Content Menu

● Understanding Surface Mount Technology (SMT)

>> Why Choose a Surface Mount Device Soldering Iron?

● Key Features to Look for in a SMD Soldering Iron

>> Tip Size and Shape

>> Temperature Control

>> Wattage

>> Ergonomics

>> Additional Tools

● Top Recommendations for Beginners

>> X-Tronic Model 3020-XTS

>> Weller WLC100

>> Hakko FX888D

>> MEAKEST Soldering Iron Kit

>> Vastar Soldering Iron Kit

● Tips for Successful SMD Soldering

>> Prepare Your Workspace

>> Use the Right Solder

>> Practice Good Technique

>> Clean Your Tools

>> Be Patient

● Conclusion

● Related Questions

>> 1. What is the difference between SMD and through-hole soldering?

>> 2. Can I use a regular soldering iron for SMD soldering?

>> 3. What type of solder is best for SMD soldering?

>> 4. How do I clean the soldering iron tip?

>> 5. Is it necessary to use a soldering station for beginners?

Soldering is an essential skill for anyone interested in electronics, whether you're a hobbyist, a student, or a professional. Among the various soldering techniques, surface mount device (SMD) soldering has gained popularity due to the compact nature of modern electronics. This article will explore the best surface mount device soldering irons for beginners, providing insights into their features, benefits, and how to choose the right one for your needs.

Understanding Surface Mount Technology (SMT)

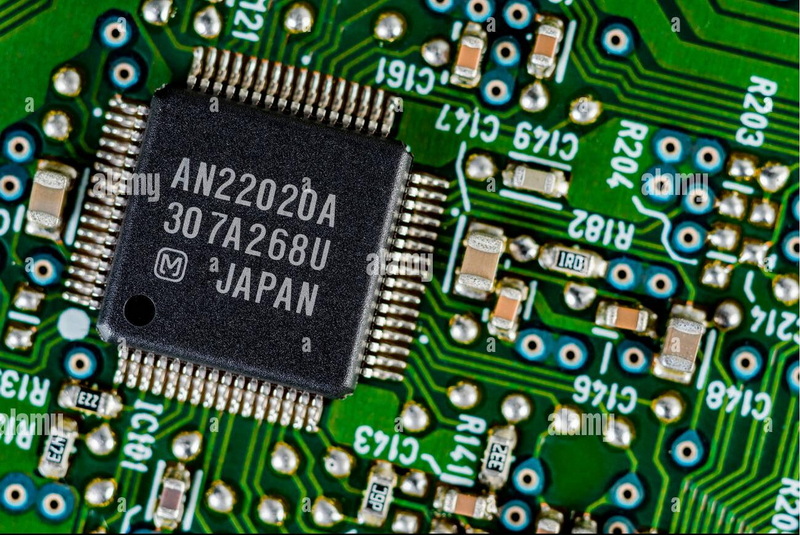

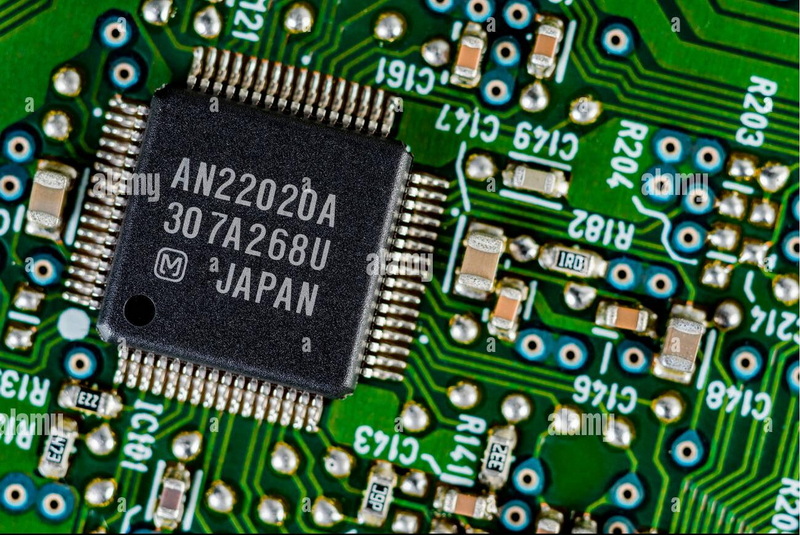

Surface mount technology (SMT) involves soldering components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole components, SMDs are smaller and can be placed on both sides of the PCB, allowing for more compact designs. This technology is widely used in modern electronics, from smartphones to computers.

Why Choose a Surface Mount Device Soldering Iron?

