Content Menu

● The Role of SMT Reel Trays in Electronics Manufacturing

● Emerging Innovations in SMT Reel Tray Design

>> 1. Smart Storage Solutions

>> 2. Modular and Flexible Designs

>> 3. Enhanced Material Handling

>> 4. High-Density Storage

>> 5. Automation and Robotics Integration

● Advantages of Innovative SMT Reel Tray Designs

● Challenges in Adopting New Technologies

● Conclusion

● FAQ Section

>> 1. What is an SMT reel tray?

>> 2. How do smart SMT reel trays improve efficiency?

>> 3. What materials are used in advanced SMT reel trays?

>> 4. Can traditional storage systems be upgraded to smart storage?

>> 5. What industries benefit most from innovative SMT reel tray designs?

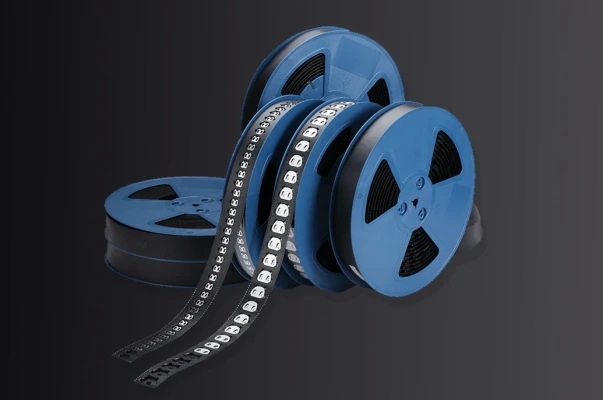

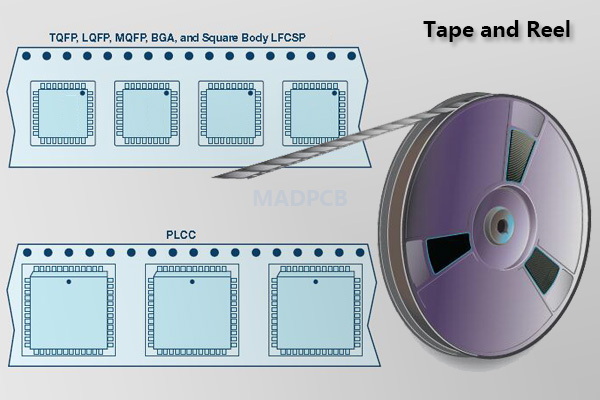

Surface Mount Technology (SMT) has revolutionized electronics manufacturing by enabling the efficient placement of components onto printed circuit boards (PCBs). Among the critical elements in this process are SMT reel trays, which store and organize components for automated assembly. As the demand for miniaturization, efficiency, and precision grows, innovations in SMT reel tray design are pushing the boundaries of what is possible. This article explores the latest advancements and trends in SMT reel tray technology.

