Content Menu

● Understanding SMT PCB Unloader Lines

● Key Features to Consider in an SMT PCB Unloader Line

>> 1. Compatibility and Integration

>> 2. Handling Capacity and Flexibility

>> 3. Precision and Gentle Handling

>> 4. Automation and Control System

>> 5. Speed and Cycle Time

>> 6. Safety Features

>> 7. Robust Construction and Durability

>> 8. Error Handling and Alarm Systems

>> 9. Ease of Maintenance and Operation

>> 10. Customization and Scalability

● Additional Considerations

>> Energy Efficiency

>> Space Requirements

>> Vendor Support and After-Sales Service

● Conclusion

● FAQ

>> 1. What is the typical cycle time for an SMT PCB unloader line?

>> 2. Can SMT PCB unloader lines handle different PCB sizes?

>> 3. How does the SMT PCB unloader ensure gentle handling of PCBs?

>> 4. Are SMT PCB unloader lines compatible with other SMT production equipment?

>> 5. What safety features are included in SMT PCB unloader lines?

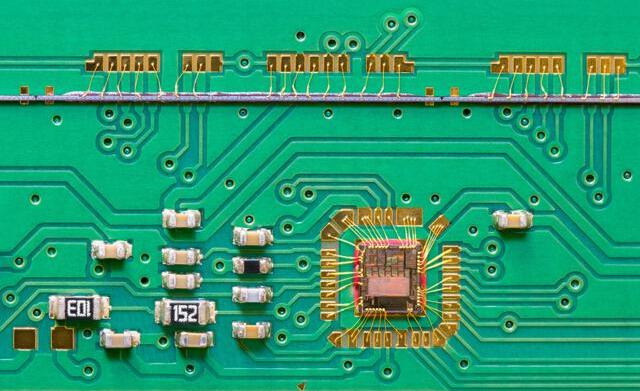

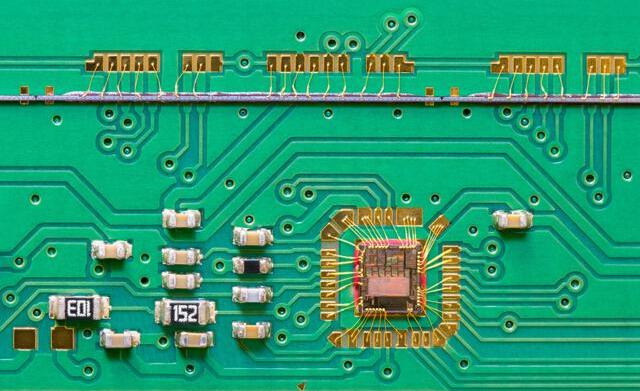

In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) PCB unloader lines play a crucial role in ensuring smooth, efficient, and damage-free handling of printed circuit boards (PCBs) after assembly. Choosing the right SMT PCB unloader line can significantly impact your production efficiency, product quality, and overall operational costs. This comprehensive article explores the essential features you should look for in an SMT PCB unloader line, helping you make an informed decision that aligns with your manufacturing needs.

Understanding SMT PCB Unloader Lines

An SMT PCB unloader line is an automated system designed to unload assembled PCBs from the production line, often from magazines or conveyors, and prepare them for subsequent processes such as inspection, testing, or packaging. These systems are integral components of SMT production lines, ensuring that PCBs are handled gently and efficiently to maintain high throughput and product integrity.

The unloader line acts as a bridge between the SMT assembly machines and downstream processes, reducing manual labor, minimizing human error, and speeding up the overall manufacturing cycle. Given the delicate nature of PCBs and the complexity of SMT components, the design and functionality of the unloader line are critical to maintaining product quality.

Key Features to Consider in an SMT PCB Unloader Line

1. Compatibility and Integration

One of the foremost considerations when selecting an SMT PCB unloader line is its compatibility with your existing SMT production equipment. The unloader should support standard industry communication protocols such as SMEMA (Surface Mount Equipment Manufacturers Association) interface, which enables seamless communication between machines on the line.

