMD, SMT)

It's important to choose a machine that not only meets your current needs but also has the flexibility to accommodate future requirements as your production evolves[2].

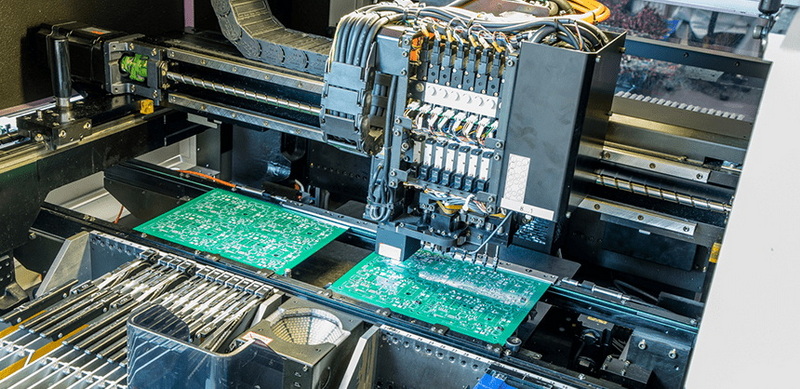

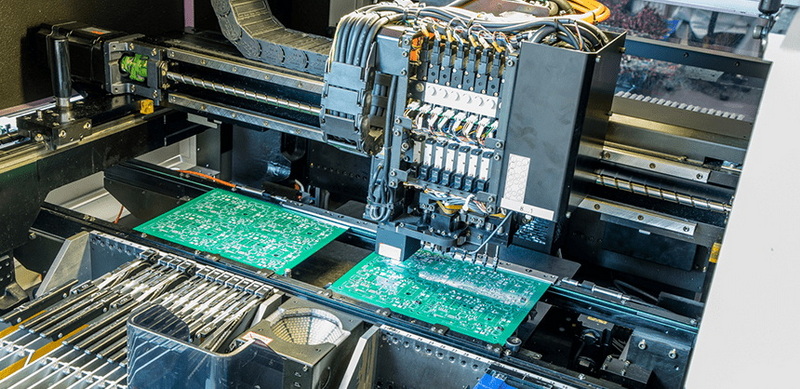

5. Production Volume and Automation

Your production volume will significantly influence the type of BGA PCB welding machine you should choose. Consider:

- Manual vs. semi-automated vs. fully automated systems

- Throughput capabilities

- Integration with existing SMT production lines

For high-volume production, automated systems with high throughput capabilities are essential. However, for smaller operations or prototype work, a manual or semi-automated system might be more appropriate and cost-effective.

6. Rework and Repair Capabilities

In addition to initial assembly, consider whether you need a machine that can handle rework and repair tasks. Look for features such as:

- Component removal capabilities

- Reballing functionality

- Ability to work with populated boards

Machines with these capabilities can significantly reduce waste and improve your ability to salvage expensive components or boards[6].

7. Quality Control and Inspection Features

Ensuring the quality of BGA solder joints is crucial. Many modern BGA PCB welding machines incorporate inspection features such as:

- X-ray inspection capabilities

- Automated optical inspection (AOI) systems

- Real-time process monitoring

These features can help identify defects early in the production process, reducing waste and improving overall quality[5].

8. Software and User Interface

The software and user interface of the BGA PCB welding machine play a crucial role in its usability and efficiency. Look for:

- Intuitive user interfaces

- Programmable process parameters

- Data logging and analysis capabilities

Advanced software can help optimize your processes, track production metrics, and ensure consistency across multiple production runs.

9. Maintenance and Support

Consider the long-term maintenance requirements and available support for the machine. Key factors include:

- Availability of spare parts

- Technical support and training options

- Warranty and service agreements

Choosing a machine from a reputable manufacturer with good after-sales support can save you significant time and money in the long run.

10. Cost and Return on Investment

While it's tempting to focus solely on the initial purchase price, it's important to consider the total cost of ownership and potential return on investment. Factors to consider include:

- Initial purchase price

- Operating costs (energy consumption, consumables)

- Potential productivity improvements

- Expected lifespan of the equipment

A more expensive machine that offers higher productivity and better quality output may provide a better return on investment over time.

Advanced Features in Modern BGA PCB Welding Machines

As technology continues to advance, BGA PCB welding machines are incorporating increasingly sophisticated features to improve performance, reliability, and ease of use.

Artificial Intelligence and Machine Learning

Some cutting-edge BGA PCB welding machines are now incorporating AI and machine learning capabilities. These features can:

- Optimize temperature profiles based on historical data

- Predict and prevent potential defects

- Automate quality control processes

By leveraging these technologies, manufacturers can achieve higher levels of consistency and quality in their BGA soldering processes.

