Content Menu

● Understanding Through-Hole Solder Joints

>> Common Issues with Through-Hole Solder Joints

● Tools Required for Touching Up Solder Joints

● Step-by-Step Process for Touching Up Solder Joints

>> 1. Preparation

>> 2. Heat the Soldering Iron

>> 3. Reflow Existing Solder

>> 4. Add New Solder

>> 5. Inspect the Joint

>> 6. Clean Up Excess Flux

● Advanced Techniques for Problematic Joints

● Best Practices for Successful Touch-Ups

● Understanding Inspection Techniques

>> Visual Inspection

>> X-ray Inspection

● Troubleshooting Common Issues

● Environmental Considerations

>> 1. Waste Management Practices:

>> 2. Use of Lead-Free Solders:

>> 3. Personal Safety Precautions:

● Expanded Techniques for Touch-Up Solder Joints

>> 1. Tinning Technique:

>> 2. Controlled Heating:

>> 3. Solder Application Techniques:

>> 4. Cooling Periods:

>> 5. Solder Joint Profiles:

● Conclusion

● FAQ

>> 1. What are common signs of a bad solder joint?

>> 2. Can I reuse old solder?

>> 3. How do I know if my solder joint is strong?

>> 4. What should I do if I lift a pad while desoldering?

>> 5. Is it necessary to use flux when touching up joints?

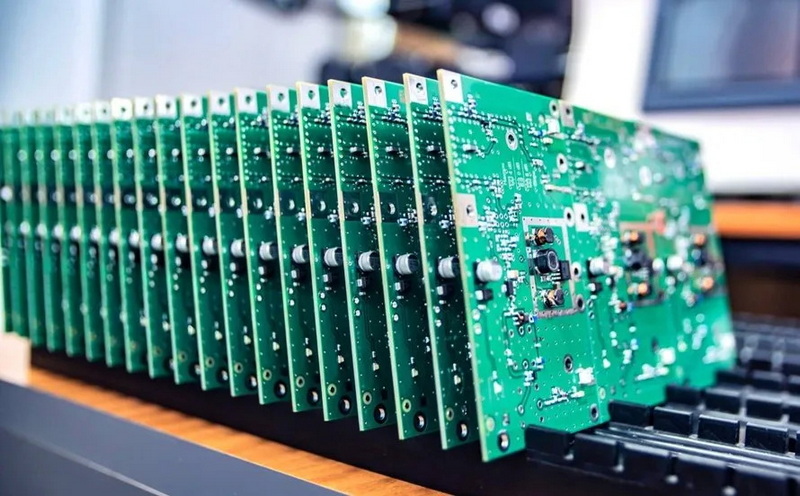

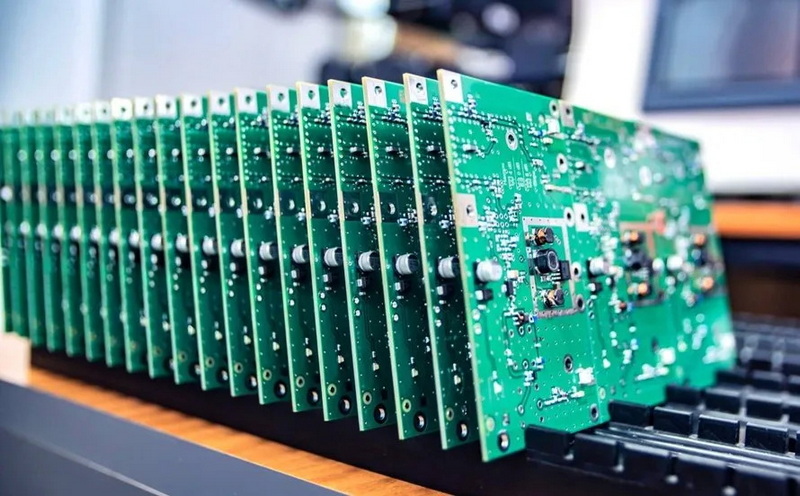

Soldering is a fundamental skill in electronics, especially when working with printed circuit boards (PCBs) that utilize through-hole components. Touching up through-hole solder joints is essential to ensure reliable electrical connections and maintain the integrity of electronic devices. This article will guide you through the correct process for touching up these solder joints, covering tools, techniques, and best practices.

