Content Menu

● Understanding SMT Stencil Racks

● Key Features to Look for in Used SMT Stencil Racks

>> 1. Secure and Dedicated Slots for Stencil Frames

>> 2. Protection Against Contamination

>> 3. Durable Material and Construction

>> 4. Space Efficiency and Capacity

>> 5. Ease of Access and Organization

>> 6. Adjustable Shelves or Dividers

>> 7. Mobility Features

>> 8. Anti-Static Properties

>> 9. Integration with Production Workflow

>> 10. Condition and Maintenance History

● Additional Considerations When Purchasing Used SMT Stencil Racks

>> Compatibility with Your Stencil Frame Types

>> Environmental Conditions and Storage Location

>> Budget and Cost-Benefit Analysis

>> Vendor Reputation and Support

● Benefits of Using Used SMT Stencil Racks

● Best Practices for Using SMT Stencil Racks

● Conclusion

● FAQ

>> 1. What are used SMT stencil racks?

>> 2. Why is it important to protect SMT stencils in racks?

>> 3. Can used SMT stencil racks be integrated with digital tracking systems?

>> 4. How do I ensure the used SMT stencil rack fits my stencil frames?

>> 5. What maintenance is required for SMT stencil racks?

Surface Mount Technology (SMT) stencil racks are essential tools in electronics manufacturing, designed to store and organize SMT stencils securely. When considering used SMT stencil racks, it is crucial to evaluate specific features that ensure the protection, accessibility, and longevity of your valuable stencil assets. This comprehensive guide will explore the key features to look for in used SMT stencil racks, helping you make an informed decision that enhances your SMT assembly line efficiency and stencil management.

