Content Menu

● Introduction to SMT Reel Shelving

● Emerging Trends in SMT Reel Shelving

>> 1. Automation and AI Integration

>> 2. IoT and Real-Time Tracking

>> 3. Modular and Scalable Designs

>> 4. Sustainability and Eco-Friendliness

>> 5. Integration with Manufacturing Systems

● Key Features of Advanced SMT Reel Shelving

● Examples of Innovative SMT Reel Shelving Solutions

● Future of SMT Reel Shelving

● Impact on Manufacturing Efficiency

● Sustainability and Environmental Considerations

● Conclusion

● FAQ

>> 1. What are the benefits of using automated SMT reel shelving systems?

>> 2. How does IoT technology enhance SMT reel shelving?

>> 3. What role does AI play in SMT reel shelving?

>> 4. How does modularity impact SMT reel shelving systems?

>> 5. What are some key features of high-quality SMT reel shelving systems?

● Citations:

The field of Surface Mount Technology (SMT) is witnessing significant advancements, particularly in the realm of reel shelving technology. As electronics manufacturing continues to evolve, the need for efficient, intelligent, and sustainable storage solutions has become paramount. This article explores the emerging innovations in SMT reel shelving, focusing on key technologies and trends that are transforming the industry.

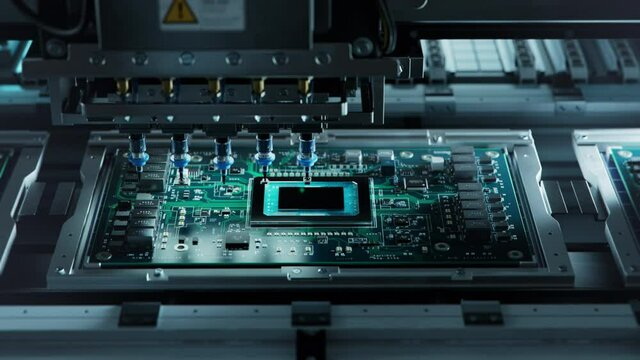

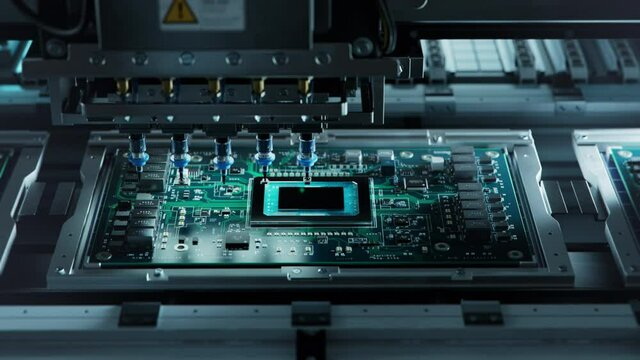

Introduction to SMT Reel Shelving

SMT reel shelving is a critical component of electronics manufacturing, providing a structured method for storing and managing reels of electronic components. These reels contain components such as resistors, capacitors, and ICs, which are mounted directly onto the surface of printed circuit boards (PCBs). Effective storage and management of these reels are essential for maintaining production efficiency, reducing errors, and ensuring component integrity.

Emerging Trends in SMT Reel Shelving

1. Automation and AI Integration

One of the most significant innovations in SMT reel shelving is the integration of automation and artificial intelligence (AI). Automated storage and retrieval systems (AS/RS) equipped with robotics and AI algorithms are revolutionizing inventory management by minimizing human error and optimizing space utilization. These systems can track component usage patterns, predict demand, and automate restocking processes, thereby enhancing production efficiency and reducing downtime.

For instance, Accu-Assembly Inc.'s AccuLiFT™ system is based on the traditional Vertical Lift Module (VLM) but includes specialized features for handling SMT component reels. It offers automated loading and unloading capabilities, significantly enhancing operational efficiency[1]. Similarly, Inovaxe's Smart Storage Solutions utilize sensors and LEDs to detect reel additions or removals, allowing for real-time tracking and efficient access to components[2].

2. IoT and Real-Time Tracking

The integration of Internet of Things (IoT) devices into SMT reel shelving systems enables real-time tracking of inventory levels and component conditions. Sensors embedded in storage racks monitor environmental factors such as humidity and temperature, ensuring that components remain in optimal condition. This proactive approach not only protects inventory but also aligns with sustainability goals by reducing waste and optimizing supply chains.

