Content Menu

● Understanding PCB SMT Loaders

● The Importance of Regular Maintenance

● Essential Maintenance Practices for PCB SMT Loaders

>> 1. Daily Cleaning and Inspection

>> 2. Lubrication of Moving Parts

>> 3. Calibration and Alignment

>> 4. Software and Firmware Updates

>> 5. Component Replacement and Preventive Maintenance

>> 6. Environmental Control

>> 7. Regular Performance Testing

>> 8. Documentation and Record Keeping

>> 9. Staff Training and Education

>> 10. Implementing a Preventive Maintenance Schedule

● The Impact of Proper Maintenance on PCB SMT Loader Performance

● Challenges in Maintaining PCB SMT Loaders

● Future Trends in PCB SMT Loader Maintenance

● Conclusion

● FAQ

>> 1. How often should I perform maintenance on my PCB SMT loader?

>> 2. What are the signs that my PCB SMT loader needs immediate maintenance?

>> 3. Can I perform all maintenance tasks in-house, or should I rely on professional services?

>> 4. How do environmental factors affect the maintenance needs of PCB SMT loaders?

>> 5. What are the most common maintenance mistakes to avoid with PCB SMT loaders?

● Citations:

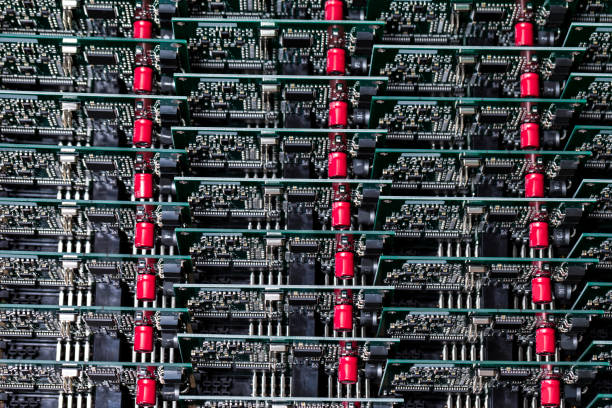

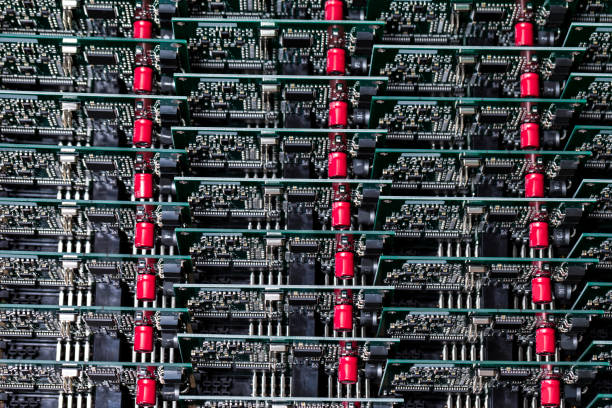

In the world of electronics manufacturing, PCB SMT loaders play a crucial role in the automated assembly process. These machines are responsible for loading printed circuit boards (PCBs) into surface mount technology (SMT) production lines, ensuring a smooth and efficient workflow. To maintain optimal performance and longevity of PCB SMT loaders, implementing proper maintenance practices is essential. This article will explore the key maintenance practices that are vital for PCB SMT loaders, providing insights into how to keep these machines running at peak efficiency.

Understanding PCB SMT Loaders

Before delving into maintenance practices, it's important to understand what PCB SMT loaders are and their significance in the electronics manufacturing process. PCB SMT loaders are automated machines designed to feed printed circuit boards into SMT assembly lines. They are a critical component of the SMT process, ensuring that PCBs are accurately and consistently loaded for component placement and soldering.

The Importance of Regular Maintenance

Regular maintenance of PCB SMT loaders is crucial for several reasons:

1. Ensuring consistent performance

2. Preventing unexpected breakdowns

3. Extending the machine's lifespan

4. Maintaining production quality

5. Reducing overall operational costs

By implementing a comprehensive maintenance program, manufacturers can avoid costly downtime and ensure that their PCB SMT loaders continue to operate at peak efficiency.

Essential Maintenance Practices for PCB SMT Loaders

1. Daily Cleaning and Inspection

One of the most fundamental maintenance practices for PCB SMT loaders is daily cleaning and inspection. This routine task helps prevent the accumulation of dust, debris, and other contaminants that can interfere with the loader's operation[1].

