Content Menu

● Introduction

● Core Skills and Knowledge

● Training Modules

● Hands-On Practice

● Advanced Techniques

● Certification and Continuous Learning

● Importance of Customized Training Programs

● Integration of Technology in Training

● Best Practices for Training Implementation

● The Role of Team Collaboration

● Conclusion

● FAQs

>> 1. What is the role of an SMT PCB line technician?

>> 2. Why is hands-on training important?

>> 3. What certifications are beneficial for SMT technicians?

>> 4. How often should training be updated?

>> 5. What are key safety protocols in SMT assembly?

● Citations:

Introduction

Surface Mount Technology (SMT) PCB line technicians are integral to the electronics manufacturing industry. They ensure the efficient operation of SMT assembly lines, which are crucial for producing high-quality printed circuit boards (PCBs). A comprehensive training plan is essential to equip these technicians with the necessary skills and knowledge to excel in their roles. This article outlines the key components of an effective training plan for SMT PCB line technicians.

Core Skills and Knowledge

To be successful, SMT PCB line technicians must possess a strong foundation in several core skills:

- Soldering: Proficiency in soldering techniques is fundamental. Technicians should be familiar with various solder types, fluxes, and the properties of solder paste.

- Troubleshooting: The ability to diagnose and resolve issues quickly is critical for maintaining production efficiency. Technicians need to understand common defects and their remedies.

- IPC Standards: Familiarity with IPC standards, such as IPC-A-610 and J-STD-001, ensures that technicians adhere to industry quality benchmarks.

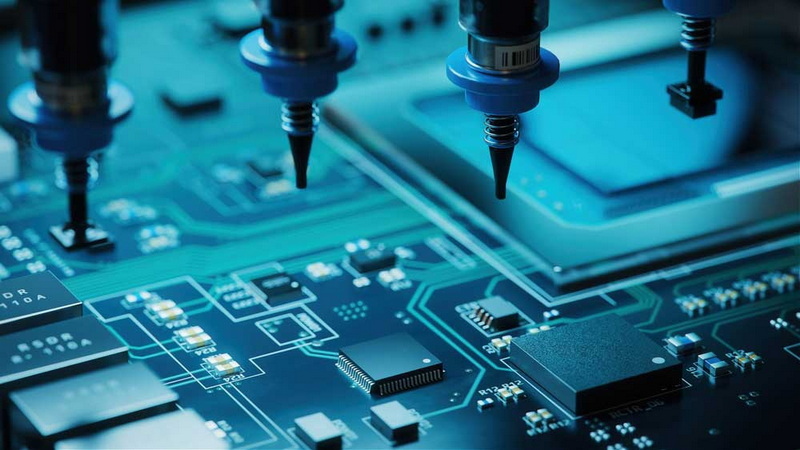

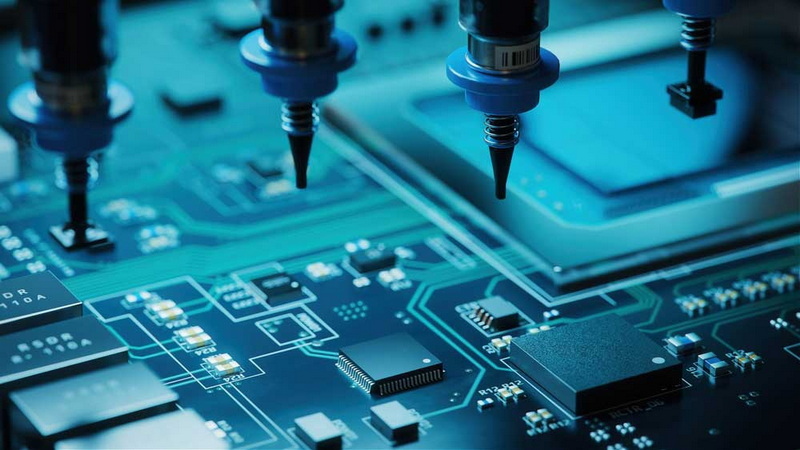

- Equipment Operation: Knowledge of how to operate and maintain equipment such as reflow ovens, pick-and-place machines, and inspection systems is vital.

