Content Menu

● Introduction to SMT Component Reel Splicing

>> Benefits of Splicing SMT Component Reels

● The Splicing Process

>> Tools Used in Splicing

● Challenges and Solutions

>> Alternatives to Metal Splices

● Best Practices for Splicing

● Advanced Techniques in SMT Splicing

>> Automated Splicing Systems

>> Quality Control Measures

>> Training and Expertise

● Industry Trends and Future Developments

>> Sustainability in SMT Splicing

>> Integration with Smart Manufacturing

● Conclusion

● Frequently Asked Questions

>> 1. What is the purpose of SMT splicing tape?

>> 2. How do SMT splicing tools work?

>> 3. What are the benefits of using SMT splicing tools?

>> 4. How can clogging issues with metal splices be addressed?

>> 5. What are some alternatives to traditional metal splices?

Splicing SMT (Surface Mount Technology) component reels is a crucial process in the electronics manufacturing industry, particularly in PCB (Printed Circuit Board) assembly. It involves joining the end of a depleted reel of components to the beginning of a new reel, ensuring continuous production without interruptions. This process is facilitated by specialized tools and techniques designed to maintain efficiency and accuracy in automated assembly lines.

Introduction to SMT Component Reel Splicing

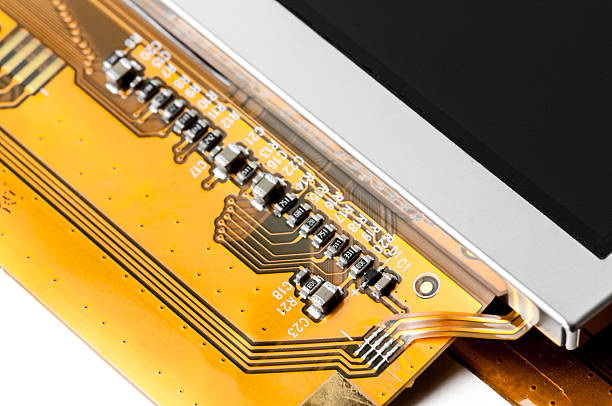

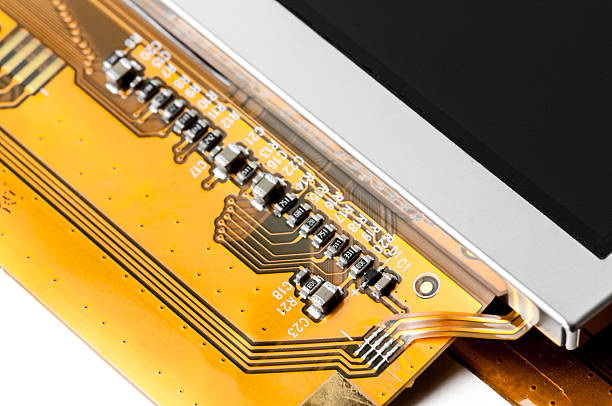

SMT component reels are used to feed components into pick-and-place machines during PCB assembly. These reels are made of a carrier tape with embossed pockets that hold individual components, covered by a top tape to keep them in place. When a reel is depleted, splicing allows the seamless transition to a new reel, minimizing downtime and maximizing production throughput.

Benefits of Splicing SMT Component Reels

1. Increased Efficiency: Splicing reduces the need to stop and reload machine feeders, thereby increasing the overall efficiency of the assembly process.

2. Reduced Downtime: By joining reels together, production can continue without interruptions, reducing downtime associated with reel changes.

3. Cost Savings: Splicing ensures that all components on a reel are used, minimizing waste and reducing costs.

The Splicing Process

The process of splicing SMT component reels involves several steps:

1. Preparation: The end of the depleted reel and the beginning of the new reel are prepared for splicing. This includes cutting the carrier tape accurately to avoid empty pockets.

2. Alignment: The ends of both reels are aligned using locating pins on the splicing tool to ensure accurate positioning.

3. Splicing: SMT splicing tape or a brass shim is used to join the two reels together. The tape is applied over the joint, ensuring a strong bond.

4. Securing the Splice: The splice is secured by folding over the cover tape and pressing firmly on both sides to ensure a seamless joint.

