Content Menu

● Understanding SMT Component Reels

>> Structure and Design

>> Types of SMT Component Reels

● The Role of SMT Component Reels in Manufacturing

>> Automated Assembly

>> Component Organization and Protection

>> Inventory Management

● SMT Component Reel Specifications

>> Reel Dimensions

>> Tape Width

>> Component Pitch

● The SMT Reel in the Manufacturing Process

>> Loading the Reel

>> Component Pickup

>> Placement on the PCB

>> Reflow Soldering

● Advantages of Using SMT Component Reels

● Challenges and Considerations

>> Moisture Sensitivity

>> Component Alignment

>> Reel Changes

>> Static Electricity

● Future Trends in SMT Component Reels

● Conclusion

● FAQ

>> 1. What is the difference between SMT and through-hole technology?

>> 2. How many components can a typical SMT reel hold?

>> 3. What is the purpose of the leader on an SMT component reel?

>> 4. How are SMT component reels stored to prevent damage?

>> 5. Can SMT component reels be reused?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more efficient, and cost-effective electronic devices. At the heart of this technology lies a crucial component: the SMT component reel. This article will delve into the world of SMT component reels, exploring their purpose, types, and significance in modern electronics manufacturing.

Understanding SMT Component Reels

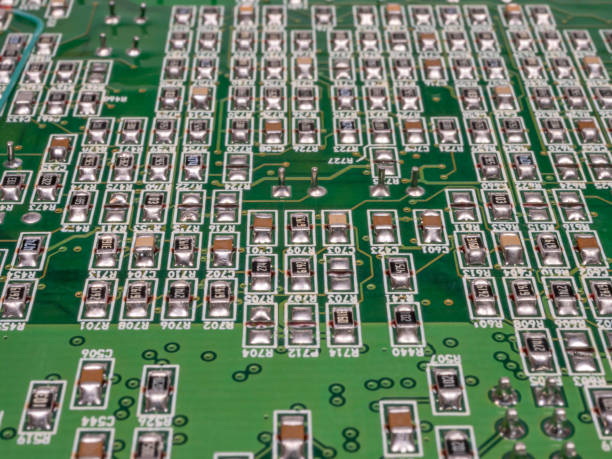

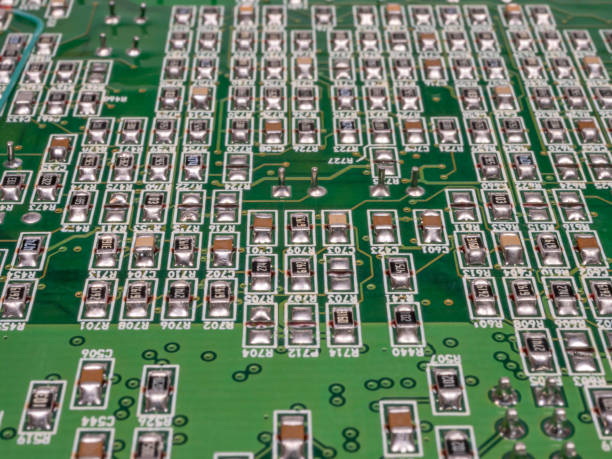

SMT component reels are specialized storage and dispensing devices used in the surface mount technology manufacturing process. These reels hold and organize surface mount components, such as resistors, capacitors, and integrated circuits, in a way that allows for efficient and automated placement onto printed circuit boards (PCBs)[1][2].

Structure and Design

SMT component reels typically consist of a plastic or cardboard spool that houses a long strip of tape. This tape contains pockets or cavities at regular intervals, each holding an individual SMT component. The reel's design ensures that components are protected during storage and transportation while remaining easily accessible for automated pick-and-place machines during the assembly process[3].

Types of SMT Component Reels

There are several types of SMT component reels, each designed to accommodate different component sizes and quantities:

1. Full Reels: These are the most common and efficient type, containing up to 10,000 components on a single reel. Full reels can hold up to 20 yards of continuous tape, making them ideal for high-volume production[6].

2. Mini Reels: Often used for higher-value components or smaller production runs, mini reels contain fewer components than full reels. They are a cost-effective option when only a specific number of parts are needed[6].

3. Cut Tape: For very low volume production or prototyping, cut tape is used. This is essentially a section of tape cut from a full reel, containing a smaller number of components[6].