The Role of SMT Reel Trays in Electronics Manufacturing

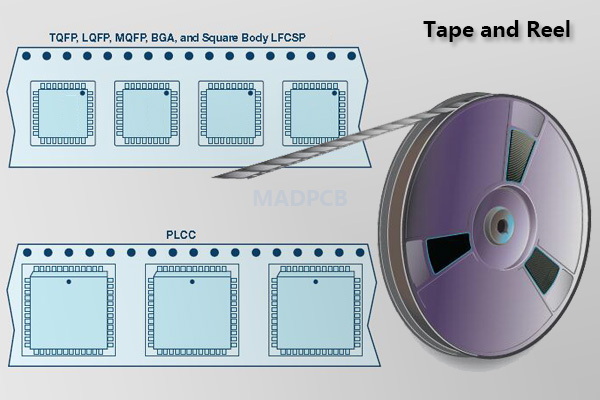

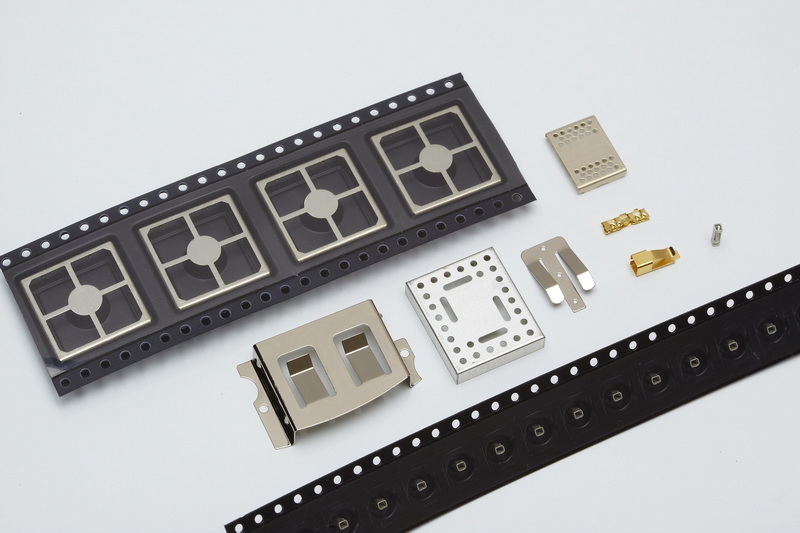

SMT reel trays are integral to the assembly process, ensuring that components are stored securely and dispensed efficiently. These trays are designed to work seamlessly with pick-and-place machines, enabling high-speed and accurate placement of components like resistors, capacitors, and integrated circuits onto PCBs. Key benefits include:

- Space Optimization: By organizing components vertically or horizontally, SMT reel trays maximize storage space.

- Automation Compatibility: Modern trays are designed to integrate with automated systems, reducing manual labor.

- Component Protection: Advanced designs protect sensitive electronic components from environmental factors like moisture and static electricity.

In addition to these core functions, SMT reel trays play a pivotal role in maintaining production flow. Efficient storage systems minimize downtime by ensuring quick access to required components. This is especially critical in industries such as automotive manufacturing, telecommunications, and consumer electronics, where high-volume production demands precision and speed.

Emerging Innovations in SMT Reel Tray Design

1. Smart Storage Solutions

Smart SMT reel trays leverage advanced technologies such as sensors, LED indicators, and software integration to enhance efficiency. For instance:

- Real-Time Tracking: Smart systems can detect when reels are added or removed and update inventory data automatically.

- Lighting Guidance: LED indicators highlight specific reels for quick retrieval, reducing picking errors.

- Integration with ERP/MES Systems: These trays can connect to enterprise resource planning (ERP) and manufacturing execution systems (MES), streamlining inventory management.

Smart storage solutions not only improve operational efficiency but also enable predictive maintenance. By monitoring usage patterns and environmental conditions, manufacturers can identify potential issues before they impact production.

2. Modular and Flexible Designs

Modular SMT reel trays allow manufacturers to customize storage configurations based on their needs. Features include:

- Adjustable compartments for different reel sizes (e.g., 7-inch or 13-inch reels).

- Modular shelving systems that enable rapid assembly and disassembly.

- Compatibility with mixed storage formats, such as combining reels with trays or sticks for diverse component types.

The adaptability of modular designs makes them ideal for facilities that produce a wide range of products. Manufacturers can reconfigure storage layouts quickly to accommodate changes in production schedules or component types.

3. Enhanced Material Handling

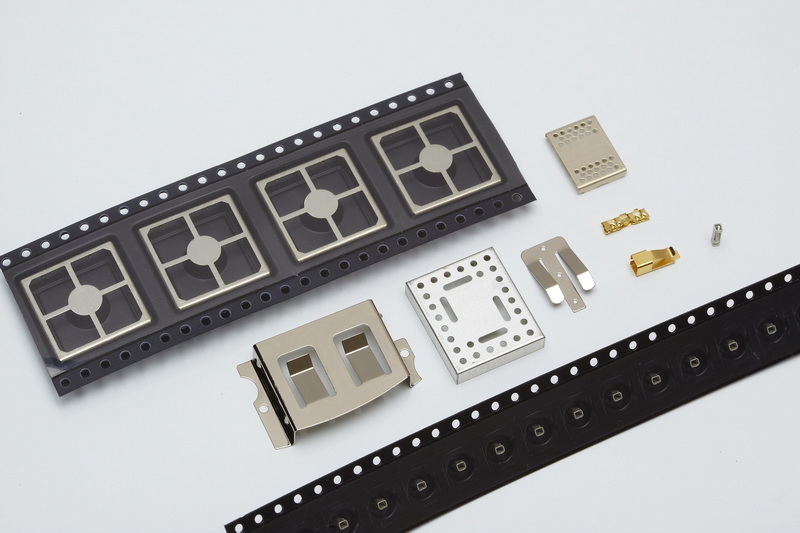

Innovations in material handling aim to reduce errors and improve efficiency:

- Automated Loading/Unloading: Some systems now include trolleys or robotic arms for automated transport of reels between storage and production lines.

