Content Menu

● Understanding SMT Nozzles

● Key Features of Panasonic SMT Nozzles

>> 1. Precision Engineering

>> 2. Diverse Range of Nozzle Types

>> 3. Advanced Material Technology

>> 4. Innovative Design Features

>> 5. Compatibility with Panasonic Equipment

● Benefits of Using Panasonic SMT Nozzles

>> 1. Increased Production Efficiency

>> 2. Cost Savings

>> 3. Enhanced Product Quality

>> 4. Flexibility in Manufacturing

● Technological Innovations in Panasonic SMT Nozzles

● The Role of Automation in SMT Manufacturing

>> 1. Automated Setup Processes

>> 2. Real-Time Monitoring Systems

>> 3. Predictive Maintenance Capabilities

● Case Studies Highlighting Success with Panasonic SMT Nozzles

>> 1. Incap UK Case Study

>> 2. Automotive Industry Applications

>> 3. Consumer Electronics Production

● Conclusion

● FAQ

>> 1. What types of components can Panasonic SMT nozzles handle?

>> 2. How do I maintain my Panasonic SMT nozzles?

>> 3. Are Panasonic SMT nozzles compatible with other brands' machines?

>> 4. What is the average lifespan of a Panasonic SMT nozzle?

>> 5. Can I customize my order for specific nozzle types?

● Citations:

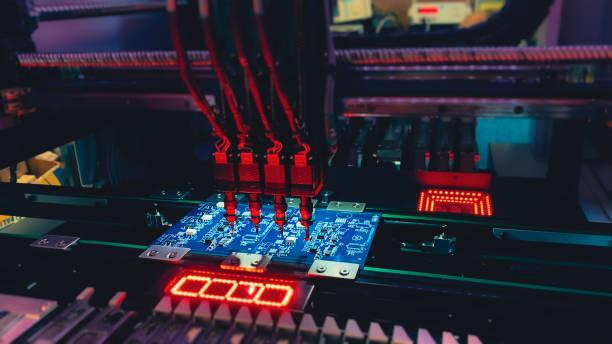

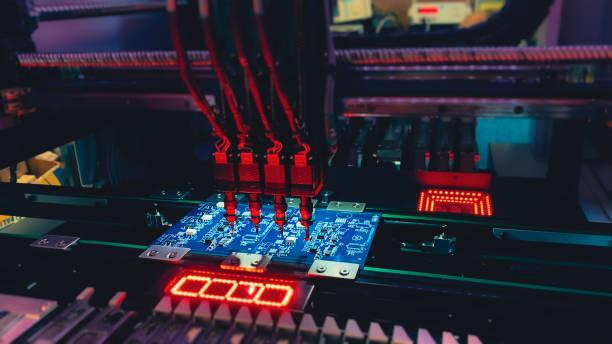

In the world of Surface Mount Technology (SMT), the efficiency and precision of component placement are paramount. At the heart of this process are SMT nozzles, which play a crucial role in ensuring that components are picked, transported, and placed accurately on printed circuit boards (PCBs). Among various manufacturers, Panasonic has established itself as a leader in the SMT nozzle market. This article explores the features that make Panasonic SMT nozzles stand out, their technological advancements, and their impact on manufacturing efficiency.

Understanding SMT Nozzles

SMT nozzles are specialized tools used in pick-and-place machines to handle electronic components during the assembly process. Their primary functions include:

- Picking: The nozzle uses vacuum suction to pick components from feeders.

- Transporting: It moves the components to the designated location on the PCB.

- Placing: The nozzle accurately places components onto the PCB, ensuring proper alignment.

The design and quality of SMT nozzles significantly influence the overall performance of SMT machines.

Key Features of Panasonic SMT Nozzles

1. Precision Engineering

Panasonic SMT nozzles are engineered with high precision to ensure accurate placement of components. This precision is critical for maintaining the integrity of electronic assemblies, especially in high-density PCBs where space is limited. Panasonic employs advanced manufacturing techniques that allow for tight tolerances, ensuring that each nozzle can consistently deliver components without misalignment.

