Content Menu

● Introduction

● What is SMT?

>> Benefits of SMT

● Role of an SMT Machine Operator

>> 1. Operating SMT Machines

>> 2. Quality Control

>> 3. Maintenance and Troubleshooting

>> 4. Programming Machines

>> 5. Collaboration with Other Departments

● Required Skills for an SMT Machine Operator

>> Technical Skills

>> Personal Attributes

● Training and Education

● Career Prospects

● Trends Impacting SMT Machine Operators

>> Automation in Manufacturing

>> Miniaturization of Components

>> Advanced Inspection Technologies

>> Sustainability Initiatives

>> Industry 4.0 Integration

● Challenges Faced by SMT Machine Operators

>> Component Placement Errors

>> Material Management Issues

>> Soldering Challenges

>> Keeping Up with Technological Advances

● Conclusion

● FAQ

>> 1. What qualifications do I need to become an SMT machine operator?

>> 2. What types of machines do SMT operators work with?

>> 3. Is there room for advancement in this career?

>> 4. What skills are essential for success as an SMT machine operator?

>> 5. How does quality control fit into the role of an SMT machine operator?

● Citations:

Introduction

In the fast-paced world of electronics manufacturing, the role of a Surface Mount Technology (SMT) machine operator is crucial. These skilled professionals are responsible for the operation and maintenance of machines that place electronic components onto printed circuit boards (PCBs). As technology advances and the demand for electronic devices continues to grow, the importance of SMT machine operators is more pronounced than ever. This article will explore the responsibilities, required skills, training, and career prospects for SMT machine operators, as well as answering common questions about this profession.

What is SMT?

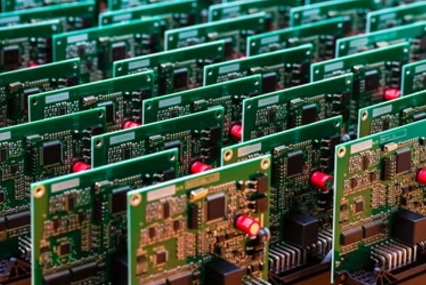

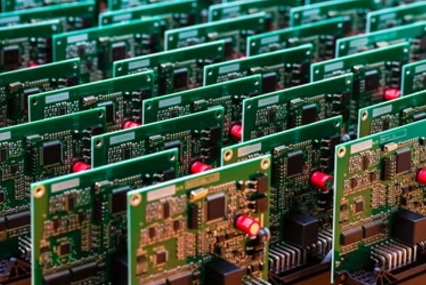

Surface Mount Technology (SMT) is a method used in electronics manufacturing to mount components directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes on the board, SMT allows for a more compact design and higher component density. This technology has revolutionized the electronics industry by enabling faster production times and reducing costs.

Benefits of SMT

- Higher Component Density: SMT allows for smaller components to be placed closer together, which is essential for modern electronic devices.

- Reduced Manufacturing Costs: The ability to automate the placement process leads to lower labor costs and faster production cycles.

- Improved Performance: SMT components typically have better electrical performance due to shorter lead lengths and reduced parasitic effects.

Role of an SMT Machine Operator

An SMT machine operator plays a vital role in ensuring that electronic components are accurately placed on PCBs. Their responsibilities typically include:

