Content Menu

● Introduction to Metro SMT Reel Storage Systems

>> Key Features of Metro SMT Reel Storage Systems

● Types of Metro SMT Reel Storage Systems

>> Super Erecta SMT Reel Shelves

>> MetroMax i and MetroMax Q Systems

● Choosing the Right Metro SMT Reel Storage System

● Implementing Your Metro SMT Reel Storage System

● Case Studies: Successful Implementations

● Advanced Technologies in SMT Reel Storage

>> RFID Smart Shelf Solutions

>> Smart Racks and Shelving Systems

● Additional Considerations for Advanced SMT Reel Storage

>> Integration of IoT and AI Technologies

>> Comparison of Vertical Carousel Modules (VCMs) and Vertical Lift Modules (VLMs)

>> Environmental Sustainability in SMT Reel Storage

● Conclusion

● FAQ

>> 1. What are the key features of Metro SMT reel storage systems?

>> 2. How do Metro SMT reel storage systems protect electronic components?

>> 3. Can Metro SMT reel storage systems accommodate different reel sizes?

>> 4. How do Metro SMT reel storage systems enhance inventory management?

>> 5. What level of automation can I expect from Metro SMT reel storage systems?

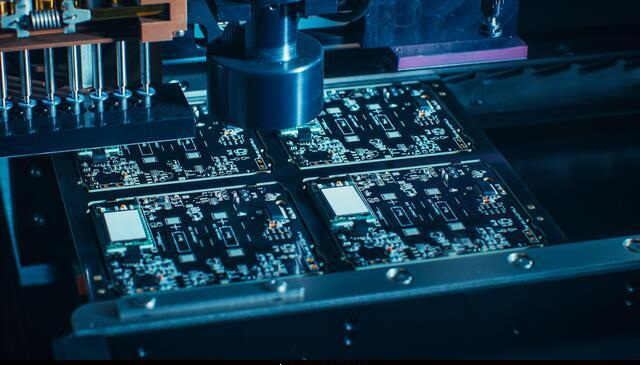

In the fast-paced world of electronics manufacturing, efficient storage and management of Surface Mount Technology (SMT) reels are crucial for maintaining production efficiency, reducing errors, and ensuring the quality of electronic components. Metro SMT reel storage systems are designed to address these needs by providing flexible, scalable, and protective storage solutions. This article will explore the key features to look for in Metro SMT reel storage systems, highlighting their importance in modern electronics manufacturing.