Integration capability ensures that the unloader line can synchronize with upstream pick-and-place machines, reflow ovens, and inspection systems, as well as downstream testers or packaging stations. This synchronization reduces downtime and prevents bottlenecks, allowing for a continuous and smooth production flow.

Additionally, compatibility with different magazine types and conveyor systems is essential. Some unloader lines are designed to handle specific magazine formats, so verifying this compatibility beforehand will avoid costly adjustments or retrofits.

2. Handling Capacity and Flexibility

Manufacturing lines often deal with a variety of PCB sizes and shapes, depending on the product range. Therefore, flexibility in handling different PCB dimensions is a critical feature of an SMT PCB unloader line.

Look for unloader systems that offer:

- Adjustable width and length settings to accommodate small, medium, and large PCBs.

- Variable magazine handling capacity, allowing the system to unload from multiple magazines or feeders.

- Support for different PCB thicknesses and weights, ensuring stable and secure handling without damage.

This flexibility allows manufacturers to switch between product lines with minimal downtime and equipment adjustment, increasing overall productivity.

3. Precision and Gentle Handling

PCBs are delicate and populated with tiny, sensitive components that can be easily damaged if mishandled. The SMT PCB unloader line must ensure precise, gentle handling to maintain product integrity.

Key technologies and design features that contribute to gentle handling include:

- Servo motors with precision ball screws for smooth and accurate lifting and positioning of magazines and PCBs.

- Pneumatic clamps that securely hold magazines without exerting excessive pressure.

- Conveyor belts with soft, anti-static materials to prevent scratches or static damage.

- Smooth transfer mechanisms that avoid sudden stops or jolts during PCB unloading.

By minimizing mechanical stress, the unloader line reduces the risk of component displacement, solder joint damage, or PCB warping.

4. Automation and Control System

A sophisticated automation and control system is essential for efficient operation and ease of use. Most modern SMT PCB unloader lines incorporate a Programmable Logic Controller (PLC) combined with a touchscreen Human-Machine Interface (HMI).

Benefits of an advanced control system include:

- Customizable unloading parameters such as speed, direction, and timing.

- Real-time monitoring of machine status, production counts, and error messages.

- Automatic error detection and recovery, minimizing downtime.

- User-friendly interface that simplifies setup, operation, and troubleshooting.

Automation reduces the need for manual intervention, which not only speeds up production but also reduces the risk of human error.

5. Speed and Cycle Time

In high-volume SMT production, speed is a critical factor. The SMT PCB unloader line should have a fast unloading cycle time to keep pace with upstream assembly machines.

Typical cycle times range from 8 to 9 seconds per PCB, but some advanced systems can operate even faster. The ability to adjust speed settings based on production needs is also beneficial, allowing for optimization between speed and handling care.

Maintaining a high throughput without compromising PCB quality is a hallmark of a well-designed unloader line.

6. Safety Features

Safety is paramount in automated manufacturing environments. The SMT PCB unloader line should be equipped with comprehensive safety features to protect both operators and equipment.

Common safety features include:

- Safety door locks that prevent access to moving parts during operation.

- Emergency stop buttons placed at accessible locations.

- Interlocking systems that halt the machine if safety guards are opened.

- Sensors and light curtains that detect obstructions or human presence in hazardous zones.

- Overload protection to prevent mechanical damage.

These features ensure compliance with workplace safety standards and reduce the risk of accidents.

7. Robust Construction and Durability

The physical construction of the SMT PCB unloader line affects its reliability and lifespan. Look for machines made with:

- High-strength iron plates for the frame, providing stability and vibration resistance.

- Aviation-grade aluminum profiles for lightweight yet durable structural components.

- Integral casting lifting platforms for smooth and precise vertical movement.

Robust construction minimizes maintenance needs and ensures consistent performance even in demanding production environments.

