Content Menu

● Understanding Frameless SMT Stencils

● Key Materials Used in Frameless SMT Stencils

>> Stainless Steel

>> Nickel Alloys

>> Polyimide and Other Materials

● Manufacturing Processes for Frameless SMT Stencils

>> Laser Cutting

>> Chemical Etching

>> Electroforming

● Advantages of Frameless SMT Stencils

>> Cost-Effectiveness

>> Space Efficiency

>> Flexibility

● Applications of Frameless SMT Stencils

>> Prototype Development

>> Low-Volume Production

>> Custom PCB Designs

● Challenges and Future Developments

>> Material Selection

>> Stencil Maintenance

● Conclusion

● FAQ

>> 1. What is a frameless SMT stencil?

>> 2. What materials are typically used for frameless SMT stencils?

>> 3. How does laser cutting work in the production of frameless SMT stencils?

>> 4. What are the advantages of using frameless SMT stencils over framed ones?

>> 5. In what applications are frameless SMT stencils most beneficial?

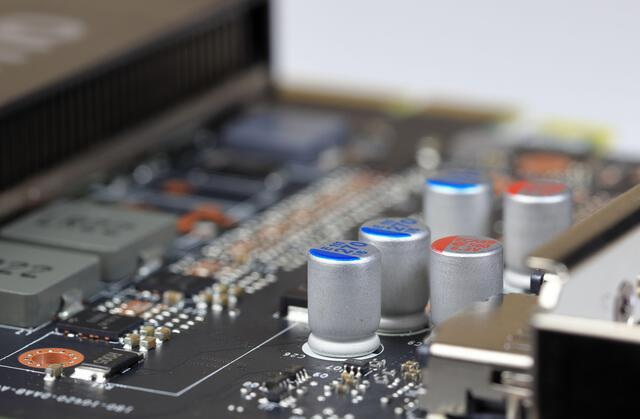

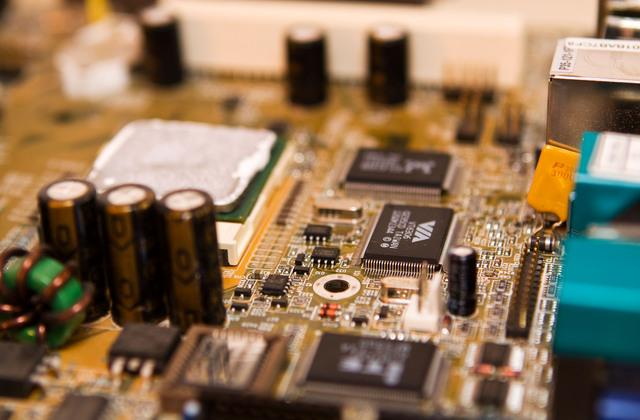

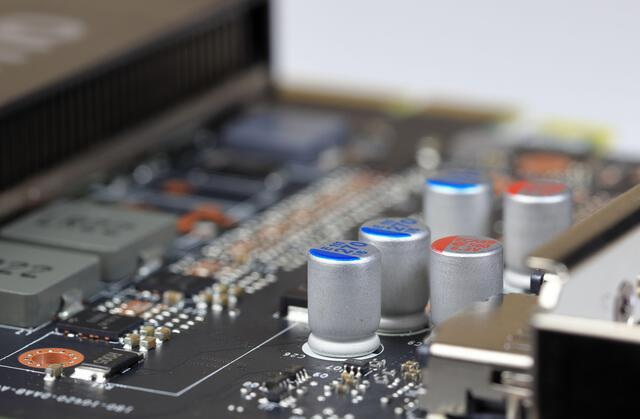

Frameless SMT stencils, also known as foil stencils, are essential tools in the surface mount technology (SMT) assembly process. They are primarily used for applying solder paste onto printed circuit boards (PCBs) with precision and efficiency. This article delves into the materials used in the production of frameless SMT stencils, their manufacturing processes, advantages, and applications.

Understanding Frameless SMT Stencils

Frameless SMT stencils differ from traditional framed stencils in that they do not have a permanent frame surrounding them. Instead, they are designed to be used with reusable stencil frames or tensioning systems. This design choice offers several advantages, including reduced costs and easier storage. Frameless stencils are particularly beneficial for low-volume production and prototyping, where flexibility and quick changes are essential.

Key Materials Used in Frameless SMT Stencils

The choice of materials for frameless SMT stencils significantly impacts their performance and longevity. The most common materials include:

Stainless Steel

Stainless steel is the most widely used material for frameless SMT stencils due to its durability and resistance to corrosion. It can withstand multiple printing cycles without deformation, making it suitable for various applications. Stainless steel alloys, particularly the 300 series, offer excellent mechanical properties that ensure consistent performance over time. The thickness of stainless steel stencils typically ranges from 0.1 mm to 0.3 mm, depending on the specific requirements of the PCB design.

Nickel Alloys

Nickel alloys such as Inconel or Monel are also used in the production of frameless SMT stencils. These materials provide superior mechanical strength and high-temperature resistance. Nickel alloy stencils are particularly advantageous in demanding environments where reliability is crucial, such as aerospace or automotive applications. However, they are generally more expensive than stainless steel alternatives.

Polyimide and Other Materials

Although less common, polyimide and other polymer-based materials are sometimes used for frameless SMT stencils. These materials are lightweight and can be more cost-effective for certain applications. However, they may lack the durability and precision offered by metal stencils.

