Content Menu

● The Evolution of PCB Solder Paste Stencil Technology

>> Laser-Cut Stencils: Precision Redefined

>> Electroformed Stencils: Durability Meets Precision

● Automation and Industry 4.0: Revolutionizing Stencil Production and Use

>> Automated Stencil Design and Production

>> Smart Stencil Printing Systems

● Eco-Friendly Innovations in the PCB Solder Paste Stencil Market

>> Lead-Free Solder Paste Compatibility

>> Sustainable Stencil Materials

● Miniaturization and High-Density Interconnect (HDI) Challenges

>> Ultra-Fine Pitch Stencils

>> 3D Printed Stencils

● Market Growth and Future Prospects

● Regional Market Dynamics

>> Asia-Pacific: The Manufacturing Powerhouse

>> North America and Europe: Focus on Innovation

● Challenges and Opportunities

>> Challenges:

>> Opportunities:

● Conclusion

● FAQs

>> 1. What is the current market size of the PCB SMT solder paste stencils market?

>> 2. How are laser-cut stencils improving PCB assembly processes?

>> 3. What role does automation play in the PCB solder paste stencil market?

>> 4. How is the trend towards miniaturization affecting stencil design?

>> 5. What are the key challenges facing the PCB solder paste stencil market?

● Citations:

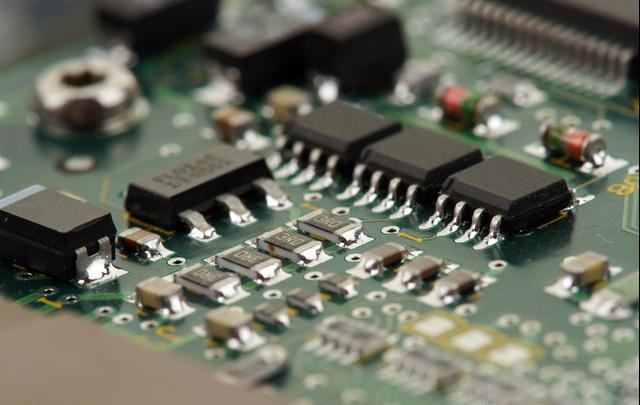

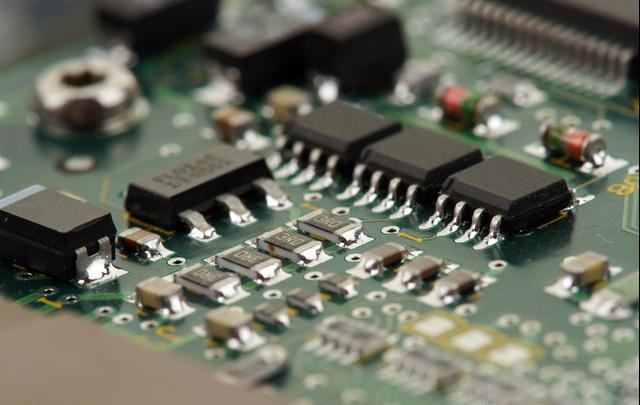

The PCB solder paste stencil market is experiencing significant growth and transformation, driven by a wave of innovations that are reshaping the electronics manufacturing industry. As the demand for smaller, more complex electronic devices continues to rise, the need for precise and efficient solder paste application has become paramount. This article explores the cutting-edge innovations propelling the PCB SMT solder paste stencils market forward, examining their impact on productivity, quality, and overall market growth.

The Evolution of PCB Solder Paste Stencil Technology

The PCB solder paste stencil market has come a long way from its humble beginnings. Traditional stencils have given way to more sophisticated solutions that cater to the increasing complexity of modern electronic devices. The evolution of this technology is closely tied to the advancements in the broader electronics industry, particularly in the realm of miniaturization and high-density circuit designs.

Laser-Cut Stencils: Precision Redefined

One of the most significant innovations in the PCB SMT solder paste stencils market is the widespread adoption of laser-cut stencils. These stencils offer unparalleled precision, crucial for the fine-pitch components that are becoming increasingly common in modern electronics[1]. Laser cutting technology allows for the creation of apertures with incredibly tight tolerances, ensuring accurate solder paste deposition even for the most demanding applications.

The advantages of laser-cut stencils include:

- Enhanced accuracy for fine-pitch components

- Improved consistency in solder paste volume

- Ability to create complex aperture designs

- Reduced risk of solder bridging

As the industry continues to push the boundaries of miniaturization, laser-cut stencils are becoming indispensable for manufacturers seeking to maintain high quality and yield rates in their PCB assembly processes.

Electroformed Stencils: Durability Meets Precision

Another innovative approach in the PCB solder paste stencil market is the development of electroformed stencils. These stencils are created through an electroplating process that results in a highly durable and precise product. Electroformed stencils are particularly well-suited for high-volume production environments where longevity and consistent performance are critical[5].

