Content Menu

● Understanding Surface Mount Technology (SMT)

>> Key Components of SMT

● Advantages of SMT in PCB Manufacturing

● The Impact of SMT on Modern Electronics

>> 1. Consumer Electronics

>> 2. Automotive Industry

>> 3. Telecommunications

>> 4. Medical Devices

● Challenges Associated with SMT

● Future Trends in SMT

● The Role of Advanced Technologies in Enhancing SMT

● Case Studies Demonstrating the Benefits of SMT

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the main advantages of using SMT?

>> 3. In which industries is SMT commonly used?

>> 4. What challenges does SMT face?

>> 5. What future trends can we expect from SMT?

● Citations:

Surface Mount Technology (SMT) has revolutionized the landscape of printed circuit board (PCB) manufacturing, fundamentally changing how electronic components are assembled. This technology allows components to be mounted directly onto the surface of PCBs, significantly enhancing manufacturing efficiency, reducing costs, and enabling the production of smaller and more complex electronic devices. In this article, we will explore the various roles that SMT plays in modern PCB manufacturing, its advantages over traditional methods, and its impact on the electronics industry.

Understanding Surface Mount Technology (SMT)

SMT is a method where electronic components are attached directly to the surface of a PCB. Unlike through-hole technology, where components are inserted through holes in the board, SMT eliminates the need for drilling holes. This change allows for a more efficient assembly process and enables manufacturers to create smaller and lighter devices.

Key Components of SMT

1. Solder Paste Application: A layer of solder paste is applied to the PCB to hold components in place.

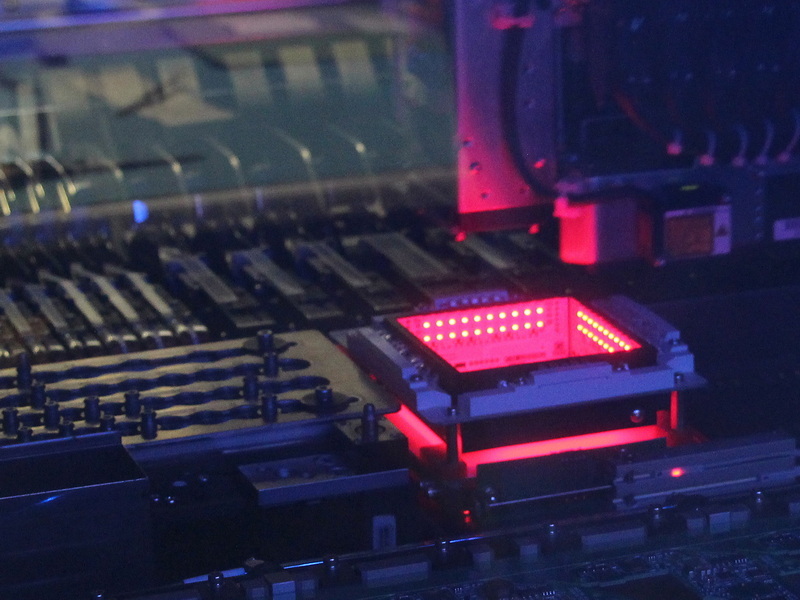

2. Pick-and-Place Machines: Automated machines place components with high precision onto the solder paste-covered pads.

3. Reflow Soldering: The PCB is heated in an oven to melt the solder paste, creating strong electrical connections.

4. Automated Optical Inspection (AOI): This technology checks for placement accuracy and solder quality, ensuring high reliability.

Advantages of SMT in PCB Manufacturing

SMT offers numerous advantages that make it a preferred choice for manufacturers:

- Higher Component Density: SMT allows for more components to be placed on a single board due to its compact design. This is crucial for modern electronics that demand miniaturization.

- Reduced Manufacturing Costs: The automation involved in SMT reduces labor costs and speeds up production times. Fewer manual interventions are required, leading to lower overall costs.

- Improved Reliability: SMT components are typically more reliable than their through-hole counterparts due to better mechanical support and reduced risk of physical damage from vibrations or shocks.