2. Diverse Range of Nozzle Types

Panasonic offers a wide variety of nozzle types designed to accommodate different component shapes and sizes. This diversity allows manufacturers to select nozzles that best fit their specific production needs. Key types include:

- Standard Nozzles: For general-purpose component placement.

- Specialty Nozzles: Designed for unique components such as BGAs (Ball Grid Arrays) or odd-shaped parts.

- High-Temperature Nozzles: Suitable for applications requiring resistance to extreme conditions.

This extensive range ensures that Panasonic can meet the varied demands of modern electronics manufacturing.

3. Advanced Material Technology

The materials used in Panasonic SMT nozzles contribute significantly to their durability and performance. Panasonic utilizes advanced materials such as ceramics and ESD-safe plastics, which enhance the longevity of nozzles and reduce wear over time. These materials also help prevent electrostatic discharge (ESD), which can damage sensitive electronic components during handling.

4. Innovative Design Features

Panasonic incorporates several innovative design features into its SMT nozzles:

- Quick Change Mechanism: This feature allows operators to quickly swap out nozzles without extensive downtime, facilitating rapid changeovers between production runs.

- Optimized Vacuum Suction: The design of Panasonic nozzles maximizes vacuum efficiency, ensuring reliable component pickup and minimizing the risk of component drop during transport.

- Integrated Sensors: Some models come equipped with sensors that monitor nozzle performance in real-time, alerting operators to any issues that may arise during operation.

These features collectively enhance operational efficiency and reduce production errors.

5. Compatibility with Panasonic Equipment

Panasonic SMT nozzles are designed to work seamlessly with its range of pick-and-place machines. This compatibility ensures optimal performance and reliability, as both the machines and nozzles are engineered to function together effectively. Users benefit from a streamlined experience when using Panasonic's integrated solutions for their manufacturing needs.

Benefits of Using Panasonic SMT Nozzles

1. Increased Production Efficiency

The precision and reliability of Panasonic SMT nozzles lead to fewer errors during the placement process. This reduction in errors translates into higher yields and less waste, ultimately increasing overall production efficiency.

2. Cost Savings

While high-quality nozzles may come at a premium price, their durability and performance can lead to significant cost savings over time. Reduced downtime due to fewer maintenance issues and lower rejection rates during quality inspections contribute to a more economical operation.

3. Enhanced Product Quality

With precise placement capabilities, Panasonic SMT nozzles help ensure that components are correctly positioned on PCBs. This accuracy is essential for maintaining high product quality standards, particularly in industries where reliability is critical, such as automotive or medical electronics.

4. Flexibility in Manufacturing

The variety of nozzle options available allows manufacturers to adapt quickly to changing production requirements. Whether scaling up production or transitioning between different product lines, Panasonic's diverse nozzle offerings provide the necessary flexibility.

Technological Innovations in Panasonic SMT Nozzles

Panasonic continuously invests in research and development to enhance its nozzle technology further. Recent innovations include:

- Smart Nozzle Systems: These systems utilize AI algorithms to optimize nozzle performance based on real-time data from production lines, enabling predictive maintenance and reducing unexpected downtime.

- Eco-Friendly Materials: In response to global sustainability trends, Panasonic is exploring environmentally friendly materials for its nozzles without compromising performance or durability.

- Modular Designs: Future models may feature modular designs that allow users to customize nozzle configurations based on specific application needs easily.

The Role of Automation in SMT Manufacturing

As manufacturing processes evolve toward automation, Panasonic has integrated advanced technologies into its SMT systems. Automation not only improves efficiency but also enhances the accuracy of component placement through consistent performance across production runs.

1. Automated Setup Processes

Panasonic's latest machines feature automated setup processes that significantly reduce manual intervention. This automation minimizes human error during setup and allows for faster changeovers between different product configurations.