Understanding Through-Hole Solder Joints

Through-hole soldering involves inserting component leads through holes in a PCB and soldering them on the opposite side. This method provides strong mechanical support and is commonly used for components like resistors, capacitors, and connectors.

Common Issues with Through-Hole Solder Joints

- Cold Joints: These occur when the solder does not melt properly, leading to poor electrical connections.

- Dry Joints: Insufficient heat or oxidation can prevent solder from adhering properly, resulting in weak connections.

- Excess Solder: Too much solder can create bridges between adjacent pads, leading to short circuits.

- Insufficient Solder: Not enough solder can leave gaps in the joint, compromising its strength.

Tools Required for Touching Up Solder Joints

Before diving into the process, it's crucial to gather the right tools:

- Soldering Iron: A good-quality soldering iron with adjustable temperature settings is essential.

- Solder: Use rosin-core solder for better adhesion and flow.

- Flux: Flux helps clean surfaces and improves solder flow.

- Desoldering Tools: A desoldering pump or wick can help remove excess solder if needed.

- Cleaning Supplies: Isopropyl alcohol and cotton swabs are useful for cleaning the PCB before and after soldering.

Step-by-Step Process for Touching Up Solder Joints

1. Preparation

Start by inspecting the PCB for any defects in the solder joints. Look for cracks, dull surfaces, or insufficient coverage. Clean the area around the joint with isopropyl alcohol to remove any grease or oxidation that could hinder solder adhesion.

2. Heat the Soldering Iron

Set your soldering iron to an appropriate temperature (around 350°C or 662°F). Allow it to heat up fully before proceeding.

3. Reflow Existing Solder

For joints that appear cold or dry:

- Place the tip of the hot soldering iron on the joint.

- Allow it to heat for a second or two until you see the existing solder begin to melt.

4. Add New Solder

Once the old solder has melted:

- Introduce a small amount of fresh solder into the joint while keeping the iron in place.

- Remove the iron once you see a shiny, smooth joint forming. The new solder should flow and cover both the pad and lead adequately.

5. Inspect the Joint

After cooling, inspect the joint visually. A good joint should be shiny and have a concave shape around the lead. If it appears dull or uneven, you may need to repeat steps 3 and 4.

6. Clean Up Excess Flux

Use a cotton swab dipped in isopropyl alcohol to clean any excess flux from around the joint. This step ensures that no corrosive residues remain on the PCB.

Advanced Techniques for Problematic Joints

In some cases, you may encounter more severe issues that require additional techniques:

- Desoldering Excess Solder: If there is too much solder on a joint, use a desoldering pump or wick to remove it before reapplying new solder.

- Using Flux: If a joint does not seem to take new solder well, apply a small amount of flux directly onto the joint before reheating it. This can improve wetting and adhesion significantly.

- Repairing Damaged Pads: If a pad has lifted from the PCB during previous work, you may need to use a wire jumper to connect the component lead directly to an adjacent trace or pad.

Best Practices for Successful Touch-Ups

To ensure your touch-ups are effective:

- Always use high-quality components and materials.

- Keep your workspace tidy and organized to avoid contamination.

- Practice good technique by ensuring both surfaces are heated adequately before adding solder.

- Regularly clean your soldering iron tip to maintain optimal heat transfer.

Understanding Inspection Techniques

After completing your touch-ups, it's essential to inspect your work thoroughly. Various inspection methods can help ensure that your joints meet quality standards:

Visual Inspection

This method involves examining joints with magnifying glasses or microscopes to identify defects such as cracks or insufficient coverage. Visual inspection is often complemented by automated optical inspection (AOI) systems that provide rapid assessments of multiple joints simultaneously.

X-ray Inspection

For complex assemblies where hidden joints exist (such as BGA packages), X-ray inspection provides insights into internal structures without damaging components. This method can detect issues like voids or insufficient wetting within joints.

Troubleshooting Common Issues

Despite careful execution, issues may arise during or after touch-ups. Here are some common problems and their solutions:

- Cold Joints: If you notice that a joint appears dull or has spikes, it may be due to inadequate heat application during soldering. Reheat and add more solder as necessary.

