Content Menu

● Understanding SMT Machines and Their Importance

● The Importance of Regular Maintenance

● Essential Maintenance Practices for SMT Machines

>> Daily Maintenance Routines

>> Weekly Maintenance Tasks

>> Monthly Maintenance Procedures

● Advanced Maintenance Strategies

>> Predictive Maintenance

>> Condition-Based Maintenance

● Calibration and Precision Maintenance

● Cleaning and Contamination Control

● Lubrication and Wear Prevention

● Training and Documentation

● Spare Parts Management

● Environmental Control

● Safety Considerations

● Conclusion

● FAQ

>> 1. How often should SMT machines be calibrated?

>> 2. What are the signs that an SMT machine needs maintenance?

>> 3. How can I extend the lifespan of SMT machine nozzles?

>> 4. What role does software play in SMT machine maintenance?

>> 5. How does proper maintenance impact the quality of PCB assembly?

● Citations:

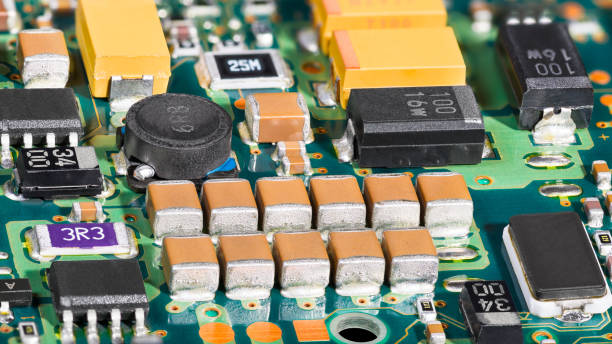

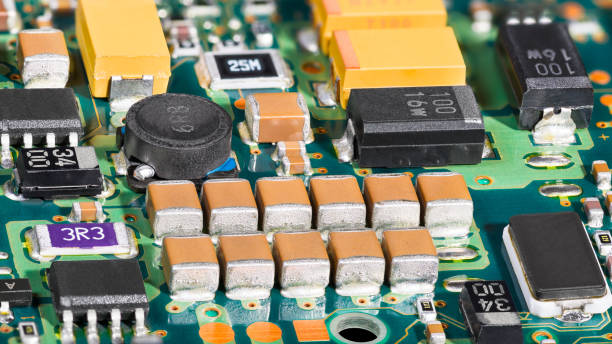

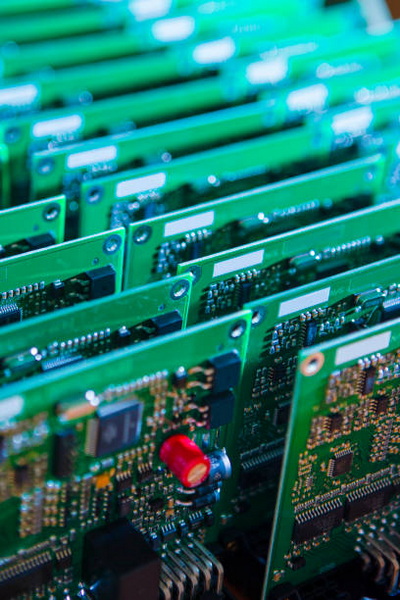

Surface Mount Technology (SMT) machines are the backbone of modern electronics manufacturing. These sophisticated devices are responsible for accurately placing and soldering components onto printed circuit boards (PCBs), enabling the production of compact and efficient electronic devices. To ensure optimal performance, longevity, and reliability of these critical machines, implementing proper maintenance practices is paramount. This article will delve into the essential maintenance practices for SMT machines, exploring various aspects of care and upkeep that are crucial for maintaining peak performance and minimizing downtime.

Understanding SMT Machines and Their Importance

Before diving into maintenance practices, it's essential to understand the significance of SMT machines in the electronics manufacturing industry. SMT machines are designed to place surface mount components onto PCBs with high precision and speed. These machines have revolutionized the production of electronic devices, allowing for smaller, more complex, and more efficient products.

The SMT process typically involves several stages, including solder paste printing, component placement, and reflow soldering. Each of these stages requires precise control and coordination to ensure high-quality results. Given the critical nature of these machines in the production line, any malfunction or inaccuracy can lead to significant quality issues and production delays.

