Content Menu

● Understanding SMD Pick and Place Machines

>> Key Components of SMD Pick and Place Machines

● Speed of SMD Pick and Place Machines

>> Factors Affecting Speed

>> Speed Categories

● Accuracy of SMD Pick and Place Machines

>> Measuring Accuracy

>> Factors Influencing Accuracy

>> Typical Accuracy Ranges

● Balancing Speed and Accuracy

>> Considerations for Balancing Speed and Accuracy

● Advanced Features Enhancing Speed and Accuracy

● Impact of Speed and Accuracy on Production

● Choosing the Right SMD Pick and Place Machine

● Recent Advancements in SMD Pick and Place Technology

● Conclusion

● FAQ

>> 1. What is the typical placement speed of an SMD pick and place machine?

>> 2. How accurate are modern SMD pick and place machines?

>> 3. What factors affect the speed and accuracy of an SMD pick and place machine?

>> 4. How do manufacturers balance speed and accuracy in SMD pick and place machines?

>> 5. What recent advancements have been made in SMD pick and place technology?

● Citations:

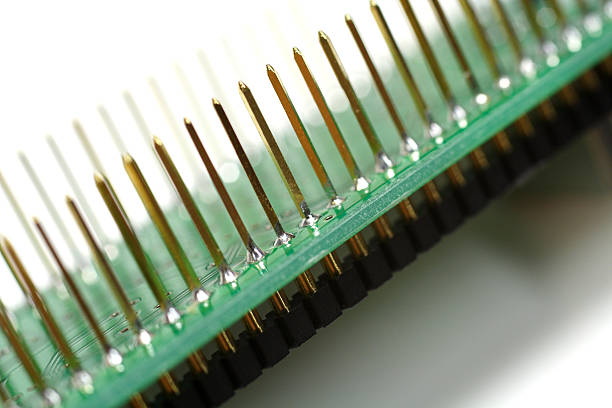

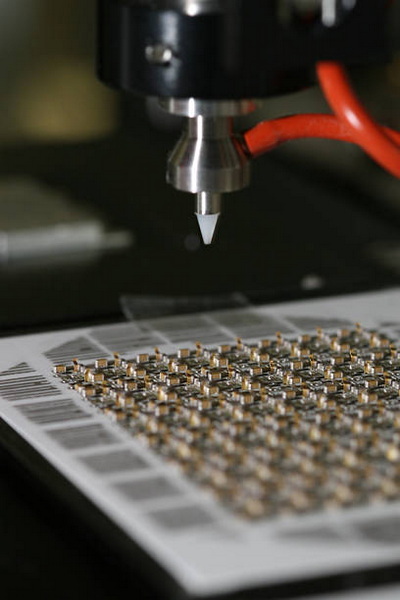

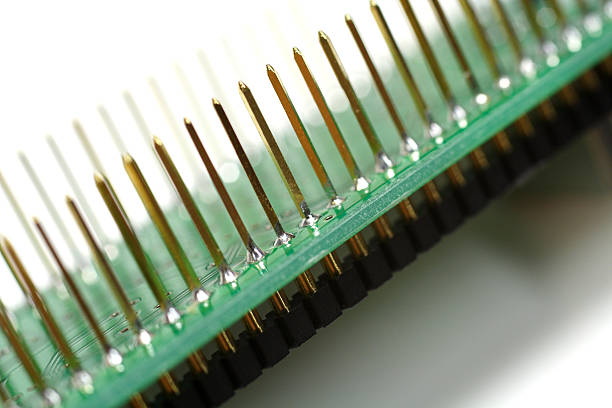

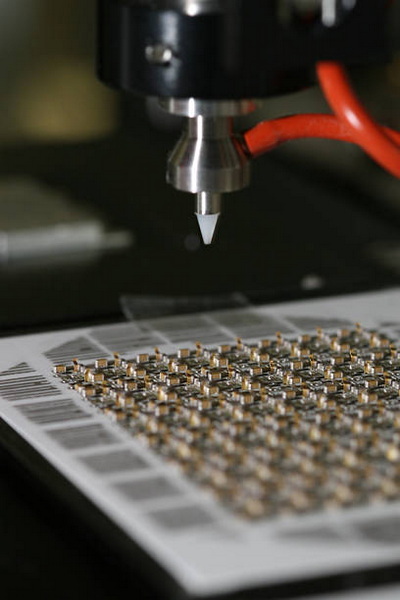

Surface Mount Device (SMD) pick and place machines are crucial components in modern electronics manufacturing. These machines are responsible for accurately placing electronic components onto printed circuit boards (PCBs) at high speeds. The speed and accuracy of these machines are critical factors that determine the efficiency and quality of the production process.

Understanding SMD Pick and Place Machines

SMD pick and place machines are automated systems designed to handle the placement of surface mount components onto PCBs. These machines use advanced vision systems, precise mechanical components, and sophisticated software to ensure accurate and rapid placement of components[1].