Understanding SMT Stencil Racks

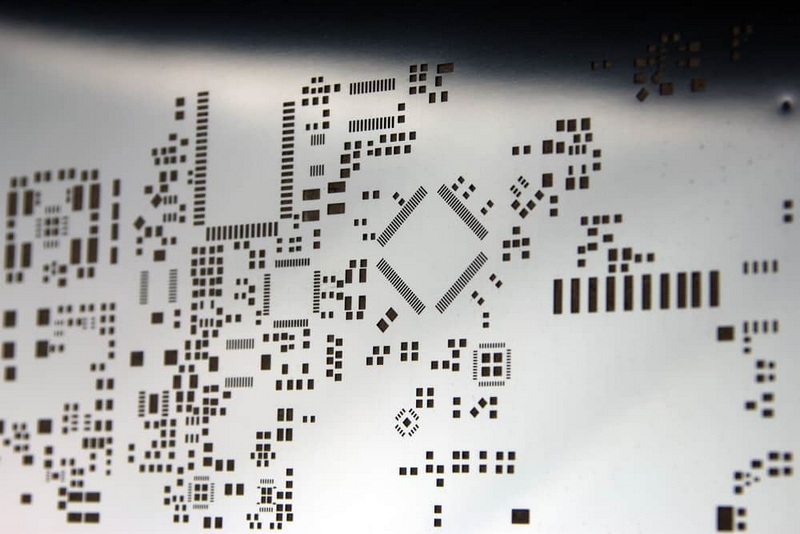

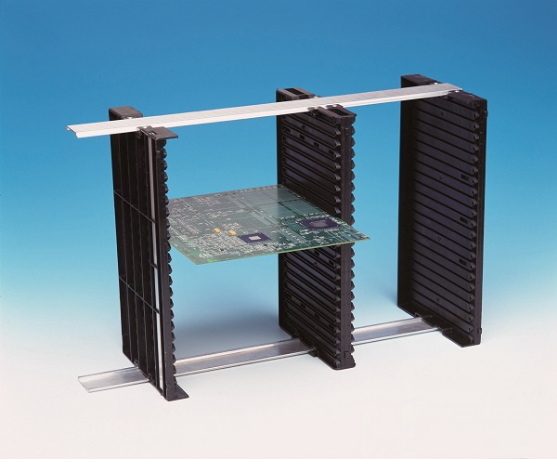

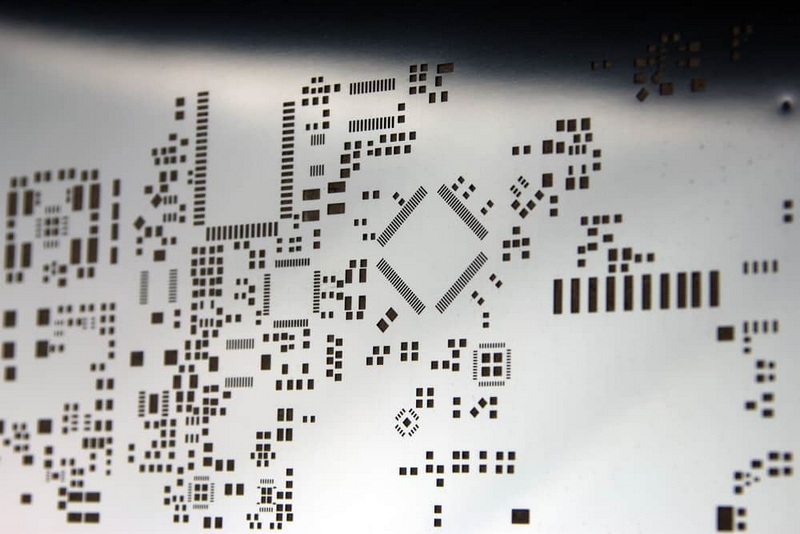

SMT stencil racks are specialized storage units designed to hold framed SMT stencils safely. These racks protect stencils from physical damage such as bending, scratching, and warping, as well as from environmental contaminants like dust, solder paste residue, and humidity. Proper storage is vital because even minor damage to a stencil can alter aperture dimensions, leading to inconsistent solder paste application and defective solder joints.

Used SMT stencil racks offer a cost-effective solution for manufacturers looking to organize their stencil inventory without the expense of new equipment. However, selecting the right used rack requires careful consideration of several features to ensure it meets your operational needs.

Key Features to Look for in Used SMT Stencil Racks

1. Secure and Dedicated Slots for Stencil Frames

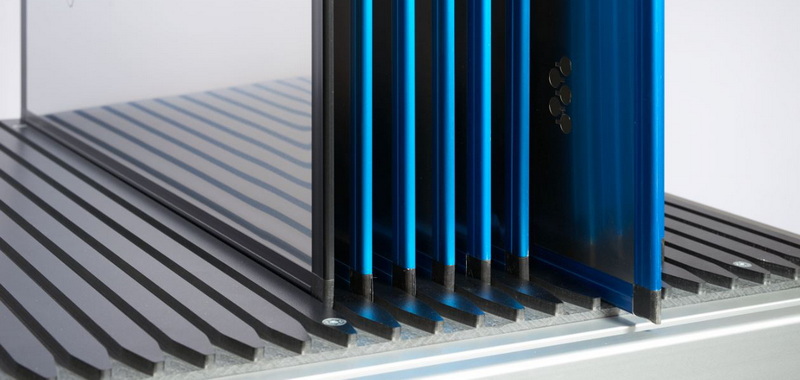

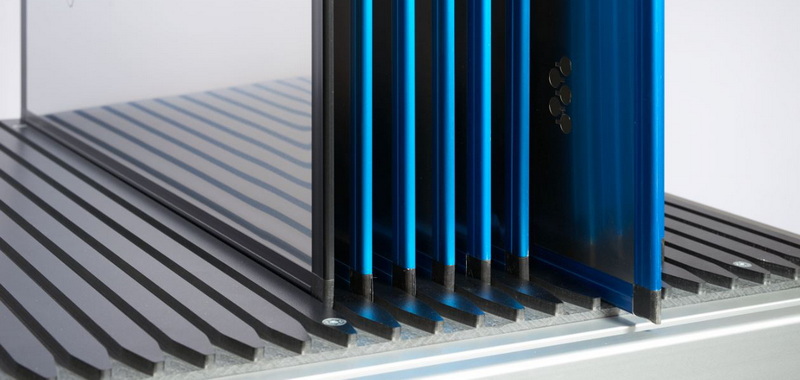

One of the most critical features of an SMT stencil rack is the presence of secure, dedicated slots or compartments for each stencil frame. These slots prevent stencils from bending or scratching by holding them firmly in place. When evaluating a used stencil rack, check that the slots are appropriately sized for your stencil frames and that they provide sufficient support to avoid warping.

The design of these slots should allow stencils to slide in and out smoothly without forcing, which can cause damage over time. Additionally, racks with cushioned or coated slot edges can further protect stencil frames from abrasion. When buying used SMT stencil racks, inspect the slot condition carefully to ensure they have not been deformed or worn down.

2. Protection Against Contamination

Used SMT stencil racks should offer protection from dust, solder paste residue, and humidity. Some racks come with covers or are designed to be placed in controlled environments to minimize exposure to contaminants that can cause corrosion or degrade stencil performance. Ensure that the used rack you consider has features or accessories that help maintain a clean storage environment.

In addition to physical covers, some stencil racks are designed with airflow considerations to prevent moisture buildup, which can lead to rust or oxidation on stencil frames. If your manufacturing environment experiences high humidity or dust levels, prioritize racks that help mitigate these risks.

