Content Menu

● Introduction

● What Are SMT Feeders?

● Types of SMT Feeders

>> Mechanical (Pneumatic) Feeders

>> Electrical Feeders

● Key Differences Between Mechanical and Electrical SMT Feeders

● Additional Types of SMT Feeders

>> Vibratory Feeders

>> Tape Feeders

>> Tray Feeders

● Choosing the Right SMT Feeder

● Importance of SMT Feeders in PCB Assembly

● Conclusion

● FAQ

>> 1. What is an SMT feeder?

>> 2. What are the main types of SMT feeders?

>> 3. Which SMT feeder is more precise?

>> 4. What factors should I consider when choosing an SMT feeder?

>> 5. Can SMT feeders handle all component types?

● Citations:

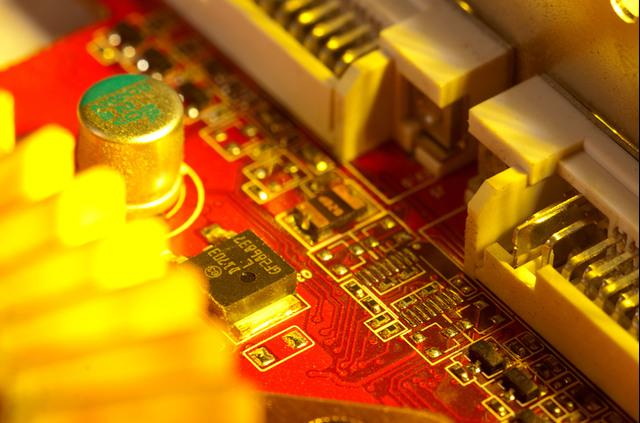

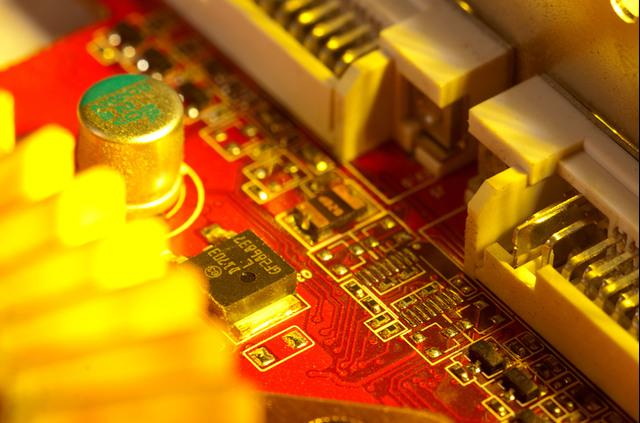

Introduction

Surface Mount Technology (SMT) feeders are essential components in the electronics manufacturing process, particularly in the assembly of printed circuit boards (PCBs). These devices ensure that electronic components are accurately and efficiently delivered to pick-and-place machines, which then position them onto PCBs. The choice of feeder can significantly impact production efficiency, accuracy, and overall manufacturing costs. This article will delve into the differences between mechanical (pneumatic) and electrical SMT feeders, providing insights into their respective advantages, disadvantages, and applications.

What Are SMT Feeders?

SMT feeders are devices that supply electronic components to pick-and-place machines during the PCB assembly process. They are designed to deliver components in a precise manner, ensuring that the assembly line operates smoothly and efficiently. The effectiveness of an SMT feeder is crucial for maintaining high production rates and minimizing errors in component placement.

Types of SMT Feeders

Mechanical (Pneumatic) Feeders

Mechanical feeders, commonly known as pneumatic feeders, utilize pressurized air to transport components from a reel or magazine to the pick-and-place head.

- Advantages:

- Speed: Pneumatic feeders can operate at high speeds, making them suitable for high-volume production lines.

- Handling Larger Components: They are particularly effective for larger components that may be difficult to manage with other feeder types.

- Disadvantages:

- Precision: While they are fast, pneumatic feeders often lack the precision of electrical feeders. This can lead to misalignment or improper placement of components.

- Maintenance: They require regular maintenance due to the complexity of the pneumatic system and potential wear on components.

Electrical Feeders

Electrical feeders use electric motors to drive the feeding mechanism, providing a more controlled and precise delivery of components.

- Advantages:

- Precision: Electrical feeders offer superior accuracy in component placement due to their controlled feeding mechanisms.

- Versatility: They can handle a wide range of component sizes and shapes, making them suitable for diverse applications.

- Ease of Programming: Electrical feeders are easier to program and adjust for different component types compared to their mechanical counterparts.

- Disadvantages:

- Cost: Generally, electrical feeders are more expensive than mechanical feeders due to their advanced technology.

- Speed Limitations: While they provide precision, they may not match the high-speed capabilities of pneumatic feeders for larger components.

