Content Menu

>> Understanding SMT and Squeegees

>>> The SMT Process

>> The Importance of Quality Squeegees

>>> Key Features to Consider:

>> Leading Squeegee SMT Suppliers

>> How to Choose the Right Squeegee

>> The Impact of Squeegee Quality on Production

>>> 1. Consistency in Paste Application

>>> 2. Reduced Downtime

>>> 3. Enhanced Print Speed

>> Innovations in Squeegee Technology

>> Case Studies: Successful Implementations

>>> Case Study 1: Electronics Manufacturer A

>>> Case Study 2: Automotive Component Supplier B

>> Conclusion

>> Frequently Asked Questions

Understanding SMT and Squeegees

SMT is a method used to produce electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). The process involves several steps, including solder paste printing, component placement, and soldering. Squeegees play a critical role in the solder paste printing phase.

The SMT Process

1. Solder Paste Printing: This is the first step in PCB assembly where solder paste is applied to the board. A stencil is used to control where the paste is deposited.

2. Component Placement: After printing, components are placed onto the PCB using pick-and-place machines.

3. Reflow Soldering: The assembly is then heated in a reflow oven, melting the solder paste to create electrical connections.

Squeegee Types:

- Metal Squeegees: Known for durability and precision, metal squeegees provide excellent control over paste deposition. They are typically made from stainless steel or other alloys that resist wear.

- Rubber Squeegees: Typically used for softer applications, rubber squeegees may not offer the same level of precision as metal ones but can be beneficial for certain types of paste or when working with delicate substrates.

The Importance of Quality Squeegees

The quality of the squeegee directly affects the solder paste application. Poor quality squeegees can lead to inconsistent paste deposits, which can cause defects in the final product. Therefore, selecting a reliable squeegee SMT supplier is crucial for manufacturers.

Key Features to Consider:

- Material: Choose between metal and rubber based on application needs.

- Durability: High-quality materials ensure longevity and reduce replacement costs.

- Compatibility: Ensure that the squeegee fits the specific printer model being used.

- Profile Design: The design of the squeegee blade can influence how effectively it spreads solder paste across different pad sizes and shapes.

Leading Squeegee SMT Suppliers

Several suppliers stand out in the market for their quality products and services. Here are some notable ones:

1. CNSMT

- Offers a wide range of squeegees from 200mm to 600mm.

- Provides customization options for various printer models.

- Known for competitive pricing and high-quality materials.