Training Modules

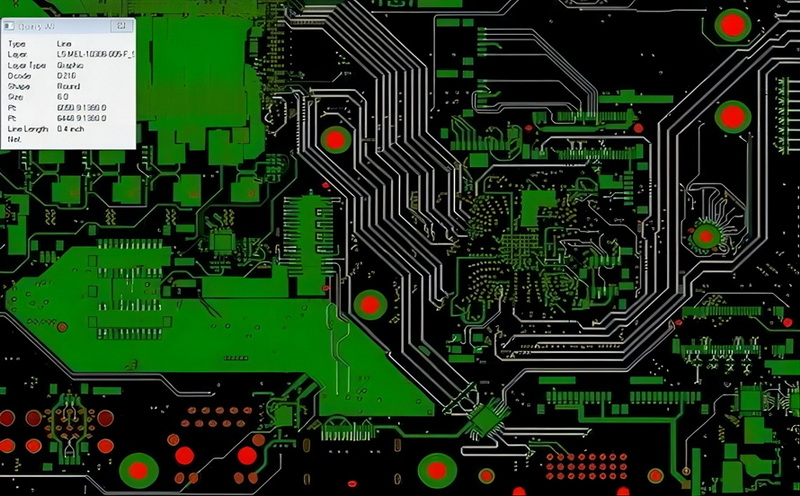

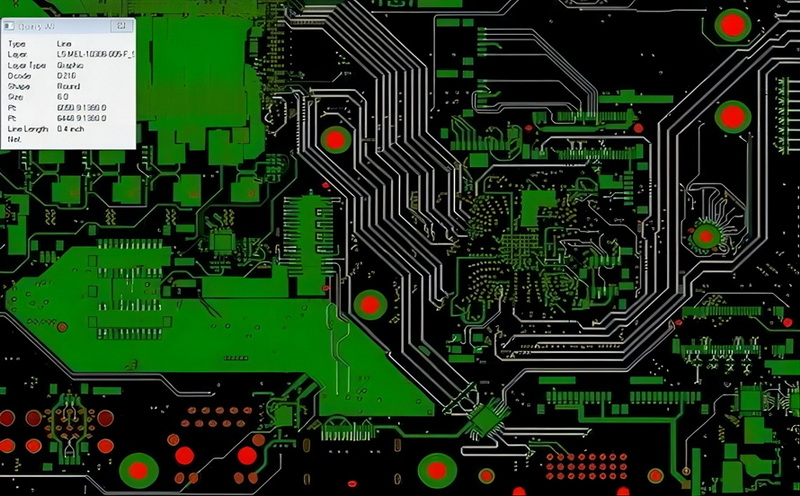

An effective training plan should include various modules that cover essential topics:

- Component Identification: Technicians must learn to identify different electronic components and understand their specifications.

- Machine Operation: Training should encompass the operation of SMT equipment, including setup procedures and routine maintenance.

- Quality Control: Understanding quality control measures is crucial. Technicians should be trained in inspection techniques, including Automated Optical Inspection (AOI) and manual inspection methods.

- Safety Protocols: Safety training should cover protocols such as Electrostatic Discharge (ESD) protection and proper handling of hazardous materials.

