Content Menu

>> Understanding SIPLACE Pick and Place Technology

>> Key Features of SIPLACE Pick and Place Machines

>> Benefits of Using SIPLACE Machines

>> Why Choose Global Soul Limited as Your SIPLACE Supplier?

>> Applications of SIPLACE Machines

>> Conclusion

>> Frequently Asked Questions

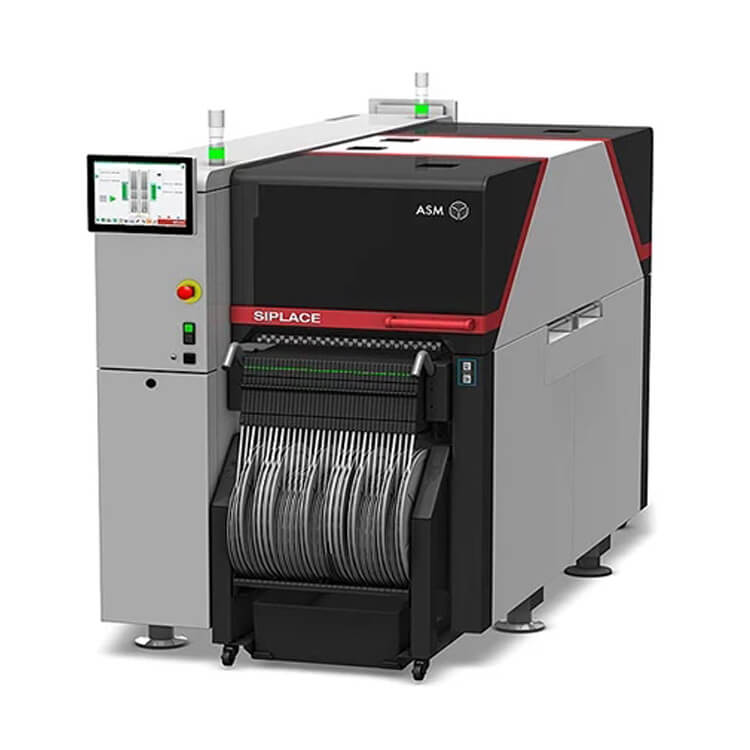

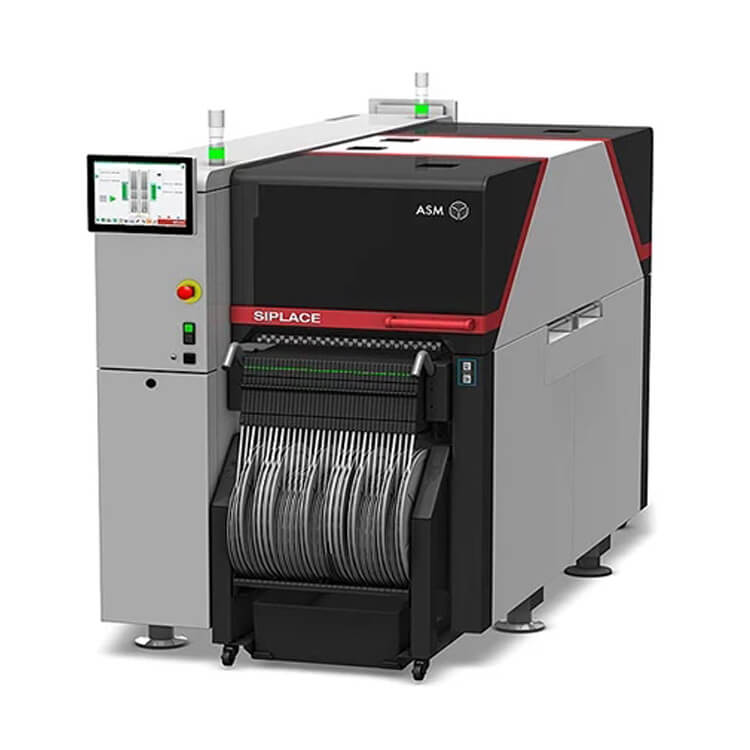

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. One of the key technologies that have revolutionized this sector is the SIPLACE pick and place machine. As a leading SIPLACE pick and place supplier, Global Soul Limited (GS-SMT LTD) has been at the forefront of providing innovative solutions for Surface Mount Technology (SMT) since its inception in 2011. This article explores the significance of SIPLACE machines in modern manufacturing, their features, benefits, and why they are indispensable for companies looking to enhance their production capabilities.

