Content Menu

● Understanding SMT Technology

>> What is SMT?

>> Benefits of SMT

● Initial Investment Costs

>> Breakdown of Equipment Costs

● Ongoing Operational Costs

● Total Cost of Ownership

● Potential Savings

● Factors Influencing Investment Decisions

● Conclusion

● FAQ

>> 1. What is included in the initial cost of an SMT line machine?

>> 2. How much does maintenance typically cost?

>> 3. What factors influence material costs in SMT assembly?

>> 4. How does automation affect labor costs?

>> 5. What is Total Cost of Ownership (TCO)?

Investing in a Surface Mount Technology (SMT) line machine is a significant decision for any electronics manufacturing business. The cost of such an investment can vary widely based on several factors, including the type of equipment, the scale of production, and the specific needs of the operation. This article will explore the various costs associated with investing in an SMT line machine, including initial purchase costs, ongoing operational expenses, and potential savings.

Understanding SMT Technology

What is SMT?

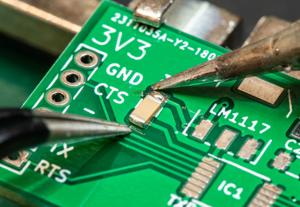

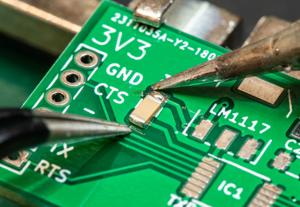

Surface Mount Technology (SMT) is a method used to produce electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). This technology has largely replaced traditional through-hole methods due to its advantages in terms of size, weight, and production efficiency. SMT allows for more compact designs and faster manufacturing processes.

Benefits of SMT

The benefits of SMT are numerous:

- Higher Component Density: SMT enables manufacturers to place components closer together on a PCB, allowing for more complex circuits in a smaller footprint.

- Improved Performance: SMT components typically have shorter leads than through-hole components, which can reduce inductance and improve electrical performance.

- Automated Assembly: SMT lines are often highly automated, which increases production speed and reduces labor costs.

- Reduced Weight: The smaller size and lighter weight of SMT components contribute to lighter final products, which is increasingly important in consumer electronics.

Initial Investment Costs

The initial investment for an SMT line machine can range significantly depending on several factors:

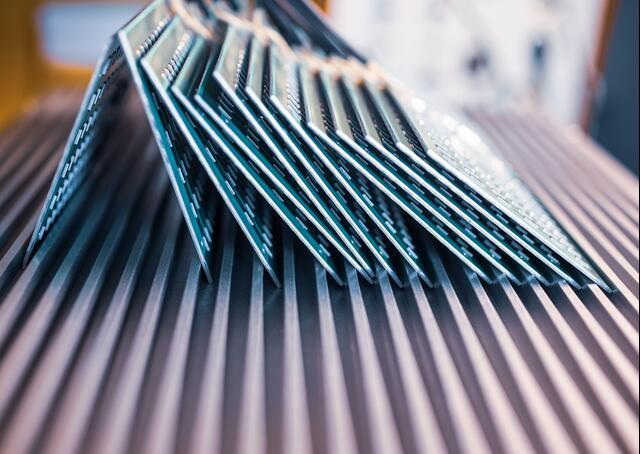

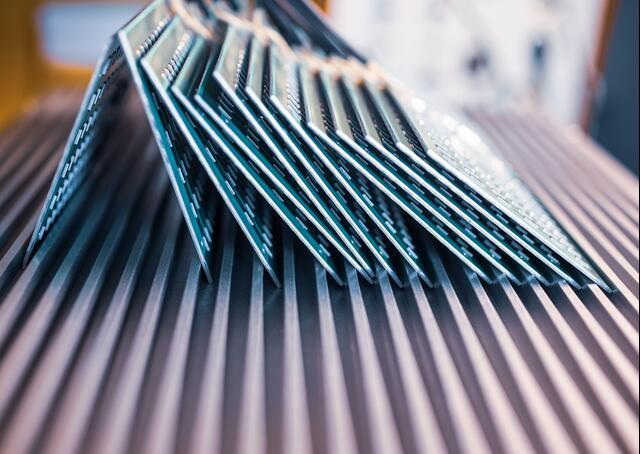

- Type of Equipment: The primary components of an SMT line include pick-and-place machines, solder paste printers, reflow ovens, and inspection systems. Each piece of equipment plays a crucial role in the assembly process.

- Quality and Brand: High-end machines from reputable brands tend to be more expensive but offer better reliability and performance. Entry-level machines may be more affordable but could compromise on speed and accuracy.

- Configuration: The configuration of the SMT line also affects costs. For instance, a fully automated line will generally cost more than a semi-automated one.

Based on industry data, the cost for a complete SMT line can range from $50,000 to over $1 million. For example, a basic pick-and-place machine can start at around $11,000, while high-end models can exceed $300,000.