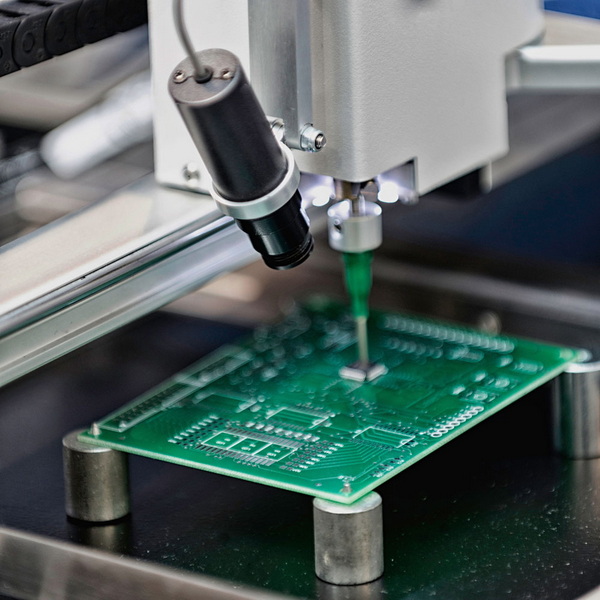

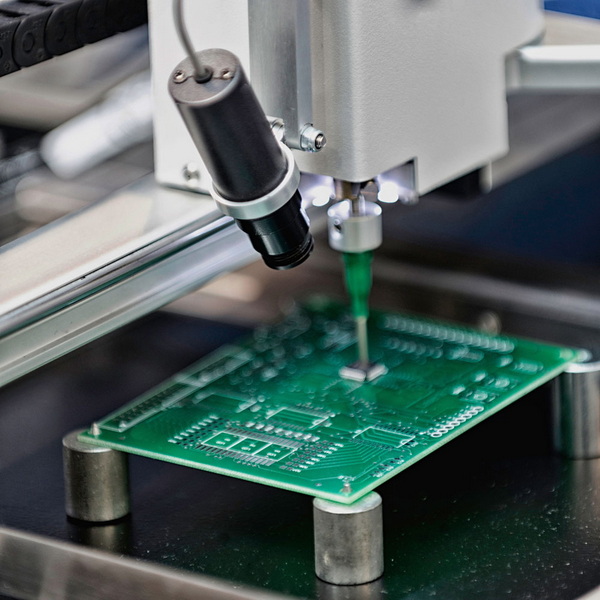

Hands-On Practice

Practical training sessions are indispensable for SMT technicians. These sessions allow trainees to work on real equipment, gaining hands-on experience that enhances their understanding of assembly processes. Key aspects include:

- Real Equipment Training: Working directly with SMT machinery helps technicians become familiar with operational nuances.

- Troubleshooting Simulations: Simulated troubleshooting scenarios can prepare technicians for real-world challenges they may face on the production floor.

Advanced Techniques

As technology evolves, so do the techniques used in SMT assembly. Advanced training topics should include:

- Reflow Profiling: Understanding how to create and adjust reflow profiles is essential for optimizing soldering processes.

- Stencil Design: Training on stencil design can help improve paste application accuracy, which is critical for high-quality assemblies.

- Defect Analysis: Technicians should learn how to analyze defects effectively, identifying root causes and implementing corrective actions.

Certification and Continuous Learning

Certifications play a significant role in validating a technician's expertise:

- IPC Certifications: Certifications like IPC-A-610 and J-STD-001 are highly valued in the industry and demonstrate a technician's commitment to quality work.

- Ongoing Education: Continuous learning through workshops, seminars, and updated training programs ensures that technicians remain current with technological advancements and industry trends.

Importance of Customized Training Programs

Training programs should not adopt a one-size-fits-all approach. Different organizations have varying needs based on their operational history, existing workforce skills, and specific equipment used. For example:

- A Contract Electronics Manufacturer (CEM) with decades of experience may require advanced troubleshooting techniques tailored to their specific equipment setup.

- An Original Equipment Manufacturer (OEM) commissioning an SMT line for the first time will need foundational training that covers basic operations and safety protocols.

Customized training programs can lead to increased efficiency by addressing specific skill gaps within the workforce. This targeted approach ensures that employees receive relevant training that directly impacts productivity[1][2].

Integration of Technology in Training

With advancements in technology, integrating digital tools into training programs has become essential:

- Online Learning Platforms: Many organizations now offer online courses that allow technicians to learn at their own pace. These platforms often include video tutorials, quizzes, and interactive modules that reinforce learning outcomes.

- Simulation Software: Utilizing simulation software can provide technicians with a virtual environment where they can practice machine operations without the risk of damaging actual equipment. This method enhances confidence before they engage with real machinery[6][7].

Best Practices for Training Implementation

To ensure effective training implementation, organizations should consider the following best practices:

- Assessment Before Training: Conducting a skills gap analysis prior to training helps identify specific areas where employees require improvement. This assessment can guide the development of tailored training programs[4][5].

- Feedback Mechanisms: Establishing feedback loops where trainees can share their experiences can help refine future training sessions. Continuous improvement based on participant feedback ensures that training remains relevant and effective[3][8].

