Content Menu

● Understanding SMT Stencils

>> Key Functions of SMT Stencils

● Types of SMT Stencils

● Manufacturing Process of SMT Stencils

● Importance of SMT Stencils in PCB Assembly

● Applications of SMT Stencils

● Advantages of Using SMT Stencils

● Challenges Associated with SMT Stencils

● Future Trends in SMT Stencil Technology

● Conclusion

● FAQ

>> 1. What materials are used for SMT stencils?

>> 2. How do you clean an SMT stencil?

>> 3. Can SMT stencils be reused?

>> 4. What factors influence stencil design?

>> 5. Why is precision important in solder paste application?

● Citations:

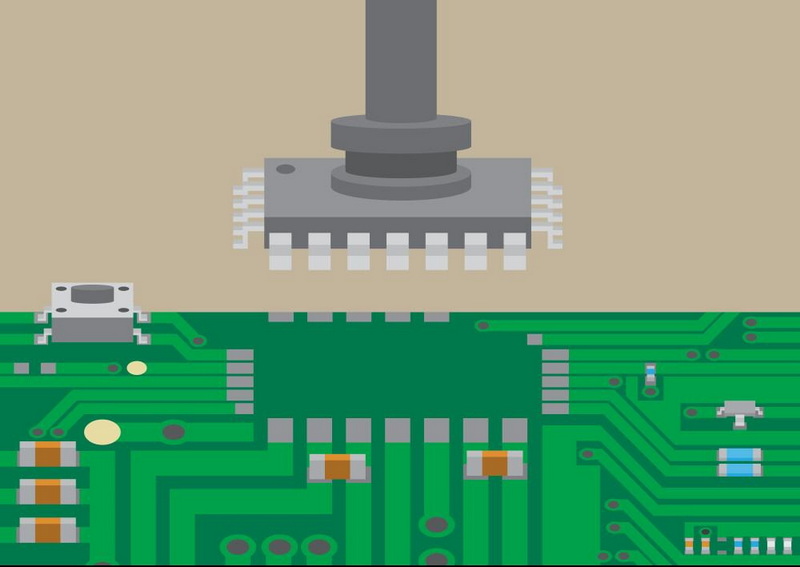

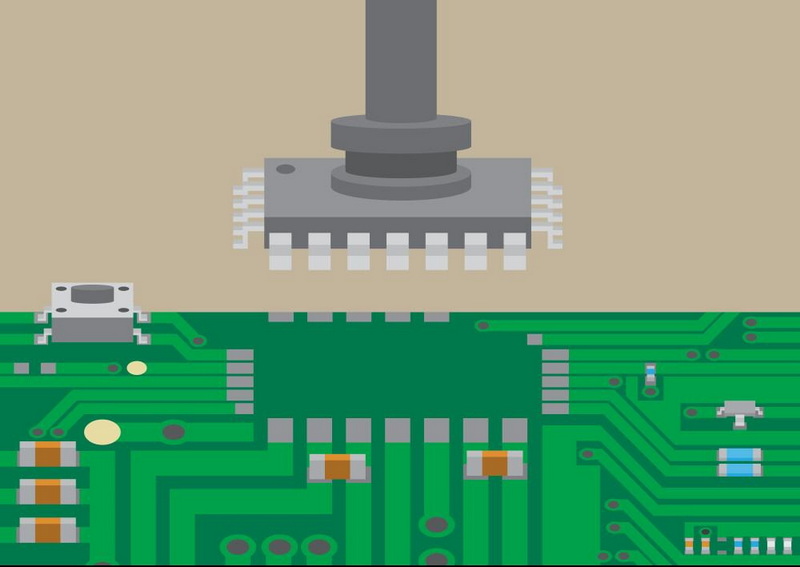

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). One of the critical tools in this process is the SMT stencil, a device that plays a vital role in ensuring the accuracy and efficiency of solder paste application. This article delves into the intricacies of SMT stencils, their types, manufacturing processes, and their significance in modern electronics manufacturing.

