Content Menu

● Understanding SMT Nozzle Holders

>> Definition and Functionality

● Key Features to Look for in an SMT Nozzle Holder

● Top SMT Nozzle Holders for PCB Assembly

>> 1. JUKI Nozzle Holders

>> 2. Yamaha Nozzle Holders

>> 3. Panasonic Nozzle Holders

>> 4. Fuji Nozzle Holders

>> 5. Hanwha Nozzle Holders

● Importance of Choosing the Right SMT Nozzle Holder

● Maintenance Tips for SMT Nozzle Holders

● The Impact of Technology on SMT Nozzle Holders

● Comparing Different Brands

● Case Studies: Successful Implementation

>> 1. Company A – JUKI Implementation

>> 2. Company B – Yamaha Advantage

>> 3. Company C – Panasonic Reliability

● Future Trends in SMT Nozzle Holder Design

● Conclusion

● FAQ

>> 1. What is an SMT nozzle holder?

>> 2. Why is it important to choose a compatible nozzle holder?

>> 3. How can I maintain my SMT nozzle holder?

>> 4. What materials are best for SMT nozzle holders?

>> 5. Can I use different brands of nozzles with my SMT machine?

● Citations:

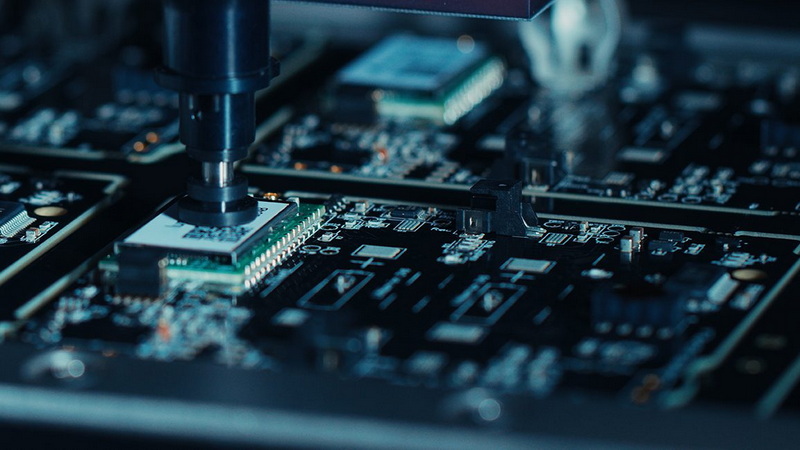

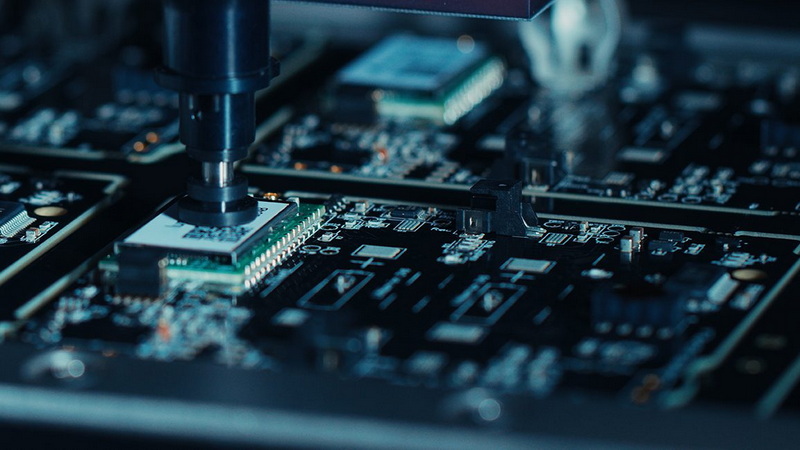

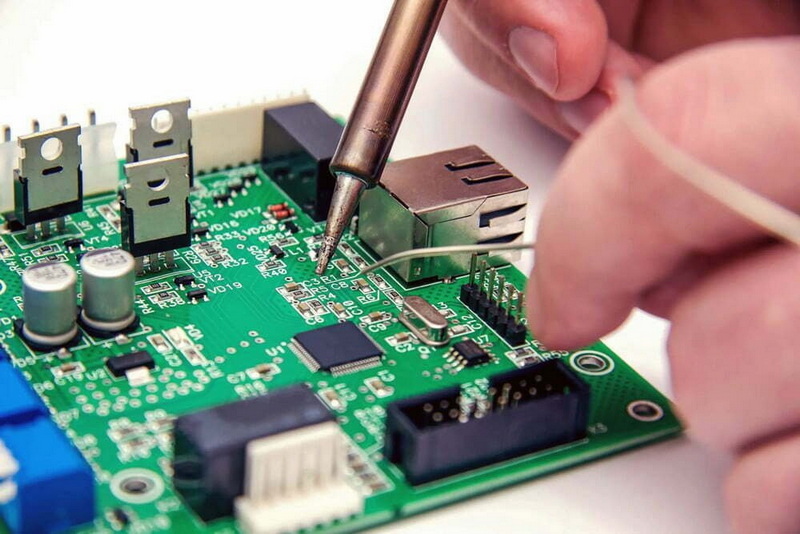

In the realm of Surface Mount Technology (SMT), the efficiency of printed circuit board (PCB) assembly heavily relies on the quality and functionality of the SMT nozzle holder. This critical component not only affects the speed and precision of component placement but also influences the overall productivity of the manufacturing process. This article delves into the best SMT nozzle holders available, their features, and how they contribute to efficient PCB assembly.