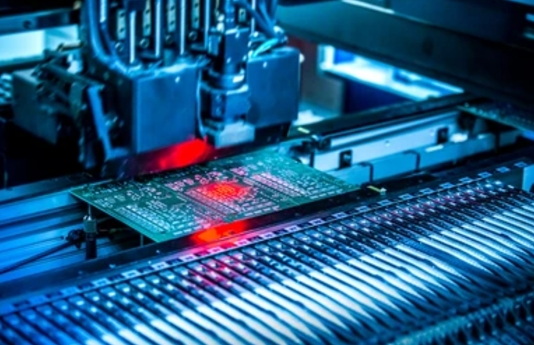

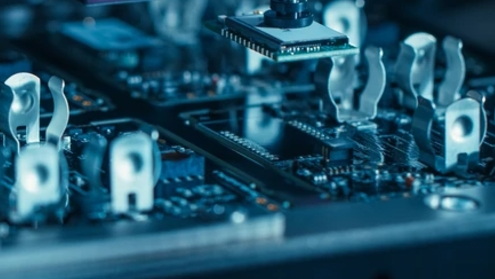

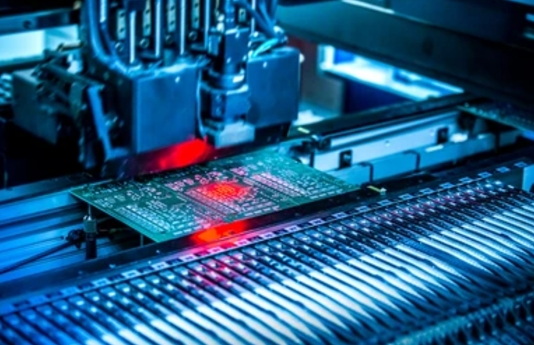

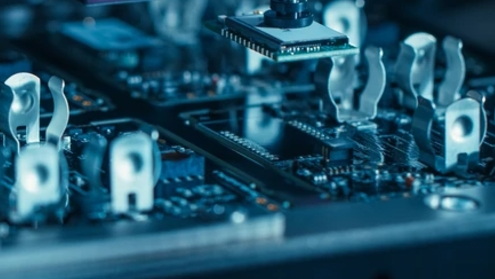

1. Operating SMT Machines

Operators are trained to run various types of SMT machines, including pick-and-place machines, solder paste printers, and reflow ovens. They must be familiar with the specific models used in their facility and understand how to adjust settings for different production runs.

2. Quality Control

Quality assurance is a significant part of an SMT operator's job. They must inspect PCBs for defects, such as misaligned components or soldering issues. Operators often use microscopes and other tools to ensure that each board meets quality standards.

3. Maintenance and Troubleshooting

Regular maintenance of SMT machines is essential for optimal performance. Operators are responsible for cleaning machines, replacing worn parts, and troubleshooting issues that may arise during production. This requires a solid understanding of both mechanical and electrical systems.

4. Programming Machines

In many cases, operators must program the machines to recognize different components and adjust placement parameters accordingly. This involves using specialized software and requires attention to detail.

5. Collaboration with Other Departments

SMT machine operators often work closely with engineers and production managers to optimize processes and resolve any issues that may occur during manufacturing.

Required Skills for an SMT Machine Operator

To excel as an SMT machine operator, individuals must possess a combination of technical skills and personal attributes:

Technical Skills

- Mechanical Aptitude: A strong understanding of machinery is essential for operating and maintaining SMT equipment.

- Attention to Detail: Precision is critical in electronics manufacturing; even minor errors can lead to significant defects.

- Problem-Solving Skills: Operators must be able to troubleshoot issues quickly to minimize downtime.

Personal Attributes

- Team Player: Collaboration with colleagues across various departments is vital for success.

- Adaptability: The electronics industry evolves rapidly; operators must be willing to learn new technologies and processes.

- Strong Work Ethic: Reliability and dedication are key traits for maintaining production schedules.

Training and Education

While some companies may hire individuals with no prior experience, most employers prefer candidates who have completed relevant training programs or possess an associate degree in electronics or a related field. Training programs typically cover:

- Basics of electronics

- Operation of SMT machinery

- Quality control procedures

- Safety protocols in manufacturing environments

Additionally, on-the-job training is common, allowing new operators to learn from experienced colleagues.

Career Prospects

The demand for skilled SMT machine operators is expected to grow as the electronics industry continues to expand. Potential career paths include:

- Senior SMT Operator: With experience, operators can advance to senior positions where they oversee teams or manage production lines.

- Process Engineer: Some operators choose to transition into engineering roles focused on improving manufacturing processes.

- Quality Assurance Specialist: Operators with a keen eye for detail may find opportunities in quality control departments.

According to industry reports, job growth in this field is projected to remain strong due to ongoing advancements in technology and increasing consumer demand for electronic devices.

Trends Impacting SMT Machine Operators

As technology evolves, several trends are shaping the landscape of surface mount technology and impacting the role of SMT machine operators:

Automation in Manufacturing

Automation has become a cornerstone of modern manufacturing processes. The integration of robotic pick-and-place machines and automated soldering systems streamlines assembly operations, enhancing efficiency while reducing human error. As automation continues to advance, operators will need to adapt by learning how to work alongside these technologies effectively[1][2].