Key steps in daily cleaning and inspection:

- Use compressed air to blow off dust and debris from the loader's surfaces

- Wipe down external surfaces with a clean, lint-free cloth

- Inspect conveyor belts and rollers for signs of wear or damage

- Check for any loose screws or components

- Ensure all safety guards and covers are in place and secure

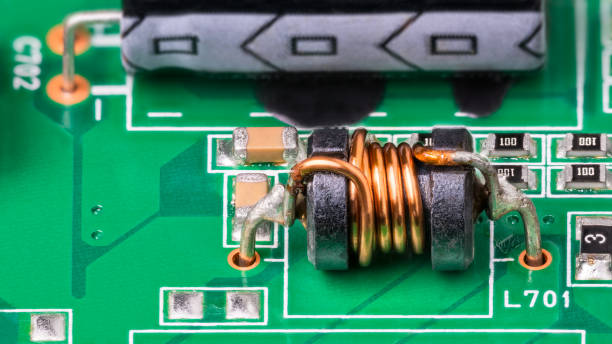

2. Lubrication of Moving Parts

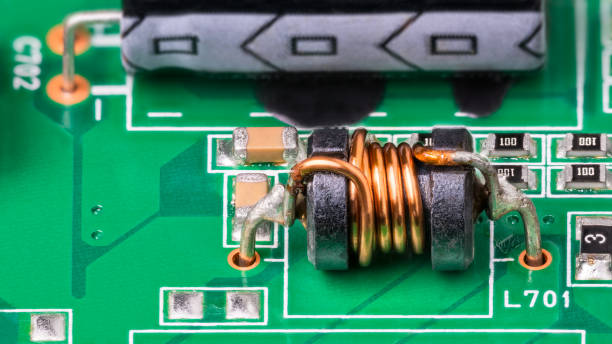

Proper lubrication is essential for the smooth operation of PCB SMT loaders. Moving parts such as bearings, gears, and chains require regular lubrication to reduce friction and wear[2].

Lubrication best practices:

- Use manufacturer-recommended lubricants

- Follow the lubrication schedule specified in the machine's manual

- Apply lubricant sparingly to avoid excess buildup

- Clean off old lubricant before applying new

- Pay special attention to high-stress areas and frequently moving parts

3. Calibration and Alignment

To ensure accurate PCB loading, regular calibration and alignment of the PCB SMT loader are crucial. This practice helps maintain precise positioning and prevents misalignment issues that can lead to production errors[4].

Calibration and alignment procedures:

- Check and adjust the loader's X, Y, and Z-axis alignments

- Verify the accuracy of PCB positioning sensors

- Calibrate the loader's vision system if applicable

- Ensure proper alignment of conveyor belts and guide rails

- Test the loader with sample PCBs to confirm accuracy

4. Software and Firmware Updates

Keeping the PCB SMT loader's software and firmware up to date is an often overlooked but critical maintenance practice. Regular updates can improve performance, add new features, and address potential security vulnerabilities[5].

Update best practices:

