Content Menu

● Understanding PCB SMT Stencil Frames

>> The Anatomy of a PCB SMT Stencil Frame

● The Importance of Stencil Frames in SMT Assembly

>> 1. Maintaining Stencil Tension

>> 2. Ensuring Precise Alignment

>> 3. Enhancing Printing Consistency

>> 4. Facilitating Quick Changeovers

● Types of PCB SMT Stencil Frames

>> Framed Stencils

>>> Advantages of Framed Stencils:

>>> Disadvantages of Framed Stencils:

>> Frameless Stencils

>>> Advantages of Frameless Stencils:

>>> Disadvantages of Frameless Stencils:

>> Adjustable Frames

● The Impact of Stencil Frames on SMT Assembly Quality

>> 1. Solder Paste Deposition Accuracy

>> 2. Component Placement Precision

>> 3. Reduced Defect Rates

>> 4. Improved Production Efficiency

● Selecting the Right PCB SMT Stencil Frame

>> 1. Production Volume

>> 2. PCB Complexity

>> 3. Manufacturing Environment

>> 4. Material Compatibility

● Best Practices for Using PCB SMT Stencil Frames

>> 1. Regular Maintenance

>> 2. Proper Storage

>> 3. Careful Handling

>> 4. Tension Verification

>> 5. Alignment Checks

● Future Trends in PCB SMT Stencil Frame Technology

>> 1. Advanced Materials

>> 2. Smart Frames

>> 3. Automated Adjustment Systems

>> 4. Eco-Friendly Solutions

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the primary purpose of a PCB SMT stencil frame?

>> 2. How does a PCB SMT stencil frame improve assembly quality?

>> 3. What are the differences between framed and frameless stencils?

>> 4. How often should PCB SMT stencil frames be maintained?

>> 5. Can PCB SMT stencil frames be used for different PCB designs?

● Citations:

In the world of electronics manufacturing, precision and efficiency are paramount. One crucial component that plays a significant role in achieving these goals is the PCB SMT stencil frame. This article will delve into the importance of stencil frames in the Surface Mount Technology (SMT) assembly process, exploring their functions, types, and impact on the overall quality of printed circuit board (PCB) production.

Understanding PCB SMT Stencil Frames

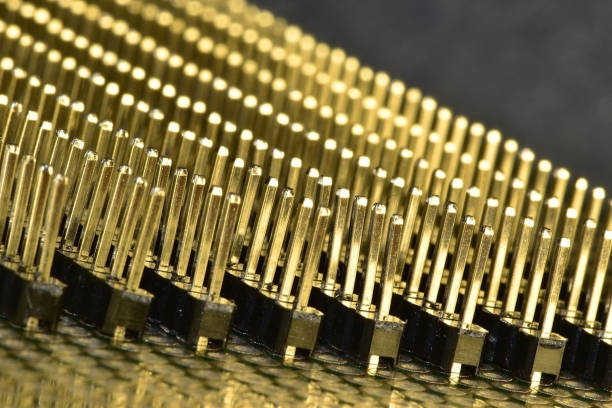

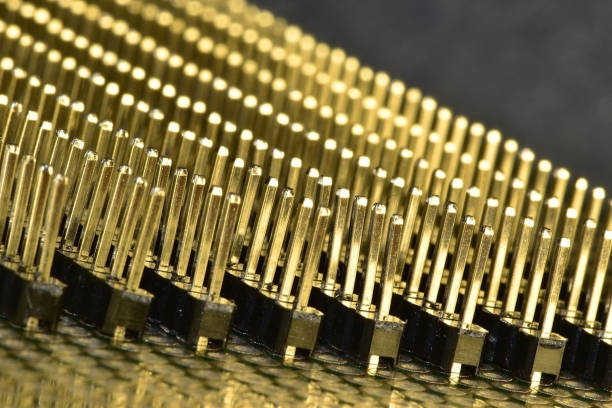

PCB SMT stencil frames are essential tools in the electronics manufacturing industry, particularly in the assembly of surface mount components. These frames serve as a support structure for the thin metal stencils used to apply solder paste to PCBs accurately. The frame's primary purpose is to maintain the stencil's tension and flatness, ensuring precise alignment with the PCB during the printing process[1].

