Content Menu

● Introduction to Inline SMT Pick and Place Machines

>> Key Components of Inline SMT Machines

● Essential Maintenance Practices

>> Daily Maintenance

>> Weekly Maintenance

>> Monthly Maintenance

>> Annual Maintenance

● Benefits of Regular Maintenance

● Types of Inline SMT Pick and Place Machines

● Troubleshooting Common Issues

● Advanced Features and Technologies

● Integration with Other Manufacturing Systems

● Training and Support

● Conclusion

● FAQs

>> 1. What are the key components of an inline SMT pick and place machine?

>> 2. How often should I clean the nozzles of an inline SMT machine?

>> 3. What are the benefits of regular maintenance for inline SMT machines?

>> 4. How do I troubleshoot component misalignment issues in an inline SMT machine?

>> 5. What types of inline SMT pick and place machines are available?

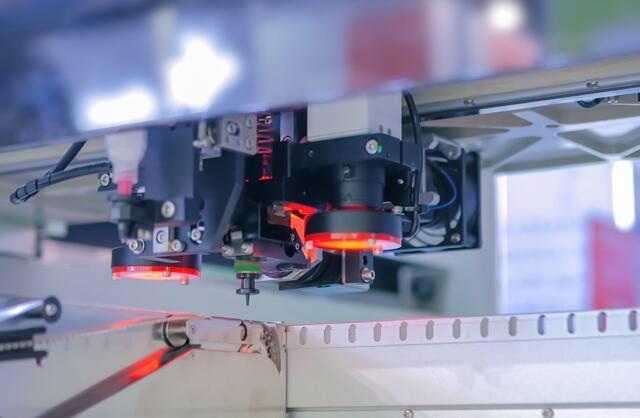

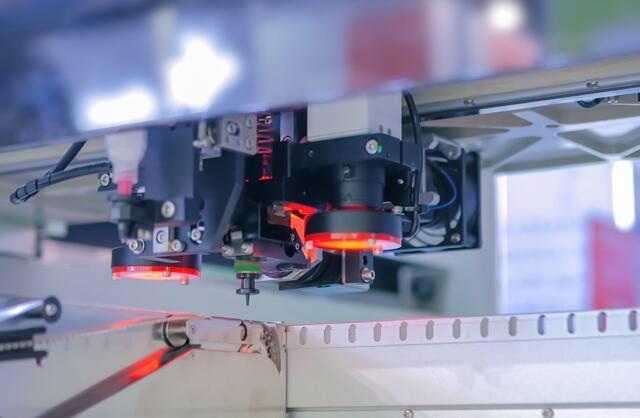

Inline SMT (Surface Mount Technology) pick and place machines are crucial components in modern electronics manufacturing, particularly for high-volume production. These machines automate the process of placing electronic components onto printed circuit boards (PCBs) with precision and speed, making them indispensable in assembly lines. To ensure optimal performance and longevity, regular maintenance is essential. In this article, we will explore the key maintenance practices for inline SMT pick and place machines.

Introduction to Inline SMT Pick and Place Machines

Inline SMT pick and place machines are designed to integrate seamlessly into automated assembly lines, allowing for continuous production without manual intervention. They are ideal for high-volume manufacturing due to their efficiency and ability to minimize downtime. These machines typically include features such as conveyor systems, multiple nozzles for component placement, and advanced vision systems for precision alignment.

Key Components of Inline SMT Machines

1. Conveyor System: This allows PCBs to move continuously through the assembly process, integrating with other machines like stencil printers and reflow ovens.

2. Multiple Nozzles: These are used for picking and placing components, with different sizes available to handle various component types.

3. Vision Systems: These ensure accurate component alignment and placement using cameras and software algorithms.

4. Feeders: These supply components to the machine, which can be organized to optimize production efficiency.

Essential Maintenance Practices

Daily Maintenance

Daily maintenance is crucial to prevent issues that could lead to downtime. Key tasks include:

- Cleaning: Regularly clean the machine's surface, nozzles, and vision systems to remove dust and debris. Use a soft cloth or compressed air for delicate components.

- Warm-Up: Ensure the machine is warmed up for at least 20 minutes before production to stabilize its systems.