- Design Flexibility: Engineers can design PCBs with components on both sides, maximizing space utilization and allowing for more complex circuit designs.

- Faster Production Speeds: Automated processes enable placement rates of thousands of components per hour, significantly reducing time-to-market for new products.

The Impact of SMT on Modern Electronics

The advent of SMT has had a profound impact on various sectors within the electronics industry:

1. Consumer Electronics

The demand for smaller and lighter devices has driven the adoption of SMT in consumer electronics. Smartphones, tablets, and wearable devices benefit from the compact designs enabled by SMT.

2. Automotive Industry

In automotive applications, reliability is paramount. SMT's ability to provide robust connections makes it ideal for automotive electronics that must withstand harsh conditions.

3. Telecommunications

Telecommunication equipment often requires high-density PCBs to support advanced features while maintaining compact sizes. SMT meets these requirements effectively.

4. Medical Devices

In medical technology, precision and reliability are critical. SMT enhances the performance and durability of medical devices, ensuring they function correctly under various conditions.

Challenges Associated with SMT

While SMT offers many benefits, it also presents some challenges:

- Initial Investment: The machinery required for SMT can be expensive, leading to higher initial setup costs compared to traditional methods.

- Complexity in Inspection: The small size of SMT components can make visual inspection difficult, requiring advanced inspection technologies like AOI.

- Fragility: Some SMT components are more fragile than through-hole components, making them susceptible to damage during handling or assembly.

Future Trends in SMT

As technology continues to advance, several trends are emerging within the realm of SMT:

- Increased Automation: The trend towards greater automation in manufacturing processes will likely continue, further enhancing efficiency and reducing costs.

- Miniaturization: As consumer demand for smaller devices grows, manufacturers will increasingly rely on SMT to meet these needs.

- Advanced Materials: The development of new materials that can withstand higher temperatures and provide better performance will enhance the capabilities of SMT.

- Integration with IoT: As the Internet of Things (IoT) expands, the need for compact and efficient electronic devices will drive further adoption of SMT technologies.

The Role of Advanced Technologies in Enhancing SMT

The evolution of PCB manufacturing is closely tied to advancements in technology that complement SMT processes:

1. Automation and Robotics: Automated systems have become integral to PCB assembly lines. Robotic arms ensure precision placement while minimizing human error. This automation not only speeds up production but also enhances consistency across batches[1][3].

2. Artificial Intelligence (AI): AI is being integrated into PCB design and manufacturing processes to optimize performance and efficiency. Machine learning algorithms analyze production data to identify patterns that help streamline operations[8][13].

3. Additive Manufacturing: 3D printing technologies are being explored alongside SMT to create complex PCB designs without traditional constraints. This capability allows for rapid prototyping and reduced material waste[18][27].

4. Advanced Testing Techniques: Ensuring quality control is paramount in PCB manufacturing. Techniques such as automated optical inspection (AOI) and X-ray inspection are becoming standard practices to detect defects early in the assembly process[10][12].

5. Sustainable Practices: With increasing awareness around environmental issues, manufacturers are adopting greener practices in their operations. This includes using eco-friendly materials and minimizing waste during production[18][30].

Case Studies Demonstrating the Benefits of SMT

Several companies have successfully implemented SMT into their manufacturing processes with notable results:

- Apple Inc. has leveraged SMT technology extensively in its product lines like iPhones and MacBooks, allowing them to produce highly compact devices without compromising performance or reliability.

- Tesla, known for its innovative electric vehicles, utilizes SMT in its battery management systems and other electronic controls that require high reliability under extreme conditions.

- In medical technology firms like Medtronic, SMT has enabled the creation of smaller implantable devices that improve patient outcomes while ensuring robust performance under varying conditions[16][21].