Understanding SMT Nozzle Holders

Definition and Functionality

An SMT nozzle holder is a device that secures the nozzle in place on a pick-and-place machine, enabling it to accurately pick up and place electronic components onto PCBs. The effectiveness of an SMT nozzle holder can significantly impact the assembly line's speed, precision, and reliability.

The primary functions of SMT nozzle holders include:

- Securing Nozzles: They hold nozzles firmly in place during operation to prevent misalignment.

- Facilitating Quick Changes: Many modern holders allow for rapid swapping of nozzles to accommodate different component sizes and types.

- Enhancing Stability: A well-designed nozzle holder minimizes vibrations that can lead to placement errors.

Key Features to Look for in an SMT Nozzle Holder

When selecting an SMT nozzle holder, consider the following features:

- Compatibility: Ensure that the holder is compatible with your specific pick-and-place machine model. Different machines may require different types of holders.

- Material Quality: High-quality materials enhance durability and reduce wear over time. Look for holders made from robust metals or high-grade plastics.

- Ease of Use: A user-friendly design allows operators to change nozzles quickly, minimizing downtime during production.

- Precision Engineering: Precision in design ensures that nozzles fit snugly, maintaining alignment during operation.

- Adjustability: Some holders offer adjustable settings for various nozzle sizes, enhancing versatility across different assembly tasks.

Top SMT Nozzle Holders for PCB Assembly

1. JUKI Nozzle Holders

- Known for their reliability and precision.

- Compatible with various JUKI pick-and-place machines.

- Designed for quick changes, minimizing downtime.

2. Yamaha Nozzle Holders

- Feature a robust design that withstands high-speed operations.

- Offer excellent compatibility with Yamaha's range of SMT machines.

- Adjustable settings for different nozzle sizes enhance flexibility.

3. Panasonic Nozzle Holders

- Renowned for their durability and performance.

- Provide stability during operation, ensuring accurate component placement.

- Easy to install and replace, reducing operator fatigue.

4. Fuji Nozzle Holders

- Designed with precision engineering to minimize errors.

- Compatible with various Fuji models, offering versatility.

- High-quality materials ensure long-lasting performance.

5. Hanwha Nozzle Holders

- Known for their innovative designs that enhance efficiency.

- Allow for quick changes between nozzles, facilitating diverse assembly tasks.

- Provide excellent stability during high-speed operations.

Importance of Choosing the Right SMT Nozzle Holder

The choice of an SMT nozzle holder can have profound implications on production efficiency:

- Increased Throughput: High-quality holders enable faster component placement, increasing overall output.

- Reduced Errors: Precision-engineered holders minimize misalignment and errors during placement, reducing waste and rework costs.

- Enhanced Flexibility: Quick-change capabilities allow manufacturers to adapt quickly to different production runs without significant downtime.

Maintenance Tips for SMT Nozzle Holders

To ensure optimal performance from your SMT nozzle holders, regular maintenance is essential:

- Regular Cleaning: Keep holders free from dust and debris to maintain suction power and prevent component damage.

- Inspect for Wear: Regularly check for signs of wear or damage that could affect performance. Replace worn parts promptly.

- Calibration Checks: Periodically calibrate your pick-and-place machine to ensure that nozzles are aligned correctly during operation.

The Impact of Technology on SMT Nozzle Holders

As technology advances, so do the designs and functionalities of SMT nozzle holders. Innovations in materials science have led to stronger yet lighter nozzle holders that can withstand the rigors of high-speed assembly lines. Additionally, advancements in automation have resulted in more sophisticated holders equipped with sensors that provide real-time feedback on performance metrics such as alignment accuracy and wear levels.

Moreover, software integration plays a crucial role in optimizing the use of nozzle holders. Modern pick-and-place machines often come with software that allows operators to program specific settings based on the type of components being used. This feature enables automatic adjustments to be made, ensuring optimal performance throughout different production runs.