Breakdown of Equipment Costs

To provide a clearer picture of the initial investment, here's a breakdown of typical costs associated with each component:

- Pick-and-Place Machines: These machines are crucial for placing components onto PCBs accurately. Prices can vary from $20,000 to $500,000, depending on speed and accuracy.

- Solder Paste Printers: Essential for applying solder paste to PCBs before component placement. Costs range from $10,000 to $150,000.

- Reflow Ovens: Used for melting solder paste to create electrical connections. Prices typically range from $30,000 to $200,000.

- Inspection Systems: Automated optical inspection (AOI) systems help ensure quality control by checking for defects. These systems can cost between $15,000 and $100,000.

Ongoing Operational Costs

After the initial investment, ongoing operational costs must also be considered:

- Maintenance Costs: Regular maintenance is essential for keeping SMT machines running efficiently. Maintenance costs can average around 10% of the machine's initial cost per year. This includes spare parts and labor for repairs.

- Labor Costs: Skilled operators are required to run SMT lines effectively. Labor costs can vary significantly based on geographic location but should be factored into the overall budget. For example, skilled technicians may command salaries ranging from $40,000 to $80,000 per year, depending on their expertise and location.

- Material Costs: The cost of electronic components, solder paste, and other materials can add up quickly. These costs fluctuate based on market demand and availability. For instance:

- Solder paste prices can range from $20 to $100 per kg, depending on the formulation.

- Electronic component prices vary widely; some resistors may cost just a few cents each while specialized ICs can exceed $100.

- Utility Costs: Operating an SMT line requires substantial energy consumption. Electricity costs can vary but should be included in the operational budget. Depending on usage patterns and local rates, monthly utility bills could range from $500 to $2,000 or more.

Total Cost of Ownership

The total cost of ownership (TCO) is a critical concept when evaluating the investment in an SMT line machine. TCO includes not only the purchase price but also all associated costs over the machine's lifespan. Factors influencing TCO include:

- Depreciation: Machines lose value over time due to wear and tear. Understanding depreciation helps businesses plan for future capital expenditures. Typically, machinery depreciates over 5 to 10 years depending on usage and technological advancements.

- Production Efficiency: Higher efficiency can lead to lower costs per unit produced. Investing in high-quality machines that offer better speed and accuracy can pay off in the long run by reducing cycle times and increasing throughput.

- Downtime Costs: Unexpected downtime due to machine failures can be costly. Investing in reliable equipment and proper maintenance can minimize these risks. It's estimated that unplanned downtime can cost manufacturers anywhere from $1 million to $5 million annually, depending on their size and production volume.

Potential Savings

Investing in an SMT line machine can lead to significant savings over time:

- Reduced Labor Costs: Automation reduces the need for manual labor, which can lead to substantial savings in labor costs. For example, an automated line may require only two operators compared to ten for a manual setup.

- Increased Production Speed: Faster production rates mean that more units can be produced in less time, improving overall profitability. A well-tuned SMT line may achieve production speeds upwards of 1000 units per hour, compared to manual processes that might only produce 200 units per hour.

- Lower Material Waste: Advanced SMT machines often come with features that minimize material waste during production through precise placement technology and better solder application methods.

Factors Influencing Investment Decisions

When considering investing in an SMT line machine, several factors should be evaluated:

- Production Volume Needs: Businesses must assess their current and projected production volumes. Higher volumes justify larger investments in automation due to economies of scale.

- Product Complexity: The complexity of products being manufactured influences machine selection; more complex products may require higher-end equipment with advanced capabilities.

- Market Trends: Keeping abreast of market trends such as miniaturization or increased demand for smart electronics may influence investment decisions as companies adapt their capabilities accordingly.

- Return on Investment (ROI): Calculating potential ROI is crucial before making any investment decision. A detailed analysis should consider both direct savings (like labor) and indirect benefits (like improved product quality).

Conclusion

Investing in an SMT line machine is a complex decision that requires careful consideration of various factors including initial costs, ongoing expenses, potential savings, and market dynamics. While the upfront investment may seem daunting at first glance—ranging from tens of thousands to millions—the long-term benefits often outweigh these initial expenditures when approached strategically. Understanding total cost ownership alongside potential efficiencies gained through automation provides businesses with insights necessary for making informed decisions aligned with their production goals.

FAQ

1. What is included in the initial cost of an SMT line machine?

The initial cost typically includes equipment purchase (pick-and-place machines, solder paste printers), setup fees, installation charges, and sometimes training for operators.

2. How much does maintenance typically cost?

Maintenance costs generally average about 10% of the initial purchase price per year and include spare parts and labor for repairs.

3. What factors influence material costs in SMT assembly?

Material costs are influenced by component prices, solder paste prices, market demand fluctuations, and supplier agreements.

4. How does automation affect labor costs?

Automation significantly reduces labor requirements as machines handle most tasks; thus lowering overall labor expenses while increasing production efficiency.

5. What is Total Cost of Ownership (TCO)?

Total Cost of Ownership (TCO) encompasses all costs associated with owning an SMT machine over its lifespan including purchase price, maintenance expenses, utility costs, and depreciation.