5. Verification: The splice is checked to ensure it will run smoothly through pick-and-place machines without causing any clogs or issues.

Tools Used in Splicing

- SMT Splice Tools: These are specialized tools designed to accurately align and join carrier tapes. They often feature locating pins and hold-downs to ensure precise alignment and secure joints.

- SMT Splicing Tape: This tape is used to hold the leader of the new reel together with the end of the current reel. It is designed to be strong yet flexible enough to allow smooth movement through assembly equipment.

- Brass Shim or Clip: Some splicing methods involve using a brass shim or clip to rivet the ends of the tapes together, providing a durable joint.

Challenges and Solutions

One common challenge with spliced reels is clogging in SMT machines due to metal splices. To address this, manufacturers can opt for non-metallic splicing methods or ensure that splices are designed to pass through feeders without causing obstructions.

Alternatives to Metal Splices

1. Leader Tape Extenders: These can be used to add extra length to a part reel, reducing the need for splicing and minimizing waste.

2. Non-Metallic Splicing Tapes: Using tapes without metal components can help avoid clogging issues in feeders.

Best Practices for Splicing

- Plan Ahead: Consider implementing splicing ahead of time to improve operational efficiency, especially when working with machines that do not allow feeder removal during operation.

- Use High-Quality Tools and Materials: Ensure that splicing tools and tapes are of high quality to maintain accuracy and durability.

- Regular Maintenance: Regularly inspect and maintain splicing tools to prevent wear and tear that could affect splice quality.

Advanced Techniques in SMT Splicing

Automated Splicing Systems

In recent years, automated splicing systems have emerged, offering enhanced precision and speed. These systems can automatically detect when a reel is nearing depletion and perform the splicing operation without human intervention, further reducing downtime.

Quality Control Measures

Implementing quality control measures is essential to ensure that splices meet the required standards. This includes regular inspections of spliced reels and testing them in production environments to verify their integrity.

Training and Expertise

Providing adequate training to personnel involved in splicing is crucial. Well-trained operators can ensure that splices are performed correctly, reducing errors and improving overall production quality.

Industry Trends and Future Developments

The electronics manufacturing industry is continuously evolving, with advancements in automation and material science influencing SMT splicing techniques. Future developments are likely to focus on improving the durability and reliability of splices, as well as reducing environmental impact through more sustainable materials.

Sustainability in SMT Splicing

As environmental concerns grow, manufacturers are looking for ways to make their processes more sustainable. This includes using eco-friendly splicing tapes and minimizing waste by optimizing reel usage.

Integration with Smart Manufacturing

The integration of SMT splicing with smart manufacturing technologies, such as IoT sensors and AI-driven monitoring systems, can enhance real-time monitoring and predictive maintenance. This integration can help identify potential issues before they occur, further optimizing production efficiency.

Conclusion

Splicing SMT component reels is a vital process in maintaining the efficiency and productivity of PCB assembly lines. By understanding the process, tools, and challenges involved, manufacturers can optimize their production workflows, reduce downtime, and improve overall quality. As technology continues to evolve, advancements in splicing techniques and tools will play a crucial role in enhancing manufacturing efficiency.

Frequently Asked Questions

1. What is the purpose of SMT splicing tape?

SMT splicing tape is used to hold the leader of the new component reel together with the end of the current reel, ensuring a strong yet flexible bond that allows smooth movement through automated assembly equipment.

2. How do SMT splicing tools work?

SMT splicing tools are designed to accurately align and join carrier tapes using locating pins and hold-downs. They facilitate precise alignment and secure joints, reducing production stoppages.

3. What are the benefits of using SMT splicing tools?

The benefits include increased efficiency, reduced downtime, and cost savings by minimizing waste and ensuring all components on a reel are used.

4. How can clogging issues with metal splices be addressed?

Clogging issues can be addressed by using non-metallic splicing methods or ensuring that splices are designed to pass through feeders without causing obstructions.

5. What are some alternatives to traditional metal splices?

Alternatives include using leader tape extenders and non-metallic splicing tapes to minimize waste and avoid clogging issues.