Content Menu

● Introduction to SMD Machines

>> Manual SMD Machines

>> Semi-Automatic SMD Machines

>> Automatic SMD Machines

● Key Differences Between Manual and Automatic SMD Machines

● Advantages of Automatic SMD Machines

● Applications of SMD Machines

● Benefits of SMT Manufacturing

● Challenges and Limitations

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary advantages of using automatic SMD machines over manual ones?

>> 2. How do semi-automatic SMD machines aid in component placement?

>> 3. What types of components can automatic SMD machines handle?

>> 4. What are the cost implications of choosing between manual and automatic SMD machines?

>> 5. How do vision systems in automatic SMD machines enhance accuracy?

● Citations:

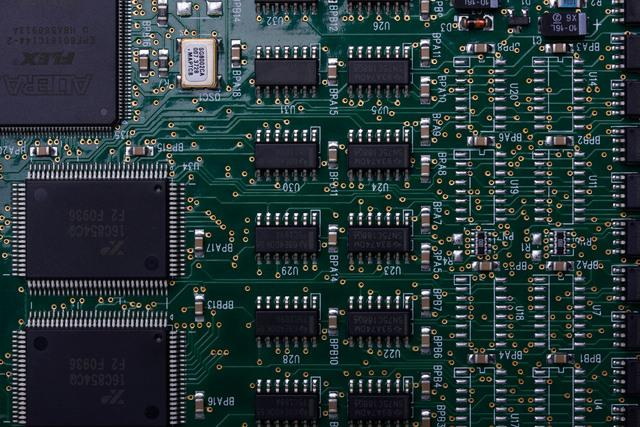

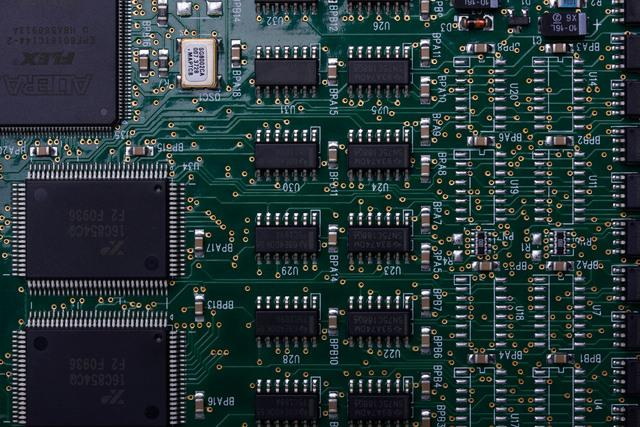

In the realm of Surface Mount Technology (SMT), the distinction between manual and automatic SMD machines is crucial for understanding the efficiency, accuracy, and scalability of electronic component assembly. SMD machines play a pivotal role in the manufacturing process, enabling the precise placement of surface mount devices (SMDs) onto printed circuit boards (PCBs). This article delves into the differences between manual and automatic SMD machines, highlighting their features, advantages, and applications.

Introduction to SMD Machines

SMD machines are essential tools in the electronics manufacturing industry, responsible for the accurate placement of SMDs onto PCBs. These machines can be broadly categorized into three types: manual, semi-automatic, and automatic. Each type serves different needs and production scales, from small-scale prototyping to large-scale industrial manufacturing.

Manual SMD Machines

Manual SMD machines involve a human operator who manually picks and places SMDs onto the PCB using the machine. These machines are beneficial for small-scale operations or when dealing with custom components that require precise human intervention. However, they are prone to human error, which can lead to inaccuracies in component placement. Despite this limitation, manual machines are cost-effective and flexible, making them suitable for low-volume production or specialized tasks like de-soldering and re-soldering specific components.

Manual soldering, a part of manual SMD assembly, requires a human operator to pick the right SMD using tweezers or a suction pick and place it on its intended position on the PCB. The operator then must use a hot soldering iron and solder wire to apply molten solder simultaneously to the PCB pad and the component terminal to bond them[3]. This process demands skill and attention to detail, as the component can move during soldering, making accurate placement challenging.

Semi-Automatic SMD Machines

Semi-automatic SMD machines combine elements of both manual and automatic systems. They provide a computerized visualization of the PCB, allowing operators to accurately place components using X and Y coordinate setups. This feature significantly reduces the risk of misplacement while still requiring human intervention. Semi-automatic machines are ideal for operations that need precision but do not require full automation, offering a balance between cost and efficiency[1].

