Content Menu

● Introduction to AOI Machines in SMT PCB Assembly

● Key Applications of AOI Machines in SMT PCB Assembly

>> 1. Solder Paste Inspection

>> 2. Pre-Reflow Inspection

>> 3. Post-Reflow Inspection

>> 4. Final Assembly Inspection

● Advantages of AOI Machines for SMT PCB Assembly

>> 1. Increased Inspection Speed

>> 2. High Accuracy and Consistency

>> 3. Reduced Labor Costs

>> 4. Early Defect Detection

>> 5. Data Collection and Analysis

● Types of AOI Systems

>> 1. Inline AOI Systems

>> 2. Offline AOI Systems

● How AOI Enhances Efficiency in SMT PCB Assembly

>> 1. Real-Time Quality Control

>> 2. Improved Yield Rates

>> 3. Faster Turnaround Times

● Advanced Features of Modern AOI Machines for SMT PCB

>> 1. Multi-Angle Inspection

>> 2. 3D Inspection Technology

>> 3. Artificial Intelligence and Machine Learning

>> 4. High-Speed Cameras and Processing

● Integration of AOI in Industry 4.0

● Challenges and Considerations in AOI Implementation

● Future Trends in AOI for SMT PCB Assembly

● Conclusion

● FAQs About AOI Machines in SMT PCB Assembly

>> 1. What is an AOI machine used for in SMT PCB assembly?

>> 2. How does an AOI machine work?

>> 3. What are the benefits of using AOI over manual inspection?

>> 4. What types of defects can AOI detect?

>> 5. Can AOI be integrated into existing production lines?

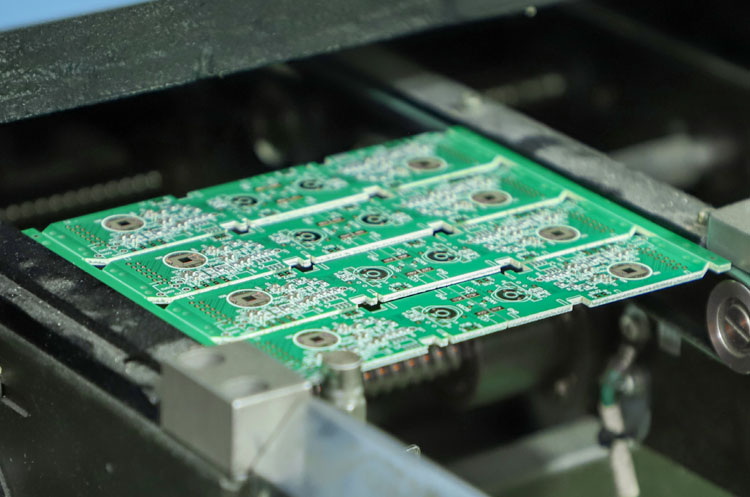

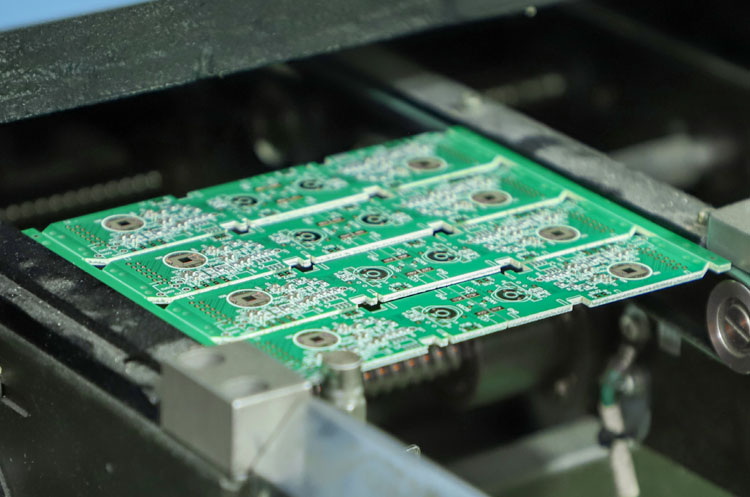

Automated Optical Inspection (AOI) machines have become indispensable in modern Surface Mount Technology (SMT) PCB assembly. With the increasing complexity of electronic devices, ensuring the quality, accuracy, and efficiency of PCB assembly processes is critical. This article explores the role of AOI machines in SMT PCB assembly, their applications, advantages, and how they contribute to enhanced production efficiency.