The Importance of Regular Maintenance

Regular maintenance of SMT machines is not just a recommendation; it's a necessity for several reasons:

1. Ensuring Accuracy: SMT machines must maintain a high level of precision to place components correctly. Regular calibration and maintenance help preserve this accuracy.

2. Preventing Downtime: Proactive maintenance can identify and address potential issues before they cause machine failures, reducing unexpected downtime.

3. Extending Machine Lifespan: Proper care and maintenance can significantly extend the operational life of SMT machines, providing a better return on investment.

4. Maintaining Product Quality: Well-maintained machines are more likely to produce consistent, high-quality results, reducing defects and waste.

5. Optimizing Efficiency: Regular maintenance ensures that all parts of the machine are working at peak efficiency, maximizing throughput and productivity.

Essential Maintenance Practices for SMT Machines

Daily Maintenance Routines

Daily maintenance is the first line of defense against potential issues and helps ensure that SMT machines are ready for each day's production. These routines typically include:

1. Cleaning: Use a dust-free cloth to clean the surface of the SMT chip processing equipment and the track transmission sensor probe. Remove any impurities or bulk materials from the feeder base and clean the waste box[2][11].

2. Air Pressure Check: Verify that the air pressure value of the testing equipment is within the correct range, typically 0.42-0.45MP[2][11].

3. Component Cleanup: Use a vacuum cleaner to remove any scattered components on the workbench inside the placement machine[2][11].

4. Visual Inspection: Conduct a quick visual inspection of key components, looking for any obvious signs of wear or damage.

5. Nozzle Check: Inspect and clean the suction nozzles to ensure they are free from debris and functioning correctly.

Weekly Maintenance Tasks

Weekly maintenance builds upon daily routines and includes more thorough cleaning and inspection processes:

1. PCB Transmission Track Cleaning: Clean the PCB transmission track to remove any accumulated impurities[2][11].

2. Camera Maintenance: Use a dust-free cloth to wipe the dust from the glass cover of the component identification camera[2][11].

3. Lubrication: Apply an appropriate amount of lubricant to moving parts such as the PCB retaining rod cylinder, belt shaft, upper and lower shafts of the workbench, and width adjustment wires[2][11].

4. Nozzle Deep Cleaning: Clean the suction nozzles thoroughly using a cotton swab and alcohol[2][11].

5. Feeder Maintenance: Inspect and clean the feeders, ensuring they are free from debris and functioning smoothly.

Monthly Maintenance Procedures

Monthly maintenance involves more comprehensive checks and preventive measures:

1. Control Box Cleaning: Use a vacuum cleaner to remove dust from the distribution box. If necessary, clean the equipment control board and use alcohol to wipe the gold finger of the control board[2].

2. Axis Lubrication: Clean and replace the lubricating oil on the X-axis, Y-axis, and Z-axis. It's recommended to use high-quality lubricants specified by the manufacturer[2].

3. Vacuum System Maintenance: Clean the vacuum part of the placement head, including the Z-axis vacuum rod[2].

4. Comprehensive Inspection: Conduct a thorough inspection of all machine components, including belts, motors, and sensors.

5. Software Updates: Check for and apply any available software updates or patches provided by the manufacturer.

Advanced Maintenance Strategies

Predictive Maintenance

Predictive maintenance uses data analysis and machine learning algorithms to predict when maintenance will be needed. This approach can help prevent unexpected breakdowns and optimize maintenance schedules. Key aspects of predictive maintenance include:

1. Data Collection: Gathering operational data from sensors and machine logs.

2. Analysis: Using advanced analytics to identify patterns and predict potential failures.

3. Scheduled Interventions: Planning maintenance activities based on predictive insights rather than fixed schedules.

Condition-Based Maintenance

Condition-based maintenance involves monitoring the actual condition of the machine to determine what maintenance needs to be performed. This approach can include:

1. Real-time Monitoring: Using sensors to continuously monitor key parameters such as temperature, vibration, and power consumption.

2. Threshold Alerts: Setting up alerts when monitored parameters exceed predefined thresholds.

3. Targeted Maintenance: Performing maintenance only when indicators show it is necessary.

Calibration and Precision Maintenance

Maintaining the precision of SMT machines is crucial for ensuring high-quality production. Regular calibration is an essential part of this process:

1. Vision System Calibration: Regularly calibrate the machine's vision system to ensure accurate component recognition and placement.