Key Components of SMD Pick and Place Machines

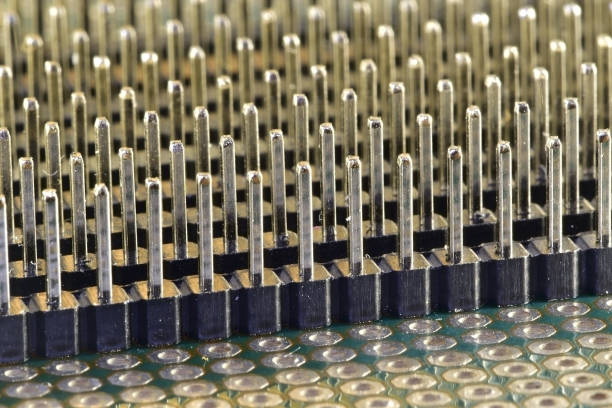

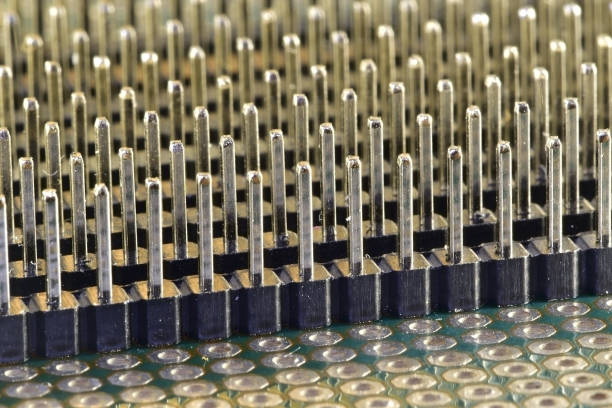

1. Placement Head: This is the core component responsible for picking up and placing components. It typically features multiple nozzles for handling different component sizes.

2. Vision System: High-resolution cameras and image processing software enable the machine to accurately identify and position components.

3. Feeders: These supply components to the machine, often in the form of reels or trays.

4. X-Y-Z Positioning System: This system allows the placement head to move precisely in three dimensions.

5. Control Software: Advanced software coordinates all machine functions and optimizes placement sequences.

Speed of SMD Pick and Place Machines

The speed of SMD pick and place machines is typically measured in components per hour (CPH). This metric indicates how many components the machine can place in a given time frame.

Factors Affecting Speed

1. Machine Type: High-speed machines can place over 30,000 CPH, while medium and low-speed machines operate at lower rates[9].

2. Component Type: Smaller, simpler components can be placed faster than larger or more complex ones.

3. Board Complexity: PCBs with more components or complex layouts may require slower placement speeds for accuracy.

4. Feeder Configuration: Efficient feeder setup can significantly impact overall placement speed.

Speed Categories

1. High-Speed Machines: These typically operate at speeds greater than 30,000 CPH and are often used for placing LED components where extreme precision is less critical[9].

2. Medium-Speed Machines: Operating in the range of 15,000 to 30,000 CPH, these machines offer a balance between speed and precision.