Introduction to Metro SMT Reel Storage Systems

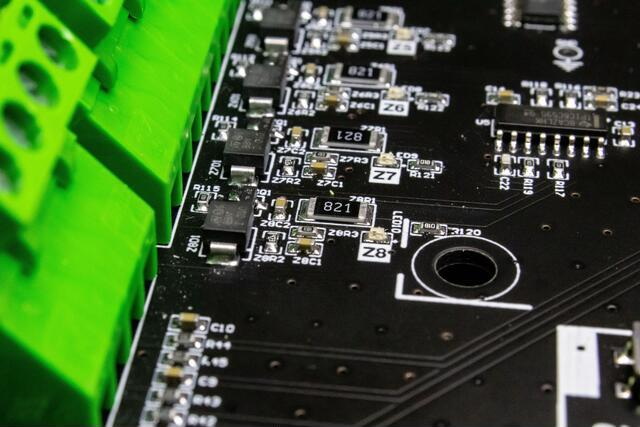

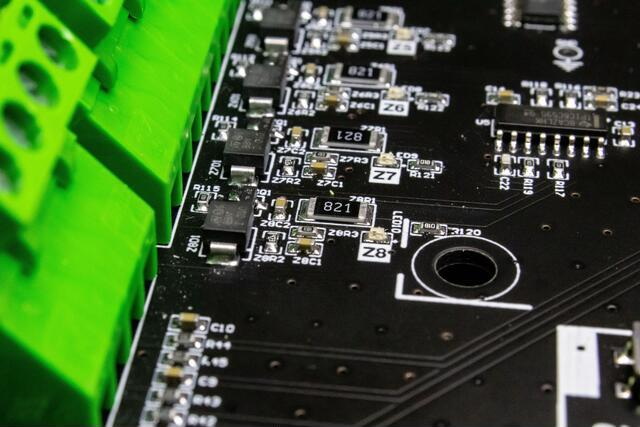

Metro SMT reel storage systems are specialized solutions for storing and managing reels of electronic components used in surface mount technology. These systems are essential for electronics manufacturing facilities as they help streamline production processes by ensuring quick access to components, reducing errors, and maintaining component integrity. The systems are designed to optimize space, enhance inventory management, and protect sensitive electronic components from environmental factors such as humidity and electrostatic discharge (ESD).

Key Features of Metro SMT Reel Storage Systems

1. Space Optimization: Metro SMT reel storage systems, such as the Super Erecta shelving, are designed to maximize space utilization. They can be configured to fit various reel sizes, including 7", 13", and 15" reels, allowing for efficient use of available storage space. Advanced systems like Vertical Carousel Modules (VCMs) and Vertical Lift Modules (VLMs) can save up to 85% of floor space compared to traditional shelving systems.

2. Efficient Inventory Management: These systems often integrate with inventory management software, providing real-time tracking of component quantities, locations, and usage history. This ensures accurate stock levels, reduces the risk of production delays due to component shortages, and enhances traceability throughout the manufacturing process.

3. Protection of Components: Metro SMT reel storage systems include features like temperature control, humidity regulation, and ESD protection to maintain the integrity and longevity of stored components. This is crucial for preventing damage from environmental factors that could compromise component quality.

4. Modularity and Scalability: The systems are modular and scalable, allowing for easy expansion as storage needs increase. This scalability is a cost-effective solution in the long run, as it eliminates the need for complete system replacements as the business grows.

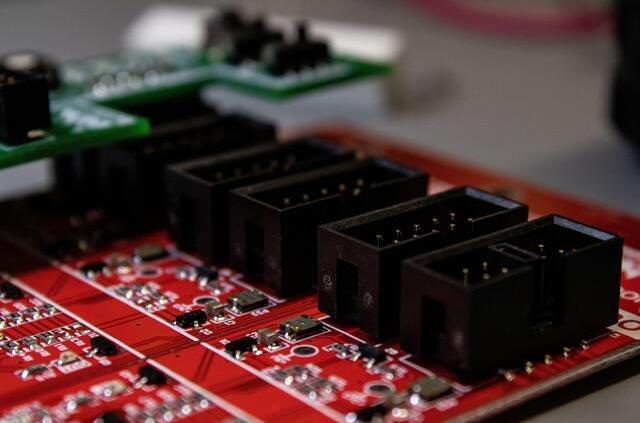

5. Integration with Manufacturing Systems: High-quality SMT reel storage systems integrate seamlessly with other manufacturing systems, including Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) systems, and automated guided vehicles (AGVs). This integration enhances overall factory automation and efficiency.

Types of Metro SMT Reel Storage Systems

Metro offers a variety of shelving solutions, including the Super Erecta style, which can be mixed and matched with standard Super Erecta shelving, posts, and casters to create a customizable reel handling and storage system. Additionally, advanced systems like MetroMax i and MetroMax Q offer corrosion-proof designs with innovative polymer materials, providing durability and easy cleanability.

Super Erecta SMT Reel Shelves

- Features: Super Erecta shelves are designed with a Super Erecta Brite finish and can handle various reel sizes. They offer a standard 18" x 36" footprint, allowing for efficient storage of up to 78 reels for 7" reels and 15 reels for 13" to 15" reels.