- Regularly check for available updates from the manufacturer

- Schedule updates during planned downtime to minimize disruption

- Back up current settings and programs before updating

- Follow manufacturer instructions carefully during the update process

- Test the loader thoroughly after updates to ensure proper functionality

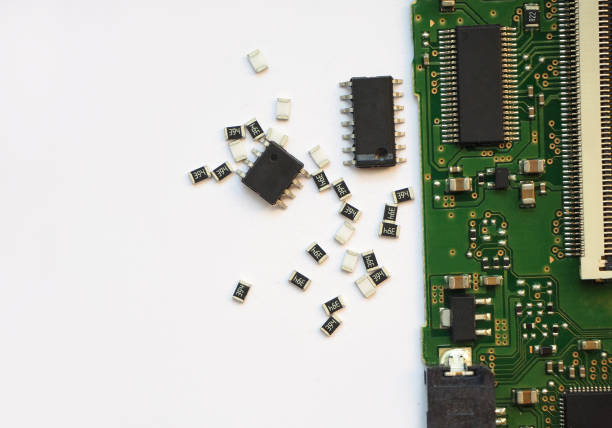

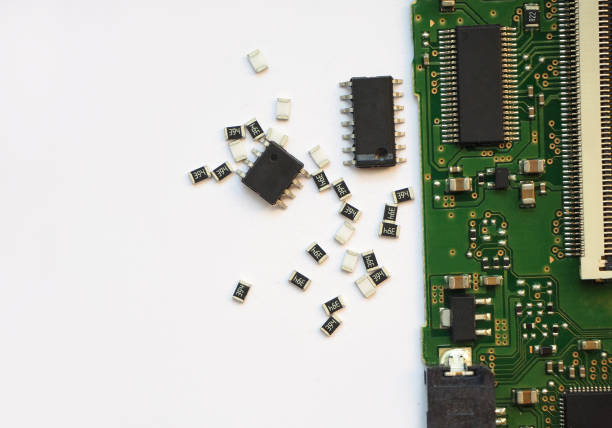

5. Component Replacement and Preventive Maintenance

Proactive replacement of wear-prone components and conducting preventive maintenance can significantly reduce the risk of unexpected breakdowns. This practice involves identifying and replacing parts before they fail, based on their expected lifespan or signs of wear[1].

Key components to monitor and replace:

- Conveyor belts and rollers

- Pneumatic components (e.g., cylinders, valves)

- Electrical connectors and cables

- Sensors and switches

- Bearings and bushings

6. Environmental Control

The environment in which PCB SMT loaders operate can significantly impact their performance and longevity. Maintaining proper environmental conditions is an essential maintenance practice[10].

Environmental control measures:

- Maintain a clean, dust-free environment

- Control temperature and humidity within recommended ranges

- Ensure proper ventilation to prevent overheating

- Use anti-static measures to protect sensitive components

- Install surge protectors to guard against power fluctuations

7. Regular Performance Testing

Conducting regular performance tests helps identify potential issues before they become major problems. These tests can reveal subtle changes in the loader's operation that may not be immediately apparent during normal use[4].

Performance testing procedures:

- Run test cycles with various PCB sizes and types

- Measure cycle times and compare to baseline performance

- Check for any unusual noises or vibrations during operation

- Verify accuracy of PCB positioning and alignment

- Test all safety features and emergency stop functions

8. Documentation and Record Keeping

Maintaining detailed records of maintenance activities, performance data, and any issues encountered is crucial for effective long-term maintenance of PCB SMT loaders[2].

Documentation best practices:

- Keep a log of all maintenance activities performed

- Record performance data and trends over time

- Document any issues or errors encountered and their resolutions

- Maintain an inventory of spare parts and their usage

- Keep all equipment manuals and technical documentation easily accessible

9. Staff Training and Education

Ensuring that operators and maintenance personnel are well-trained in the proper use and maintenance of PCB SMT loaders is essential for effective maintenance practices[5].

Training considerations:

- Provide comprehensive initial training for all new staff

- Conduct regular refresher courses on maintenance procedures

- Keep staff updated on new features or changes in maintenance practices

- Encourage staff to report any unusual machine behavior promptly

- Foster a culture of proactive maintenance among all team members

10. Implementing a Preventive Maintenance Schedule

Developing and adhering to a comprehensive preventive maintenance schedule is perhaps the most critical maintenance practice for PCB SMT loaders. This schedule should encompass all the practices mentioned above and be tailored to the specific needs of your equipment and production environment[1][2].

Key elements of a preventive maintenance schedule:

- Daily cleaning and inspection routines

- Weekly, monthly, and quarterly maintenance tasks

- Scheduled component replacements based on expected lifespans

- Regular calibration and alignment checks

- Software and firmware update schedules

- Performance testing intervals

- Staff training and refresher courses

The Impact of Proper Maintenance on PCB SMT Loader Performance

Implementing these essential maintenance practices can have a significant positive impact on the performance and longevity of PCB SMT loaders. Some of the key benefits include:

1. Increased Reliability: Regular maintenance reduces the likelihood of unexpected breakdowns, ensuring more consistent production.

2. Improved Accuracy: Proper calibration and alignment maintenance ensure that PCBs are loaded with high precision, reducing errors in subsequent assembly steps.

3. Extended Equipment Lifespan: By addressing wear and tear proactively, the overall lifespan of the PCB SMT loader can be significantly extended.

4. Enhanced Efficiency: Well-maintained loaders operate more efficiently, with faster cycle times and fewer interruptions.

5. Cost Savings: While maintenance requires an investment of time and resources, it ultimately leads to cost savings by preventing expensive repairs and production delays.

6. Better Quality Control: Properly maintained loaders contribute to higher overall production quality by ensuring consistent and accurate PCB loading.

7. Improved Safety: Regular maintenance checks help identify and address potential safety hazards before they can cause accidents.