Introduction to AOI Machines in SMT PCB Assembly

AOI machines are advanced inspection tools that utilize optical technology to detect defects in printed circuit boards (PCBs) during the manufacturing process. These machines employ high-resolution cameras and sophisticated algorithms to inspect various aspects of PCBs, such as component placement, solder joint quality, and surface defects. By automating the inspection process, AOI eliminates human error and significantly improves production speed and accuracy.

Key Applications of AOI Machines in SMT PCB Assembly

1. Solder Paste Inspection

- Purpose: Ensures that solder paste is correctly applied to the PCB.

- Defects Detected: Insufficient solder, bridging, misalignment, and deformities.

- Impact: Early detection of solder paste issues prevents downstream defects, reducing rework and improving overall product quality.

2. Pre-Reflow Inspection

- Purpose: Verifies the correct placement, polarity, and orientation of components before reflow soldering.

- Defects Detected: Misplaced components, missing parts, or incorrect orientations.

- Impact: Prevents defects from being baked into the board during reflow.

3. Post-Reflow Inspection

- Purpose: Examines solder joints and component alignment after reflow soldering.

- Defects Detected: Tombstoning, lifted leads, insufficient solder joints, and component shifting.

- Impact: Ensures high-quality solder joints and minimizes field failures.

4. Final Assembly Inspection

- Purpose: Conducts a comprehensive check of the finished PCB assembly.

- Defects Detected: Mechanical damage, surface contamination, and missing components.

- Impact: Guarantees that only defect-free products are shipped to customers.

Advantages of AOI Machines for SMT PCB Assembly

1. Increased Inspection Speed

AOI systems can inspect hundreds of components per minute, significantly faster than manual inspection methods. This speed is essential for high-volume production environments.

2. High Accuracy and Consistency

Advanced imaging technology and algorithms enable AOI machines to detect even microscopic defects with precision. This ensures consistent quality across all PCBs produced.

3. Reduced Labor Costs

By automating the inspection process, AOI reduces reliance on manual labor, lowering operational costs while improving efficiency.

4. Early Defect Detection

AOI identifies defects early in the manufacturing process, preventing defective products from progressing through the production line. This minimizes rework costs and material waste.

5. Data Collection and Analysis

AOI systems collect detailed inspection data that manufacturers can use to analyze defect trends and improve process control. This feedback loop enhances overall production quality.

Types of AOI Systems

1. Inline AOI Systems

- Integrated directly into production lines.

- Provide real-time feedback for immediate defect correction.

- Ideal for high-volume manufacturing environments.

2. Offline AOI Systems

- Operate as standalone units for batch inspections or targeted analysis.

- Useful for low-volume production or detailed examination of specific areas.

How AOI Enhances Efficiency in SMT PCB Assembly

1. Real-Time Quality Control

Inline AOI systems provide immediate feedback on defects during production, enabling quick corrective actions without halting operations.

2. Improved Yield Rates

By detecting defects early and ensuring high-quality output at every stage of production, AOI significantly increases yield rates while reducing waste.

3. Faster Turnaround Times

AOI machines operate continuously without downtime, allowing manufacturers to meet tight deadlines without compromising quality.

