Content Menu

● Understanding SMT and AOI

● What Is An SMT Offline AOI Machine?

>> Key Features of Offline AOI Machines

● How Does An SMT Offline AOI Machine Work?

● Advantages of Using Offline AOI Machines

● Applications of Offline AOI Machines

● Challenges and Limitations

● Future Trends in Offline AOI Technology

● Conclusion

● FAQ

>> 1. What types of defects can an SMT offline AOI machine detect?

>> 2. How does an offline AOI machine differ from an inline AOI machine?

>> 3. Can an offline AOI machine improve production efficiency?

>> 4. Is manual intervention still required when using an offline AOI machine?

>> 5. What factors should be considered when selecting an offline AOI machine?

In the rapidly evolving world of electronics manufacturing, ensuring the quality and reliability of products is paramount. One critical technology that has emerged in this context is the Automated Optical Inspection (AOI) machine, particularly in its offline configuration. This article will delve into what an SMT offline AOI machine is, how it operates, its advantages, challenges, and its role in the manufacturing process.

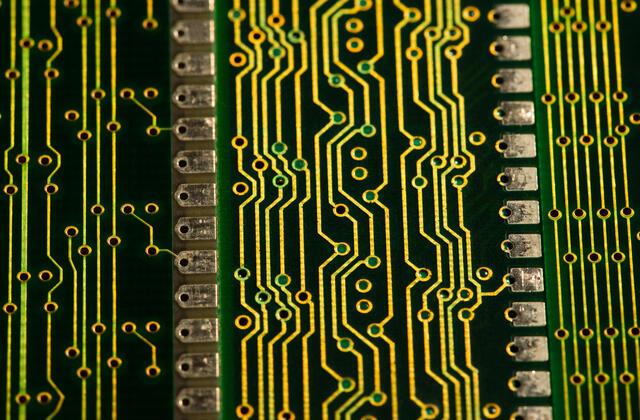

Understanding SMT and AOI

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technique has become the standard in electronics manufacturing due to its efficiency and ability to accommodate smaller components. SMT allows for higher component density, enabling manufacturers to create more compact devices that are lighter and more powerful.

Automated Optical Inspection (AOI) refers to the use of optical devices to inspect PCBs for defects. AOI machines can be categorized into two types: inline AOI, which inspects PCBs as they move through the production line, and offline AOI, which inspects finished boards after they have been assembled. Offline AOI machines are particularly valuable for their ability to provide a thorough inspection without interrupting the flow of production.

What Is An SMT Offline AOI Machine?

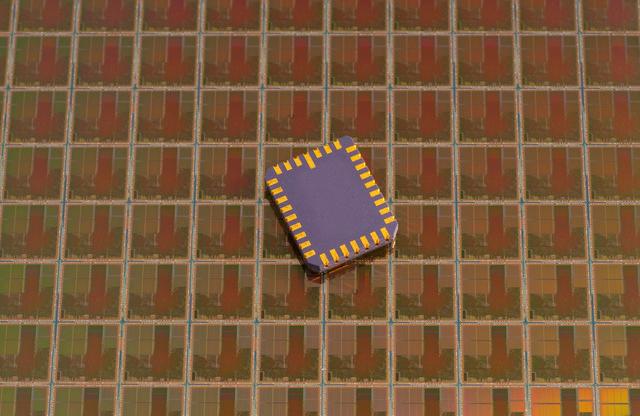

An SMT offline AOI machine is a standalone inspection device that evaluates PCBs after they have undergone assembly but before they are packaged or shipped. These machines utilize high-resolution cameras and sophisticated software algorithms to detect defects such as misplaced components, solder joint issues, and other anomalies.

Key Features of Offline AOI Machines

- High-Resolution Imaging: Offline AOIs use advanced cameras to capture detailed images of PCBs from multiple angles. This multi-angle imaging ensures that even the smallest defects can be detected.

- Image Processing Algorithms: The captured images are analyzed against a predefined standard or "golden board" to identify any discrepancies. These algorithms can differentiate between acceptable variations and actual defects.

- Flexible Inspection Capabilities: These machines can detect a wide range of defects, including incorrect component placement, soldering issues, and more. They can be programmed to inspect various PCB designs, making them versatile tools in manufacturing.

- Data Logging and Reporting: Offline AOIs can log inspection results for quality control and process improvement purposes. This data can be invaluable for identifying trends in defects over time.

How Does An SMT Offline AOI Machine Work?

The operation of an SMT offline AOI machine involves several steps:

1. Image Acquisition: The machine captures images of the PCB using high-resolution cameras. Multiple angles are often used to ensure comprehensive coverage.

2. Image Processing: The software analyzes the captured images using algorithms that compare them against a reference model. Any deviations are flagged as potential defects.

3. Defect Identification: The machine identifies various defect types such as missing components, incorrect orientations, insufficient solder, or other issues. Advanced algorithms allow for distinguishing between different types of defects based on their characteristics.

4. Feedback Mechanism: If defects are detected, the machine provides detailed feedback to operators for corrective action. This may involve reworking or replacing faulty components.

5. Reporting: After inspection, the machine generates reports detailing defect types and locations, which can be used for further analysis and process optimization.