IoT integration also supports predictive maintenance, allowing manufacturers to identify potential issues before they disrupt production. This capability is crucial for maintaining operational continuity and reducing downtime[3].

3. Modular and Scalable Designs

Modern SMT reel shelving solutions are designed to be modular and scalable, allowing manufacturers to easily expand or reconfigure their storage systems as production demands change. This modularity is crucial for maintaining operational flexibility and reducing the need for complete system replacements as businesses grow.

Inovaxe's solutions, for example, allow for daisy-chaining multiple units together to increase capacity without requiring significant additional space[6]. Similarly, ASYS Group's Dry Tower system offers a modular design that can be adapted to various storage needs, ensuring long-term investment security[7].

4. Sustainability and Eco-Friendliness

There is a growing emphasis on sustainability in the electronics sector, with manufacturers adopting eco-friendly practices to minimize environmental impact. SMT reel shelving systems are being designed to optimize space, reduce waste, and utilize energy-efficient technologies, aligning with global sustainability goals.

The use of automated systems reduces manual handling, which not only minimizes worker fatigue but also decreases the risk of component damage, thereby reducing electronic waste[3].

5. Integration with Manufacturing Systems

High-quality SMT reel shelving systems often integrate with various manufacturing systems, including Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and Automated Guided Vehicles (AGVs). This integration enhances automation and efficiency by enabling seamless data exchange and workflow automation, which is critical for maintaining operational agility and competitiveness.

Accu-Assembly's AccuLiFT™ and AccuCart™ systems, for instance, use the same database to manage inventory, supporting Just-in-Time (JIT) delivery and ensuring inventory accuracy[1]. Similarly, Neo Light Plus integrates with MES, WMS, and ERP systems to streamline material handling processes[5].

Key Features of Advanced SMT Reel Shelving

Advanced SMT reel shelving systems incorporate several key features that enhance operational efficiency and component protection:

- Space Optimization: Vertical storage solutions like Vertical Carousel Modules (VCMs) and Vertical Lift Modules (VLMs) maximize vertical space, saving up to 85% of floor space compared to traditional shelving systems[3].

- Efficient Inventory Management: Integration with inventory management software provides real-time tracking of component quantities, locations, and usage history, ensuring accurate stock levels and reducing the risk of production delays[3].

- Component Protection: Features such as temperature control, humidity regulation, and ESD protection maintain the integrity and longevity of stored components by preventing damage from environmental factors[3].

- Modularity and Scalability: Modular designs allow for easy expansion or reconfiguration as storage needs change, providing a cost-effective solution for growing businesses[3].

Examples of Innovative SMT Reel Shelving Solutions

Several companies are at the forefront of innovation in SMT reel shelving technology:

- Accu-Assembly Inc.'s AccuLiFT™ and AccuCart™: These systems offer flexible storage configurations and automated loading/unloading capabilities, enhancing operational efficiency and inventory management[1].

- Inovaxe's Smart Storage Solutions: These solutions utilize sensors and LEDs to detect reel additions or removals, allowing for real-time tracking and efficient access to components[2].

- ASYS Group's Dry Tower: This fully automated system provides controlled storage and re-drying of moisture-sensitive components, ensuring their integrity and optimizing material logistics[7].

Future of SMT Reel Shelving

As the electronics manufacturing sector continues to evolve, the future of SMT reel shelving will be shaped by technological advancements, sustainability, and the need for operational agility. The integration of AI, IoT, and automation will remain critical for enhancing efficiency, reducing waste, and ensuring component integrity.

Manufacturers are increasingly adopting intelligent storage solutions that optimize space, reduce waste, and enhance operational efficiency. The integration of AI and IoT technologies into these systems is revolutionizing inventory management by providing real-time tracking and predictive analytics, which help in optimizing production cycles and reducing downtime[3].

Impact on Manufacturing Efficiency

The adoption of advanced SMT reel shelving systems has a profound impact on manufacturing efficiency. By optimizing storage space, automating inventory management, and integrating with manufacturing systems, these solutions significantly reduce production downtime and enhance workflow efficiency.

For example, Inovaxe's solutions can reduce kitting time from hours to minutes and provide a return on investment (ROI) within 3 to 6 months[2]. Similarly, ASYS Group's Dry Tower system has been instrumental in minimizing search and waiting times, allowing companies to handle high growth without additional manpower[7].