The Role of SMT Component Reels in Manufacturing

SMT component reels play a crucial role in the efficiency and accuracy of electronic manufacturing processes. Their design and functionality contribute significantly to the advantages of SMT over traditional through-hole technology.

Automated Assembly

One of the primary benefits of using SMT component reels is the ability to automate the assembly process. Pick-and-place machines can rapidly and accurately retrieve components from the reels and place them onto PCBs. Some advanced placement machines can place over 136,000 components per hour, significantly increasing production speed and efficiency[5].

Component Organization and Protection

SMT reels help keep components organized and protected during storage and transportation. The tape's pockets securely hold each component, preventing damage and ensuring that components remain in the correct orientation for placement[2].

Inventory Management

The use of reels simplifies inventory management in electronics manufacturing. Each reel typically contains a known quantity of components, making it easier to track stock levels and plan for production needs[3].

SMT Component Reel Specifications

Understanding the specifications of SMT component reels is crucial for ensuring compatibility with manufacturing equipment and processes.

Reel Dimensions

SMT component reels come in various sizes, with common diameters including 7", 13", and 15". The choice of reel size depends on factors such as component size, quantity needed, and the specifications of the pick-and-place equipment being used[2].

Tape Width

The width of the tape used in SMT component reels varies depending on the size of the components it holds. Common tape widths include 8mm, 12mm, 16mm, and 24mm. Larger components generally require wider tape[2].

Component Pitch

The pitch refers to the distance between the centers of adjacent components on the tape. This specification is crucial for ensuring proper alignment during the pick-and-place process[3].

The SMT Reel in the Manufacturing Process

To fully appreciate the importance of SMT component reels, it's essential to understand their role in the manufacturing process.

Loading the Reel

The process begins with loading the SMT component reel into the pick-and-place machine. Most modern machines have multiple reel feeders, allowing for the simultaneous use of various component types[6].

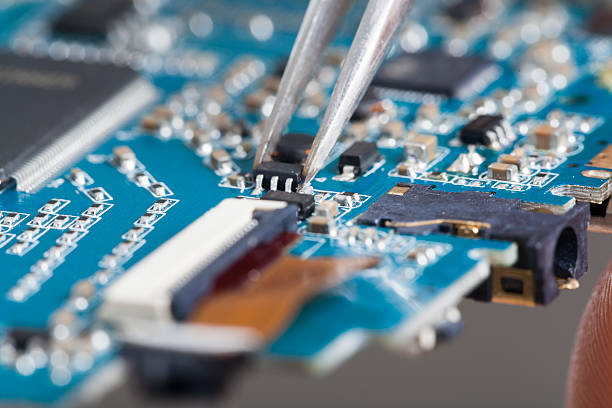

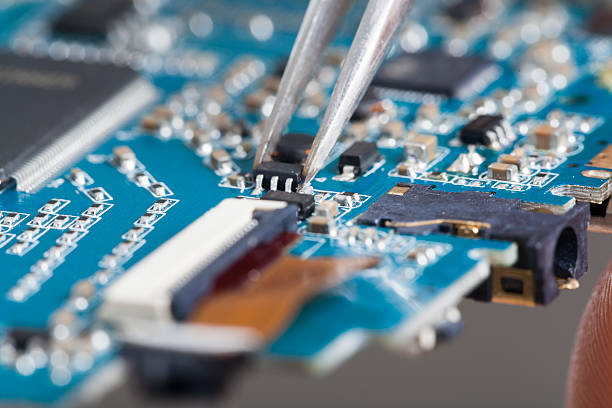

Component Pickup

As the PCB moves into position, the pick-and-place machine's nozzle retrieves components from the reel. The machine uses vision systems and precise positioning to ensure accurate placement[1].

Placement on the PCB

Once picked up, the component is quickly moved to its designated position on the PCB. The machine's precision allows for high-density placement, contributing to the compact design of modern electronic devices[5].

Reflow Soldering

After all components are placed, the PCB undergoes reflow soldering. This process melts the solder paste, creating permanent electrical connections between the components and the board[1].

Advantages of Using SMT Component Reels

The use of SMT component reels offers numerous advantages in electronic manufacturing:

1. Increased Production Speed: The automated nature of SMT assembly, facilitated by component reels, allows for much faster production compared to manual or through-hole assembly methods[5].

2. Higher Component Density: SMT allows for more components to be placed in a given area, leading to smaller, more compact electronic devices[5].

3. Improved Accuracy: Automated placement from reels ensures consistent and accurate positioning of components, reducing errors and improving product quality[1].