6. Integration with Manufacturing Systems: Many offline AOI machines can be integrated with other manufacturing systems such as Enterprise Resource Planning (ERP) software. This integration allows for seamless data sharing across departments and enhances overall production efficiency.

Advantages of Using Offline AOI Machines

The implementation of offline AOI machines in SMT manufacturing offers several benefits:

- Improved Quality Control: By detecting defects early in the production process, manufacturers can address issues before they escalate into larger problems. This proactive approach minimizes waste and reduces costs associated with rework.

- Cost Efficiency: Automated inspection reduces reliance on manual labor for quality checks, which can be time-consuming and prone to human error. This not only saves labor costs but also speeds up the inspection process.

- Increased Production Efficiency: Offline AOIs can operate at high speeds without slowing down production lines, enabling rapid inspection of multiple boards. This efficiency is crucial in meeting tight production schedules.

- Comprehensive Data Analysis: The ability to log inspection data allows manufacturers to identify trends and make informed decisions about process improvements. Analyzing this data can lead to better quality control practices and enhanced product reliability.

- Flexibility in Production: Since offline AOIs are not tied to a specific production line, they offer flexibility in how inspections are scheduled and conducted. Manufacturers can adapt their inspection processes based on current production needs without disrupting ongoing operations.

Applications of Offline AOI Machines

Offline AOI machines are versatile tools used in various stages of PCB assembly:

- Pre-Reflow Inspection: After solder paste application but before component placement, offline AOIs can verify that solder paste has been applied correctly. This step is crucial as it sets the foundation for successful soldering during reflow.

- Post-Reflow Inspection: After components have been soldered onto the PCB, offline AOIs check for proper placement and solder joint integrity. This ensures that all components are securely attached and functioning as intended.

- Final Quality Assurance: Before products leave the manufacturing facility, offline AOIs conduct final inspections to ensure compliance with quality standards. This step is vital for maintaining customer satisfaction and brand reputation.

- Prototype Testing: During the development phase of new products, offline AOIs can be used to test prototypes for design flaws or assembly issues before mass production begins.

Challenges and Limitations

While offline AOI machines provide significant benefits, there are challenges associated with their use:

- False Positives/Negatives: The accuracy of defect detection can be affected by variations in component design or manufacturing processes, leading to false alarms or missed defects. Continuous calibration and updates to software algorithms may be necessary to mitigate these issues.

- Programming Complexity: Setting up an offline AOI machine requires expertise in programming and understanding specific inspection criteria for different PCB designs. Manufacturers may need specialized personnel or training programs to ensure effective use of these systems.

- Cost Considerations: Initial investment in high-quality offline AOI systems can be substantial; however, they often pay off through improved efficiency and reduced defect rates over time. Manufacturers must weigh these costs against potential savings from reduced rework and improved product quality.

- Maintenance Requirements: Like any sophisticated machinery, offline AOI machines require regular maintenance to ensure optimal performance. This includes cleaning optical components and updating software as needed.

Future Trends in Offline AOI Technology

As technology continues to advance, several trends are shaping the future of offline AOI machines:

- Artificial Intelligence (AI) Integration: The incorporation of AI into image processing algorithms promises enhanced defect detection capabilities by learning from past inspections and adapting to new designs over time.

- 3D Inspection Technologies: Emerging 3D inspection technologies allow for more comprehensive analysis of PCBs by providing depth information that traditional 2D imaging cannot capture. This advancement could lead to even higher accuracy in defect detection.

- Increased Automation: Future offline AOI systems may feature greater automation capabilities, including automated setup processes that reduce programming time and improve overall efficiency.

- IoT Connectivity: The Internet of Things (IoT) is expected to play a significant role in future manufacturing processes. Offline AOIs could become part of interconnected systems that share real-time data across various stages of production for enhanced decision-making.

Conclusion

In conclusion, SMT offline AOI machines play a vital role in ensuring the quality and reliability of electronic products. By automating the inspection process, these machines help manufacturers detect defects early, reduce labor costs, and improve overall production efficiency. As technology continues to advance with innovations such as AI integration and IoT connectivity, we can expect further enhancements in offline AOI capabilities, making them an indispensable tool in modern electronics manufacturing.

FAQ

1. What types of defects can an SMT offline AOI machine detect?

Offline AOI machines can detect various defects such as missing components, incorrect polarity, insufficient or excessive solder, misalignment, bridging issues among others.

2. How does an offline AOI machine differ from an inline AOI machine?

An offline AOI machine operates outside the main production line and inspects completed PCBs after assembly while inline AOIs inspect boards continuously as they move through the production line.

3. Can an offline AOI machine improve production efficiency?

Yes, by identifying defects early in the assembly process, offline AOIs help reduce rework costs and improve overall production efficiency by ensuring high-quality outputs before final assembly stages.

4. Is manual intervention still required when using an offline AOI machine?

While offline AOIs automate much of the inspection process, manual intervention may still be needed for addressing flagged defects or conducting further investigations based on inspection results.

5. What factors should be considered when selecting an offline AOI machine?

When choosing an offline AOI system, consider factors such as resolution capabilities, software features for data analysis, ease of programming, cost-effectiveness, and support from the manufacturer.