- Check Connections: Verify that all moving parts are securely connected and that screws are not loose.

Weekly Maintenance

Weekly checks help maintain the machine's performance and prevent wear:

- Lubrication: Apply lubricating oil to moving parts to reduce friction and prevent premature wear.

- Nozzle Inspection: Check suction nozzles for blockages and clean them as necessary.

- Feeder Maintenance: Ensure feeders are clean and functioning correctly to prevent component jams.

Monthly Maintenance

More in-depth maintenance is required monthly:

- Deep Cleaning: Perform thorough cleaning of feeders, nozzles, and vision systems.

- Performance Tests: Conduct tests to evaluate machine accuracy and identify potential issues.

- Lubricant Replacement: Replace lubricants on movable shafts and axes to maintain smooth operation.

Annual Maintenance

Annual checks are vital for ensuring long-term reliability:

- Power Connection Check: Verify that power connections are secure and functioning properly.

- Component Inspection: Inspect for wear on critical components and replace them if necessary.

Benefits of Regular Maintenance

Regular maintenance offers several benefits:

- Optimized Performance: Ensures the machine operates at peak levels, maintaining quality and productivity.

- Preventive Measures: Prevents unexpected breakdowns and costly downtime.

- Extended Lifespan: Extends the machine's lifespan, maximizing return on investment.

Types of Inline SMT Pick and Place Machines

Inline SMT machines vary in configuration and features, including:

- High-Speed Models: Machines like the Charmhigh CHM-861 offer high-speed placement with multiple heads and feeders.

- Modular Designs: Allow for flexibility and scalability in production setups.

Troubleshooting Common Issues

Common issues with inline SMT machines include:

- Component Misalignment: Check vision system calibration and nozzle condition.

- Feeder Jams: Regularly clean and maintain feeders to prevent component misfeeds.

- Nozzle Blockages: Use compressed air to clear blockages and ensure smooth component pickup.

Advanced Features and Technologies

Modern inline SMT machines often incorporate advanced technologies to enhance efficiency and accuracy:

- AI and Machine Learning: Some machines use AI to optimize production processes and predict maintenance needs.

- Real-Time Monitoring: Allows operators to monitor machine performance in real-time, enabling quick response to issues.

- Automated Calibration: Simplifies the calibration process, reducing downtime and improving accuracy.

Integration with Other Manufacturing Systems

Inline SMT machines are often integrated with other systems in the assembly line, such as:

- Stencil Printers: Apply solder paste to PCBs before component placement.

- Reflow Ovens: Solder components onto the PCB after placement.

- Inspection Systems: Verify the quality of PCBs post-assembly.

Training and Support

Proper training for operators is crucial to ensure they understand the machine's capabilities and maintenance requirements. Manufacturers often provide comprehensive training programs and technical support to help users optimize machine performance.

Conclusion

Inline SMT pick and place machines are critical for efficient electronics manufacturing. Regular maintenance is essential to ensure these machines operate at optimal levels, providing high-quality component placement and minimizing downtime. By implementing a structured maintenance schedule, manufacturers can enhance productivity, reduce costs, and extend the lifespan of their equipment.

FAQs

1. What are the key components of an inline SMT pick and place machine?

Inline SMT pick and place machines include a conveyor system, multiple nozzles, advanced vision systems, and feeders. These components work together to automate the process of placing electronic components onto PCBs efficiently.

2. How often should I clean the nozzles of an inline SMT machine?

Nozzles should be cleaned regularly, ideally as part of daily maintenance, to prevent blockages and ensure smooth component pickup. Use a lint-free cloth or compressed air for cleaning.

3. What are the benefits of regular maintenance for inline SMT machines?

Regular maintenance optimizes machine performance, prevents unexpected breakdowns, and extends the machine's lifespan. It also enhances product quality by ensuring consistent component placement.

4. How do I troubleshoot component misalignment issues in an inline SMT machine?

To troubleshoot misalignment, check the calibration of the vision system and inspect nozzles for wear or damage. Ensure that the machine is properly calibrated and that nozzles are clean and functioning correctly.

5. What types of inline SMT pick and place machines are available?

Inline SMT machines come in various configurations, including high-speed models with multiple heads and feeders, and modular designs that offer flexibility in production setups.