The Anatomy of a PCB SMT Stencil Frame

A typical PCB SMT stencil frame consists of several key components:

1. Frame body: Usually made of aluminum or stainless steel, providing rigidity and stability.

2. Tensioning mechanism: Allows for adjusting the stencil's tension to maintain flatness.

3. Mounting points: Used to secure the frame to the stencil printer.

4. Alignment features: Ensure proper positioning of the stencil relative to the PCB.

The Importance of Stencil Frames in SMT Assembly

Stencil frames play a crucial role in the SMT assembly process, contributing significantly to the quality and efficiency of PCB production. Here are some key reasons why stencil frames are essential:

1. Maintaining Stencil Tension

One of the primary functions of a PCB SMT stencil frame is to maintain proper tension in the stencil foil. Consistent tension across the entire stencil surface is critical for achieving accurate solder paste deposition. The frame ensures that the stencil remains taut and flat, preventing any sagging or warping that could lead to inconsistent paste application[1].

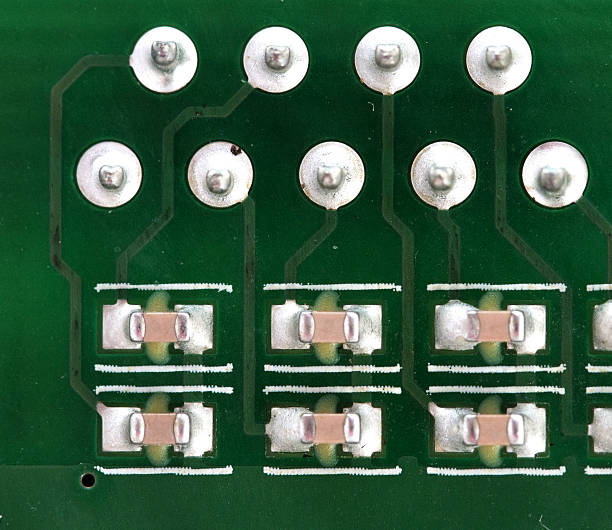

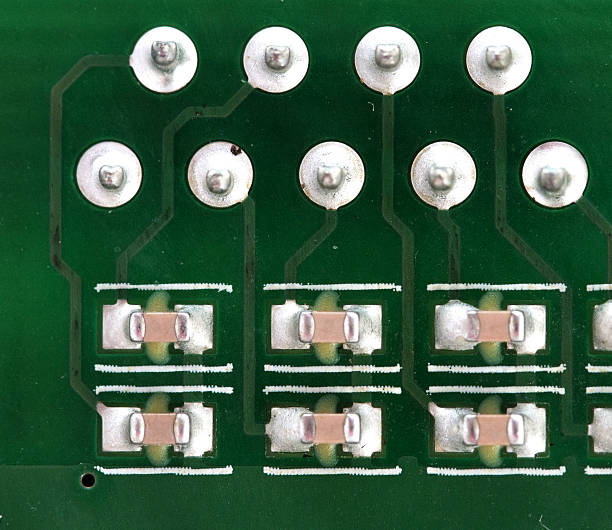

2. Ensuring Precise Alignment

Stencil frames are designed with alignment features that help position the stencil accurately over the PCB. This precise alignment is crucial for ensuring that solder paste is deposited only on the intended areas of the board. Misalignment can lead to solder bridging, insufficient solder, or other defects that compromise the quality of the final product[3].

3. Enhancing Printing Consistency

By providing a stable platform for the stencil, frames contribute to consistent printing results across multiple boards. This consistency is especially important in high-volume production environments where repeatability is key to maintaining quality standards[5].

4. Facilitating Quick Changeovers

In production environments where multiple PCB designs are manufactured, stencil frames enable quick and easy changeovers between different stencils. This flexibility helps reduce downtime and increase overall production efficiency[7].

Types of PCB SMT Stencil Frames

There are several types of stencil frames used in SMT assembly, each with its own advantages and applications:

Framed Stencils

Framed stencils are permanently attached to a rigid frame, typically made of aluminum. These stencils offer excellent stability and are ideal for high-volume production runs[1].