Conclusion

Surface Mount Technology plays a pivotal role in modern PCB manufacturing by enhancing efficiency, reducing costs, and enabling miniaturization. Its advantages over traditional through-hole methods have made it the standard in various industries including consumer electronics, automotive applications, telecommunications, and medical devices. Despite some challenges associated with its implementation, such as initial investment costs and inspection complexities, the future of SMT looks promising as it continues to evolve alongside advancements in technology.

The integration of automation, AI, advanced materials, sustainable practices, and innovative testing techniques will further solidify SMT's position as a cornerstone of modern electronics manufacturing. As industries continue to demand smaller, faster, and more efficient devices, embracing Surface Mount Technology will be essential for manufacturers aiming to stay competitive in an increasingly dynamic market.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), eliminating the need for drilled holes used in traditional through-hole technology.

2. What are the main advantages of using SMT?

The main advantages include higher component density on PCBs, reduced manufacturing costs due to automation, improved reliability of connections, design flexibility allowing dual-sided component placement, and faster production speeds.

3. In which industries is SMT commonly used?

SMT is commonly used in consumer electronics, automotive industries, telecommunications equipment, and medical devices due to its ability to produce compact and reliable electronic assemblies.

4. What challenges does SMT face?

Challenges include high initial investment costs for machinery, complexity in inspecting small components accurately, and potential fragility issues with certain surface-mounted components.

5. What future trends can we expect from SMT?

Future trends include increased automation in manufacturing processes, continued miniaturization of electronic devices, development of advanced materials for better performance under high temperatures, and integration with IoT technologies.

Citations:

[1] https://www.zjyingxing.com/info/what-role-does-smt-machine-play-in-modern-indu-102642276.html

[2] https://levisonenterprises.com/5-advantages-to-using-smt/

[3] https://www.mpe-electronics.co.uk/2024/01/23/future-pcb-industry-trends-to-watch-out-for

[4] https://www.linkedin.com/advice/1/what-benefits-challenges-using-surface-mount-technology

[5] https://www.hayawin.com/news-5-advantages-to-using-smt-in-your-electronic-manufacturing-project.html

[6] https://www.wevolver.com/article/smt-process

[7] https://www.pcb-hero.com/blogs/lisas-column/surface-mount-technology-advantages-and-disadvantages

[8] https://www.technotronix.us/pcbblog/top-trends-in-printed-circuit-board-manufacturing-for-2024/

[9] https://www.viasion.com/blog/common-challenges-in-smt-assembly-and-solutions/

[10] https://finestpcb.com/how-does-smt-affect-and-speed-up-pcb-production-time/

[11] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[12] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[13] https://www.pcbpower.us/blog/the-future-of-pcb-assembly-trends-challenges-and-opportunities

[14] https://jhdpcb.com/blog/efficient-smt-assembly/

[15] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[16] https://arkcircuits.com/blog/impact-of-smt-on-modern-pcb-design/

[17] https://www.pcbelec.com/smt-advantages-and-disadvantages.html

[18] https://www.circuits-central.com/blog/the-future-of-pcb-manufacturing-emerging-technologies-and-trends-part-2/

[19] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[20] https://www.linkedin.com/pulse/impact-smt-printing-pcb-assembly-quality-0c0mc

[21] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-pcb-boards-high-performance-solutions-for-modern-electronics/

[22] https://www.pcbpower.us/blog/unveiling-the-advantages-and-disadvantages-of-surface-mount-technology

[23] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[24] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[25] https://blog.matric.com/what-is-smt-assembly

[26] https://www.pcbway.com/blog/PCB_Assembly/Advantages_and_Disadvantages_of_Surface_Mounting_Technology.html

[27] https://novaenginc.com/the-future-of-circuit-board-assembly-trends-and-innovations/

[28] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[29] https://www.pcbasic.com/blog/surface_mount_technology_smt.html

[30] https://www.pentalogix.com/blog/2023/11/17/the-future-of-pcb-fabrication-emerging-technologies-and-trends/

[31] https://www.linkedin.com/pulse/latest-trends-technological-innovations-pcb-industry-2024-yolin-gan-hddac