- Benefits: These shelves can be configured and reconfigured to meet exact needs, integrate with standard SES components, and provide maximized space utilization. They are conductive with the use of aluminum split sleeves, ensuring ESD protection.

MetroMax i and MetroMax Q Systems

- Features: These systems feature corrosion-proof polymer designs with stainless steel corners, offering durability and resistance to common cleaners and sanitizers. They are easily cleanable and provide removable polymer shelf mats for enhanced hygiene.

- Benefits: MetroMax i and MetroMax Q systems are interchangeable, allowing for flexibility in storage configurations. They offer high temperature cart wash capabilities and are designed for easy adjustment and mobility.

Choosing the Right Metro SMT Reel Storage System

When selecting a Metro SMT reel storage system, several factors should be considered:

1. Storage Capacity and Scalability: Assess the number and sizes of reels you need to store and choose a system that can accommodate your requirements with room for growth.

2. Accessibility and Retrieval Speed: Consider systems that offer quick access to stored reels, such as automated carousel or lift mechanisms. Advanced systems can retrieve reels in less than 4 seconds and return them in less than 8 seconds.

3. Inventory Management and Traceability: Look for systems that integrate with inventory management software for real-time tracking and accurate stock levels.

4. Automation and Industry 4.0 Compatibility: Choose systems that align with Industry 4.0 principles, offering integration with AGVs and robotic picking systems.

5. Environmental Control: Consider systems that provide temperature control, humidity regulation, and ESD protection to safeguard sensitive components.

Implementing Your Metro SMT Reel Storage System

Proper implementation of your chosen SMT reel storage system is crucial to maximize its benefits:

1. Placement and Integration: Carefully plan the placement of your storage system within your facility, ensuring proximity to production lines and integration with existing inventory management software.

2. Training and SOPs: Provide thorough training on operating the system and develop clear standard operating procedures (SOPs) for storing and retrieving reels.

3. Monitoring and Optimization: Continuously monitor the performance of your SMT reel storage system and look for opportunities to optimize its use.

Case Studies: Successful Implementations

Several companies have successfully implemented Metro SMT reel storage systems to improve their manufacturing efficiency:

- Electronics Manufacturer: A medium-sized electronics manufacturer implemented a vertical carousel SMT reel storage system, achieving a 70% reduction in floor space used for component storage and a 50% decrease in time spent retrieving components.

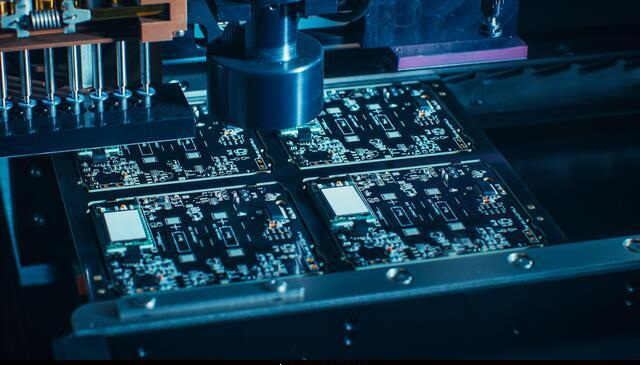

- Large-Scale Production Facility: A large electronics production facility invested in a fully automated AS/RS for SMT reel storage, resulting in a 90% reduction in manual handling of components and a 30% increase in overall production efficiency.