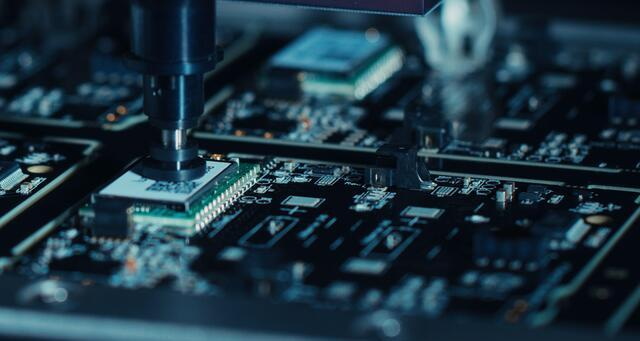

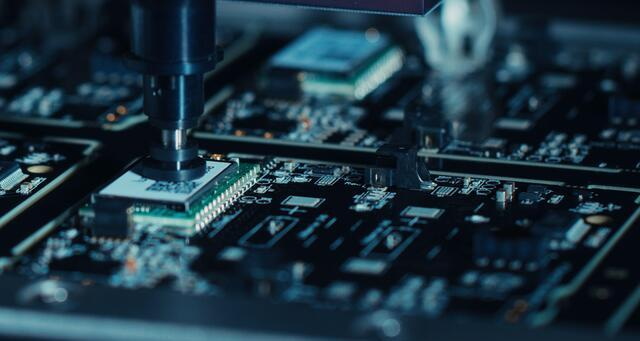

Automatic SMD Machines

Automatic SMD machines, such as the SMD machine automatic, are designed for high-speed and high-accuracy component placement. These machines utilize advanced technologies like dual cameras, electronic feeders, and multiple nozzles to handle a wide range of components, from small 0201 packages to larger BGA components. Automatic machines are preferred in large-scale manufacturing due to their ability to minimize labor costs, enhance production speed, and ensure consistent accuracy. They are equipped with sophisticated vision systems that enable precise alignment and placement of components, making them indispensable for high-volume production environments.

Key Differences Between Manual and Automatic SMD Machines

| Feature | Manual SMD Machines | Automatic SMD Machines |

| Accuracy | Prone to human error | High accuracy with minimal error |

| Speed | Slow, manual operation | High-speed operation |

| Cost | Cost-effective, low investment | Higher initial investment |

| Scalability | Limited scalability | Highly scalable for large production volumes |

| Application | Suitable for low-volume, custom, or specialized tasks | Ideal for high-volume, high-precision manufacturing |

Advantages of Automatic SMD Machines

Automatic SMD machines offer several advantages over manual systems:

- Accuracy and Precision: Automatic machines ensure consistent and precise placement of components, reducing the risk of errors.

- Speed and Efficiency: They operate at much higher speeds than manual machines, significantly increasing production throughput.

- Scalability: Automatic machines are designed to handle large volumes of components, making them suitable for industrial-scale manufacturing.

- Cost-Effectiveness: While the initial investment is higher, automatic machines reduce labor costs and minimize waste over time.

Applications of SMD Machines

SMD machines are used across various industries, including electronics manufacturing, automotive, aerospace, and consumer electronics. The choice between manual, semi-automatic, and automatic machines depends on the specific needs of the production environment, including volume, precision requirements, and budget constraints.

In industries like aerospace and defense, where space and weight constraints are critical, SMT technology provides compact and reliable electronic components[12]. Similarly, in the medical device manufacturing sector, automatic SMD soldering machines ensure precise control over temperature, soldering time, and pressure, guaranteeing the reliability and quality of solder joints[9].

Benefits of SMT Manufacturing

SMT manufacturing offers several benefits, including:

- Compact Design and Space Performance: SMT components allow for smaller and more lightweight devices, which is critical in industries like consumer electronics and healthcare[4].

- Better Manufacturing Velocity: Automated SMT lines achieve much faster assembly rates than manual or semi-automated through-hole assembly[8].

- Stronger Reliability and Performance: SMT services are recognized for their strong electrical connections, reducing the risk of loose or defective solder joints[4].

- Cost-Effective Manufacturing: While SMT systems may have a higher initial cost, they reduce labor requirements and material waste, making them cost-effective in the long term[4].

Challenges and Limitations

Despite the advantages, SMT manufacturing also presents some challenges:

- Component Fragility: SMT components are more fragile and can be easily damaged during handling[10].

- High Soldering Technology Requirements: SMT requires advanced soldering techniques to ensure reliable connections[10].

- Visual Inspection Challenges: Due to the small size of components, visual inspection can be difficult, making quality control more complex[10].

Conclusion

In conclusion, the choice between manual and automatic SMD machines depends on the production scale, precision requirements, and budget of the manufacturing facility. Manual machines are suitable for small-scale or specialized operations, while automatic machines are ideal for high-volume, high-precision manufacturing. As technology advances, automatic SMD machines continue to evolve, offering enhanced accuracy and efficiency, making them a crucial component in modern electronics manufacturing.