2. Real-Time Monitoring Systems

With integrated monitoring systems, operators can track machine performance metrics in real time. These systems provide insights into operational efficiency, allowing manufacturers to make data-driven decisions that enhance productivity.

3. Predictive Maintenance Capabilities

By utilizing machine learning algorithms, Panasonic's systems can predict when maintenance is required before issues arise. This proactive approach reduces unplanned downtime and extends the lifespan of both machines and nozzles.

Case Studies Highlighting Success with Panasonic SMT Nozzles

Several companies have successfully implemented Panasonic SMT nozzles into their manufacturing processes, showcasing their effectiveness in real-world applications:

1. Incap UK Case Study

Incap UK recently upgraded its manufacturing capabilities by integrating advanced Panasonic machinery featuring high-performance SMT nozzles. This upgrade resulted in a 33% increase in production capacity while also improving operational efficiency through optimized material control and faster setup times.

2. Automotive Industry Applications

Automotive manufacturers have adopted Panasonic's SMT solutions due to their ability to handle complex assemblies with high precision. The use of specialized nozzles designed for unique automotive components has led to enhanced production quality and reduced assembly errors across various vehicle models.

3. Consumer Electronics Production

In consumer electronics manufacturing, where speed and accuracy are critical, companies utilizing Panasonic's advanced nozzle technology have reported significant improvements in throughput and product quality, leading to better market competitiveness.

Conclusion

Panasonic SMT nozzles stand out in a competitive market due to their precision engineering, diverse range of options, advanced material technology, innovative design features, and compatibility with Panasonic equipment. These attributes not only enhance manufacturing efficiency but also contribute significantly to cost savings and product quality improvements. As technology continues to evolve, Panasonic remains committed to developing solutions that meet the ever-changing demands of the electronics manufacturing industry while embracing automation for enhanced productivity.

FAQ

1. What types of components can Panasonic SMT nozzles handle?

Panasonic SMT nozzles can handle a wide variety of components including standard chips, BGAs, odd-shaped parts, and large connectors thanks to their diverse range of designs tailored for different applications.

2. How do I maintain my Panasonic SMT nozzles?

Regular maintenance includes cleaning the nozzle tips after each use, inspecting for wear or damage, and replacing them as necessary to ensure optimal performance during production runs.

3. Are Panasonic SMT nozzles compatible with other brands' machines?

While designed primarily for use with Panasonic equipment, some models may be compatible with other brands; however, it is advisable to consult with a technician for specific compatibility inquiries.

4. What is the average lifespan of a Panasonic SMT nozzle?

The lifespan varies depending on usage conditions but generally ranges from several months to a few years with proper maintenance practices in place.

5. Can I customize my order for specific nozzle types?

Yes, Panasonic offers customization options for certain nozzle types based on specific requirements or unique component shapes needed for your production line.

Citations:

[1] https://incapcorp.com/panasonic-highlights-incap-uk-in-new-case-study-on-advanced-smt-machinery/

[2] https://eu.connect.panasonic.com/gb/en/products/smart-factory-smt-tht-fatp-and-beyond

[3] https://connect.panasonic.com/en/products-services_fa/products/mounting-related

[4] https://www.smtfactory.com/Hanwha-Samsung-JUKI-Panasonic-Yamaha-SMT-Nozzle-Pick-and-Place-Machine-Original-SMT-Nozzle-pd588637998.html

[5] https://ap.connect.panasonic.com/ph/en/smart-factory-smt-tht-fatp-and-beyond

[6] https://www.rhsmt.com/panasonic-nozzle-1002n-n610098970aa-product/

[7] https://spectrumsmt.com/case-studies/

[8] https://otovon.in/pages/smt-nozzles-for-pick-and-place-machines

[9] https://otovon.in/pages/smt-nozzles-for-panasonic

[10] https://www.rhsmt.com/news/the-integral-role-of-smt-nozzles-in-modern-electronics-assembly/