Advantages of Framed Stencils:

- Enhanced accuracy and consistency in solder paste application

- Increased durability and lifespan

- Suitable for use with automated pick-and-place machines

Disadvantages of Framed Stencils:

- Higher cost due to the additional materials and labor required

- Limited flexibility for adjustments during assembly

- Larger storage and transportation requirements

Frameless Stencils

Also known as foils, frameless stencils are not permanently attached to a frame. They are more flexible and cost-effective, making them suitable for low-volume production or prototyping[3].

Advantages of Frameless Stencils:

- Lower cost compared to framed stencils

- Space-saving storage

- Easier to transport

Disadvantages of Frameless Stencils:

- May require additional equipment for tensioning

- Potentially less stable than framed stencils

- Not ideal for high-volume production

Adjustable Frames

These frames allow for the use of different stencil sizes within the same frame. They offer flexibility in production while maintaining the benefits of a framed stencil[5].

The Impact of Stencil Frames on SMT Assembly Quality

The quality of the PCB SMT stencil frame directly influences the outcome of the assembly process. Here are some ways in which stencil frames contribute to overall quality:

1. Solder Paste Deposition Accuracy

A well-designed stencil frame ensures that the stencil remains flat and properly tensioned during the printing process. This results in more accurate solder paste deposition, reducing the likelihood of defects such as insufficient solder or solder bridging[1].

2. Component Placement Precision

Accurate solder paste deposition facilitated by a quality stencil frame leads to more precise component placement. When components are placed on well-defined solder paste deposits, they are less likely to shift during the reflow process, resulting in better electrical connections and overall reliability[3].

3. Reduced Defect Rates

By maintaining consistent stencil tension and alignment, PCB SMT stencil frames help reduce defect rates in the assembly process. This leads to fewer reworks, lower production costs, and higher overall product quality[5].

4. Improved Production Efficiency

Stencil frames that allow for quick changeovers and maintain consistent performance contribute to improved production efficiency. This is particularly important in high-mix, low-volume production environments where flexibility is key[7].

Selecting the Right PCB SMT Stencil Frame

Choosing the appropriate stencil frame for your SMT assembly process is crucial for achieving optimal results. Consider the following factors when selecting a stencil frame:

1. Production Volume

For high-volume production, framed stencils are generally preferred due to their stability and consistency. For lower volumes or prototyping, frameless stencils may be more cost-effective[1].

2. PCB Complexity

More complex PCB designs with fine-pitch components may require stencil frames that offer higher tension and better alignment capabilities to ensure accurate paste deposition[3].

3. Manufacturing Environment

Consider the compatibility of the stencil frame with your existing equipment and production processes. Some frames may be better suited for automated systems, while others are more appropriate for manual or semi-automated processes[5].

4. Material Compatibility

Ensure that the frame material is compatible with your production environment and cleaning processes. Some materials may be more resistant to certain chemicals or environmental factors[7].

Best Practices for Using PCB SMT Stencil Frames

To maximize the benefits of using stencil frames in your SMT assembly process, consider the following best practices:

1. Regular Maintenance

Perform regular inspections and maintenance on your stencil frames to ensure they remain in good condition. This includes cleaning, checking for damage, and verifying proper tension[1].

2. Proper Storage

Store stencil frames in a clean, dry environment to prevent damage or contamination. For frameless stencils, use appropriate storage solutions to maintain their flatness[3].

3. Careful Handling

Handle stencil frames with care to avoid bending or damaging the stencil foil. Use appropriate lifting and mounting techniques to prevent accidents[5].

4. Tension Verification

Regularly verify the tension of your stencils, especially for adjustable frames. Proper tension is crucial for maintaining print quality and consistency[7].

5. Alignment Checks

Perform regular alignment checks to ensure that the stencil remains properly positioned relative to the PCB. This is particularly important after changeovers or adjustments[1].

Future Trends in PCB SMT Stencil Frame Technology

As the electronics industry continues to evolve, so too does the technology behind PCB SMT stencil frames. Some emerging trends include:

1. Advanced Materials

Development of new frame materials that offer improved stability, durability, and resistance to environmental factors[3].