2. XY Axis Calibration: Check and adjust the accuracy of the XY axis movement to maintain precise component placement.

3. Z Axis Calibration: Ensure the Z axis is calibrated correctly for proper pick-up and placement force.

4. Nozzle Height Adjustment: Regularly check and adjust nozzle heights to maintain consistent pick-and-place operations.

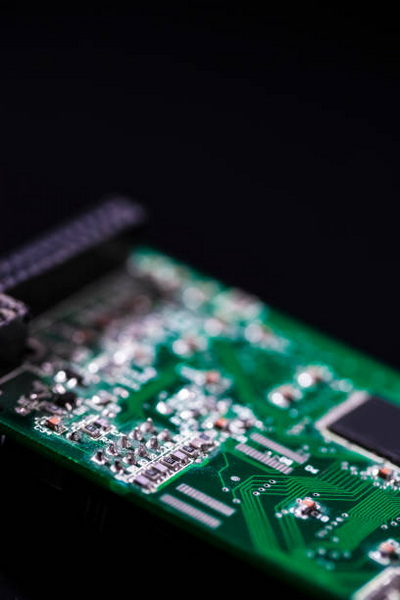

Cleaning and Contamination Control

Cleanliness is paramount in SMT machine maintenance. Contamination can lead to various issues, including misplaced components and poor solder joints. Key cleaning practices include:

1. Nozzle Cleaning: Regularly clean nozzles to prevent clogs and ensure consistent suction[7].

2. Feeder Cleaning: Clean feeders to prevent component jams and ensure smooth operation.

3. Conveyor Belt Maintenance: Keep conveyor belts clean and properly tensioned to ensure smooth PCB transport.

4. Air System Maintenance: Regularly check and clean air filters to maintain proper air pressure and quality.

Lubrication and Wear Prevention

Proper lubrication is essential for reducing wear on moving parts and ensuring smooth operation:

1. Identify Lubrication Points: Know which parts of the machine require regular lubrication.

2. Use Appropriate Lubricants: Always use lubricants recommended by the manufacturer for specific parts.

3. Establish Lubrication Schedules: Create and follow a schedule for regular lubrication of all moving parts.

4. Monitor Wear: Regularly inspect parts for signs of wear and replace them as needed.

Training and Documentation

Effective maintenance relies heavily on well-trained staff and proper documentation:

1. Staff Training: Ensure that maintenance staff are properly trained on SMT machine maintenance procedures.

2. Maintenance Manuals: Keep up-to-date maintenance manuals readily available for reference.

3. Maintenance Logs: Maintain detailed logs of all maintenance activities, including routine checks and repairs.

4. Standard Operating Procedures (SOPs): Develop and regularly update SOPs for maintenance tasks.

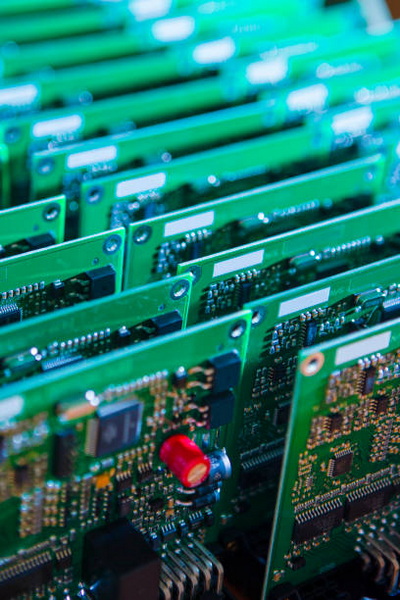

Spare Parts Management

Efficient spare parts management is crucial for minimizing downtime:

1. Inventory Management: Maintain an inventory of critical spare parts.

2. Supplier Relationships: Establish good relationships with suppliers to ensure quick access to parts when needed.

3. Part Lifecycle Management: Keep track of the lifecycle of critical components and plan for replacements.

Environmental Control

The environment in which SMT machines operate can significantly impact their performance and longevity:

1. Temperature Control: Maintain a consistent temperature in the production area to prevent thermal expansion issues.

2. Humidity Control: Control humidity levels to prevent issues with static electricity and component oxidation.

3. Dust Control: Implement measures to minimize dust in the production environment.

Safety Considerations

Safety should always be a top priority in SMT machine maintenance:

1. Lockout/Tagout Procedures: Implement proper lockout/tagout procedures when performing maintenance.

2. Personal Protective Equipment (PPE): Ensure maintenance staff use appropriate PPE.

3. Safety Training: Provide regular safety training for all staff involved in machine operation and maintenance.

Conclusion

Maintaining SMT machines is a complex but essential task in electronics manufacturing. By implementing a comprehensive maintenance strategy that includes daily, weekly, and monthly routines, along with advanced predictive and condition-based approaches, manufacturers can ensure the longevity, accuracy, and efficiency of their SMT machines. Regular cleaning, calibration, lubrication, and inspection form the cornerstone of effective maintenance practices.

