Content Menu

● What Makes a Reliable SMT Station Supplier?

>> Understanding Surface Mount Technology

>>> Advantages of SMT

>> Key Components of an SMT Station

>> Criteria for Selecting an SMT Station Supplier

>> The Role of Global Soul Limited in SMT Supply

>> The Future of SMT Technology

>>> Emerging Trends in SMT

>> Frequently Asked Questions (FAQs)

>> Conclusion

Understanding Surface Mount Technology

Surface Mount Technology (SMT) refers to a method where electronic components are mounted directly onto the surface of PCBs. This technique allows for automated assembly processes that significantly enhance production efficiency and reduce costs compared to traditional through-hole technology. SMT components are generally smaller and lighter, making them ideal for compact electronic devices.

Advantages of SMT

- Higher Component Density: SMT allows more components to be placed on a PCB, optimizing space.

- Reduced Manufacturing Costs: Automation in SMT reduces labor costs and material waste.

- Improved Performance: SMT connections tend to have better electrical performance due to shorter lead lengths.

- Flexibility in Design: The compact nature of SMT enables designers to create more complex circuits without increasing board size.

Key Components of an SMT Station

An effective SMT station typically consists of several key components:

1. Stencil Printer: Applies solder paste to the PCB pads with precision. The quality of solder paste application is crucial for ensuring reliable connections.

Stencil Printer *(Image showing a stencil printer in action)*

2. Pick and Place Machine: Accurately places components onto the solder paste. These machines can handle various component sizes and types, including fine-pitch devices.

Pick and Place Machine *(Image depicting a pick and place machine placing components)*

3. Reflow Oven: Melts the solder paste to create permanent connections. Different reflow profiles can be set based on component types and board design.