3. Low-Speed Machines: These machines operate below 15,000 CPH but often offer greater flexibility in component types and sizes.

Accuracy of SMD Pick and Place Machines

Accuracy is a critical factor in SMD pick and place machines, as it directly impacts the quality and reliability of the final product.

Measuring Accuracy

Accuracy is typically measured in micrometers (μm) or thousandths of an inch (mil). It refers to how close the machine can place a component to its intended position on the PCB.

Factors Influencing Accuracy

1. Mechanical Precision: The quality of the machine's mechanical components, including guide rails and screw rods, significantly affects accuracy[9].

2. Vision System Resolution: Higher resolution cameras and more sophisticated image processing algorithms improve placement accuracy.

3. Component Size: Smaller components generally require higher placement accuracy.

4. Environmental Factors: Temperature, humidity, and vibration can all impact machine accuracy.

Typical Accuracy Ranges

1. Standard Accuracy: Most pick and place machines offer accuracy in the range of ±0.001 inches (25.4 μm)[7].

2. High Precision: For applications requiring extreme precision, such as semiconductor and die placement, accuracies of 10-15 microns may be necessary[7].

3. Ultra-High Precision: Some specialized machines can achieve accuracies as high as ±0.0001 inches (2.54 μm)[3].

Balancing Speed and Accuracy

While both speed and accuracy are crucial, manufacturers often need to find the right balance between these two factors based on their specific production requirements.

Considerations for Balancing Speed and Accuracy

1. Production Volume: High-volume production may prioritize speed, while lower-volume, high-precision products may focus more on accuracy.

2. Component Mix: A diverse range of component types and sizes may require a machine that offers flexibility over raw speed.

3. Quality Requirements: Industries with stringent quality standards, such as aerospace or medical devices, may prioritize accuracy over speed.

4. Cost Considerations: Higher-speed and higher-accuracy machines generally come at a premium price point.

Advanced Features Enhancing Speed and Accuracy

Modern SMD pick and place machines incorporate various advanced features to improve both speed and accuracy:

1. Multi-Head Systems: Machines with multiple placement heads can significantly increase throughput.

2. On-the-Fly Component Recognition: Advanced vision systems can inspect and orient components during the placement process, reducing cycle times.

3. Automatic Nozzle Changes: This feature allows the machine to quickly switch between different nozzle types for various component sizes.

4. Closed-Loop Servo Control: This system provides real-time feedback for more precise component placement[6].

5. Automatic Feeder Calibration: Some machines can automatically calibrate feeder positions, ensuring consistent pick-up locations[6].

Impact of Speed and Accuracy on Production

The speed and accuracy of SMD pick and place machines have a significant impact on overall production efficiency and quality:

1. Throughput: Faster machines can produce more PCBs in less time, increasing overall production capacity.

2. Defect Rates: Higher accuracy reduces the likelihood of misplaced components, leading to fewer defects and rework.

3. Component Compatibility: More accurate machines can handle a wider range of component sizes, including ultra-small components like 01005 packages[3].

4. Production Flexibility: Machines that offer a good balance of speed and accuracy can handle a variety of product types, from high-volume simple boards to complex, low-volume designs.

Choosing the Right SMD Pick and Place Machine

Selecting the appropriate SMD pick and place machine requires careful consideration of several factors:

1. Production Requirements: Assess your typical production volumes and the complexity of your PCB designs.

2. Component Types: Consider the range of component sizes and types you regularly use.

3. Accuracy Needs: Determine the level of placement accuracy required for your products.

4. Budget Constraints: Balance the machine's capabilities with your budget, considering long-term ROI.

5. Future Scalability: Choose a machine that can accommodate potential future production increases or changes in product mix.

Recent Advancements in SMD Pick and Place Technology

The field of SMD pick and place technology is continually evolving, with recent advancements focusing on:

1. Artificial Intelligence: AI-driven systems are being developed to optimize placement sequences and predict maintenance needs.

2. Industry 4.0 Integration: Modern machines are increasingly capable of integrating with broader smart factory systems for improved data collection and process optimization.