Key benefits of electroformed stencils include:

- Exceptional durability for extended production runs

- Superior paste release properties

- Ability to create ultra-fine apertures

- Excellent repeatability across large production volumes

The adoption of electroformed stencils has enabled manufacturers to achieve higher throughput and lower defect rates, contributing to the overall growth of the PCB SMT solder paste stencils market.

Automation and Industry 4.0: Revolutionizing Stencil Production and Use

The integration of automation and Industry 4.0 technologies is transforming the PCB solder paste stencil market, driving efficiency and precision to new heights. These advancements are not only improving the production of stencils but also enhancing their application in the PCB assembly process.

Automated Stencil Design and Production

Artificial Intelligence (AI) and Machine Learning (ML) are being increasingly employed in the design and production of solder paste stencils. These technologies enable:

- Rapid optimization of stencil designs based on PCB layout data

- Predictive maintenance for stencil production equipment

- Automated quality control processes

By leveraging AI and ML, manufacturers can significantly reduce design time, minimize errors, and improve overall stencil quality[3].

Smart Stencil Printing Systems

The PCB SMT solder paste stencils market is also benefiting from the development of smart stencil printing systems. These systems incorporate sensors and real-time data analysis to:

- Adjust printing parameters on-the-fly

- Detect and correct misalignments

- Monitor solder paste volume and viscosity

- Provide feedback for continuous process improvement

These smart systems not only enhance the precision of solder paste application but also contribute to reduced waste and improved overall efficiency in PCB assembly.

Eco-Friendly Innovations in the PCB Solder Paste Stencil Market

As sustainability becomes an increasingly important focus in manufacturing, the PCB solder paste stencil market is responding with eco-friendly innovations. These developments are not only beneficial for the environment but also align with global regulations and consumer preferences.

Lead-Free Solder Paste Compatibility

The shift towards lead-free solder pastes has necessitated innovations in stencil design and materials. New stencil technologies are being developed to:

- Improve the release properties for lead-free pastes

- Enhance the thermal stability of stencils during the reflow process

- Reduce the risk of solder balling and bridging associated with lead-free solders

These advancements are crucial for manufacturers looking to comply with RoHS and other environmental regulations while maintaining high-quality standards in their PCB assembly processes[2].

Sustainable Stencil Materials

Research into sustainable materials for stencil production is gaining momentum. Innovations in this area include:

- Biodegradable coatings for improved paste release

- Recyclable stencil materials

- Energy-efficient production processes

These eco-friendly innovations not only reduce the environmental impact of stencil production but also offer potential cost savings for manufacturers in the long run.

Miniaturization and High-Density Interconnect (HDI) Challenges

The trend towards miniaturization in electronics continues to push the boundaries of what's possible in PCB design. This trend presents both challenges and opportunities for the PCB SMT solder paste stencils market.

Ultra-Fine Pitch Stencils

To address the needs of high-density interconnect (HDI) boards, manufacturers are developing ultra-fine pitch stencils. These stencils feature:

- Apertures as small as 0.3mm or less

- Enhanced surface treatments for improved paste release

- Specialized designs to prevent paste bridging

The development of these ultra-fine pitch stencils is crucial for the production of next-generation electronic devices, including smartphones, wearables, and advanced automotive electronics[4].

3D Printed Stencils

3D printing technology is making inroads into the PCB solder paste stencil market, offering new possibilities for complex designs. 3D printed stencils provide:

- Rapid prototyping capabilities

- The ability to create unique aperture shapes

- Customization for specific PCB layouts

While still in its early stages, 3D printing technology holds promise for revolutionizing stencil production, especially for low-volume, high-mix manufacturing environments.

Market Growth and Future Prospects

The innovations driving the PCB solder paste stencil market are contributing to significant market growth. According to recent market research, the global PCB SMT solder paste stencils market is expected to grow from $2.61 billion in 2024 to $3.6 billion by 2032, with a compound annual growth rate (CAGR) of 4.12%[2].

Several factors are contributing to this growth:

- Increasing demand for consumer electronics and IoT devices

- Growth in the automotive electronics sector, particularly with the rise of electric vehicles

- Expansion of 5G infrastructure and telecommunications equipment

- Advancements in medical electronics and wearable devices

As these industries continue to evolve and demand more sophisticated PCB assemblies, the PCB solder paste stencil market is poised for continued innovation and growth.

Regional Market Dynamics

The PCB solder paste stencil market exhibits distinct regional dynamics, with Asia-Pacific emerging as the dominant player. This regional leadership is primarily due to the concentration of electronics manufacturing hubs in countries like China, Japan, and South Korea[5].