Internet of Things (IoT) Integration

IoT integration is becoming more common in advanced BGA PCB welding equipment. This allows for:

- Remote monitoring and control of machines

- Real-time data collection and analysis

- Predictive maintenance scheduling

These capabilities can significantly improve operational efficiency and reduce downtime.

Virtual and Augmented Reality

Some manufacturers are exploring the use of VR and AR technologies in BGA PCB welding machines. These technologies can:

- Provide immersive training experiences for operators

- Offer real-time guidance during complex procedures

- Enhance troubleshooting and maintenance processes

While still in the early stages, these technologies have the potential to revolutionize how operators interact with BGA PCB welding equipment.

Environmental Considerations

As environmental concerns become increasingly important, it's worth considering the environmental impact of your BGA PCB welding equipment. Look for machines that:

- Are energy-efficient

- Support lead-free soldering processes

- Minimize waste production

Some manufacturers are now offering eco-friendly options that can help reduce your carbon footprint while still delivering high-quality results.

Conclusion

Choosing the right BGA PCB welding machine is a critical decision that can significantly impact your production quality, efficiency, and overall costs. By carefully considering factors such as temperature control, alignment accuracy, reflow capabilities, board compatibility, production volume, rework abilities, quality control features, software interfaces, maintenance requirements, and cost-effectiveness, you can select a machine that best meets your specific needs.

As technology continues to advance, staying informed about the latest developments in BGA PCB welding equipment is crucial. Features such as AI integration, IoT connectivity, and even VR/AR capabilities are beginning to reshape the industry, offering new possibilities for improved performance and efficiency.

Ultimately, the best BGA PCB welding machine for your operation will depend on your unique requirements, production volume, and budget. By thoroughly evaluating your needs and carefully considering the factors outlined in this article, you can make an informed decision that will support your manufacturing goals and help ensure the success of your PCB assembly processes.

FAQ

1. What is BGA technology and why is it important in PCB assembly?

BGA (Ball Grid Array) technology is a type of surface-mount packaging used for integrated circuits. It's important in PCB assembly because it allows for higher connection density, improved electrical performance, better heat dissipation, and a smaller footprint compared to traditional leaded packages. This makes it ideal for complex, high-performance electronic devices.

2. How does temperature control affect BGA PCB welding?

Temperature control is crucial in BGA PCB welding as it directly impacts the quality of the solder joints. Precise control ensures that both the BGA component and the PCB reach the correct temperatures at the right times, preventing issues such as cold solder joints or component damage. Advanced machines often feature multi-zone heating for optimal temperature management.

3. What are the advantages of automated BGA PCB welding machines?

Automated BGA PCB welding machines offer several advantages:

- Higher throughput for increased production volume

- Improved consistency and repeatability

- Reduced human error

- Better alignment accuracy

- Integration with existing SMT production lines

However, they typically require a higher initial investment compared to manual systems.

4. How important is post-welding inspection in BGA PCB assembly?

Post-welding inspection is critical in BGA PCB assembly. Due to the hidden nature of BGA solder joints, visual inspection alone is often insufficient. Advanced inspection methods such as X-ray and Automated Optical Inspection (AOI) are crucial for detecting defects like voids, bridges, or insufficient solder. Early detection of these issues can significantly reduce waste and improve overall product quality.

5. What environmental factors should be considered when choosing a BGA PCB welding machine?

When selecting a BGA PCB welding machine, consider its energy efficiency, support for lead-free soldering processes, and waste minimization capabilities. Some manufacturers offer eco-friendly options that can help reduce your carbon footprint. Additionally, consider the machine's longevity and upgradability, as a longer-lasting machine reduces the environmental impact of frequent replacements.

Citations:

[1] https://www.neodensmt.com/news/what-are-smt-and-bga-processes-81935753.html

[2] https://www.global-pcba.com/cn/Info.asp?gCateID=71875945.6

[3] https://www.lygroupchina.com/news/selection-of-bga-rework-station-83263086.html

[4] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345

[5] https://www.pcbasic.com/blog/how_to_ensure_the_quality_of_bga_welding_during_pcba_manufacturing.html

[6] https://www.seamarkzm.com/how-to-choose-the-best-bga-rework-station.html

[7] https://www.pcbcart.com/article/content/soldering-bga-components-in-smt-assembly.html

[8] https://www.seamarkzm.com/how-to-choose-bga-rework-station.html