Advanced Technologies in SMT Reel Storage

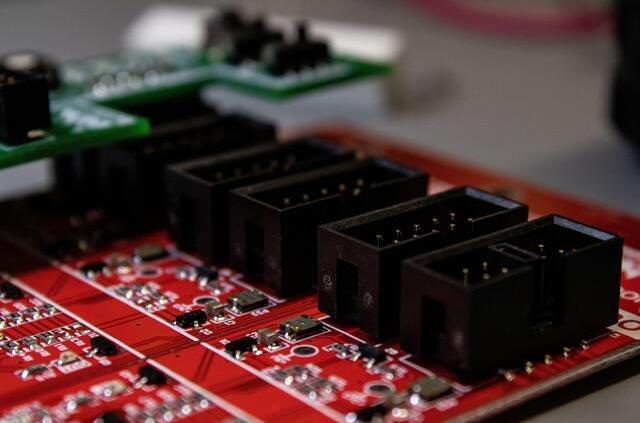

The integration of advanced technologies such as RFID and smart shelving systems is transforming the efficiency of SMT reel storage. These systems allow for real-time tracking and automated retrieval, significantly reducing manual intervention and errors.

RFID Smart Shelf Solutions

RFID smart shelf solutions integrate RFID tags with storage systems to track reel locations and automate pick-up and return processes. This technology enhances warehouse efficiency by reducing the time spent on manual inventory management and component retrieval.

Smart Racks and Shelving Systems

Smart racks and shelving systems use sensors and LED indicators to guide operators to the correct reel locations, ensuring quick and accurate retrieval. These systems can be integrated with inventory management software to provide real-time updates on stock levels and usage history.

Additional Considerations for Advanced SMT Reel Storage

Integration of IoT and AI Technologies

The future of SMT reel storage involves the integration of IoT and AI technologies to enhance automation and predictive maintenance. IoT sensors can monitor environmental conditions and component usage, while AI algorithms can predict stock levels and optimize storage configurations based on historical data.

Comparison of Vertical Carousel Modules (VCMs) and Vertical Lift Modules (VLMs)

Both VCMs and VLMs are popular choices for high-density storage, but they differ in their operational mechanisms. VCMs rotate vertically to bring stored items to an ergonomic access point, while VLMs use a vertical lift mechanism to retrieve trays of stored items. VCMs are often preferred for their faster retrieval times, while VLMs offer more flexibility in terms of storage customization.

Environmental Sustainability in SMT Reel Storage

As manufacturing moves towards more sustainable practices, SMT reel storage systems are also evolving to reduce environmental impact. This includes using eco-friendly materials in shelving construction and optimizing energy consumption through smart lighting and climate control systems.

By incorporating these advanced technologies and considerations, Metro SMT reel storage systems can not only improve production efficiency but also contribute to a more sustainable and technologically advanced manufacturing environment.

Conclusion

Metro SMT reel storage systems offer a range of features that are essential for efficient electronics manufacturing. By optimizing space, enhancing inventory management, and protecting sensitive components, these systems significantly improve production efficiency and reduce costs. When choosing a Metro SMT reel storage system, consider factors such as storage capacity, accessibility, inventory management, environmental control, and automation compatibility to ensure that your system meets both current and future needs.

FAQ

1. What are the key features of Metro SMT reel storage systems?

Metro SMT reel storage systems feature space optimization, efficient inventory management, protection of components, modularity, and integration with manufacturing systems. They are designed to accommodate various reel sizes and offer customizable storage options.

2. How do Metro SMT reel storage systems protect electronic components?

These systems protect electronic components through features like temperature control, humidity regulation, and ESD protection. They ensure that components remain in optimal condition, reducing the risk of damage from environmental factors.

3. Can Metro SMT reel storage systems accommodate different reel sizes?

Yes, Metro SMT reel storage systems are designed to accommodate various reel sizes, typically ranging from 7" to 15" in diameter. They also offer customizable storage options for other component types.

4. How do Metro SMT reel storage systems enhance inventory management?

Metro SMT reel storage systems enhance inventory management by integrating with inventory management software, providing real-time tracking of component quantities, locations, and usage history. This ensures accurate stock levels and reduces the risk of production delays.

5. What level of automation can I expect from Metro SMT reel storage systems?

The level of automation in Metro SMT reel storage systems can vary. Basic systems may offer guided retrieval systems, while more advanced solutions provide fully automated storage and retrieval with robotic systems, integrating with AGVs for material transport.