Understanding SMT Stencils

An SMT stencil is a thin sheet, typically made of stainless steel or nickel alloys, with precisely cut openings corresponding to the pads on a PCB where solder paste needs to be applied. The primary function of these stencils is to facilitate the accurate deposition of solder paste onto the PCB pads, ensuring that surface mount devices (SMDs) can be effectively soldered during assembly.

Key Functions of SMT Stencils

- Solder Paste Application: Stencils allow for controlled application of solder paste, which is essential for creating reliable solder joints.

- Precision and Consistency: They ensure that the right amount of solder paste is deposited uniformly across multiple PCBs, reducing defects and improving overall product quality.

- Efficiency: By automating the solder paste application process, stencils significantly speed up PCB assembly compared to manual methods.

Types of SMT Stencils

There are primarily two types of SMT stencils used in PCB assembly:

- Framed Stencils: These stencils are mounted within a frame that provides stability and precision during the printing process. They are ideal for high-volume production due to their durability and accuracy.

- Frameless Stencils: Also known as foils, these are less expensive and are suitable for low-volume production or prototyping. They do not have a permanent frame, making them easier to store.

Manufacturing Process of SMT Stencils

The manufacturing of SMT stencils involves several critical steps:

1. Material Selection: High-quality stainless steel or nickel alloys are commonly used due to their durability and resistance to corrosion.

2. Laser Cutting: The stencil material is precisely cut using lasers to create apertures that correspond to the SMD pads on the PCB.

3. Alignment Features: Registration marks or fiducials are added to ensure accurate alignment during the printing process.

4. Finishing Touches: The edges may be smoothed or treated to enhance performance and longevity.

Importance of SMT Stencils in PCB Assembly

The use of SMT stencils in PCB assembly cannot be overstated:

- Enhanced Quality Control: By ensuring precise solder paste application, stencils help maintain high-quality standards in electronic manufacturing.

- Reduced Production Costs: Efficient use of materials and reduced waste lead to lower production costs over time.

- Support for Advanced Technologies: As electronic devices become more compact and complex, SMT stencils enable manufacturers to adapt quickly to new designs and technologies.

Applications of SMT Stencils

SMT stencils are used across various applications in electronics manufacturing:

- Consumer Electronics: From smartphones to home appliances, SMT stencils help assemble compact electronic devices efficiently.

- Automotive Industry: Modern vehicles rely heavily on electronics; thus, accurate soldering facilitated by stencils is crucial for safety and performance.

- Medical Devices: Precision in assembly is vital for medical equipment; therefore, SMT stencils play an essential role in this sector as well.

Advantages of Using SMT Stencils

Integrating SMT stencils into PCB assembly offers several benefits:

- Precision Deposition: SMT stencils ensure precise and uniform solder paste deposition on PCB pads, minimizing solder bridging and ensuring consistent solder joint quality. This precision is essential for reliable electrical connections, enhancing product performance and longevity.

- Enhanced Efficiency: Stencils streamline the PCB assembly process by enabling simultaneous solder paste application across multiple PCBs. This reduces assembly time, accelerates production throughput, and helps manufacturers meet tight deadlines and delivery schedules.

- Flexibility and Adaptability: Modern SMT stencil technologies adapt to diverse PCB designs and component configurations. Customizable stencil designs accommodate fine-pitch components, complex layouts, and varying board thicknesses, supporting the integration of new technologies without compromising quality.

- Environmental Considerations: SMT stencils contribute to sustainability by optimizing resource use and reducing material waste. Improved efficiency and minimized defects reduce energy consumption and carbon emissions. Advanced materials and coatings promote longevity and recyclability, reducing environmental impact.