Reflow Oven *(Image illustrating a reflow oven with PCBs inside)*

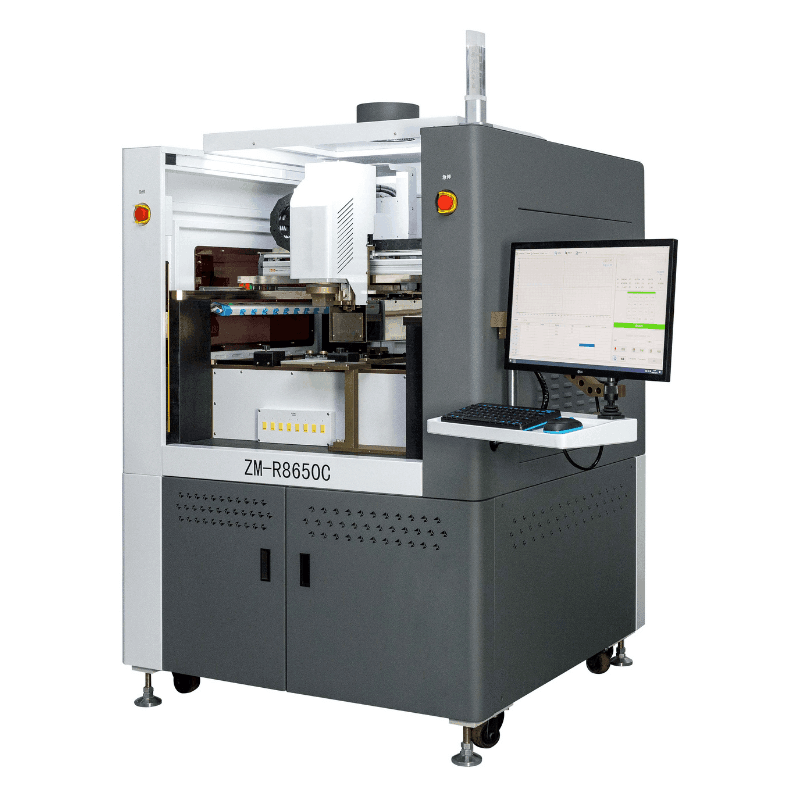

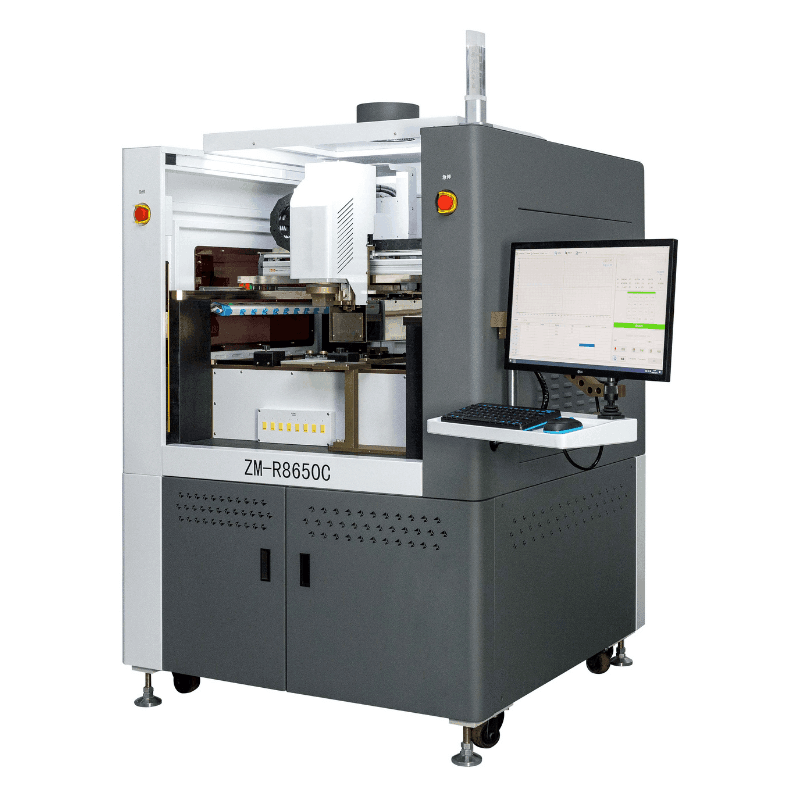

4. Inspection Equipment: Ensures quality control through automated optical inspection (AOI) or X-ray inspection systems to detect defects.

Inspection Equipment *(Image showing an AOI system inspecting PCBs)*

5. Conveyor Systems: Facilitate the movement of PCBs between different stages of the assembly process, ensuring smooth workflow.

Criteria for Selecting an SMT Station Supplier

When searching for an SMT station supplier, consider the following criteria:

- Product Range: A good supplier should offer a comprehensive range of SMT equipment, including printers, pick and place machines, reflow ovens, and inspection systems. The ability to provide all necessary equipment from one source simplifies procurement and integration.

- Quality Assurance: Look for suppliers that adhere to international quality standards such as ISO 9001 or IPC-A-610. Quality certifications indicate a commitment to manufacturing excellence.

- Technical Support: Reliable technical support is crucial for troubleshooting and maintenance. Suppliers that offer training programs can help your team maximize equipment performance.

- Customization Options: Suppliers that offer tailored solutions can better meet specific production needs. Customization might include machine configurations or specialized software solutions.

- Industry Reputation: Research suppliers' reputations through customer reviews, case studies, and industry certifications. A strong track record in the industry often correlates with reliability and quality service.

The Role of Global Soul Limited in SMT Supply

Founded in 2011 in Shenzhen, China, Global Soul Limited (GS-SMT LTD) specializes in providing solutions for Surface Mount Technology. With a focus on customer satisfaction and quality priority, GS-SMT offers a wide range of products including:

- SMT Spare Parts: Such as nozzles, feeders, and other critical components that ensure your machines operate smoothly.

SMT Spare Parts *(Image showing various SMT spare parts)*

- Used SMT Equipment: High-quality pre-owned machinery that provides cost-effective solutions without compromising performance.

Used SMT Equipment *(Image depicting used SMT equipment available for sale)*

- Customized Services: Tailored services that address unique production challenges faced by clients, ensuring optimal performance and efficiency.

GS-SMT's commitment to innovation and technological development positions it as a leading player in the SMT supply landscape. Their experienced team works closely with clients to understand their specific needs and provide solutions that enhance productivity.

The Future of SMT Technology

As technology advances, the future of SMT is poised for significant growth. Innovations such as artificial intelligence in manufacturing processes and improved automation will further enhance production capabilities. Additionally, with the rise of IoT devices and smart electronics, the demand for efficient SMT solutions will continue to escalate.

Emerging Trends in SMT

1. Automation and Robotics: Increased use of robotics in assembly lines will lead to higher efficiency and precision.

Robotic Automation *(Image showing robots working on an assembly line)*

2. AI Integration: AI-driven analytics will optimize production schedules, predict maintenance needs, and improve quality control processes.

3. Sustainable Practices: There is a growing emphasis on environmentally friendly manufacturing practices within the electronics industry. Suppliers that adopt sustainable practices will have a competitive edge.

4. Miniaturization: As devices become smaller, there will be an increased need for advanced SMT techniques that accommodate micro-components without sacrificing performance.

5. Enhanced Inspection Technologies: The development of more sophisticated inspection technologies will ensure higher quality standards are met consistently throughout production runs.

Frequently Asked Questions (FAQs)

1. What is Surface Mount Technology?

- Surface Mount Technology is a method used to mount electronic components directly onto the surface of PCBs, allowing for automated assembly processes.

2. Why choose an SMT station supplier?

- An SMT station supplier provides essential equipment that enhances production efficiency, reduces costs, and improves product quality.

3. What are key components of an SMT station?

- Key components include stencil printers, pick and place machines, reflow ovens, inspection equipment, and conveyor systems.

4. How does GS-SMT stand out among suppliers?

- GS-SMT focuses on customer satisfaction, offers a wide range of products including spare parts and used equipment, and provides customized services tailored to specific needs.

5. What is the future outlook for SMT technology?

- The future looks promising with advancements in automation, AI integration expected to drive further efficiencies in electronics manufacturing, alongside trends towards sustainability.

Conclusion

The importance of selecting a reliable SMT station supplier cannot be overstated in today's competitive electronics market. By understanding the intricacies of Surface Mount Technology and evaluating potential suppliers based on established criteria, manufacturers can significantly enhance their production capabilities.

Investing in high-quality equipment from reputable suppliers like Global Soul Limited not only ensures operational efficiency but also positions businesses favorably within the industry's fast-paced landscape. As technology continues to advance, staying informed about trends and innovations will be key to maintaining competitiveness in electronics manufacturing.