3. Improved User Interfaces: More intuitive software interfaces are making machine programming and operation easier for operators.

4. Enhanced Flexibility: New machines are being designed to handle an even wider range of component types and sizes, including odd-shaped components.

Conclusion

The speed and accuracy of SMD pick and place machines are crucial factors in modern electronics manufacturing. While high-speed machines can place over 30,000 components per hour, accuracy levels can reach as high as ±0.0001 inches for specialized applications. The choice between speed and accuracy often depends on specific production requirements, component types, and quality standards.

As technology continues to advance, SMD pick and place machines are becoming increasingly sophisticated, offering improved performance, flexibility, and integration capabilities. Manufacturers must carefully consider their specific needs when selecting a machine, balancing factors such as production volume, component mix, accuracy requirements, and budget constraints.

The ongoing development of SMD pick and place technology promises to further enhance both speed and accuracy, potentially revolutionizing electronics manufacturing processes. As these machines continue to evolve, they will play an even more critical role in enabling the production of increasingly complex and miniaturized electronic devices.

FAQ

1. What is the typical placement speed of an SMD pick and place machine?

The placement speed of SMD pick and place machines varies widely depending on the machine type and application. High-speed machines can place over 30,000 components per hour (CPH), while medium-speed machines typically operate in the range of 15,000 to 30,000 CPH. Low-speed machines, which often offer greater flexibility, usually operate below 15,000 CPH[9].

2. How accurate are modern SMD pick and place machines?

Modern SMD pick and place machines offer a range of accuracy levels. Most standard machines provide accuracy in the range of ±0.001 inches (25.4 μm). High-precision machines, often used for semiconductor and die placement, can achieve accuracies of 10-15 microns. Some specialized machines can even reach accuracies as high as ±0.0001 inches (2.54 μm)[3][7].

3. What factors affect the speed and accuracy of an SMD pick and place machine?

Several factors influence the speed and accuracy of SMD pick and place machines:

- Component size and type

- PCB complexity

- Machine mechanical precision

- Vision system quality

- Environmental factors (temperature, humidity, vibration)

- Feeder configuration

- Software optimization[1][9]

4. How do manufacturers balance speed and accuracy in SMD pick and place machines?

Manufacturers balance speed and accuracy by considering factors such as:

- Production volume requirements

- Component mix and sizes

- Quality standards for the final product

- Budget constraints

- Long-term scalability needs

They may choose machines that offer the best compromise between speed and accuracy for their specific applications, or use multiple machines optimized for different tasks in their production line[1][7].

5. What recent advancements have been made in SMD pick and place technology?

Recent advancements in SMD pick and place technology include:

- Integration of artificial intelligence for optimized placement and predictive maintenance

- Industry 4.0 compatibility for improved data collection and process integration

- More intuitive user interfaces for easier programming and operation

- Enhanced flexibility to handle a wider range of component types and sizes

- Improved vision systems for more accurate component recognition and placement

- Multi-head systems for increased throughput[6][9]

Citations:

[1] https://www.zjyingxing.com/info/what-are-the-determining-factors-of-smt-pick-a-87768689.html

[2] https://liteplacer.com/introduction-f-a-q/

[3] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

[4] https://www.tronstol.com/the-knowledge-and-steps-you-need-to-know-about-smt-pick-and-place-machine-programs.html

[5] https://electronics.stackexchange.com/questions/529958/are-pick-place-machines-allergic-to-bags-of-parts

[6] https://www.neodensmt.com/pick-and-place-machine/automatic-smd-pick-and-place-machine.html

[7] https://www.restronicsmetro.com/blog/everything-you-need-to-know-about-smt-pick-and-place-machines

[8] https://www.qhsmt.com/2023/11/29/smt-pick-and-place-most-asked-power-electronics-supply-questions-and-answers/

[9] https://www.tronstol.com/common-types-and-positioning-accuracy-of-smt-pick-and-place-machine.html

[10] https://www.ddmnovastar.com/smt-quick-tips-selecting-a-pick-and-place-machine