2. Smart Frames

Integration of sensors and monitoring systems into stencil frames to provide real-time data on tension, alignment, and performance[5].

3. Automated Adjustment Systems

Development of frames with automated tension and alignment adjustment capabilities, reducing the need for manual interventions[7].

4. Eco-Friendly Solutions

Creation of more sustainable and recyclable frame materials to align with growing environmental concerns in the industry[1].

Conclusion

PCB SMT stencil frames play a crucial role in the surface mount assembly process, contributing significantly to the quality, efficiency, and consistency of PCB production. By maintaining proper stencil tension, ensuring accurate alignment, and facilitating quick changeovers, these frames help manufacturers achieve higher quality standards and improved production efficiency.

As the electronics industry continues to advance, with increasingly complex PCB designs and tighter tolerances, the importance of high-quality stencil frames will only grow. By understanding the various types of frames available, their impact on assembly quality, and best practices for their use, manufacturers can make informed decisions to optimize their SMT assembly processes.

Whether opting for framed, frameless, or adjustable stencil frames, the key is to select a solution that best fits the specific requirements of your production environment. With the right PCB SMT stencil frame in place, manufacturers can ensure consistent, high-quality results in their surface mount assembly operations, meeting the demands of today's sophisticated electronic devices.

Frequently Asked Questions (FAQ)

1. What is the primary purpose of a PCB SMT stencil frame?

The primary purpose of a PCB SMT stencil frame is to provide support and maintain tension for the thin metal stencil used in applying solder paste to printed circuit boards during the surface mount assembly process. It ensures the stencil remains flat and properly aligned with the PCB, resulting in accurate and consistent solder paste deposition[1].

2. How does a PCB SMT stencil frame improve assembly quality?

A PCB SMT stencil frame improves assembly quality by maintaining consistent stencil tension and alignment, which leads to more accurate solder paste deposition. This results in better component placement, reduced defect rates, and overall higher quality in the final assembled PCB[3].

3. What are the differences between framed and frameless stencils?

Framed stencils are permanently attached to a rigid frame, offering excellent stability and consistency, making them ideal for high-volume production. Frameless stencils, or foils, are not attached to a frame, providing more flexibility and cost-effectiveness for low-volume production or prototyping. Framed stencils are generally more durable but require more storage space, while frameless stencils are more compact but may need additional tensioning equipment[5].

4. How often should PCB SMT stencil frames be maintained?

PCB SMT stencil frames should be regularly inspected and maintained to ensure optimal performance. This typically includes cleaning after each use, checking for damage or wear, and verifying proper tension. The frequency of maintenance may vary depending on production volume and environmental factors, but a general rule is to perform a thorough inspection at least once per week or every 1000 prints, whichever comes first[7].

5. Can PCB SMT stencil frames be used for different PCB designs?

Yes, PCB SMT stencil frames can be used for different PCB designs, especially when using adjustable frames or frameless stencils. Adjustable frames allow for the use of different stencil sizes within the same frame, providing flexibility in production. However, it's important to ensure that the frame is compatible with the stencil size and that proper alignment and tension are maintained for each new PCB design[1].

Citations:

[1] https://jlcpcb.com/blog/why-pcb-stencils-are-key-to-high-quality-smt-assembly

[2] https://www.sunstone.com/docs/pcb-whitepapers/using-stencils-to-simplify-the-printed-circuit-board-assembly-process.pdf?sfvrsn=e510e67b_8

[3] https://www.lioncircuits.com/faq/pcb-assembly/what-is-a-smt-stencil-and-why-is-it-needed-for-assembly

[4] https://education.ipc.org/product/manufacturing-engineering-electronics-assembly-stencil-printing

[5] https://www.wevolver.com/article/pcb-stencil

[6] https://www.pcbelec.com/the-production-process-of-pcb-smt-stencil.html

[7] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[8] https://www.stencilsunlimited.com/t/smt-stencils

[9] https://www.pcbonline.com/blog/pcb-stencil-introduction.html

[10] https://jlcpcb.com/blog/how-to-choose-a-smt-stencil

[11] https://www.nextpcb.com/blog/smt-stencil

[12] https://www.pcbway.com/pcb_prototype/SMT_stencil_and_Laser_Stencil.html