Asia-Pacific: The Manufacturing Powerhouse

The Asia-Pacific region's dominance in the PCB SMT solder paste stencils market is characterized by:

- High volume production capabilities

- Presence of major consumer electronics manufacturers

- Rapid adoption of advanced manufacturing technologies

- Government initiatives supporting electronics manufacturing

As the region continues to invest in advanced manufacturing capabilities, it is likely to maintain its leading position in the global market.

North America and Europe: Focus on Innovation

While Asia-Pacific leads in production volume, North America and Europe are at the forefront of innovation in the PCB solder paste stencil market. These regions are characterized by:

- Strong focus on research and development

- Leadership in developing eco-friendly manufacturing processes

- Early adoption of Industry 4.0 technologies

- Emphasis on high-precision, low-volume production

The innovations emerging from these regions often set the stage for global trends in the PCB SMT solder paste stencils market.

Challenges and Opportunities

Despite the positive growth outlook, the PCB solder paste stencil market faces several challenges that present opportunities for further innovation:

Challenges:

1. Increasing complexity of PCB designs

2. Demand for ever-finer pitch components

3. Pressure to reduce manufacturing costs

4. Environmental regulations and sustainability concerns

Opportunities:

1. Development of advanced materials for improved stencil performance

2. Integration of AI and ML for optimized stencil design and production

3. Creation of multi-functional stencils for complex assembly processes

4. Expansion into emerging markets and applications, such as flexible electronics

Addressing these challenges through innovative solutions will be key to sustaining growth in the PCB SMT solder paste stencils market.

Conclusion

The PCB solder paste stencil market is undergoing a period of rapid innovation and growth, driven by advancements in technology and changing demands in the electronics industry. From laser-cut and electroformed stencils to the integration of AI and automation, these innovations are reshaping the landscape of PCB assembly processes.

As the market continues to evolve, manufacturers who embrace these innovations and adapt to the changing needs of the industry will be well-positioned for success. The future of the PCB SMT solder paste stencils market looks promising, with opportunities for growth across various sectors and regions.

The ongoing focus on miniaturization, sustainability, and efficiency will likely spur further innovations in the coming years, ensuring that the PCB solder paste stencil market remains a dynamic and crucial component of the electronics manufacturing ecosystem.

FAQs

1. What is the current market size of the PCB SMT solder paste stencils market?

The global PCB SMT solder paste stencils market was valued at approximately $2.61 billion in 2024 and is projected to reach $3.6 billion by 2032, growing at a CAGR of 4.12% during this period[2].

2. How are laser-cut stencils improving PCB assembly processes?

Laser-cut stencils offer enhanced precision for fine-pitch components, improved consistency in solder paste volume, and the ability to create complex aperture designs. These advantages result in reduced solder bridging and higher quality PCB assemblies, particularly for miniaturized electronic devices[1].

3. What role does automation play in the PCB solder paste stencil market?

Automation is revolutionizing the PCB solder paste stencil market by enabling rapid optimization of stencil designs, predictive maintenance for production equipment, and automated quality control processes. Smart stencil printing systems also incorporate real-time data analysis to adjust printing parameters and detect misalignments, leading to improved efficiency and reduced waste[3].

4. How is the trend towards miniaturization affecting stencil design?

The trend towards miniaturization is driving the development of ultra-fine pitch stencils with apertures as small as 0.3mm or less. These stencils often feature enhanced surface treatments and specialized designs to prevent paste bridging, catering to the needs of high-density interconnect (HDI) boards used in next-generation electronic devices[4].

5. What are the key challenges facing the PCB solder paste stencil market?

The main challenges include increasing complexity of PCB designs, demand for finer pitch components, pressure to reduce manufacturing costs, and compliance with environmental regulations. These challenges present opportunities for innovation in materials, design processes, and manufacturing techniques to meet the evolving needs of the electronics industry[5].

Citations:

[1] https://sites.google.com/view/stratosphererobotics/stratos-robotics/pcb-solder-paste-stencil-market-by-application

[2] https://www.wiseguyreports.com/reports/pcb-smt-solder-paste-stencils-market

[3] https://www.openpr.com/news/3803725/pcb-solder-paste-stencil-market-size-trends-2031-by-key-players

[4] https://www.24marketreports.com/semiconductor-and-electronics/global-pcb-smt-solder-paste-stencils-forecast-2024-2030-209

[5] https://www.pcbdirectory.com/news/pcb-solder-paste-stencil-market-to-witness-steady-growth-driven-by-electronics-and-miniaturization-trends

[6] https://www.marketresearchintellect.com/product/pcb-solder-paste-stencil-market/

[7] https://www.verifiedmarketreports.com/product/pcb-solder-paste-stencil-market/

[8] https://datahorizzonresearch.com/pcb-solder-paste-stencil-market-20625