When it comes to soldering SMDs, having the right tools is crucial. A surface mount device soldering iron is specifically designed to handle the delicate nature of these components. Here are some reasons why you should consider investing in one:

1. Precision: SMD soldering irons typically have finer tips, allowing for precise soldering on small pads and components.

2. Temperature Control: Many models offer adjustable temperature settings, which is essential for preventing damage to sensitive components.

3. Ease of Use: Designed with beginners in mind, these soldering irons often come with user-friendly features that simplify the soldering process.

Key Features to Look for in a SMD Soldering Iron

When selecting a soldering iron for surface mount devices, consider the following features:

Tip Size and Shape

The tip of the soldering iron is critical for SMD work. Look for a fine tip that can easily reach small pads. Common shapes include:

- Chisel Tips: Good for larger pads and heat transfer.

- Pointed Tips: Ideal for precision work on small components.

Temperature Control

A soldering iron with adjustable temperature settings allows you to work with various components without risking damage. Look for models that can reach temperatures between 350°F to 450°F (about 180°C to 230°C), which is suitable for most SMD soldering tasks.

Wattage

Higher wattage soldering irons heat up faster and maintain temperature better during use. For SMD soldering, a wattage between 20W to 60W is generally sufficient.

Ergonomics

Since soldering can be a time-consuming task, choose a soldering iron that feels comfortable in your hand. Look for features like a rubberized grip and lightweight design.

Additional Tools

Some soldering kits come with additional tools such as tweezers, solder wick, and cleaning sponges, which can be beneficial for beginners.

Top Recommendations for Beginners

Here are some of the best surface mount device soldering irons suitable for beginners:

X-Tronic Model 3020-XTS

The X-Tronic Model 3020-XTS is a highly recommended soldering station for beginners. It features:

- Adjustable temperature control (200°F to 480°F).

- A digital display for easy reading.

- A variety of tips for different soldering tasks.

Weller WLC100

The Weller WLC100 is another excellent choice, known for its reliability and performance. Key features include:

- 40W adjustable power.

- Lightweight and ergonomic design.

- Compatible with various tip sizes.

Hakko FX888D

The Hakko FX888D is a professional-grade soldering station that is user-friendly for beginners. It offers:

- Fast heating and recovery time.

- Digital temperature control.

- A wide range of compatible tips.

MEAKEST Soldering Iron Kit

This kit is perfect for beginners, providing everything needed to start soldering. It includes:

- A temperature-controlled soldering iron.

- Various soldering tips.

- Additional tools like tweezers and a solder sucker.

Vastar Soldering Iron Kit

The Vastar kit is budget-friendly and ideal for beginners. It features:

- A 60W soldering iron with adjustable temperature.

- A variety of accessories, including solder and a cleaning sponge.

Tips for Successful SMD Soldering

To ensure successful soldering of surface mount devices, follow these tips:

Prepare Your Workspace

Ensure your workspace is clean and well-lit. Use a magnifying glass or microscope if necessary to see small components clearly.

Use the Right Solder

For SMD soldering, use a thin solder wire (0.5mm or smaller) with a rosin core. This type of solder flows better and is easier to work with.

Practice Good Technique

- Heat the pad, not the component.

- Apply solder to the joint, allowing it to flow into place.

- Use tweezers to hold components in place while soldering.

Clean Your Tools

Regularly clean the tip of your soldering iron to prevent oxidation and ensure good heat transfer.

Be Patient

Soldering SMDs can be challenging at first. Take your time and practice on scrap boards before working on your projects.

Conclusion

Choosing the right surface mount device soldering iron is crucial for beginners looking to dive into the world of electronics. With the right tools and techniques, you can master SMD soldering and create impressive projects. The X-Tronic Model 3020-XTS, Weller WLC100, Hakko FX888D, MEAKEST Soldering Iron Kit, and Vastar Soldering Iron Kit are all excellent choices that cater to different needs and budgets. Remember to practice and be patient as you develop your soldering skills.

Related Questions

1. What is the difference between SMD and through-hole soldering?

SMD soldering involves soldering components directly onto the surface of a PCB, while through-hole soldering requires inserting leads through holes in the board.

2. Can I use a regular soldering iron for SMD soldering?

While you can use a regular soldering iron, a dedicated SMD soldering iron with a fine tip and temperature control is recommended for better precision and control.

3. What type of solder is best for SMD soldering?

A thin solder wire (0.5mm or smaller) with a rosin core is ideal for SMD soldering, as it flows better and is easier to work with.

4. How do I clean the soldering iron tip?

You can clean the soldering iron tip using a damp sponge or brass sponge. Regular cleaning prevents oxidation and improves heat transfer.

5. Is it necessary to use a soldering station for beginners?

While not strictly necessary, a soldering station with adjustable temperature and a stable base is highly beneficial for beginners, providing better control and safety.