Comparing Different Brands

When considering which brand of SMT nozzle holder to use, it's beneficial to compare their offerings based on several criteria:

| Brand | Compatibility | Material Quality | Ease of Use | Precision Engineering | Adjustability |

| JUKI | High | Excellent | User-friendly | High | Moderate |

| Yamaha | Excellent | Very Good | Easy | Very High | High |

| Panasonic | Good | Excellent | Easy | High | Low |

| Fuji | Excellent | Very Good | Moderate | Very High | Moderate |

| Hanwha | Good | Excellent | Easy | High | High |

This table illustrates how each brand stacks up against key factors that influence usability and effectiveness in PCB assembly processes.

Case Studies: Successful Implementation

To further illustrate the importance of selecting the right SMT nozzle holder, consider these case studies:

1. Company A – JUKI Implementation

Company A switched to JUKI nozzle holders after experiencing frequent misplacements during high-speed runs. The transition led to a 30% increase in throughput due to improved alignment and reduced downtime from quick-change capabilities.

2. Company B – Yamaha Advantage

After integrating Yamaha's adjustable nozzle holders into their production line, Company B reported a significant decrease in setup times when switching between different component types. This flexibility allowed them to respond more rapidly to market demands without sacrificing quality.

3. Company C – Panasonic Reliability

Company C has relied on Panasonic nozzle holders for years due to their durability under continuous use. Regular maintenance checks ensured that wear was kept at bay, allowing them to maintain high production standards without unexpected downtimes.

Future Trends in SMT Nozzle Holder Design

Looking ahead, several trends are expected to shape the future of SMT nozzle holder design:

- Smart Technology Integration: As factories move towards Industry 4.0 standards, smart technologies will likely be integrated into nozzle holders. These innovations could include IoT connectivity for real-time monitoring and data analytics capabilities that help optimize performance further.

- Sustainability Focus: With growing awareness around environmental issues, manufacturers may prioritize eco-friendly materials in their designs while also focusing on reducing waste through more efficient manufacturing processes.

- Customization Options: As companies increasingly seek tailored solutions for their unique production needs, manufacturers may offer more customizable options for nozzle holders that cater specifically to individual client requirements or specialized applications.

Conclusion

Selecting the best SMT nozzle holder is crucial for achieving efficient PCB assembly. With a variety of options available from leading manufacturers like JUKI, Yamaha, Panasonic, Fuji, and Hanwha, it is essential to consider compatibility, material quality, ease of use, precision engineering, and adjustability when making your choice. By investing in high-quality nozzle holders and maintaining them properly, manufacturers can significantly enhance their production efficiency while reducing errors and costs associated with rework.

In conclusion, a well-chosen SMT nozzle holder not only improves the speed and accuracy of component placement but also contributes to a more streamlined manufacturing process overall. As technology continues to evolve within this field, staying informed about advancements will be key for manufacturers aiming to maintain a competitive edge in PCB assembly operations.

FAQ

1. What is an SMT nozzle holder?

An SMT nozzle holder is a device that secures nozzles on pick-and-place machines used in PCB assembly. It ensures accurate placement of electronic components by holding the nozzles firmly in place during operation.

2. Why is it important to choose a compatible nozzle holder?

Choosing a compatible nozzle holder ensures that it fits securely on your specific pick-and-place machine model. This compatibility is crucial for maintaining alignment and preventing operational errors during component placement.

3. How can I maintain my SMT nozzle holder?

Regular maintenance includes cleaning the holder to remove dust and debris, inspecting it for wear or damage, and performing calibration checks on your pick-and-place machine to ensure proper alignment with nozzles.

4. What materials are best for SMT nozzle holders?

High-quality metals or durable plastics are ideal materials for SMT nozzle holders as they enhance durability and reduce wear over time while ensuring stability during high-speed operations.

5. Can I use different brands of nozzles with my SMT machine?

While some machines allow the use of various brands' nozzles if they are compatible in size and design, it's generally recommended to use nozzles specifically designed for your machine brand to ensure optimal performance and reliability.

Citations:

[1] https://www.itechsmt.com/blogs/news/how-to-use-the-smt-nozzle-flexiable

[2] https://cnsmtline.com/smt-nozzle/

[3] https://juguanghengsmt.en.made-in-china.com/product/ftPruHCdgGhM/China-SMT-Machine-Accessories-Npm-16-Nozzle-Holder-with-Large-Spring-Nozzle.html

[4] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[5] http://www.alibaba.com/product-detail/SMT-Spare-Parts-JUKI-Nozzle-holder-60823171126.html

[6] https://es.hayawin.com/resources/how-to-optimize-pcb-design-for-smt-assembly-process-flow.html

[7] https://www.dafton-smt.com/news/top-10-brands-of-smt-machines-76108422.html

[8] https://www.gssmt-parts.com/what-is-the-function-of-smt-nozzle.html

[9] https://www.youtube.com/watch?v=4HrH_8pUk3I

[10] https://m.made-in-china.com/hot-china-products/Smt_Nozzle_Holder-6.html