Challenges Associated with SMT Stencils

Despite their advantages, there are challenges associated with using SMT stencils that require proactive management:

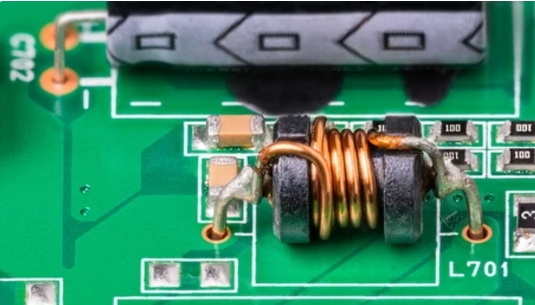

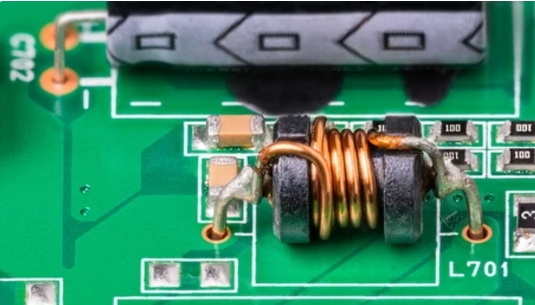

- Stencil Cleaning and Maintenance: Solder paste residue can accumulate in stencil apertures, diminishing print quality and affecting solder paste release. Regular cleaning and maintenance are essential to maintain stencil performance and prolong its life.

- *Solvent Cleaning*: Specialized cleaning agents dissolve and remove solder paste residues effectively.

- *Ultrasonic Cleaning*: High-frequency sound waves agitate cleaning solutions to thoroughly clean intricate stencil designs.

- *Automated Cleaning Systems*: Advanced systems integrate programmable cleaning cycles ensuring consistent results while minimizing human error.

Future Trends in SMT Stencil Technology

As technology advances, so does the design and functionality of SMT stencils:

- Nano-coatings: These coatings improve paste release properties and reduce cleaning frequency, enhancing overall efficiency. For instance, ceramic nano-coatings like NanoSlic Gold increase transfer efficiency while minimizing variation in the printing process.

- Additive Manufacturing: 3D printing technologies allow for custom-designed stencils that can accommodate unique PCB layouts and configurations. This flexibility enables manufacturers to create highly specialized stencils tailored for specific applications or designs.

- Advanced Coating Technologies: Innovations such as Chemical Vapor Deposited (CVD) coatings enhance stencil performance by providing consistent thickness across all areas. This eliminates variations associated with traditional spraying methods, resulting in improved transfer efficiency[2].

Conclusion

In summary, SMT stencils are indispensable tools in modern electronics manufacturing. They enhance precision, efficiency, and quality control during the assembly process. As technology continues to evolve, so too will the capabilities and applications of these stencils. Manufacturers must stay abreast of advancements in stencil technology to maintain competitiveness in a rapidly changing industry. Investing in high-quality stencil technology not only ensures superior product quality but also supports sustainable manufacturing practices that benefit both business operations and environmental goals.

FAQ

1. What materials are used for SMT stencils?

SMT stencils are typically made from stainless steel or nickel alloys due to their durability and resistance to corrosion.

2. How do you clean an SMT stencil?

Cleaning an SMT stencil involves using specialized cleaning solutions or ultrasonic cleaners designed to remove solder paste residues without damaging the stencil material.

3. Can SMT stencils be reused?

Yes, both framed and frameless SMT stencils can be reused multiple times as long as they are properly cleaned after each use.

4. What factors influence stencil design?

Stencil design is influenced by factors such as aperture size, thickness, wall angle, registration features which must all be tailored to specific PCB designs.

5. Why is precision important in solder paste application?

Precision in solder paste application is crucial because it ensures reliable electrical connections while reducing defects that could lead to product failure.

Citations:

[1] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[2] https://www.stentech.com/company/cvd-treatment-for-smt-stencils

[3] https://www.twistedtraces.com/blog/understanding-smt-stencils-the-backbone-of-electronics-manufacturing

[4] https://nagisha.co.id/smt-stencil-roll/

[5] https://www.smthelp.com/3-ways-for-cleaning-smt-stencil-introduction

[6] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/

[7] https://www.lpkfusa.com/fileadmin/mediafiles/user_upload/Knowledge_Center/Conquering_SMT_Stencil_Challenges_2009-03.pdf

[8] https://artist-3d.com/comprehensive-guide-to-smt-stencils/

[9] https://www.oem-pcb.com/news/the-role-of-stencils-in-smt-precision-effici-80830062.html

[10] https://www.pcbx.com/article/SMT-Assembly-Procedure-and-Future-Trends