- Excessive Solder: If there's too much solder causing bridges between pads, use desoldering techniques to remove excess material before reworking.

- Lifted Pads: If pads lift off during desoldering attempts, consider using wire jumpers as a workaround by connecting leads directly to traces.

Environmental Considerations

In addition to technical aspects surrounding effective touch-ups on through-hole connections within PCBs—environmental factors also play pivotal roles when addressing electronic repairs:

1. Waste Management Practices:

- Proper disposal methods must be adhered to concerning any waste generated during repair processes including unused flux residues along with spent materials such as burnt-out components.

- Many local regulations mandate recycling programs specifically tailored towards electronic waste—ensuring minimal environmental impact while promoting sustainable practices within communities engaged heavily within technological sectors.

2. Use of Lead-Free Solders:

- While traditional lead-based solders have been widely used due their favorable melting points & fluidity characteristics—growing concerns regarding health risks associated have prompted many manufacturers towards adopting lead-free alternatives.

- These newer formulations often require higher temperatures alongside different handling techniques but provide safer options without compromising performance metrics overall.

3. Personal Safety Precautions:

- Always work within well-ventilated spaces while utilizing fume extraction systems where applicable—this minimizes inhalation exposure risks associated with harmful chemicals released during heating processes involving fluxes/solders themselves.

- Protective eyewear should also be worn consistently throughout all stages involving direct contact with hot materials ensuring eyes remain shielded from potential splashes occurring unexpectedly during operations themselves.

Expanded Techniques for Touch-Up Solder Joints

When touching up through-hole joints specifically designed for electronic components like resistors or capacitors:

1. Tinning Technique:

- Before starting any touch-up work on existing joints, ensure that your iron tip is tinned properly—this means applying a small amount of fresh solder onto it before making contact with any component leads or pads.

- Tinning helps improve thermal conductivity which ensures efficient heat transfer when working on joints.

2. Controlled Heating:

- When reheating existing joints during touch-ups, apply heat gradually rather than abruptly; this reduces thermal shock which could damage sensitive components nearby.

- Maintain contact with both lead and pad simultaneously until they reach an adequate temperature—typically around $$200^\circ C$$ (392°F)—before introducing new solder.

3. Solder Application Techniques:

- Apply fresh rosin-core solder from below while keeping your iron tip above; this allows molten metal from fresh additions to flow naturally into gaps created by old material without causing excessive buildup.

- Observe how well new additions integrate with existing material—if they don't flow smoothly together after heating adequately then additional cleaning might be required prior attempting another touch-up attempt.

4. Cooling Periods:

- After applying new molten material into reworked areas allow sufficient time (approximately five seconds) before stressing connections; this ensures solidification occurs without introducing mechanical strain which could lead back towards cold-joint formation.

5. Solder Joint Profiles:

- A well-executed touch-up should leave behind profiles resembling small volcanoes—concave shapes indicating proper wetting across both surfaces involved in bonding together rather than flat tops which signal inadequate adhesion levels.

Conclusion

Touching up through-hole solder joints is not merely about fixing defects; it encompasses understanding various aspects ranging from technical execution down towards environmental responsibility associated with electronic repairs overall! By following proper techniques combined alongside awareness surrounding sustainability concerns—you'll not only enhance performance levels across devices but contribute positively towards preserving our planet's resources too!

FAQ

1. What are common signs of a bad solder joint?

Common signs include cracks in the solder, dull surfaces instead of shiny ones, insufficient coverage over pads, or visible gaps between leads and pads.

2. Can I reuse old solder?

While it's possible to reuse old solder by reflowing it, it's generally better practice to add fresh solder for improved adhesion and reliability.

3. How do I know if my solder joint is strong?

A strong solder joint should appear shiny and smooth without cracks or gaps; it should also cover at least 75% of the pad area around the lead.

4. What should I do if I lift a pad while desoldering?

If you lift a pad, you can use a wire jumper to connect the component lead directly to an adjacent trace or use conductive epoxy as a last resort if damage is severe.

5. Is it necessary to use flux when touching up joints?

Using flux is highly recommended as it helps clean surfaces and promotes better wetting of new solder onto existing material.