Key Differences Between Mechanical and Electrical SMT Feeders

The differences between mechanical and electrical SMT feeders can be summarized as follows:

| Feature | Mechanical (Pneumatic) Feeders | Electrical Feeders |

| Precision | Lower precision; more prone to misalignment | Higher precision; consistent placement |

| Speed | Generally faster for larger components | Slower but consistent for various sizes |

| Maintenance | Requires frequent maintenance due to complexity | Easier maintenance; fewer moving parts |

| Application | Best for high-speed operations with larger components | Versatile; suitable for various component types |

Additional Types of SMT Feeders

Besides mechanical and electrical feeders, several other feeder types play critical roles in SMT assembly:

Vibratory Feeders

Vibratory feeders use mechanical vibrations to feed components into position. They consist of a vibrating bowl or tray that sorts and orients smaller components before delivering them to the pick-and-place machine.

- Advantages:

- High-speed capability for small components.

- Consistent component orientation enhances accuracy.

- Disadvantages:

- Limited handling capability for larger or heavier components.

Tape Feeders

Tape feeders utilize reels of adhesive tape that hold electronic components securely. They are versatile and support a wide range of component sizes.

- Advantages:

- Reliable feeding mechanism with minimal risk of misfeeds.

- Suitable for both small and medium-sized productions.

- Disadvantages:

- Not ideal for large or irregularly shaped components.

Tray Feeders

Tray feeders utilize trays with compartments to hold larger or non-standard components securely.

- Advantages:

- Flexibility in handling various component types.

- Easy loading and retrieval during production changes.

- Disadvantages:

- May require more space compared to tape or stick feeders.

Choosing the Right SMT Feeder

Selecting the appropriate SMT feeder depends on several factors:

- Component Size: Larger components may be better suited for pneumatic feeders due to their handling capabilities.

- Speed Requirements: If high-speed production is essential, mechanical feeders might be preferable; however, if precision is critical, electrical feeders should be considered.

- Precision Needs: For applications requiring high accuracy in component placement, electrical feeders are typically the better choice.

- Maintenance Considerations: Evaluate the maintenance requirements of each feeder type based on your operational capabilities.

Understanding these factors will help manufacturers choose the most suitable feeder type for their specific assembly processes.

Importance of SMT Feeders in PCB Assembly

The role of SMT feeders in PCB assembly cannot be overstated. They significantly influence:

- Production Efficiency: By automating the component feeding process, SMT feeders increase production throughput while reducing cycle times. This leads to higher overall efficiency in manufacturing operations.

- Placement Accuracy: Precise feeder operation is crucial for accurate component placement on PCBs. This minimizes errors and ensures proper circuit functionality, which is vital for product reliability.

- Cost Reduction: Reliable SMT feeders help reduce labor costs associated with manual component handling. Their durability also contributes to long-term cost savings through reduced downtime and maintenance needs.

- Flexibility in Production: Different types of SMT feeders allow manufacturers to adapt quickly to changes in production demands. This flexibility is essential in today's fast-paced electronics market where product lifecycles are shorter than ever.

Conclusion

Both mechanical and electrical SMT feeders have distinct advantages and disadvantages that cater to different manufacturing needs. Mechanical (pneumatic) feeders excel in speed and handling larger components but may compromise precision. In contrast, electrical feeders provide superior accuracy and versatility but at a higher cost. The choice between these two types should be guided by specific production requirements, including component size, speed, precision needs, and maintenance capabilities. By making an informed decision regarding feeder selection, manufacturers can enhance their PCB assembly processes' efficiency and quality.

FAQ

1. What is an SMT feeder?

An SMT feeder supplies components to the pick-and-place machine for PCB assembly.

2. What are the main types of SMT feeders?

The main types are mechanical (pneumatic), electrical, vibratory, tape, stick, and tray feeders.

3. Which SMT feeder is more precise?

Electrical feeders are generally more precise than mechanical feeders.

4. What factors should I consider when choosing an SMT feeder?

Consider component size, speed requirements, precision needs, and maintenance considerations.

5. Can SMT feeders handle all component types?

Different feeders are suited for different component types and sizes based on their design specifications.

Citations:

[1] https://www.zjyingxing.com/info/what-is-the-difference-in-smt-pick-and-place-m-87699059.html

[2] https://www.itechsmt.com/blogs/news/what-is-the-difference-between-electric-feeder-and-pneumatic-feeder

[3] https://www.hayawin.com/products/smt-feeder.html

[4] https://www.zjyingxing.com/info/what-is-the-difference-between-electric-feeder-84375865.html

[5] https://www.smtmanufacturing.net/smt-feeder-all-you-need-to-know/

[6] https://www.hayawin.com/news-what-is-a-smt-feeder-3-main-types.html

[7] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[8] https://www.itechsmt.com/blogs/news/hot-sales-smt-feeders

[9] https://www.etonsmtmachine.com/news/do-you-know-which-application-types-are-used-f-49377201.html

[10] https://www.neodensmt.com/news/how-to-choose-smt-feeder-44883121.html