Content Menu

>> Introduction to Siemens Pick and Place Machines

>> The Importance of Pick and Place Machines in SMT

>> Key Features of Siemens Pick and Place Machines

>> Benefits of Using Siemens Pick and Place Machines

>> Real-World Applications of Siemens Pick and Place Machines

>> Future Trends in Pick and Place Technology

>> Conclusion

>> Frequently Asked Questions

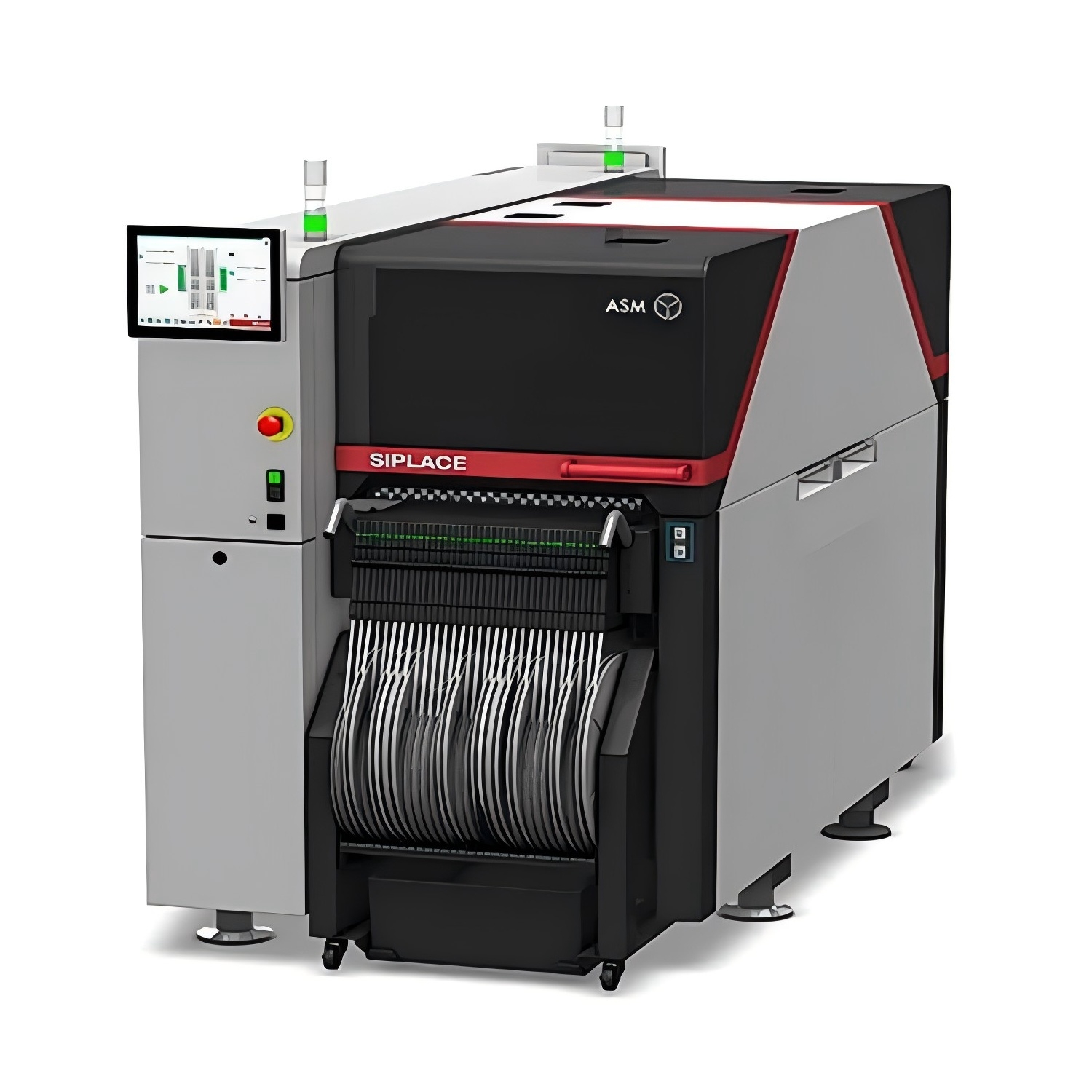

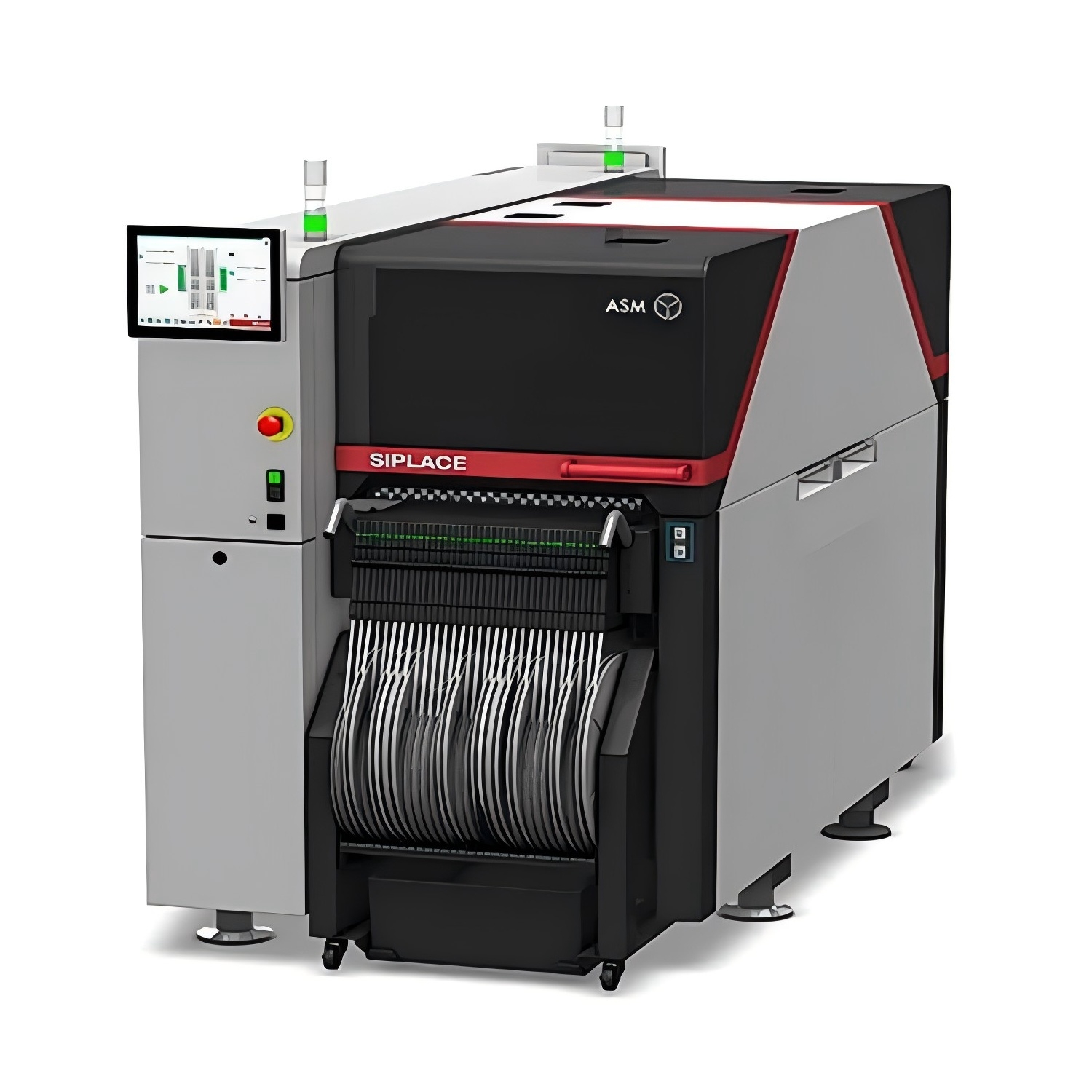

Introduction to Siemens Pick and Place Machines

Siemens has long been a leader in automation and manufacturing technologies, particularly in the realm of pick and place machines. These machines are integral to SMT processes, where components are mounted onto printed circuit boards (PCBs) with high speed and accuracy. The Siemens SIPLACE series, known for its innovative technology and reliability, exemplifies the advancements in this field.

The Importance of Pick and Place Machines in SMT

1. High-Speed Production: Siemens pick and place machines are designed to achieve high throughput rates. For instance, models like the SIPLACE X3 S can reach an IPC speed of 78,100 components per hour (cph) and a theoretical speed of 127,875 cph. This capability is crucial for manufacturers aiming to meet high demand without sacrificing quality.

2. Precision and Accuracy: The mounting accuracy of these machines is impressive, with specifications indicating ±41μm for component placement. Such precision is vital in modern electronics where even minor misalignments can lead to significant failures.

3. Versatility: Siemens machines can handle a wide range of component sizes—from tiny 01005 packages to larger components measuring up to 50x40mm. This versatility allows manufacturers to produce various products on the same line without extensive reconfiguration.

