Content Menu

● Understanding SMT Assembly Lines

>> What is an SMT Assembly Line?

>> Key Components of SMT Assembly Lines

● The Role of SMT Assembly Line Equipment in Improving Production Speed

>> 1. Automation and Efficiency

>> 2. Precision and Quality Control

>> 3. Streamlined Workflow

>> 4. Flexibility and Scalability

>> 5. Advanced Technologies

>> 6. Cost Reduction

>> 7. Enhanced Collaboration and Communication

>> 8. Training and Skill Development

>> 9. Environmental Considerations

>> 10. Future Trends in SMT Technology

● The Impact of SMT Assembly Lines on Production Speed

>> Case Studies

● Conclusion

● FAQ

>> 1. What is the main advantage of using SMT assembly lines?

>> 2. How does automation in SMT lines improve efficiency?

>> 3. What types of equipment are essential in an SMT assembly line?

>> 4. How does quality control work in SMT assembly lines?

>> 5. Can SMT assembly lines be adapted for different products?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, lighter, and more reliable electronic devices. The SMT assembly line is a critical component of this technology, facilitating high-speed assembly processes that significantly enhance production speed. This article explores the various roles of SMT assembly line equipment in improving production speed, the components involved, and the overall impact on manufacturing efficiency.

Understanding SMT Assembly Lines

What is an SMT Assembly Line?

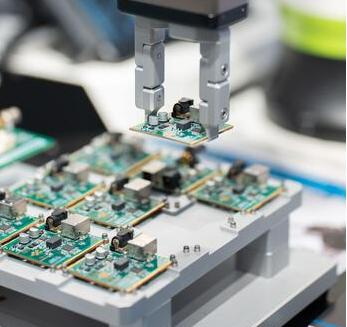

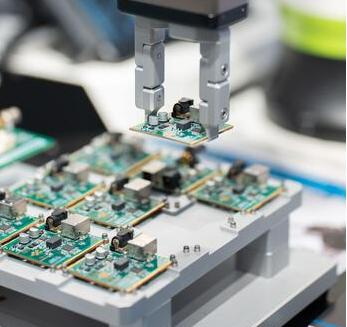

An SMT assembly line is a specialized production line designed for the automated assembly of printed circuit boards (PCBs) using surface mount technology. This process involves mounting electronic components directly onto the surface of PCBs, which allows for a more compact design and improved performance of electronic devices. The SMT assembly line typically includes several key pieces of equipment that work together to streamline the manufacturing process.

Key Components of SMT Assembly Lines

1. Solder Paste Printer: This machine applies solder paste to the PCB in precise locations where components will be placed. The accuracy of this step is crucial for ensuring reliable solder joints.

2. Pick-and-Place Machine: This equipment is responsible for placing electronic components onto the PCB. It uses advanced robotics and vision systems to ensure that components are positioned accurately and quickly.

3. Reflow Oven: After components are placed, the PCB is passed through a reflow oven, where the solder paste is melted to create permanent connections between the components and the board.

4. Inspection Systems: These systems, including Automated Optical Inspection (AOI) machines, check the quality of the assembly by identifying defects such as misaligned components or insufficient solder.

5. Conveyor Systems: These systems transport PCBs between different stages of the assembly process, ensuring a smooth and continuous workflow.

The Role of SMT Assembly Line Equipment in Improving Production Speed

1. Automation and Efficiency

One of the primary roles of SMT assembly line equipment is to automate the assembly process. Automation reduces the need for manual labor, which not only speeds up production but also minimizes human error. For instance, pick-and-place machines can place thousands of components per hour, far exceeding the capabilities of manual assembly. This high-speed operation is essential for meeting the demands of modern electronics manufacturing, where time-to-market is critical.

2. Precision and Quality Control

SMT assembly line equipment is designed for precision. The use of advanced vision systems in pick-and-place machines ensures that components are placed accurately, reducing the likelihood of defects. Additionally, inspection systems like AOI provide real-time feedback on the quality of the assembly, allowing for immediate corrections. This focus on precision not only improves production speed but also enhances the overall quality of the final product, reducing the need for rework and scrap.

3. Streamlined Workflow

The integration of various machines in an SMT assembly line creates a streamlined workflow. Each piece of equipment is designed to work in harmony with the others, minimizing downtime and bottlenecks. For example, the solder paste printer and pick-and-place machine are often linked, allowing for a continuous flow of PCBs through the assembly process. This seamless operation is crucial for maintaining high production speeds.