2. SMT Industrial

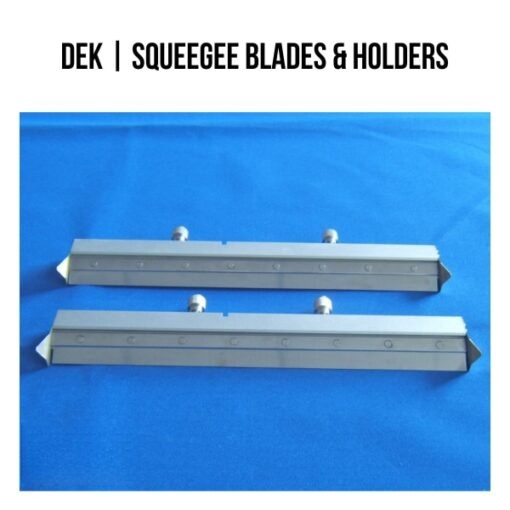

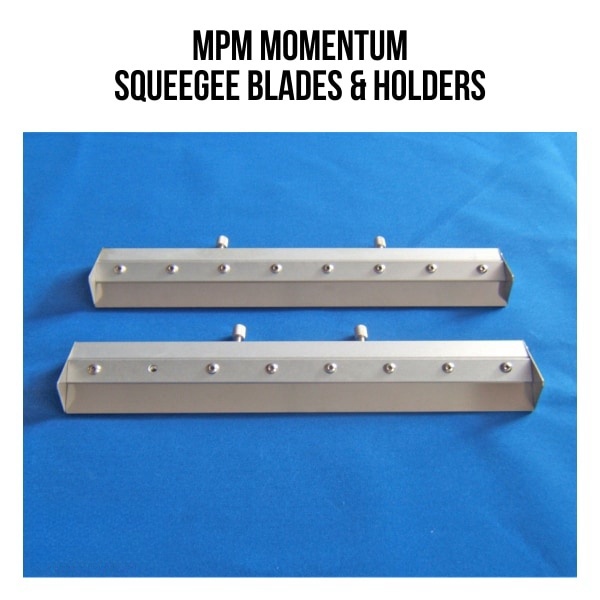

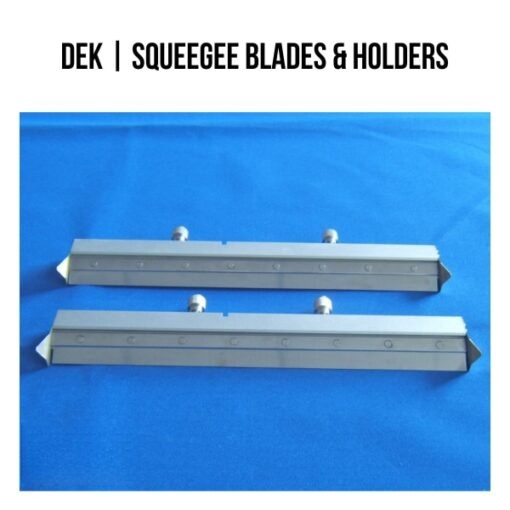

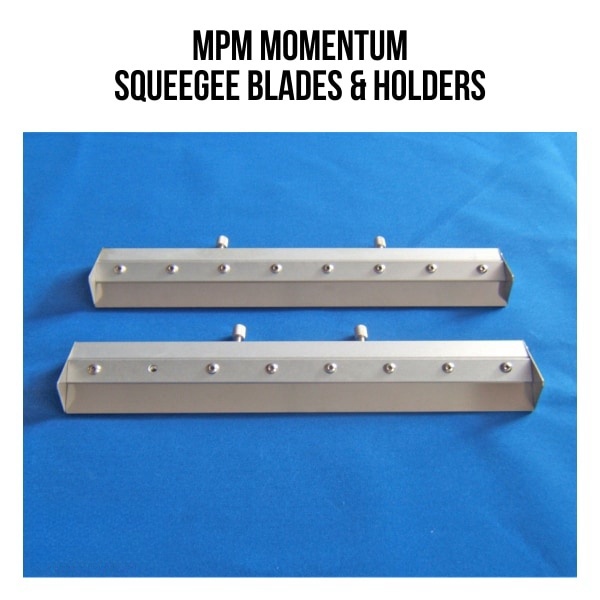

- Specializes in replacement squeegee blades for various printer brands.

- Stocks all sizes of blades compatible with DEK, EKRA, Juki, and more.

3. High-Tech Conversions

- Provides OEM compatible holders and blades developed through extensive research.

- Focuses on maximizing printing process efficiency.

4. PCB Assembly Supplies

- Offers a comprehensive line of cutting-edge squeegee blades and holders tailored for PCB assembly.

How to Choose the Right Squeegee

When selecting a squeegee from an SMT supplier, consider the following factors:

- Application Requirements: Identify whether you need a metal or rubber squeegee based on your specific printing needs.

- Supplier Reputation: Research suppliers' reviews and testimonials to gauge reliability.

- Cost vs. Quality: While it might be tempting to choose cheaper options, investing in high-quality squeegees can save costs in the long run due to reduced defects and downtime.

- Maintenance Needs: Consider how easy it is to clean and maintain the squeegee, as this can affect its lifespan and performance.

The Impact of Squeegee Quality on Production

The quality of squeegees has a direct correlation with production efficiency and product reliability. Here's how:

1. Consistency in Paste Application

High-quality squeegees ensure uniform application of solder paste across all pads on a PCB. This consistency reduces defects such as insufficient solder or bridging between pads, which can lead to failures in electronic devices.

2. Reduced Downtime

Using durable materials means fewer replacements are needed over time. This reduces downtime during production as operators do not have to frequently stop to change out worn-out tools.

3. Enhanced Print Speed

Quality squeegees allow for faster printing speeds without compromising on accuracy. This is particularly important in high-volume manufacturing environments where time efficiency directly impacts profitability.

Innovations in Squeegee Technology

The industry is witnessing innovations aimed at improving squeegee performance:

- Coated Squeegees: Some manufacturers are developing coated blades that reduce friction and improve paste transfer efficiency.

- Ergonomic Designs: New designs focus on operator comfort during long production runs, reducing fatigue and improving handling.

- Smart Technology Integration: Some advanced systems now integrate sensors that monitor paste thickness during application, allowing real-time adjustments to ensure optimal results.

Case Studies: Successful Implementations

To illustrate the importance of selecting quality squeegees from reputable suppliers, consider these case studies:

Case Study 1: Electronics Manufacturer A

An electronics manufacturer faced issues with inconsistent solder paste deposits leading to increased defect rates. After switching to high-quality metal squeegees from CNSMT, they reported a 30% reduction in defects within three months due to improved paste application consistency.

Case Study 2: Automotive Component Supplier B

A supplier specializing in automotive components required precise soldering due to strict industry standards. By partnering with Permalex for their specialized squeegee blades, they enhanced their production yield by 25%, meeting rigorous quality benchmarks without increasing costs.

Conclusion

Squeegees are vital components in SMT processes, significantly influencing solder paste application quality. Partnering with reputable squeegee SMT suppliers ensures access to high-quality tools essential for efficient PCB assembly. As technology advances and manufacturing demands increase, understanding how to select and utilize these tools effectively will remain crucial for success in electronics manufacturing.

Frequently Asked Questions

1. What is the main function of a squeegee in SMT?

- The primary function is to apply solder paste evenly onto PCBs during the printing process.

2. How do I know which type of squeegee to use?

- It depends on your specific application; metal squeegees are better for precision, while rubber ones are suitable for softer applications.

3. What should I look for in a squeegee supplier?

- Look for product variety, customization options, quality assurance, and customer support.

4. Can I use any squeegee with my printer?

- No, you must ensure compatibility between your printer model and the squeegee type you choose.

5. What are the benefits of using high-quality squeegees?

- They provide better paste deposition control, reduce defects, enhance efficiency, and lower long-term costs.