Content Menu

● Understanding SMT

>> 1. Material Preparation and Inspection

>> 2. Stencil Preparation

>> 3. Solder Paste Printing

>> 4. Solder Paste Inspection (SPI)

>> 5. Component Placement

>> 6. Glue Curing (If Applicable)

>> 7. Reflow Soldering

>> 8. Inspection After Soldering

>> 9. Testing

>> 10. Cleaning

>> 11. Final Inspection and Packaging

● Equipment Used in an SMT Line

● Advantages of SMT Lines

● Challenges in SMT Manufacturing

● Conclusion

● FAQ

>> 1. What are the main advantages of using an SMT line?

>> 2. How does solder paste application work in an SMT line?

>> 3. What types of inspections are performed during the SMT process?

>> 4. What happens if defects are found during inspection?

>> 5. Can SMT processes be adapted for different types of components?

● Citations:

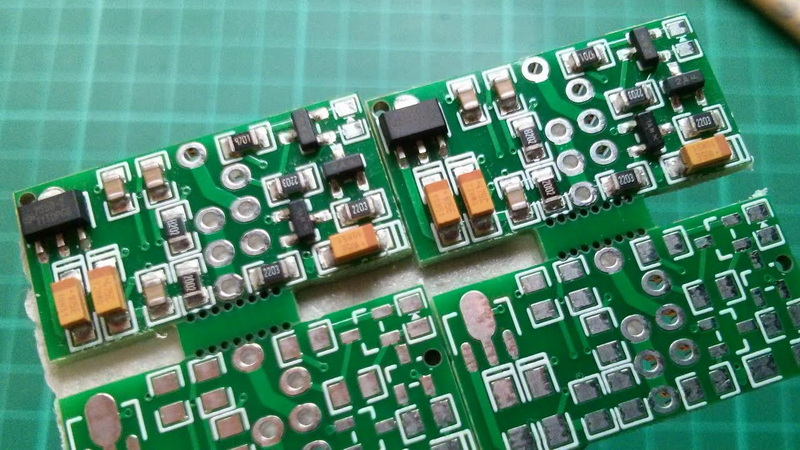

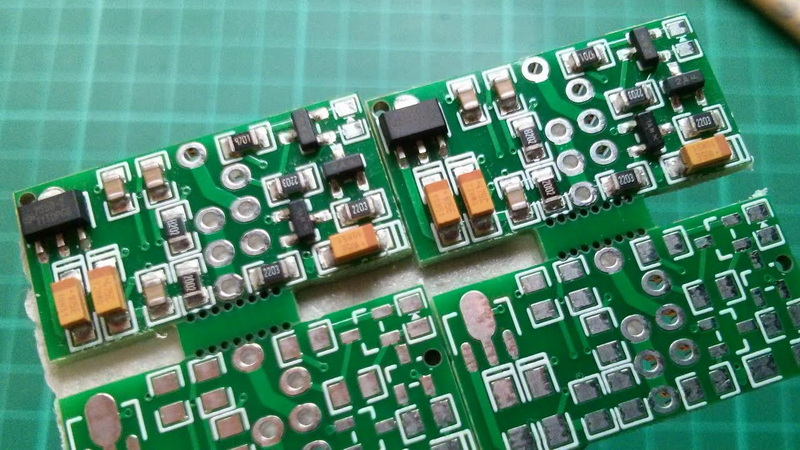

Surface Mount Technology (SMT) has transformed the electronics manufacturing landscape, allowing for the efficient assembly of electronic components directly onto the surface of printed circuit boards (PCBs). This method not only enhances production speed but also improves accuracy, making it a preferred choice for modern electronics manufacturing. In this article, we will delve into the typical process flow of an SMT line, detailing each step involved, the equipment used, and the quality control measures implemented throughout the process.

Understanding SMT

SMT is a method that allows electronic components to be mounted directly onto the surface of PCBs without the need for through-holes. This technique offers several advantages over traditional methods, including:

- Reduced size and weight of electronic devices

- Higher component density, allowing for more features in smaller devices

- Lower manufacturing costs due to reduced labor and material waste

- Increased production speed with automated processes

The SMT production process can be broken down into several key stages, each crucial for ensuring high-quality assembly.

1. Material Preparation and Inspection

The first step in the SMT process involves preparing and inspecting materials. This includes:

- Selecting components: Ensure all surface mount components (SMCs) are available and meet specifications.

- Inspecting PCBs: Quality control inspectors examine PCBs for defects or damage before they enter the assembly line.

Proper preparation is essential as any flaws at this stage can lead to significant issues later in the assembly process.