4. Cost-Effectiveness: While the initial setup cost for SMT manufacturing can be high, the increased speed and efficiency lead to lower per-unit costs in high-volume production[5].

5. Flexibility: SMT reels can accommodate a wide range of component types and sizes, allowing for greater design flexibility in electronic products[2].

Challenges and Considerations

While SMT component reels offer many benefits, there are also challenges to consider:

Moisture Sensitivity

Some SMT components are sensitive to moisture and can be damaged if exposed to humid conditions for extended periods. Proper storage and handling of reels are crucial to maintain component integrity[3].

Component Alignment

Ensuring proper alignment of components on the tape is critical. Misaligned components can lead to pickup errors or incorrect placement on the PCB[6].

Reel Changes

In high-volume production, frequent reel changes may be necessary. This can lead to downtime if not managed efficiently. Some manufacturers use splicing techniques to join reels, minimizing production interruptions[7].

Static Electricity

SMT components can be sensitive to static electricity. Proper ESD (Electrostatic Discharge) protection measures must be in place when handling and storing component reels[2].

Future Trends in SMT Component Reels

As electronics manufacturing continues to evolve, so too will the technology surrounding SMT component reels. Some potential future developments include:

1. Smart Reels: Integration of RFID or other tracking technologies to improve inventory management and traceability.

2. Eco-Friendly Materials: Development of more sustainable materials for reel and tape construction to reduce environmental impact.

3. Increased Automation: Further advancements in automated reel handling and splicing to minimize human intervention and increase efficiency.

4. Miniaturization: As components continue to shrink, reel and tape designs may evolve to accommodate even smaller parts.

Conclusion

SMT component reels are an integral part of modern electronics manufacturing, enabling the efficient and accurate placement of components onto PCBs. Their design and functionality contribute significantly to the advantages of surface mount technology, including increased production speed, higher component density, and improved accuracy.

As the electronics industry continues to evolve, with demands for smaller, more complex devices, the role of SMT component reels will remain crucial. Understanding their specifications, proper usage, and potential challenges is essential for anyone involved in electronics manufacturing or design.

The future of SMT component reels is likely to see further innovations, driven by the need for greater efficiency, sustainability, and the ability to handle increasingly miniaturized components. As we move forward, these seemingly simple storage devices will continue to play a vital role in shaping the landscape of electronic product manufacturing.

FAQ

1. What is the difference between SMT and through-hole technology?

Surface Mount Technology (SMT) involves placing components directly onto the surface of a PCB, while through-hole technology requires components to be inserted through holes in the board. SMT allows for higher component density, faster assembly, and often results in smaller, more compact devices[5].

2. How many components can a typical SMT reel hold?

The number of components on an SMT reel can vary widely depending on the component size and reel dimensions. Full reels can hold up to 10,000 components, while mini reels or cut tape may contain significantly fewer[6].

3. What is the purpose of the leader on an SMT component reel?

The leader is the starting section of tape on an SMT component reel. It feeds into the pick-and-place machine but typically doesn't contain components. The leader's purpose is to allow the machine to properly engage with the tape without wasting components[6].

4. How are SMT component reels stored to prevent damage?

SMT component reels should be stored in a controlled environment to protect against moisture and static electricity. Many manufacturers use dry cabinets or moisture-barrier bags with desiccants for moisture-sensitive components. ESD-safe containers are also used to prevent static damage[2].

5. Can SMT component reels be reused?

While the plastic or cardboard reel itself can potentially be reused, the tape containing components is typically a single-use item. Once all components have been used, the empty tape is discarded. Some manufacturers may have recycling programs for empty reels[3].

Citations:

[1] https://global.neotel.tech/2023/01/04/smt-reel-rack-from-the-past-to-the-future/

[2] https://global.neotel.tech/2023/01/05/what-is-smt-reel-storage-solution/

[3] https://global.neotel.tech/2022/02/24/5-things-you-must-know-about-smt-reel/

[4] https://developers.google.com/search/docs/appearance/structured-data/product-snippet?hl=zh-cn

[5] https://en.wikipedia.org/wiki/Surface-mount_technology

[6] https://www.youtube.com/watch?v=f1ALETP6sAs

[7] https://www.khj.com.cn/news/the-ultimate-guide-to-smt-splicing-tape-everything-you-need-to-know-143816.html

[8] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[9] https://jhdpcb.com/blog/smt-manufacturing-technology/