Key Features of Siemens Pick and Place Machines

- MultiStar Placement Heads: The SIPLACE MultiStar head allows for different placement modes, enhancing flexibility during production runs. This feature eliminates the need for manual changes between setups, streamlining operations.

- Advanced Imaging Systems: Integrated camera systems help ensure that components are accurately placed by providing real-time feedback during the assembly process.

- Automated Setup and Maintenance: Siemens machines often include features that automate setup processes, reducing downtime and increasing overall productivity. For example, the SIPLACE software facilitates quick new product imports and programming.

- User-Friendly Interface: The intuitive user interface of Siemens pick and place machines simplifies operation, allowing operators to quickly learn how to manage production lines effectively. This ease of use is essential in fast-paced manufacturing environments where training time must be minimized.

- Data Analytics Capabilities: Many Siemens machines come equipped with data analytics tools that monitor performance metrics in real-time. This capability allows manufacturers to identify bottlenecks or inefficiencies quickly, enabling proactive adjustments to maintain optimal productivity levels.

Benefits of Using Siemens Pick and Place Machines

1. Cost Efficiency: By optimizing production speeds and reducing errors, these machines help lower manufacturing costs. The initial investment in a Siemens pick and place machine is often offset by the savings generated through increased efficiency.

2. Improved Quality Control: With advanced sensors and imaging technology, Siemens machines enhance quality control measures during production. This capability minimizes defects and ensures that products meet stringent industry standards.

3. Scalability: As businesses grow, their production needs evolve. Siemens pick and place machines can easily be integrated into existing lines or scaled up to accommodate increased output demands.

4. Enhanced Flexibility: The ability to switch between different product types without extensive reconfiguration allows manufacturers to respond quickly to market changes or customer demands. This flexibility is crucial in industries where product life cycles are short.

5. Reduced Labor Costs: Automation through Siemens pick and place machines reduces the need for manual labor in component placement tasks. This not only cuts labor costs but also minimizes human error, further enhancing production quality.

Real-World Applications of Siemens Pick and Place Machines

Siemens pick and place machines are utilized across various industries beyond traditional electronics manufacturing:

- Automotive Industry: In automotive manufacturing, these machines assemble complex electronic systems that control vehicle functions such as navigation, safety features, and entertainment systems.

- Consumer Electronics: Companies producing smartphones, tablets, and other consumer devices rely on Siemens pick and place technology for efficient assembly processes that meet high consumer demand.

- Medical Devices: Precision is critical in medical device manufacturing; thus, Siemens machines play a vital role in assembling devices that require strict adherence to quality standards.

- Telecommunications: As telecommunications technology advances, so does the complexity of components used in devices such as routers and switches. Siemens pick and place machines help streamline this assembly process.

Future Trends in Pick and Place Technology

The future of pick and place technology looks promising with several emerging trends:

1. Integration of AI and Machine Learning: As AI technologies advance, we can expect more intelligent systems capable of learning from past operations to optimize future performance automatically.

2. Increased Customization Options: Manufacturers will likely demand more customized solutions tailored to specific production needs, leading companies like Siemens to innovate further their offerings.

3. Sustainability Initiatives: There is a growing emphasis on sustainable manufacturing practices. Future pick and place machines may incorporate energy-efficient technologies or eco-friendly materials in their design.

4. Collaborative Robotics (Cobots): The integration of collaborative robots alongside traditional pick and place systems will enhance flexibility on the production floor while maintaining high efficiency levels.

5. Remote Monitoring Capabilities: Enhanced connectivity will allow manufacturers to monitor machine performance remotely, facilitating quicker response times for maintenance or troubleshooting issues.

Conclusion

Siemens pick and place machines are indispensable in today's electronics manufacturing environment, offering unmatched speed, precision, and flexibility. Their advanced features not only enhance productivity but also ensure high-quality outputs essential for maintaining competitive advantage in a global market.

Frequently Asked Questions

1. What is a pick and place machine?

- A pick and place machine is an automated device used in electronics manufacturing to place components onto PCBs with high speed and accuracy.

2. How does a Siemens pick and place machine improve production efficiency?

- These machines utilize advanced technology that allows for rapid component placement while minimizing errors, thus enhancing overall throughput.

3. What types of components can be handled by Siemens pick and place machines?

- They can handle a wide range of components from very small packages (like 01005) to larger ones (up to 50x40mm).

4. Are Siemens pick and place machines suitable for small-scale manufacturers?

- Yes, they offer scalability options that make them suitable for both large-scale operations as well as smaller manufacturers looking to improve their processes.

5. What maintenance is required for these machines?

- Regular maintenance includes cleaning nozzles, updating software, calibrating sensors, and inspecting mechanical parts to ensure optimal performance.