Content Menu

● Introduction

● Understanding Surface Mount Technology (SMT)

● Types of Surface Mount Device Packages

● Materials Used in SMD Packaging

● The Role of Packaging in SMT Efficiency

● Conclusion

● Related Questions

>> 1. What is surface mount technology (SMT)?

>> 2. What are the advantages of using surface mount devices?

>> 3. How does material choice affect surface mount device packaging?

>> 4. What types of components typically use surface mount packaging?

>> 5. Why is automated assembly important in SMT?

Introduction

Surface mount device (SMD) packaging is a critical aspect of modern electronics manufacturing, enabling efficient assembly and compact designs. This article delves into the various materials used in SMD packaging, the types of packages available, and their significance in the context of surface mount technology (SMT).

Understanding Surface Mount Technology (SMT)

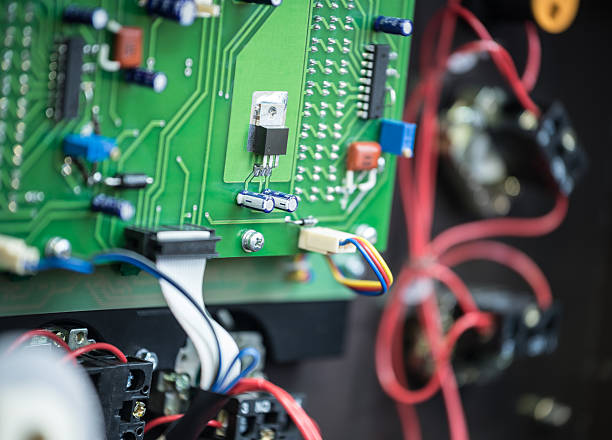

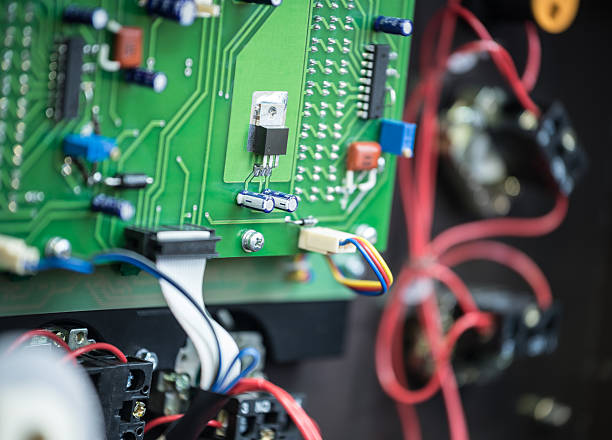

Surface mount technology (SMT) is a method where electronic components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, which requires components to be inserted into holes drilled in the PCB, SMT allows for a more compact design, facilitating higher circuit densities and smaller devices. This transition has been pivotal in the evolution of electronics, leading to the development of various SMD packages that cater to different applications.

Types of Surface Mount Device Packages

There are several standard types of SMD packages, each designed to accommodate specific components and functionalities. Here are some of the most common:

- Small Outline Integrated Circuit (SOIC): This package is widely used for integrated circuits (ICs) and features gull-wing leads for easy soldering.

- Quad Flat Package (QFP): Known for its flat shape and multiple pins on all four sides, QFPs are suitable for high pin-count applications.

- Ball Grid Array (BGA): BGAs use an array of solder balls on the underside for connection to the PCB, providing excellent thermal and electrical performance.

- Plastic Leaded Chip Carrier (PLCC): This package is often used for programmable devices and has leads that extend from the sides.

- Thin Small Outline Package (TSOP): TSOPs are designed for memory devices and feature a thinner profile than standard SOICs.

Materials Used in SMD Packaging

The choice of materials for SMD packaging is crucial as it affects performance, reliability, and manufacturability. Here are some key materials commonly used:

- Plastics: Most SMD packages are made from various types of plastics, such as epoxy resins and thermoplastics. These materials provide insulation and protection against environmental factors.

- Ceramics: For high-frequency applications or environments requiring greater thermal stability, ceramic materials are often used. They offer superior performance characteristics but at a higher cost.

- Metals: Some packages incorporate metal components for enhanced thermal management. For example, lead frames made from copper or aluminum are common in many SMD packages.

- Adhesives: Adhesives are sometimes used to secure components during assembly or to enhance reliability under thermal stress.

The Role of Packaging in SMT Efficiency

The packaging method chosen for SMDs significantly influences the efficiency of the SMT process. Here's how:

- Automated Assembly: Many SMD packages are designed for automated pick-and-place machines, which streamline assembly processes and reduce labor costs.

- Space Utilization: The compact nature of SMD packages allows more components to fit on a PCB, maximizing space utilization and enabling smaller device designs.

- Thermal Management: Proper packaging materials help manage heat dissipation, which is essential for maintaining performance and reliability in electronic devices.Factors Influencing Material Selection

When selecting materials for SMD packaging, several factors come into play:

- Electrical Performance: The dielectric properties of materials can affect signal integrity; thus, materials must be chosen based on their electrical characteristics.

- Thermal Properties: Materials must withstand operational temperatures without degrading. Thermal conductivity is also a consideration for heat-sensitive applications.

- Mechanical Strength: The physical robustness of packaging materials ensures that components can endure handling during manufacturing and end-use conditions.

Conclusion

In conclusion, surface mount device packaging plays a vital role in modern electronics by enabling efficient assembly processes and compact designs. The selection of appropriate materials—ranging from plastics to ceramics—directly impacts the performance and reliability of electronic devices. As technology continues to advance, innovations in packaging will further enhance SMT capabilities, driving the development of smaller, more powerful electronic products.

Related Questions

1. What is surface mount technology (SMT)?

Surface mount technology (SMT) is a method where electronic components are directly attached to the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole mounting methods.

2. What are the advantages of using surface mount devices?

The advantages include reduced size and weight of electronic assemblies, improved manufacturing efficiency through automation, increased circuit density on PCBs, and enhanced performance due to shorter electrical paths.

3. How does material choice affect surface mount device packaging?

Material choice affects thermal management, electrical performance, mechanical strength, and overall reliability of the packaged components during operation.

4. What types of components typically use surface mount packaging?

Common components include resistors, capacitors, diodes, transistors, and integrated circuits (ICs), all available in various SMD package types tailored for specific applications.

5. Why is automated assembly important in SMT?

Automated assembly reduces labor costs, increases production speed, enhances precision during component placement, and minimizes errors compared to manual assembly methods.