Challenges in Maintaining PCB SMT Loaders

While the benefits of proper maintenance are clear, there are several challenges that manufacturers may face in implementing and maintaining an effective maintenance program for their PCB SMT loaders:

1. Time Constraints: In high-volume production environments, finding time for regular maintenance can be challenging.

2. Cost Considerations: The initial investment in maintenance equipment, spare parts, and training can be significant.

3. Technical Complexity: Modern PCB SMT loaders are complex machines, requiring specialized knowledge for proper maintenance.

4. Balancing Preventive and Reactive Maintenance: Determining the right balance between preventive maintenance and addressing immediate issues can be difficult.

5. Keeping Up with Technological Advancements: As loader technology evolves, maintenance practices must adapt accordingly.

Future Trends in PCB SMT Loader Maintenance

As technology continues to advance, the field of PCB SMT loader maintenance is likely to see several emerging trends:

1. Predictive Maintenance: Utilizing data analytics and machine learning to predict maintenance needs before issues occur.

2. IoT Integration: Connecting loaders to the Internet of Things (IoT) for real-time monitoring and remote diagnostics.

3. Augmented Reality (AR) Assisted Maintenance: Using AR technology to guide technicians through complex maintenance procedures.

4. Automated Self-Diagnostics: Incorporating advanced self-diagnostic capabilities into loaders to identify and potentially self-correct issues.

5. Eco-Friendly Maintenance Practices: Developing more sustainable maintenance methods and materials to reduce environmental impact.

Conclusion

Proper maintenance of PCB SMT loaders is crucial for ensuring efficient, accurate, and reliable operation in electronics manufacturing. By implementing a comprehensive maintenance program that includes regular cleaning, lubrication, calibration, software updates, and preventive maintenance, manufacturers can significantly extend the lifespan of their equipment, improve production quality, and reduce overall operational costs.

While challenges exist in maintaining these complex machines, the benefits far outweigh the investment required. As technology continues to evolve, maintenance practices will need to adapt, embracing new tools and techniques to keep pace with advancements in PCB SMT loader design and functionality.

Ultimately, a well-maintained PCB SMT loader is a cornerstone of efficient and high-quality electronics production. By prioritizing maintenance and fostering a culture of proactive care, manufacturers can ensure that their PCB SMT loaders continue to perform at their best, contributing to the overall success of their production processes.

FAQ

1. How often should I perform maintenance on my PCB SMT loader?

The frequency of maintenance depends on several factors, including usage, environment, and manufacturer recommendations. Generally, daily cleaning and inspection are essential, with more comprehensive maintenance tasks performed weekly, monthly, or quarterly. Always refer to your loader's manual for specific maintenance schedules.

2. What are the signs that my PCB SMT loader needs immediate maintenance?

Signs that your loader may need immediate attention include unusual noises or vibrations, decreased accuracy in PCB positioning, slower cycle times, frequent error messages, or visible wear on components. Any sudden change in performance should be investigated promptly.

3. Can I perform all maintenance tasks in-house, or should I rely on professional services?

While many routine maintenance tasks can be performed in-house by trained staff, some more complex procedures may require professional service. It's important to assess your team's capabilities and the complexity of the maintenance task. When in doubt, consult with the loader manufacturer or a certified service provider.

4. How do environmental factors affect the maintenance needs of PCB SMT loaders?

Environmental factors such as temperature, humidity, and dust levels can significantly impact a loader's performance and maintenance requirements. High humidity can lead to corrosion, while excessive dust can interfere with moving parts and sensors. Maintaining a controlled environment can reduce the frequency and intensity of required maintenance.

5. What are the most common maintenance mistakes to avoid with PCB SMT loaders?

Common maintenance mistakes include neglecting regular cleaning, over-lubricating components, ignoring minor issues until they become major problems, using incorrect replacement parts, and failing to keep accurate maintenance records. Avoiding these mistakes can significantly improve the effectiveness of your maintenance program and the longevity of your loader.

Citations:

[1] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=59416&news_id=27399

[2] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[3] https://www.aimsolder.com/wp-content/uploads/legacy-files/smt_ts.pdf

[4] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[5] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[6] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html

[7] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[8] https://smtnet.com/library/files/upload/SMT-troubleshooting-guide.pdf

[9] https://www.protoexpress.com/blog/how-to-troubleshoot-and-repair-your-pcb/

[10] https://www.seamarkzm.com/maintenance-and-calibration-of-smt-inspection-machines.html

[11] https://www.zjyingxing.com/info/common-problems-and-causes-of-smt-77363808.html

[12] https://www.neodensmt.com/news/use-and-maintenance-of-smt-loader-machine-40601157.html