Frequently Asked Questions

1. What are the primary advantages of using automatic SMD machines over manual ones?

- Automatic SMD machines offer higher accuracy, faster operation speeds, and better scalability compared to manual machines. They are ideal for large-scale production environments where precision and speed are critical.

2. How do semi-automatic SMD machines aid in component placement?

- Semi-automatic SMD machines provide a computerized view of the PCB and use X and Y coordinates to help operators accurately place components. This reduces the risk of misplacement while still requiring human intervention.

3. What types of components can automatic SMD machines handle?

- Automatic SMD machines can handle a wide range of components, from small packages like 0201 to larger components such as BGA and QFN. They are versatile and can accommodate various component sizes and types.

4. What are the cost implications of choosing between manual and automatic SMD machines?

- Manual SMD machines are cost-effective with a lower initial investment but may incur higher labor costs over time. Automatic machines require a higher upfront investment but reduce labor costs and improve efficiency in the long run.

5. How do vision systems in automatic SMD machines enhance accuracy?

- The vision systems in automatic SMD machines, such as dual cameras, enable precise alignment and placement of components. These systems improve accuracy by recognizing and adjusting for component variations, ensuring that components are placed correctly on the PCB.

Citations:

[1] https://www.hayawin.com/resources/a-guide-to-smt-machines-what-they-are-and-how-to-choose.html

[2] https://www.greencircuits.com/automated-or-hand-pcb-assembly/

[3] https://www.pcbpower.us/blog/using-manual-soldering-in-smt-assembly-manufacturing-process

[4] https://www.smtmanufacturing.net/what-are-the-primary-benefits-of-the-use-of-smt/

[5] https://www.zjyingxing.com/info/what-role-does-smt-machine-play-in-modern-indu-102642276.html

[6] https://uetpcb.com/the-advantages-of-smt-manufacturing/

[7] https://www.seamarkzm.com/comparison-of-manual-smd-reel-counting-with-automated-counting-systems.html

[8] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[9] https://www.seamarkzm.com/medical-device-manufacturing-made-easy-with-automatic-smd-soldering.html

[10] https://www.wevolver.com/article/smt-process

[11] https://www.zjyingxing.com/info/what-are-the-advantages-of-advanced-smt-machin-82695955.html

[12] https://www.hayawin.com/news-characteristics-and-applications-of-smt-manufacturing-technology.html

[13] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[14] https://www.acceleratedassemblies.com/blog/manual-vs-automated-pcb-assembly-whats-the-real-difference

[15] https://ecitech.com/insights/why-manual-soldering-is-still-important-in-smt-assembly-manufacturing-process/

[16] https://www.ipcb.com/pcba-tech/9102.html

[17] https://www.minder-hightech.com/cn/product/SMT-full-line-description-manual-and-automatic.html

[18] https://www.garter.co.jp/en/difference.html

[19] https://www.neodensmt.com/news/manual-and-automated-smt-assembly-29502217.html

[20] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[21] https://www.technotronix.us/pcbblog/manual-vs-automated-assembly-which-one-is-right-for-you/

[22] https://www.pcbunlimited.com/t/smt-equipment

[23] https://www.eevblog.com/forum/manufacture/smt-production-line-manual-vs-automatic/

[24] https://www.pcbgogo.com/Article/Why_SMT_Technology_Benefit_PCB_Assembly_.html

[25] https://en.wikipedia.org/wiki/Surface-mount_technology

[26] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

[27] https://artdaily.com/news/155744/The-Advantages-of-Using-an-SMT-Machine-in-Electronic-Manufacturing-

[28] https://www.mpe-electronics.co.uk/2024/10/22/advantages-and-disadvantages-of-surface-mount-technology

[29] https://jhdpcb.com/blog/smt-manufacturing-technology/

[30] https://siemensmfg.com/the-advantages-of-surface-mount-technology-in-custom-electronics-manufacturing/

[31] https://www.pcbpower.us/blog/unveiling-the-advantages-and-disadvantages-of-surface-mount-technology

[32] https://www.hwgcsmt.com/info/the-wide-ranging-application-of-automated-sm-102763498.html

[33] https://essemtec.com/en/applications/

[34] https://www.pcb-hero.com/blogs/lisas-column/surface-mount-technology-advantages-and-disadvantages

[35] https://www.pcbonline.com/blog/smd-vs-smt-vs-tht.html

[36] https://www.wevolver.com/article/smt-vs-smd-vs-tht-a-comprehensive-guide-to-electronics-assembly-techniques

[37] https://www.pcb-hero.com/blogs/lickys-column/types-and-features-of-excellent-smt-machines

[38] https://www.circuits-central.com/blog/pcb-assembly-techniques-manual-vs-automated/