Moreover, investing in staff training, maintaining proper documentation, and managing spare parts efficiently can significantly reduce downtime and improve overall productivity. By prioritizing these maintenance practices, manufacturers can optimize their SMT operations, reduce costs, and maintain high-quality standards in PCB assembly.

As technology continues to evolve, so too will the maintenance practices for SMT machines. Staying informed about the latest developments in maintenance techniques and technologies will be crucial for keeping pace with the ever-changing landscape of electronics manufacturing.

FAQ

1. How often should SMT machines be calibrated?

SMT machines should typically be calibrated on a regular schedule, which can vary depending on usage and manufacturer recommendations. Generally, a full calibration should be performed at least once a month, with more frequent checks for critical components. Some manufacturers recommend calibration every 1-2 weeks for high-volume production environments. It's important to consult your machine's manual and consider your specific production needs when establishing a calibration schedule.

2. What are the signs that an SMT machine needs maintenance?

Several signs indicate that an SMT machine may need maintenance:

- Decreased placement accuracy or increased placement errors

- Unusual noises or vibrations during operation

- Inconsistent solder paste deposition

- Frequent component pick-up failures

- Errors in component recognition

- Decreased overall production speed

- Increased rate of defective PCBs

If you notice any of these signs, it's crucial to perform a thorough inspection and necessary maintenance to prevent more serious issues.

3. How can I extend the lifespan of SMT machine nozzles?

To extend the lifespan of SMT machine nozzles:

- Clean nozzles regularly with appropriate cleaning solutions

- Inspect nozzles daily for wear or damage

- Rotate nozzles to distribute wear evenly

- Use the correct nozzle size for each component

- Avoid over-tightening nozzles when installing

- Store unused nozzles properly to prevent damage

- Replace nozzles at the first sign of significant wear or damage

Regular maintenance and proper handling can significantly extend nozzle life and maintain placement accuracy.

4. What role does software play in SMT machine maintenance?

Software plays a crucial role in modern SMT machine maintenance:

- Machine Control Software: Helps in diagnostics and troubleshooting

- Maintenance Management Software: Schedules and tracks maintenance activities

- Data Analysis Software: Analyzes machine performance data to predict maintenance needs

- Calibration Software: Assists in precise machine calibration

- Inventory Management Software: Tracks spare parts and consumables

Utilizing these software tools can streamline maintenance processes, improve efficiency, and help prevent unexpected downtime.

5. How does proper maintenance impact the quality of PCB assembly?

Proper maintenance significantly impacts PCB assembly quality in several ways:

- Ensures accurate component placement

- Maintains consistent solder paste application

- Reduces the likelihood of component damage during placement

- Ensures proper functioning of vision systems for accurate component recognition

- Maintains consistent conveyor speed and alignment

- Reduces the risk of contamination-related defects

- Ensures consistent reflow profile in reflow ovens

By maintaining SMT machines properly, manufacturers can significantly reduce defect rates, improve yield, and ensure consistent high-quality PCB assembly.

Citations:

[1] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html

[2] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=59416&news_id=27399

[3] https://www.sunzontech.com/how-to-do-smt-pick-and-place-machine-maintenance-work/

[4] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[5] https://www.neodensmt.com/news/properly-maintain-the-smt-machine-42392089.html

[6] https://goldlandsmt.com/how-to-maintain-an-smt-machine/

[7] https://www.smtmachine.eu/the-ultimate-guide-to-smt-machine-maintenance/

[8] https://smtnet.com/library/files/upload/Essentials%20of%20SMT.pdf

[9] https://www.hct-smt.com/blog/keep-your-machines-running-smoothly--expert-tips-for-automatic-smt-mounter-pick-and-place-machine-maintenance

[10] https://www.allion.com/tech_surface_mount_tech/

[11] https://www.sztech-smt.com/smt-machine-maintenance-sztech-smt/

[12] https://www.buysmt.com/2447/