- Mentorship Programs: Pairing less experienced technicians with seasoned professionals fosters a culture of learning within the organization. Mentorship can enhance knowledge transfer while building team cohesion[6][9].

The Role of Team Collaboration

Team collaboration is vital in SMT environments. Technicians do not operate in isolation; they work closely with engineers, operators, and quality control personnel. Effective communication among team members is essential for achieving production goals:

- Regular team meetings can facilitate discussions about challenges faced during production runs, allowing for collective problem-solving efforts.

- Sharing insights on potential improvements encourages a collaborative atmosphere where everyone contributes to enhancing operational efficiency[6][10].

Conclusion

A well-structured training plan is essential for developing skilled SMT PCB line technicians. By covering core skills, providing hands-on practice, integrating advanced techniques, and ensuring continuous learning through certifications, organizations can cultivate a competent workforce ready to meet industry demands. Customized training programs tailored to specific organizational needs further enhance technician capabilities while promoting efficiency within production lines. Investing in technician development ultimately leads to higher quality products and improved operational success in the competitive electronics manufacturing landscape.

FAQs

1. What is the role of an SMT PCB line technician?

They are responsible for operating and maintaining SMT equipment, ensuring quality control, and troubleshooting issues throughout the assembly process.

2. Why is hands-on training important?

It allows technicians to gain practical experience working directly with machinery, enhancing their understanding of assembly processes while preparing them for real-world challenges.

3. What certifications are beneficial for SMT technicians?

Certifications like IPC-A-610 and J-STD-001 are highly recommended as they validate a technician's skills related to quality standards in electronics manufacturing.

4. How often should training be updated?

Training should be updated regularly to keep up with technological advancements and changes in industry standards to ensure workforce competency remains high.

5. What are key safety protocols in SMT assembly?

Protocols include ESD protection measures, proper handling of components, adherence to machine safety guidelines, and compliance with environmental regulations during assembly processes.

Citations:

[1] https://hawkerrichardson.com.au/blog/smt-line-efficiency-and-training/

[2] https://manufacturing-today.com/news/global-skills-enhancement-by-smt-across-47-nations/

[3] https://www.solder.net/training-courses/advance-smt-rework/

[4] https://www.scientific-management.com/skills-training-programs/

[5] https://itmconsulting.com/workshops/

[6] https://www.pcbasic.com/blog/smt_technician.html

[7] https://rework.co.uk/blog/how-to-achieve-high-precision-in-surface-mount-assemblies/

[8] https://www.zippia.com/smt-operator-jobs/skills/

[9] https://faroads.com/start-smt-line-guide-2024/

[10] https://www.circuittechnology.com/Training-ID/49/Training-Category/

[11] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[12] https://www.bomi.org/SMT.aspx

[13] https://www.winow-pcba.com/pcb-assembly-training-a-comprehensive-guide/

[14] https://www.controltek.com/sites/www.controltek.com/files/job-opportunity-documents/SMT%20Machine%20Operator%20I%20(1).pdf

[15] https://www.electronicdesign.com/markets/automation/article/21176834/technotronix-6-best-practices-for-a-smoother-pcb-assembly-process

[16] https://www.ziprecruiter.com/career/Smt-Operator/What-Is-How-to-Become

[17] https://www.solder.net/training-courses/lead-free-advanced-training/

[18] https://www.elemaster.com/en/job/smt-technician/

[19] https://www.viasion.com/blog/smt-pcb-assembly-process-8-basic-steps/

[20] https://smt.asmpt.com/en/news-center/press/smart-working-in-smt-factories/

[21] https://www.fictron.com/training%20catalogue/5-Advanced%20SMT%20Rework%20and%20Soldering%20Techniques.pdf

[22] https://www.ziprecruiter.com/career/SMT-Operator/Resume-Keywords-and-Skills

[23] https://www.gssmt-parts.com/what-are-the-best-practices-for-maintaining-a-pcb-smt-solution-line.html

[24] https://registration.soldertraining.net/w/courses/15-smt-rework/778

[25] https://iysskillstech.com/sample-skills-profiles/smt-technician-skills-profile

[26] https://smt.fuji.co.jp/en/service_support/training_program

[27] https://core-emt.com/training-courses-on-smt-equipment-smt-software-training