8. Error Handling and Alarm Systems

An effective error handling and alarm system is essential for minimizing downtime and maintaining production quality.

Features to look for include:

- Acoustic-optic alarms with multi-color lights and audible signals that alert operators to issues immediately.

- Detailed error codes and messages displayed on the touchscreen interface for quick diagnosis.

- Automatic stop and recovery functions to prevent damage when faults occur.

- Data logging for tracking errors and maintenance history.

Quick identification and resolution of problems help keep the production line running smoothly.

9. Ease of Maintenance and Operation

Ease of use and maintenance directly impact the productivity and operational costs of SMT PCB unloader lines.

Consider machines with:

- Intuitive touchscreen controls that reduce operator training time.

- Modular design for easy access to components during maintenance.

- Clear documentation and diagnostic tools to facilitate troubleshooting.

- Minimal tool requirements for routine adjustments and repairs.

Simplifying operation and maintenance reduces downtime and increases overall equipment effectiveness (OEE).

10. Customization and Scalability

Manufacturers often need equipment that can evolve with their production demands. Customizable and scalable SMT PCB unloader lines provide long-term value.

Possible customization options include:

- Number of magazine positions, allowing multiple magazines to be unloaded simultaneously.

- Adjustable lifting steps to handle different magazine heights.

- Selectable flow directions, enabling the line to unload PCBs from left to right or right to left.

- Integration of additional modules such as barcode readers or inspection cameras.

Scalability ensures that the unloader line can adapt to new products, increased volumes, or process changes without requiring a complete system replacement.

Additional Considerations

Energy Efficiency

Energy-efficient SMT PCB unloader lines reduce operational costs and environmental impact. Features such as low-power servo motors and optimized pneumatic systems contribute to lower energy consumption without sacrificing performance.

Space Requirements

Factory floor space is often limited. Compact or L-shaped unloader line configurations can optimize space utilization while maintaining throughput. Consider the available footprint and workflow when selecting a system.

Vendor Support and After-Sales Service

Reliable technical support, timely spare parts availability, and responsive after-sales service are vital for minimizing downtime and protecting your investment. Choose suppliers with a proven track record and strong customer service.

Conclusion

Selecting the right SMT PCB unloader line is a strategic decision that affects the efficiency, quality, and cost-effectiveness of your SMT production line. Key features to prioritize include compatibility with existing equipment, flexible handling capabilities, precision and gentle PCB handling, advanced automation and control systems, high-speed operation, robust safety mechanisms, durable construction, and user-friendly operation. Additional considerations such as energy efficiency, space optimization, and vendor support further influence the overall value.

By carefully evaluating these aspects, manufacturers can ensure seamless PCB unloading, reduce defects, and enhance overall productivity. Investing in a high-quality SMT PCB unloader line ultimately leads to smoother production processes, lower costs, and higher customer satisfaction.

FAQ

1. What is the typical cycle time for an SMT PCB unloader line?

The typical cycle time for unloading a single PCB is around 8 to 9 seconds, though this can be customized to meet specific production requirements and throughput goals.

2. Can SMT PCB unloader lines handle different PCB sizes?

Yes, most unloader lines feature adjustable width and length settings, allowing them to accommodate a wide range of PCB sizes and magazine configurations, from small to large boards.

3. How does the SMT PCB unloader ensure gentle handling of PCBs?

Unloader lines use precision servo motors, pneumatic clamps, and specially designed conveyor systems that minimize mechanical stress and prevent damage or misalignment of sensitive components during unloading.

4. Are SMT PCB unloader lines compatible with other SMT production equipment?

Most unloader lines support standard interfaces such as SMEMA, enabling seamless integration and communication with other SMT line equipment for synchronized operation.

5. What safety features are included in SMT PCB unloader lines?

Common safety features include safety door locks, emergency stop buttons, interlocking systems, and sensors that detect obstructions or errors, automatically stopping the machine to protect operators and PCBs.