3. Durable Material and Construction

The material and build quality of the stencil rack affect its durability and ability to protect stencils over time. Stainless steel is a preferred material for stencil racks due to its strength, corrosion resistance, and longevity. When purchasing a used rack, inspect it for signs of rust, structural damage, or wear that could compromise its protective function.

Aluminum and coated steel are also common materials that offer a balance between weight and durability. However, cheaper or poorly maintained racks made from inferior materials may not provide adequate protection and could deteriorate quickly. Pay close attention to welds, joints, and moving parts like hinges or wheels if present.

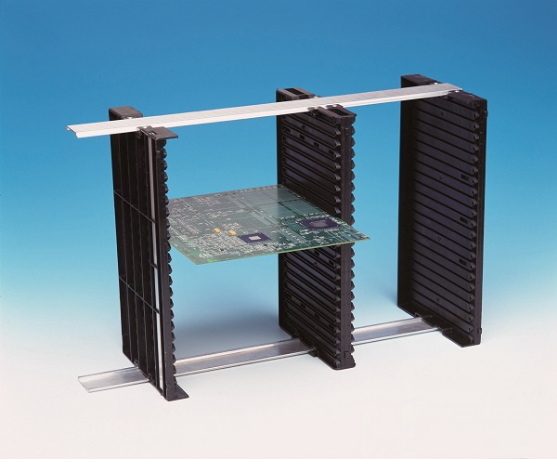

4. Space Efficiency and Capacity

Factory floor space is often limited and costly. A good used SMT stencil rack should maximize storage density while maintaining easy access to each stencil. Look for racks with vertical or compact designs that can store a large number of stencils within a minimal footprint. The capacity should match your stencil inventory size, allowing for organized storage without overcrowding.

Some racks are modular, allowing you to add or remove sections based on your current needs, which is especially useful if your stencil inventory fluctuates. Additionally, consider the height and width of the rack concerning your workspace constraints to ensure it fits comfortably without obstructing workflow.

5. Ease of Access and Organization

Efficient stencil retrieval is vital for minimizing downtime during stencil changeovers. Used racks with clear labeling or numbering systems enable operators to quickly identify and retrieve the correct stencil. Some racks feature color coding or pick-by-light indicators to further speed up the process. Evaluate whether the used rack supports easy organization and access to improve your assembly line throughput.

Ergonomic considerations are also important. Racks designed at an appropriate height reduce operator strain and improve safety. Sliding shelves or pull-out drawers can enhance accessibility, especially for racks with many stencil slots stacked vertically.

6. Adjustable Shelves or Dividers

Flexibility in storage is important since stencil frames can vary in size. Many stencil racks have adjustable shelves or dividers that allow customization of the storage space to accommodate different stencil dimensions. When selecting a used rack, check if the shelves or compartments can be adjusted or reconfigured to suit your stencil sizes.

This feature is particularly valuable if your manufacturing process involves a wide variety of stencil sizes or if you anticipate changes in stencil design. Adjustable racks help maintain order and prevent damage caused by forcing stencils into ill-fitting slots.

7. Mobility Features

In some manufacturing environments, the ability to move stencil racks around the production floor is beneficial. Used racks equipped with wheels or casters provide mobility, facilitating convenient access and efficient stencil changeovers. If mobility is important for your operations, ensure the used rack has sturdy, lockable wheels to prevent accidental movement.

Mobile stencil racks can be especially useful in flexible manufacturing setups or when stencils need to be transported between different workstations. However, consider the rack's stability when on wheels, as excessive movement or vibration can damage delicate stencil frames.

8. Anti-Static Properties

Electrostatic discharge (ESD) can damage sensitive electronic components and affect stencil materials. Some stencil racks incorporate anti-static materials or coatings to minimize ESD risks. If your production environment requires ESD protection, verify that the used stencil rack has appropriate anti-static features.

Anti-static racks help reduce the risk of static buildup that could attract dust or cause damage to sensitive components during stencil handling. This feature is particularly important in cleanroom environments or when working with highly sensitive semiconductor devices.

9. Integration with Production Workflow

Advanced stencil racks can integrate with manufacturing execution systems (MES) or enterprise resource planning (ERP) software, enabling digital tracking of stencil usage, maintenance, and inventory. While this feature is more common in new racks, some used racks may have compatible systems or can be retrofitted with digital tracking solutions. This integration improves stencil lifecycle management and reduces human errors.

Digital tracking can include barcode or RFID scanning capabilities that log stencil check-in and check-out times, usage counts, and cleaning schedules. This data helps optimize stencil utilization and maintenance, ultimately improving product quality and reducing costs.