Understanding SIPLACE Pick and Place Technology

What is SIPLACE?

SIPLACE is a brand under ASMPT that specializes in high-performance pick and place machines used in SMT processes. These machines are designed to automate the placement of electronic components onto printed circuit boards (PCBs) with high accuracy and speed.

How Do SIPLACE Machines Work?

The operation of SIPLACE machines involves several key steps:

1. Feeding Components: Components are loaded into feeders, which are then attached to the machine.

2. Vision System: The machine uses advanced vision systems to identify the correct placement spots on the PCB.

3. Placement: The machine's robotic arms pick components from feeders and place them onto the PCB with precision.

4. Quality Control: After placement, the machine often conducts checks to ensure components are correctly positioned.

Key Features of SIPLACE Pick and Place Machines

- High Speed: SIPLACE machines can achieve theoretical speeds of up to 81,500 components per hour (CPH), making them suitable for high-volume production lines.

- Precision Placement: With accuracy levels as fine as ±50 microns, these machines ensure that even the smallest components are placed correctly.

- Flexibility: Models like the SIPLACE SX offer modular designs that allow manufacturers to scale operations based on demand without extensive downtime.

Benefits of Using SIPLACE Machines

1. Increased Efficiency: Automating the placement process significantly reduces production time compared to manual methods.

2. Cost-Effectiveness: While the initial investment may be high, the long-term savings through reduced labor costs and increased production rates make SIPLACE machines a wise choice.

3. Enhanced Quality Control: Integrated quality control systems help maintain high standards by minimizing defects during production.

Why Choose Global Soul Limited as Your SIPLACE Supplier?

As a global electronics specialist based in Shenzhen, China, GS-SMT LTD offers comprehensive solutions tailored to meet various manufacturing needs:

- Wide Range of Products: GS-SMT provides not only SIPLACE machines but also SMT spare parts, used equipment, and consumables.

- Expertise in Customer Service: With a commitment to customer satisfaction, GS-SMT prioritizes quality and timely delivery.

- Competitive Pricing: The company offers competitive pricing structures that cater to different budgets without compromising on quality.

Applications of SIPLACE Machines

SIPLACE pick and place machines are utilized across various industries:

- Consumer Electronics: From smartphones to home appliances, these machines play a crucial role in assembling electronic devices.

- Automotive Industry: They are essential for producing PCBs used in vehicles, ensuring reliability and performance.

- Medical Devices: Precision placement is critical in medical technology, where errors can lead to severe consequences.

Conclusion

In summary, SIPLACE pick and place machines represent a cornerstone technology in modern electronics manufacturing. Their ability to enhance efficiency, precision, and quality makes them indispensable for companies aiming to stay competitive in a rapidly evolving market. Global Soul Limited stands out as a reliable supplier of these advanced systems, providing comprehensive support to manufacturers worldwide.

Frequently Asked Questions

1. What is a pick and place machine?

A pick and place machine automates the process of placing electronic components onto PCBs with high speed and accuracy.

2. Why is precision important in PCB assembly?

Precision ensures that components function correctly within electronic devices; even small misplacements can lead to failures.

3. What industries use SIPLACE machines?

Industries such as consumer electronics, automotive, and medical devices widely use SIPLACE machines for PCB assembly.

4. How does Global Soul Limited support its customers?

GS-SMT offers a wide range of products, expert customer service, competitive pricing, and timely delivery.

5. What are the advantages of using used SMT equipment?

Used SMT equipment can significantly reduce initial investment costs while still providing reliable performance for manufacturers.