2. Stencil Preparation

Stencil preparation is vital for accurate solder paste application. A stencil is created based on the PCB design, featuring openings that correspond to solder pads on the board. This stencil ensures that solder paste is applied only where needed.

3. Solder Paste Printing

Solder paste, a mixture of metal solder and flux, is applied to the PCB using a stencil printer. The process involves:

- Aligning the stencil with the PCB.

- Using a squeegee to spread solder paste across the stencil openings.

This step must be performed with precision; improper application can lead to insufficient solder joints or solder bridges between components.

4. Solder Paste Inspection (SPI)

After printing, solder paste inspection is conducted to verify that paste has been applied correctly. Automated systems use cameras to check for:

- Thickness

- Coverage

- Shape and alignment of solder paste

Defective boards are flagged for rework, preventing issues in subsequent steps.

5. Component Placement

The next stage involves placing SMCs onto the PCB using pick-and-place machines. These machines operate as follows:

- Loading components: Components are fed from reels or trays into the machine.

- Placement: The machine uses vacuum nozzles to pick up components and place them accurately on the soldered pads.

Modern pick-and-place machines can achieve high speeds, placing thousands of components per hour with remarkable precision.

6. Glue Curing (If Applicable)

In some cases, adhesive glue is used alongside solder paste to secure components during wave soldering processes. After component placement, these boards may move to a glue curing station where operators cure the adhesive in an oven to ensure a strong bond between components and PCB.

7. Reflow Soldering

Once components are placed, the PCB moves into a reflow oven where soldering occurs through heat. The reflow process consists of several stages:

1. Preheat Zone: Gradually raises temperature (1–2 °C/s) to around 140–160 °C.

2. Soaking Zone: Maintains temperature for about 90 seconds to ensure even heating.

3. Reflow Zone: Increases temperature to 210–230 °C, melting solder paste to form joints.

4. Cooling Zone: Rapidly cools down to solidify solder joints.

This controlled heating is critical; too rapid heating can damage components while insufficient heating may lead to weak connections.

8. Inspection After Soldering

Post-reflow inspection is essential for quality assurance. Automated Optical Inspection (AOI) systems check for:

- Missing or misaligned components

- Defective solder joints

- Solder bridges

In some cases, X-ray inspection may be used for hidden connections or complex assemblies.

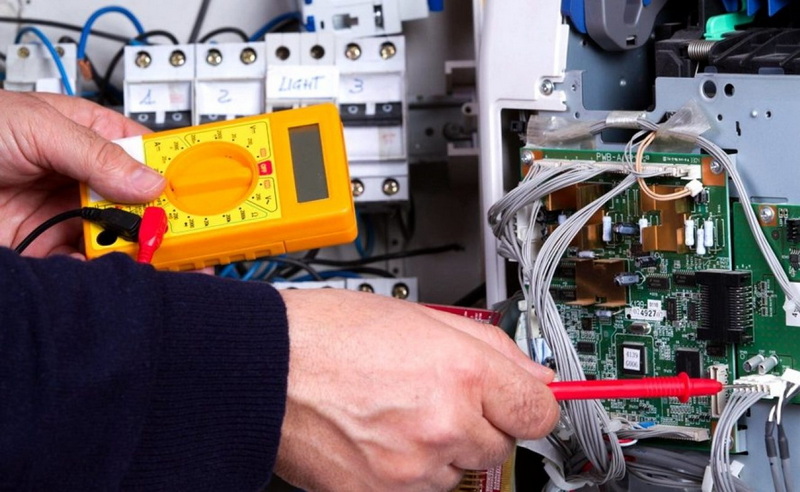

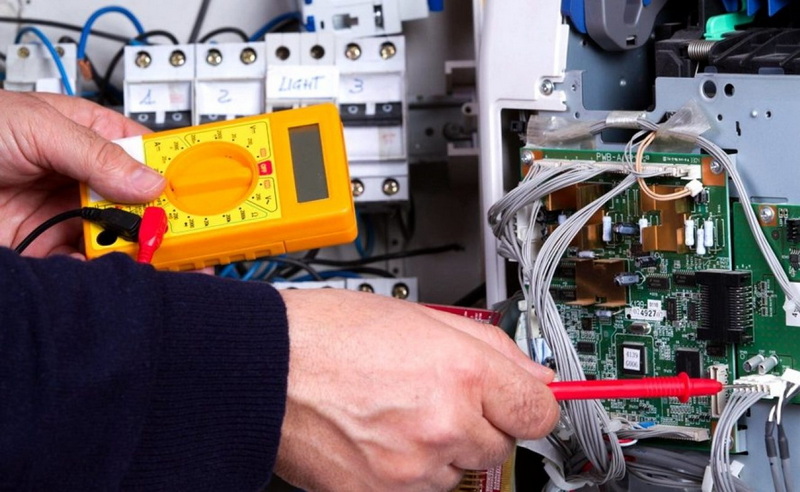

9. Testing

After inspection, PCBs undergo functional testing or in-circuit testing (ICT) to ensure they operate correctly. Any defects identified during testing are addressed through rework processes.