- Moisture Control: Desiccator cabinets with nitrogen atmospheres protect sensitive components from humidity.

- Static Protection: Advanced materials and coatings prevent electrostatic discharge, safeguarding delicate electronics during handling.

Enhanced material handling solutions also improve worker safety by reducing manual lifting tasks. For example, automated loading systems eliminate the need for operators to carry heavy reels across production floors.

4. High-Density Storage

To address space constraints in manufacturing facilities, high-density storage solutions are becoming popular:

- Vertical carousels optimize the use of vertical space while maintaining easy access to reels.

- Compact designs allow hundreds of reels to be stored per square foot without compromising accessibility.

High-density storage systems are particularly beneficial for small-scale manufacturers who need to maximize productivity within limited physical spaces. These solutions also reduce clutter on production floors, improving overall organization.

5. Automation and Robotics Integration

The integration of robotics into SMT reel tray systems is transforming material handling:

- AI-powered machine vision enhances pick-and-place accuracy by identifying specific components on reels.

- Automated guided vehicles (AGVs) transport reels autonomously within production facilities, reducing manual intervention.

Robotics integration is driving significant improvements in efficiency and accuracy. By automating repetitive tasks like reel transportation and component identification, manufacturers can focus their workforce on higher-value activities such as quality control or system optimization.

Advantages of Innovative SMT Reel Tray Designs

These advancements offer several benefits:

1. Increased Efficiency: Automated systems reduce setup times and improve throughput.

2. Cost Savings: By minimizing labor costs and errors, manufacturers achieve significant savings.

3. Scalability: Modular designs enable easy expansion as production demands grow.

4. Enhanced Reliability: Improved component protection ensures higher product quality.

5. Sustainability: Many new designs incorporate eco-friendly materials or energy-efficient technologies that align with green manufacturing practices.

In addition to these advantages, innovative SMT reel tray designs contribute to better traceability during production cycles. With real-time tracking capabilities, manufacturers can monitor the movement of components throughout their facilities, ensuring compliance with industry standards.

Challenges in Adopting New Technologies

Despite their advantages, innovative SMT reel tray designs come with challenges:

1. Initial Costs: Advanced systems often require significant upfront investment.

2. Training Requirements: Operators need training to use new technologies effectively.

3. Compatibility Issues: Ensuring compatibility with existing equipment can be complex.

4. Maintenance Needs: High-tech systems may require specialized maintenance procedures that increase operational costs.

To overcome these challenges, manufacturers should conduct thorough cost-benefit analyses before adopting new technologies. Partnering with experienced suppliers who offer robust support services can also help mitigate risks associated with implementation.

Conclusion

The evolution of SMT reel tray design reflects the broader trends in electronics manufacturing—automation, miniaturization, and efficiency. From smart storage solutions to robotic integration, these innovations are transforming how manufacturers handle components during assembly. As technology continues to advance, we can expect even more sophisticated solutions that address current limitations while further enhancing productivity.

By adopting cutting-edge SMT reel tray designs, manufacturers gain a competitive edge in fast-paced industries where precision and speed are paramount. Whether through smart systems that track inventory automatically or modular layouts that adapt to changing needs, these innovations represent the future of efficient electronics manufacturing.

FAQ Section

1. What is an SMT reel tray?

An SMT reel tray is a storage solution used in electronics manufacturing to hold and organize surface mount components on reels. These trays facilitate efficient component dispensing for pick-and-place machines during PCB assembly.

2. How do smart SMT reel trays improve efficiency?

Smart SMT reel trays use technologies like sensors, LED indicators, and software integration to automate inventory tracking, guide operators during component retrieval, and reduce errors in material handling.

3. What materials are used in advanced SMT reel trays?

Modern SMT reel trays often use industrial-grade materials like aluminum alloys for durability and lightweight construction. Some also feature anti-static coatings to protect sensitive components from electrostatic discharge.

4. Can traditional storage systems be upgraded to smart storage?

Yes, many manufacturers offer modular upgrades that integrate smart features like lighting guidance and real-time tracking into existing storage systems.

5. What industries benefit most from innovative SMT reel tray designs?

Industries such as consumer electronics, automotive manufacturing (especially electric vehicles), telecommunications (e.g., 5G devices), and healthcare (e.g., medical sensors) benefit significantly from these advancements due to their need for precision and efficiency.