4. Flexibility and Scalability

Modern SMT assembly lines are highly flexible and can be easily reconfigured to accommodate different products or production volumes. This adaptability allows manufacturers to respond quickly to changing market demands without significant downtime. For instance, if a new product requires different components, the pick-and-place machine can be programmed to handle the new specifications, ensuring that production speed is maintained.

5. Advanced Technologies

The incorporation of advanced technologies, such as 3D solder paste inspection and machine learning algorithms, further enhances the capabilities of SMT assembly line equipment. These technologies allow for more accurate assessments of the assembly process and can predict potential issues before they occur. By leveraging data analytics, manufacturers can optimize their production processes, leading to faster turnaround times and improved efficiency.

6. Cost Reduction

Another significant role of SMT assembly line equipment in improving production speed is cost reduction. By increasing the speed and efficiency of the assembly process, manufacturers can produce more units in less time, which directly impacts their bottom line. Additionally, the reduction in defects and rework leads to lower material costs and waste, further enhancing profitability. The initial investment in advanced SMT equipment can be offset by the long-term savings achieved through increased production efficiency.

7. Enhanced Collaboration and Communication

Modern SMT assembly lines often incorporate Industry 4.0 principles, which emphasize connectivity and data sharing among machines and systems. This interconnectedness allows for better collaboration between different stages of the production process. For example, real-time data from inspection systems can be communicated back to the pick-and-place machines to adjust settings dynamically, ensuring optimal performance. This level of communication enhances overall production speed and efficiency.

8. Training and Skill Development

As SMT technology evolves, so does the need for skilled operators who can manage and maintain the equipment. Manufacturers are increasingly investing in training programs to ensure that their workforce is equipped with the necessary skills to operate advanced SMT assembly lines. This investment not only improves production speed but also fosters a culture of continuous improvement and innovation within the organization.

9. Environmental Considerations

In recent years, there has been a growing emphasis on sustainability in manufacturing. SMT assembly lines can contribute to environmental goals by reducing waste and energy consumption. For instance, advanced reflow ovens are designed to operate more efficiently, using less energy while maintaining optimal soldering conditions. By adopting environmentally friendly practices, manufacturers can improve their production speed while also meeting regulatory requirements and consumer expectations for sustainability.

10. Future Trends in SMT Technology

The future of SMT assembly lines is likely to be shaped by several emerging trends. One such trend is the increasing use of artificial intelligence (AI) and machine learning to enhance production processes. These technologies can analyze vast amounts of data to identify patterns and optimize operations, leading to even greater improvements in production speed. Additionally, the rise of the Internet of Things (IoT) will enable more connected and intelligent manufacturing environments, further enhancing the capabilities of SMT assembly lines.

The Impact of SMT Assembly Lines on Production Speed

The role of SMT assembly line equipment in improving production speed cannot be overstated. By automating processes, ensuring precision, and streamlining workflows, SMT lines enable manufacturers to produce high-quality electronic devices at unprecedented speeds. This efficiency not only benefits manufacturers by reducing costs and increasing output but also enhances the overall competitiveness of the electronics industry.

Case Studies

Several companies have successfully implemented SMT assembly lines to improve their production speed. For example, a leading electronics manufacturer reported a 30% increase in production speed after upgrading their SMT line with the latest pick-and-place technology and inspection systems. Similarly, another company was able to reduce their production cycle time by 40% by optimizing their workflow and integrating advanced inspection technologies.

Conclusion

In conclusion, SMT assembly line equipment plays a vital role in enhancing production speed in the electronics manufacturing industry. Through automation, precision, streamlined workflows, flexibility, and the adoption of advanced technologies, SMT lines enable manufacturers to meet the growing demands for high-quality electronic devices efficiently. As the industry continues to evolve, the importance of SMT assembly lines will only increase, making them a cornerstone of modern electronics manufacturing.

FAQ

1. What is the main advantage of using SMT assembly lines?

The main advantage of using SMT assembly lines is the significant increase in production speed due to automation and precision in the assembly process.

2. How does automation in SMT lines improve efficiency?

Automation reduces the need for manual labor, minimizes human error, and allows for high-speed operations, enabling manufacturers to produce more units in less time.

3. What types of equipment are essential in an SMT assembly line?

Essential equipment includes solder paste printers, pick-and-place machines, reflow ovens, inspection systems, and conveyor systems.

4. How does quality control work in SMT assembly lines?

Quality control is achieved through inspection systems like Automated Optical Inspection (AOI), which check for defects in real-time, ensuring high-quality assembly.

5. Can SMT assembly lines be adapted for different products?

Yes, modern SMT assembly lines are highly flexible and can be reconfigured to accommodate different products or production volumes without significant downtime.