Manufacturing Processes for Frameless SMT Stencils

The manufacturing process of frameless SMT stencils involves several techniques that ensure precision and quality:

Laser Cutting

Laser cutting is the most common method used to create frameless SMT stencils. High-energy laser beams cut through stainless steel or nickel alloy sheets to form precise apertures that correspond to the solder pads on a PCB. This method allows for sharp edges and high accuracy in defining solder paste deposition areas, which is vital for reliable electrical connections. Laser cutting technology has advanced significantly, enabling the production of stencils with complex geometries and fine features.

Chemical Etching

Chemical etching is a subtractive process where material is removed using chemical solutions to create apertures in the stencil. While this method can produce intricate designs, it is generally less precise than laser cutting and is better suited for larger openings. Chemical etching is also more environmentally friendly compared to laser cutting, as it generates fewer emissions.

Electroforming

Electroforming is an additive process that builds up the stencil by depositing nickel around a photoresist template of apertures matching the board design. This technique allows for very fine apertures and smooth walls but has a higher initial cost and longer processing time compared to other methods. Electroformed stencils are ideal for high-density PCBs where precise control over solder paste deposition is critical.

Advantages of Frameless SMT Stencils

Frameless SMT stencils offer several benefits that make them an attractive option for many manufacturers:

Cost-Effectiveness

Frameless stencils are significantly less expensive than framed alternatives. This lower cost makes them ideal for small batch production and prototyping where budget constraints are a concern. Additionally, the reusable frames can be used with multiple stencil foils, further reducing overall costs.

Space Efficiency

Without a permanent frame, frameless stencils take up less storage space. This feature is particularly advantageous for companies that manage multiple designs or need to store large quantities of stencils. The compact nature of frameless stencils also facilitates easier transportation and handling.

Flexibility

The ability to interchange different stencil foils within a single reusable frame allows manufacturers to adapt quickly to changing production needs. This flexibility is crucial in environments where product designs frequently change or when prototyping new products. Frameless stencils can be easily modified or replaced if design changes occur, reducing downtime and increasing productivity.

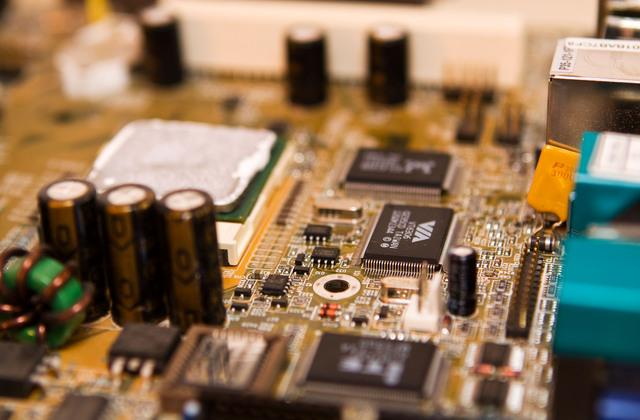

Applications of Frameless SMT Stencils

Frameless SMT stencils are utilized across various sectors due to their versatility:

Prototype Development

They are ideal for prototype PCB assembly, allowing engineers to test designs quickly without significant investment in equipment or materials. The rapid turnaround time for frameless stencils supports agile development methodologies, where iterative design improvements are common.

Low-Volume Production

Companies engaged in low-volume production benefit from the cost savings associated with frameless stencils, enabling them to maintain profitability while producing smaller runs of products. This is particularly important in niche markets where demand is limited but product customization is high.

Custom PCB Designs

Frameless stencils can be tailored to specific PCB designs, accommodating unique layouts and component placements effectively. This customization capability is essential for high-reliability applications such as medical devices or aerospace electronics.

Challenges and Future Developments

Despite their advantages, frameless SMT stencils also present some challenges:

Material Selection

Choosing the right material for a frameless SMT stencil can be challenging due to the trade-offs between cost, durability, and precision. Manufacturers must carefully evaluate their production needs and environmental conditions to select the most appropriate material.

Stencil Maintenance

Frameless stencils require regular cleaning and maintenance to ensure optimal performance. Improper handling or storage can lead to damage or contamination, affecting solder paste application quality.

In terms of future developments, advancements in laser cutting technology and the introduction of new materials are expected to further enhance the precision and durability of frameless SMT stencils. Additionally, there is a growing interest in sustainable manufacturing practices, which may lead to more environmentally friendly production methods for stencils.

Conclusion

Frameless SMT stencils represent a vital component in modern electronics manufacturing, providing precision and flexibility while being cost-effective. Made primarily from stainless steel or nickel alloys, these stencils undergo various manufacturing processes such as laser cutting and chemical etching to ensure high-quality performance. Their advantages make them particularly suited for prototyping and low-volume production environments.

In summary, frameless SMT stencils play an essential role in ensuring efficient solder paste application on PCBs, which is critical for achieving reliable electronic assemblies.

FAQ

1. What is a frameless SMT stencil?

A frameless SMT stencil is a thin metal sheet without a permanent frame that is used to apply solder paste onto printed circuit boards (PCBs). They are designed to work with reusable stencil frames.

2. What materials are typically used for frameless SMT stencils?

Frameless SMT stencils are commonly made from stainless steel or nickel alloys due to their durability, corrosion resistance, and ability to withstand multiple printing cycles.

3. How does laser cutting work in the production of frameless SMT stencils?

Laser cutting uses high-energy laser beams to cut precise apertures into stainless steel or nickel alloy sheets based on CAD designs, ensuring accurate solder paste deposition areas.

4. What are the advantages of using frameless SMT stencils over framed ones?

Frameless SMT stencils are more cost-effective, take up less storage space, and offer greater flexibility for quick design changes compared to framed alternatives.

5. In what applications are frameless SMT stencils most beneficial?

Frameless SMT stencils are ideal for prototype development, low-volume production runs, and custom PCB designs due to their adaptability and cost savings.