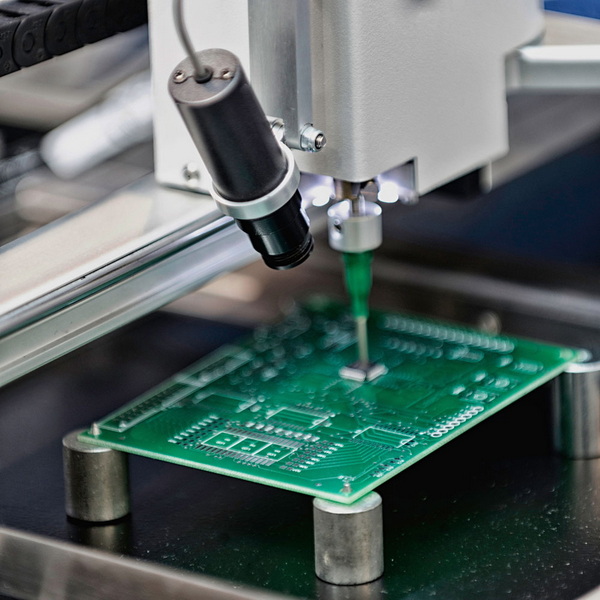

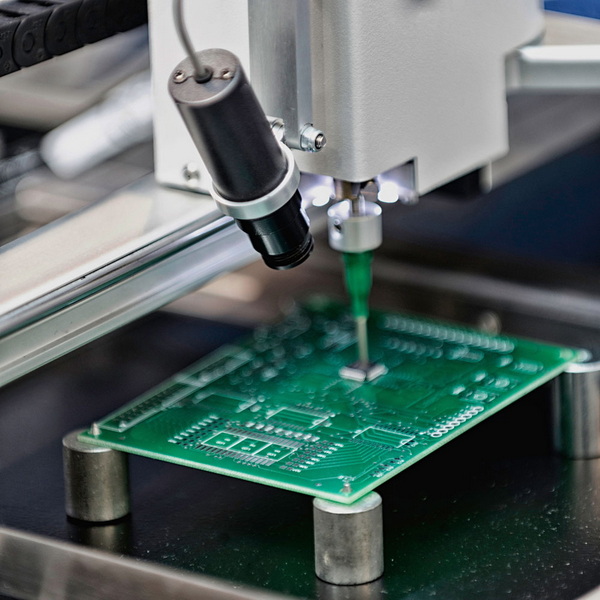

Advanced Features of Modern AOI Machines for SMT PCB

1. Multi-Angle Inspection

Modern AOI machines for SMT PCB assembly often feature multi-angle inspection capabilities. This allows for a more comprehensive examination of components and solder joints from various perspectives, enhancing defect detection accuracy.

2. 3D Inspection Technology

Advanced AOI systems incorporate 3D inspection technology, which provides depth information in addition to 2D images. This is particularly useful for detecting issues like component coplanarity and solder joint volume.

3. Artificial Intelligence and Machine Learning

The integration of AI and machine learning algorithms in AOI machines for SMT PCB assembly has significantly improved defect classification and reduced false positives. These systems can learn from historical data and continuously improve their inspection accuracy.

4. High-Speed Cameras and Processing

State-of-the-art AOI machines utilize high-speed cameras and powerful processors to handle the immense data flow required for real-time inspection in high-volume production environments.

Integration of AOI in Industry 4.0

AOI machines play a crucial role in the implementation of Industry 4.0 principles in SMT PCB assembly. They contribute to the creation of smart factories by:

1. Providing real-time data for process monitoring and control.

2. Enabling predictive maintenance through trend analysis of defect data.

3. Facilitating seamless communication with other production equipment for automated process adjustments.

Challenges and Considerations in AOI Implementation

While AOI machines offer numerous benefits, there are some challenges to consider:

1. Initial Investment: High-quality AOI systems can be expensive, requiring careful cost-benefit analysis.

2. Programming and Setup: Proper programming and setup are crucial for accurate inspection, which may require specialized training.

3. False Positives: Balancing sensitivity to catch all defects while minimizing false positives is an ongoing challenge.

4. Keeping Pace with Technology: As PCB technology advances, AOI systems must evolve to handle new components and assembly techniques.

Future Trends in AOI for SMT PCB Assembly

The future of AOI in SMT PCB assembly looks promising, with several emerging trends:

1. Increased Automation: Further integration with robotic systems for automated defect correction.

2. Enhanced AI Capabilities: More sophisticated AI algorithms for improved defect detection and classification.

3. Miniaturization: AOI systems capable of inspecting increasingly smaller components and finer pitches.

4. Cloud Integration: Cloud-based data storage and analysis for improved process control across multiple production lines or facilities.

Conclusion

Automated Optical Inspection (AOI) machines play a pivotal role in increasing efficiency in SMT PCB assembly by ensuring high-quality standards while reducing costs and production time. Their ability to detect defects early in the process not only saves resources but also enhances customer satisfaction by delivering reliable products. As technology continues to advance, AOI systems will remain at the forefront of quality control in PCB manufacturing, driving innovation and efficiency in the electronics industry.

FAQs About AOI Machines in SMT PCB Assembly

1. What is an AOI machine used for in SMT PCB assembly?

AOI machines are used to inspect PCBs for defects such as misaligned components, poor solder joints, and surface contamination at various stages of the assembly process.

2. How does an AOI machine work?

AOI machines use high-resolution cameras and advanced algorithms to capture images of PCBs and compare them against predefined standards to identify defects.

3. What are the benefits of using AOI over manual inspection?

AOI offers higher speed, accuracy, consistency, and cost-effectiveness compared to manual inspection methods.

4. What types of defects can AOI detect?

AOI can detect a wide range of defects including insufficient solder paste, tombstoning, lifted leads, component misplacement, and surface scratches.

5. Can AOI be integrated into existing production lines?

Yes, inline AOI systems are designed to integrate seamlessly into existing production lines for real-time quality control.