10. Condition and Maintenance History

When buying used SMT stencil racks, assess their overall condition carefully. Look for any signs of damage, wear, or corrosion that could affect performance. If possible, obtain maintenance records or history of the rack to understand how well it has been cared for. Well-maintained racks are more likely to provide reliable service and protect your stencils effectively.

Inspect moving parts such as hinges, locks, or wheels to ensure smooth operation. Also, verify that any included covers or protective elements are intact and functional. A thorough inspection prevents unexpected repairs or replacements shortly after purchase.

Additional Considerations When Purchasing Used SMT Stencil Racks

Compatibility with Your Stencil Frame Types

SMT stencil frames come in various sizes and materials, including stainless steel, aluminum, and nickel. Before purchasing used SMT stencil racks, confirm that the rack's slot dimensions and support mechanisms are compatible with your specific stencil frames. Using racks designed for different frame types can lead to improper fit, increasing the risk of damage.

Environmental Conditions and Storage Location

Consider the environment where the stencil racks will be stored. If the area is prone to dust, humidity, or temperature fluctuations, select used racks that provide adequate protection or can be placed inside controlled cabinets. Additionally, racks with protective coatings or materials resistant to corrosion are preferable in challenging environments.

Budget and Cost-Benefit Analysis

While used SMT stencil racks are generally more affordable than new ones, it is important to balance cost savings with quality and functionality. Avoid racks that appear heavily worn or that lack essential features, as they may lead to higher long-term costs due to stencil damage or operational inefficiencies.

Vendor Reputation and Support

Purchasing used SMT stencil racks from reputable vendors or manufacturers with a track record of quality control can provide added confidence. Some sellers offer warranties or support services, which can be valuable for addressing any issues that arise after purchase.

Benefits of Using Used SMT Stencil Racks

- Cost Savings: Used racks offer a budget-friendly alternative to new storage solutions without compromising essential features.

- Immediate Availability: Used racks are often available for quicker delivery compared to manufacturing lead times for new racks.

- Sustainability: Purchasing used equipment supports environmental sustainability by reducing waste and resource consumption.

- Proven Designs: Many used racks come from established models with proven durability and functionality.

- Customization Potential: Some used racks can be modified or retrofitted to better suit your specific needs.

Best Practices for Using SMT Stencil Racks

- Always clean stencils thoroughly before storage to remove solder paste residues.

- Label stencil frames clearly with part numbers or job codes for easy identification.

- Store stencil racks in clean, temperature- and humidity-controlled areas to prevent corrosion and warping.

- Implement a routine inspection and cleaning schedule for both stencils and racks.

- Train operators on proper stencil handling and storage procedures to maximize stencil lifespan.

- Use anti-static mats or gloves when handling stencils to reduce ESD risks.

- Document stencil usage and maintenance to track stencil lifecycle and plan replacements proactively.

Conclusion

Choosing the right used SMT stencil racks is a strategic decision that can significantly impact your SMT assembly efficiency and stencil longevity. Key features such as secure slots, contamination protection, durable construction, space efficiency, ease of access, and mobility should guide your selection process. By carefully evaluating these aspects and maintaining proper stencil storage practices, manufacturers can ensure consistent solder paste application quality, reduce downtime, and optimize production workflows while benefiting from the cost advantages of used equipment.

Selecting used SMT stencil racks with the right combination of features and condition enables you to protect your stencil investment, streamline operations, and support high-quality electronics manufacturing. Remember to consider your specific operational needs, environmental factors, and stencil frame compatibility to make the best choice.

FAQ

1. What are used SMT stencil racks?

Used SMT stencil racks are pre-owned storage units designed to hold and organize framed SMT stencils securely. They protect stencils from physical damage and contamination while facilitating easy access during assembly processes.

2. Why is it important to protect SMT stencils in racks?

SMT stencils are precision tools with delicate apertures that can be easily damaged by scratches, dents, or warping. Proper protection in racks maintains stencil integrity, ensuring consistent solder paste application and reducing defects.

3. Can used SMT stencil racks be integrated with digital tracking systems?

Some used racks may be compatible with MES or ERP systems or can be retrofitted with digital tracking solutions. This integration helps monitor stencil usage, maintenance, and inventory for better lifecycle management.

4. How do I ensure the used SMT stencil rack fits my stencil frames?

Check the slot dimensions and adjustability features of the rack to ensure it can securely hold your stencil frames. Adjustable shelves or dividers provide flexibility for different stencil sizes.

5. What maintenance is required for SMT stencil racks?

Regular cleaning to remove dust and residues, inspection for damage or corrosion, and storing racks in controlled environments help maintain their protective function and extend their service life.