Sustainability and Environmental Considerations

The emphasis on sustainability in SMT reel shelving is not only about reducing waste and optimizing space but also about adopting energy-efficient technologies. By minimizing manual handling and reducing the need for extensive storage facilities, manufacturers can lower their carbon footprint and align their operations with global environmental goals.

Moreover, the use of automated systems reduces the risk of component damage, which in turn reduces electronic waste. This approach supports a circular economy by ensuring that components are used efficiently and effectively throughout their lifecycle.

Conclusion

Innovations in SMT reel shelving technology are transforming the electronics manufacturing landscape by offering more efficient, intelligent, and sustainable storage solutions. As manufacturers continue to adopt advanced technologies, the importance of these systems will only grow, driving operational efficiency and competitiveness in the industry.

FAQ

1. What are the benefits of using automated SMT reel shelving systems?

Automated SMT reel shelving systems offer several benefits, including space optimization, improved inventory management, enhanced productivity, and reduced risk of component damage. They also provide real-time tracking and integration with manufacturing systems, leading to cost savings and improved efficiency.

2. How does IoT technology enhance SMT reel shelving?

IoT technology enhances SMT reel shelving by enabling real-time tracking of inventory levels and component conditions. Sensors monitor environmental factors, ensuring components remain in optimal condition and aligning with sustainability goals by reducing waste and optimizing supply chains.

3. What role does AI play in SMT reel shelving?

AI plays a crucial role in optimizing SMT reel shelving by analyzing usage patterns and predicting demand. This predictive capability minimizes downtime and ensures production lines remain operational, enhancing overall productivity.

4. How does modularity impact SMT reel shelving systems?

Modularity in SMT reel shelving systems allows for easy expansion or reconfiguration as storage needs change. This scalability is cost-effective, eliminating the need for complete system replacements as businesses grow and ensuring operational flexibility.

5. What are some key features of high-quality SMT reel shelving systems?

High-quality SMT reel shelving systems typically include features such as space optimization, efficient inventory management, component protection (e.g., temperature control, ESD protection), and modularity. They also integrate with various manufacturing systems to enhance automation and efficiency.

Citations:

[1] https://smttoday.com/2024/05/29/accu-assembly-inc-expands-component-storage-management-with-acculift-and-accucart-products/

[2] https://inovaxe.com/smt-reel-storage/

[3] https://www.gssmt-parts.com/what-are-the-key-features-of-high-quality-smt-reel-storage-systems.html

[4] https://smttoday.com/2025/02/20/inovaxe-to-unveil-smart-storage-technologies-at-apex/

[5] https://accelonix.co.uk/product/smt-component-storage-rack-position-checking/

[6] https://inovaxe.com

[7] https://www.asys-group.com/en/products/smart-factory/material-logistics/central-storage-systems

[8] https://inovaxe.com/optimize-storage-efficiency-with-inovaxe-at-smtai-2024/

[9] https://www.ilink-digital.com/insights/blog/top-10-technology-trends-shaping-2025-transformations-across-industries/

[10] https://www.valuespectrum.com/corporate_news/1221053-trends-shaping-the-15-4-billion-smart-shelves-industry-2025-2030-rising-demand-for-retail-automation-fuels-adoption-advancements-in-iot-sensors-propel-innovation

[11] https://www.smthelp.com/smt-reel-storage-solution.html

[12] https://robopacusa.com/the-top-packaging-trends-well-see-in-2025/

[13] https://www.linkedin.com/pulse/future-surface-mount-technology-smt-industry-key-trends-p-virkhe-zxnyf

[14] https://www.azom.com/news.aspx?newsID=63084

[15] https://www.openpr.com/news/3823072/global-smart-shelves-market-2025-exponential-growth-driven

[16] https://www.globalsmt.net/trade-show-news/accu-assembly-to-debut-accucart-smart-rack-for-feeders-at-apex-2025/

[17] https://www.msesupplies.com/products/mse-pro-870l-smt-reel-storage-cabinet-1-60-rh

[18] https://www.thebusinessresearchcompany.com/report/smart-shelves-global-market-report

[19] https://www.allsmt.com/electronic-manufacturing-innovations-2025

[20] https://smt.asmpt.com/en/products/storage-solutions/material-tower/