Miniaturization of Components

The trend towards smaller electronic devices necessitates the use of ultra-miniature components in PCB assembly. This miniaturization presents challenges in handling and placing these tiny parts accurately. Operators must develop skills in precision handling techniques and utilize advanced machinery capable of managing these intricate designs[4][7].

Advanced Inspection Technologies

With increasing demands for defect-free products, sophisticated inspection technologies are being integrated into SMT processes. High-resolution cameras and machine learning algorithms allow real-time defect detection during assembly. Operators will need training on these advanced systems to ensure quality control standards are met[7][8].

Sustainability Initiatives

As environmental concerns grow within the electronics industry, sustainability practices are becoming more critical. Operators may find themselves involved in initiatives aimed at reducing waste and energy consumption during manufacturing processes[1][6]. Understanding eco-friendly practices will become increasingly important as companies strive to meet regulatory standards.

Industry 4.0 Integration

The concept of Industry 4.0 emphasizes smart factories where machines communicate with each other through IoT technologies. This shift requires operators not only to manage physical machinery but also engage with data analytics tools that optimize production workflows[10]. Familiarity with these technologies will enhance operational efficiency.

Challenges Faced by SMT Machine Operators

Despite the rewarding nature of being an SMT machine operator, several challenges exist within this profession:

Component Placement Errors

One common issue faced by operators is component placement errors caused by miscalibrated machines or incorrect component feeders. These errors can lead to circuit malfunctions or board failures[9]. Regular calibration and maintenance are essential in minimizing such risks.

Material Management Issues

Effective material management is crucial in preventing stock shortages or excess inventory situations. Poor tracking can lead to missing parts or inefficient use of resources[3]. Operators must be adept at monitoring material flow throughout the production process.

Soldering Challenges

Soldering issues such as solder bridges or cold solder joints can compromise product reliability[9]. Operators need thorough training on soldering techniques and regular maintenance of soldering equipment to mitigate these problems.

Keeping Up with Technological Advances

As new technologies emerge within the industry, continuous learning becomes vital for operators who want to remain competitive in their field[10]. Companies often provide ongoing training opportunities; however, individual initiative is also crucial for professional growth.

Conclusion

The role of an SMT machine operator is integral to the success of modern electronics manufacturing. With responsibilities ranging from operating complex machinery to ensuring quality control, these professionals play a vital part in producing reliable electronic products. As technology evolves alongside consumer demands, so too will the skills required for this position—making it an exciting field for those interested in pursuing a career in electronics manufacturing.

In summary, being an SMT machine operator offers not only a stable career but also opportunities for advancement in a rapidly growing industry that values innovation and adaptability.

FAQ

1. What qualifications do I need to become an SMT machine operator?

Most employers prefer candidates with an associate degree in electronics or related fields along with relevant training programs that provide necessary skills.

2. What types of machines do SMT operators work with?

SMT operators typically work with pick-and-place machines, solder paste printers, reflow ovens, and inspection equipment.

3. Is there room for advancement in this career?

Yes, experienced SMT operators can advance to senior positions or transition into roles such as process engineers or quality assurance specialists.

4. What skills are essential for success as an SMT machine operator?

Key skills include mechanical aptitude, attention to detail, problem-solving abilities, teamwork, adaptability, and a strong work ethic.

5. How does quality control fit into the role of an SMT machine operator?

Quality control is a significant responsibility; operators must inspect PCBs for defects and ensure all products meet industry standards before shipping.

Citations:

[1] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[2] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[3] https://www.criticalmanufacturing.com/blog/material-optimization-in-the-smt-and-electronics-assembly-industries/

[4] https://www.raypcb.com/surface-mount-technology/

[5] https://www.globenewswire.com/news-release/2024/10/14/2962707/0/en/Surface-Mount-Technology-Equipment-SMT-Market-to-Surge-to-8-32-Billion-by-2028-Global-Long-term-Forecast-to-2033.html

[6] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[7] https://www.verifiedmarketreports.com/blog/top-7-trends-in-surface-mount-technology-smt-equipment/

[8] https://itbrief.asia/story/smt-market-to-reach-usd-16-8-billion-by-2034-fmi

[9] https://www.andwinpcba.com/smt-patching-common-issues-and-challenges/

[10] https://www.zjyingxing.com/info/what-is-the-future-of-smt-machine-82208106.html