10. Cleaning

Following testing, PCBs may require cleaning to remove any residual flux or contaminants that could affect performance or reliability.

11. Final Inspection and Packaging

The final step involves a thorough inspection of the completed assemblies before packaging them for shipment or further assembly processes.

Equipment Used in an SMT Line

An SMT line comprises various machines that work together seamlessly to ensure efficient production:

- Stencil Printer: Applies solder paste on PCBs using a stencil.

- Pick-and-Place Machine: Accurately places surface mount components onto PCBs.

- Reflow Oven: Melts solder paste to create electrical connections between components and PCBs.

- Conveyor System: Moves boards through each step of the SMT line.

- Solder Paste Inspection (SPI): Checks quality of solder paste application before component placement.

- Automated Optical Inspection (AOI): Inspects boards after reflow for defects.

- Cleaning Machine: Removes excess flux and debris from PCBs post-soldering.

Each piece of equipment plays a crucial role in maintaining high production standards and minimizing errors throughout the assembly process.

Advantages of SMT Lines

The adoption of SMT lines offers numerous advantages over traditional through-hole technology:

- Higher Density: Allows for more components in less space.

- Reduced Costs: Lower material costs due to less waste and reduced labor costs from automation.

- Improved Reliability: Fewer mechanical connections result in better electrical performance.

- Faster Production Rates: Automated processes significantly increase throughput compared to manual methods.

Challenges in SMT Manufacturing

Despite its advantages, SMT manufacturing does face challenges:

- Complexity of Design: Advanced designs may require sophisticated equipment and skilled operators.

- Thermal Management: Managing heat during reflow processes is crucial; overheating can damage sensitive components.

- Quality Control: Ensuring consistent quality requires rigorous inspection processes at multiple stages.

Conclusion

The SMT line process is a sophisticated assembly method that enhances efficiency and accuracy in electronics manufacturing. Each stage—ranging from material preparation through final inspection—plays a crucial role in ensuring that high-quality products are produced consistently. As technology advances, SMT lines continue to evolve, incorporating new techniques and equipment that further streamline production and improve product reliability.

FAQ

1. What are the main advantages of using an SMT line?

SMT lines offer reduced manufacturing costs, increased production speed, higher component density, and improved overall efficiency compared to traditional methods.

2. How does solder paste application work in an SMT line?

Solder paste is applied using a stencil printer that ensures precise placement on designated pads on the PCB before component placement occurs.

3. What types of inspections are performed during the SMT process?

Inspections include solder paste inspection (SPI), automated optical inspection (AOI), and functional testing after assembly to ensure quality at each stage.

4. What happens if defects are found during inspection?

Defective boards are typically flagged for rework or repair before proceeding further in the assembly process to prevent poor-quality products from reaching customers.

5. Can SMT processes be adapted for different types of components?

Yes, SMT processes can be customized based on component types and specific product requirements, allowing flexibility in production lines.

Citations:

[1] https://www.pcbasic.com/blog/smt_production_line.html

[2] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[3] https://minearc.com/what-is-an-smt-line/

[4] https://mermarinc.com/2022/12/24/smt-line/

[5] https://www.youtube.com/watch?v=W3U9TUYpZ4s

[6] https://www.quick-pcba.com/the-main-equipment-in-an-smt-line/

[7] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[8] https://en.wikipedia.org/wiki/Surface-mount_technology

[9] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[10] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[11] https://insightsolutionsglobal.com/smt-surface-mount-technology-manufacturing-process/

[12] https://www.fs-pcba.com/smt-process-flow/

[13] https://www.viasion.com/blog/smt-pcb-assembly-process-8-basic-steps/

[14] https://wevolver-project-images.s3.us-west-1.amazonaws.com/0.tkw1ip2lrwdpcb.jpg?sa=X&ved=2ahUKEwiKrsnHkPmKAxUmV0EAHRMbFvEQ_B16BAgHEAI

[15] https://www.protoexpress.com/kb/smt-assembly/